Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54results about How to "Good physical and chemical compatibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ceramic wall flow filter manufacture

InactiveUS20060272306A1Good chemical stabilityImprove physical stabilityDispersed particle filtrationLoose filtering material filtersHoneycombPorous ceramics

Porous ceramic wall flow filter bodies of unitary or segmented construction wherein the honeycomb channels are alternately plugged with plugging cements incorporating low expansion refractory fillers and permanent inorganic bonding agents, the latter imparting improved plug integrity and plug bonding to the porous ceramic honeycomb channel walls.

Owner:CORNING INC

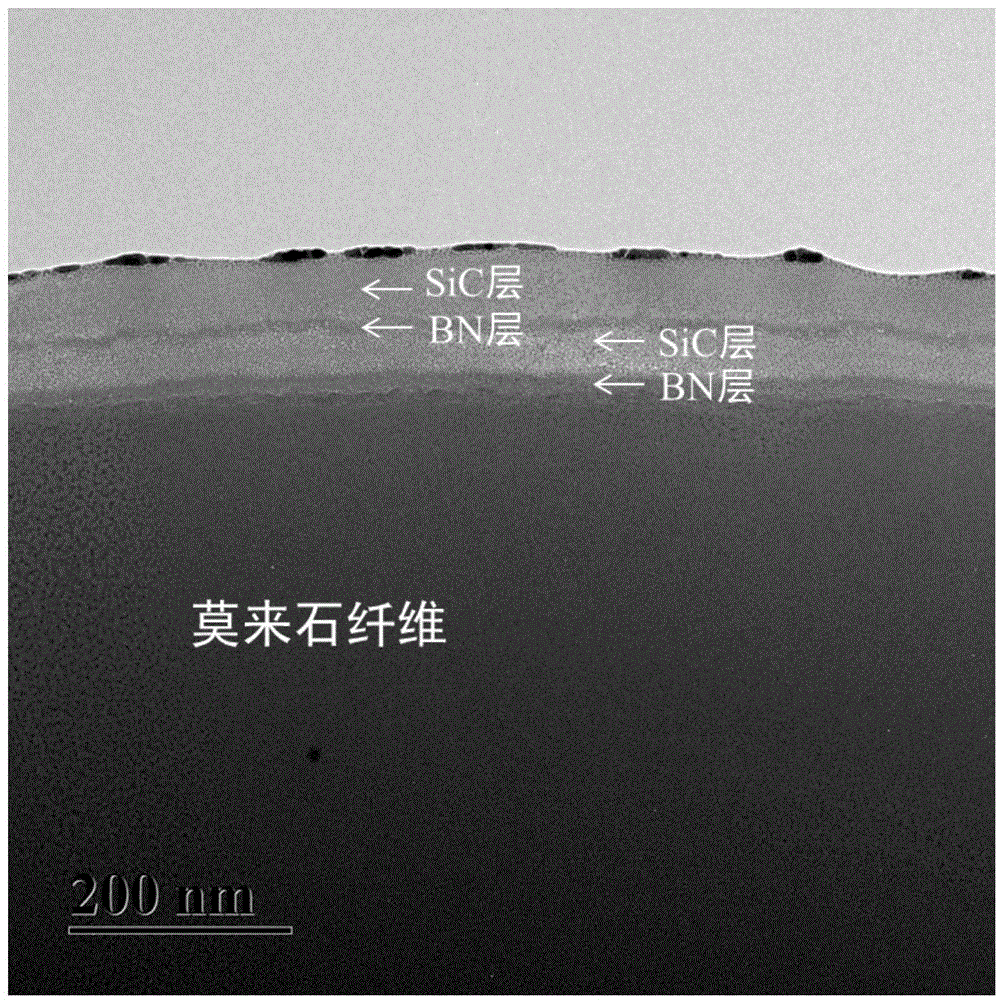

(BN/SiC)n composite interface-phase coating, coating fiber and preparation method

The invention discloses a (BN / SiC)n composite interface-phase coating. The (BN / SiC)n composite interface-phase coating has a periodic laminated structure, wherein BN layers and SiC layers are alternatively and periodically overlapped; the thickness of the BN layers is not greater than that of the SiC layer. A coating fiber comprises a fiber substrate and the (BN / SiC)n composite interface-phase coating; the innermost layer closest to the fiber substrate is the NB layer and the outermost layer further away from the fiber substrate is the SiC layer. A preparation method for the coating fiber comprises the steps: cleaning the fiber substrate; putting into a deposition hearth, vacuumizing and filling with inert gases to exchange with air; realizing a preset vacuum degree and a preset temperature; bringing precursors into the reaction by carrier gas in a bubbling manner, maintaining a specified pressure of a reaction system, and alternatively depositing the BN layers and the SiC layers on the fiber substrate through changing a precursor gas source. The product has the advantages of good compatibility, high-temperature resistance, anti-oxidation and good toughening effect.

Owner:NAT UNIV OF DEFENSE TECH

Preparation method of inorganic composite coating on the surface of quartz fiber reinforced quartz matrix composite material

ActiveCN102276278AImprove moisture resistanceExcellent dielectric propertiesAluminium hydroxidePhosphate

The invention which belongs to the technical field of special functional ceramic materials relates to a preparation method of an inorganic composite coating on the surface of a silica fiber-reinforced silica-based composite material. The preparation method comprises procedures of surface treatment, coating slurry preparation, spray, thermal treatment, and coating with a material for modification,wherein the temperature of the thermal treatment is 500-650DEG C. According to the invention, a solid phase reaction is carried out on three substances of lithium carbonate, aluminum hydroxide, and silica when being calcined, and a low expansion ceramic material is prepared by controlling the ratio among the three substances; a borate or a phosphate and the like are simultaneously introduced to prepare a low temperature flux to reduce the melting temperature of the integral body of the low expansion ceramic material; and a solidification hydrolysis reaction is finally carried out on an inorganic silicone resin to form a compact protection layer on the surface of a transition layer to reach effects of modification and double layer protection. The preparation method of the invention is scientific and reasonable, and is easy to implement, the material of the inorganic composite coating obtained with the preparation method has a good moistureproof performance, and has a good physicochemical match with the silica fiber-reinforced silica-based composite material, and simultaneously can improve dielectric properties of the silica fiber-reinforced silica-based composite material.

Owner:ZHONGCAI HIGH NEW MATERIAL +1

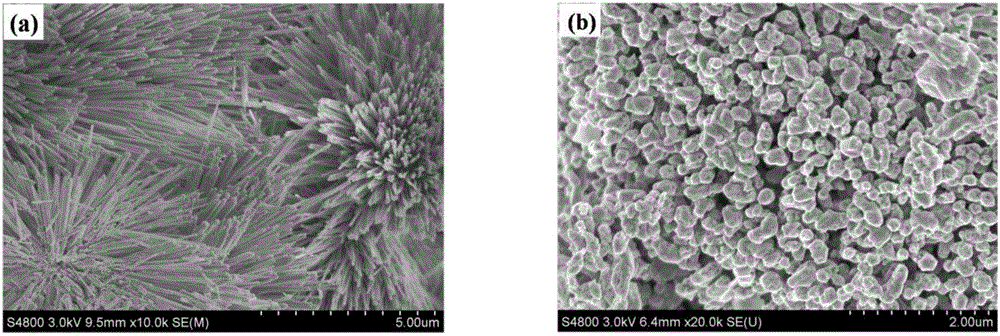

Preparation method of Y4Si3O12 crystal whiskers

ActiveCN102677174ASimple process controlLow costPolycrystalline material growthFrom normal temperature solutionsAnhydrous ethanolDistilled water

The invention relates to a preparation method of Y4Si3O12 crystal whiskers, which comprises the steps of: dissolving Y (NO)3.6H2O and Na2SiO3.9H2O in anhydrous ethanol to obtain solution A; adding ethylenediaminetetraacetic acid (EDTA) and high-density polyethylene (HDPE) into the solution A and magnetically agitating for ultrasonic reaction to obtain solution B; and placing the solution B in a hydrothermal reaction kettle lined with polytetrafluoroethylene for constant-temperature reaction, conducting centrifugal separation, successively washing with distilled water and anhydrous ethanol and finally drying to obtain Y4Si3O12 crystal whiskers. The preparation method of the Y4Si3O12 crystal whiskers has the advantages that the process is simple to control, the cost is lower, the preparation temperature is low, the later-stage crystallization is not required and the possible defects that the crystal grains grow up, are coarsened or curled and the like in the later-stage heat treatment process are avoided to some extent. The appearance control can be realized and the Y4Si3O12 crystal whiskers with high purity and even grain size can be prepared.

Owner:宿迁益创智能科技有限公司

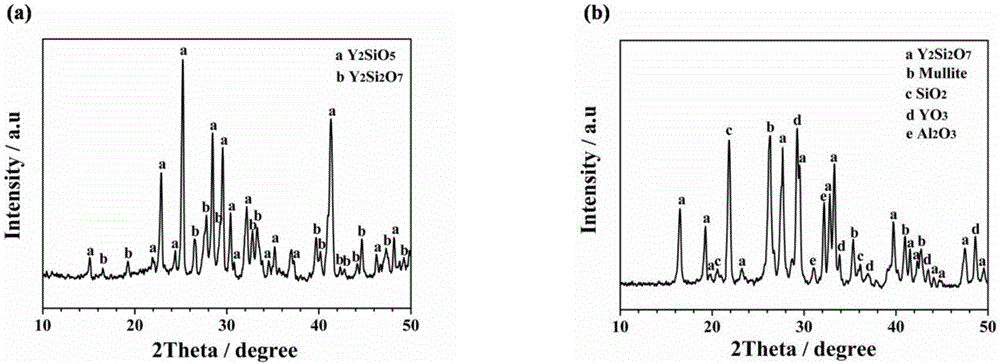

Preparation method of carbon/carbon composite material beta-Y2Si2O7 whisker-toughened Y2SiO5/YAS glass-ceramic composite antioxidant coating

The invention discloses a preparation method of a carbon / carbon composite material beta-Y2Si2O7 whisker-toughened Y2SiO5 / YAS glass-ceramic composite antioxidant coating. The preparation method comprises preparing a beta-Y2Si2O7 whisker-toughened Y2SiO5 porous coating on the surface of C / C-SiC through a simple pulsed arc discharge deposition method, and preparing a YAS glass-ceramic outer coating through a thermal impregnation method. The carbon / carbon composite material beta-Y2Si2O7 whisker-toughened Y2SiO5 / YAS glass-ceramic composite antioxidant coating can be well bonded to a base so that the control of the composite coating structure is realized, a preparation cycle is short and processes are simple. The coating is prepared at a low temperature and has a low cost.

Owner:SHAANXI UNIV OF SCI & TECH

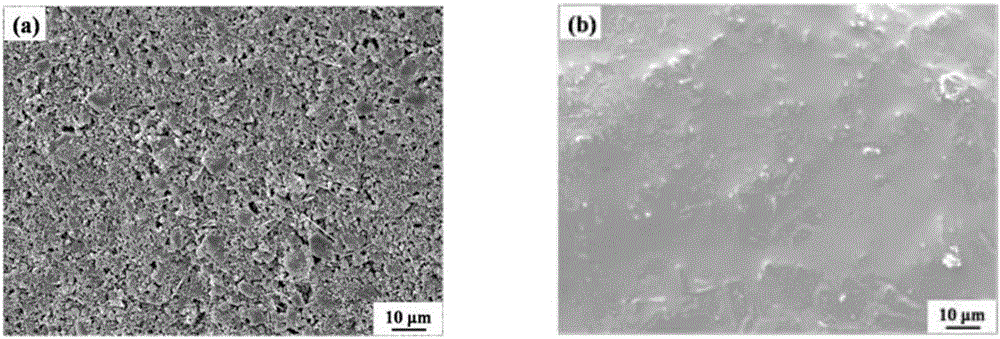

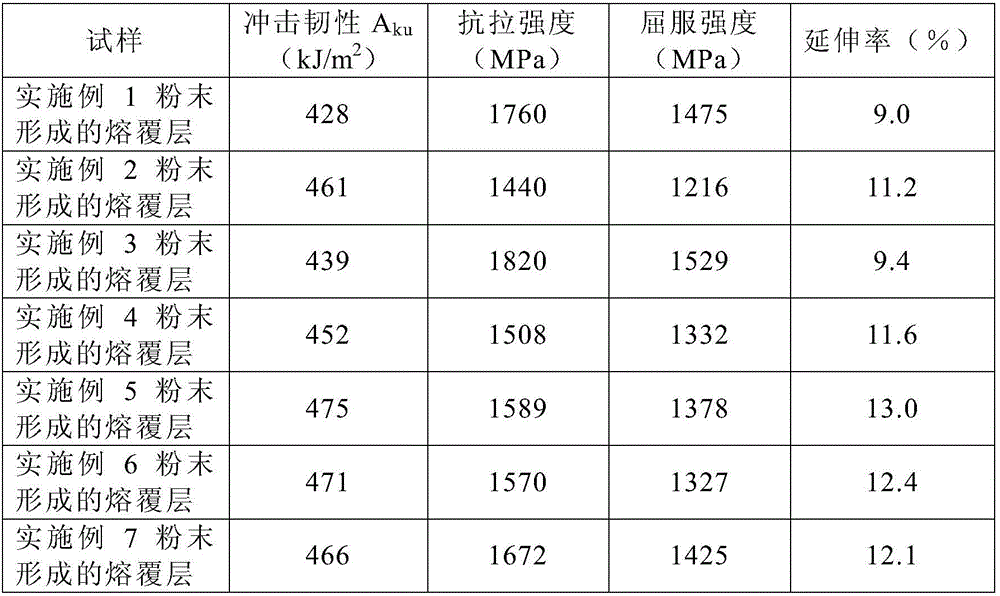

Laser cladding powder for 30CrMnSiNi2A steel and preparation method

ActiveCN106480363AHigh bonding strengthLess metallurgical defectsTransportation and packagingMetal-working apparatusRare earthUltimate tensile strength

The invention relates to laser cladding powder for 30CrMnSiNi2A steel and a preparation method. The laser cladding powder is prepared from the following components in weight percent: 0.8% to 1.0% of Cr, 0.75% to 1.10% of Mn, 0.65% to 1.10% of Si, 2.0% to 3.2% of Ni, 0.16% to 0.22% of C, 0.15% to 0.20% of Cu, 0.015% to 0.020% of P, 0.01% to 0.015% of S, 0.001% to 0.015% of rare earth and the balance of Fe. The invention further provides the preparation method of the laser cladding powder, the laser cladding powder is exclusively used in a laser cladding technique of the 30CrMnSiNi2A steel, excellent bonding strength and low metallurgical defects and dilution rate of a cladding interface are guaranteed, the toughness of a cladding layer is increased, the wettability of the cladding powder is improved, the cracking of the cladding layer is inhibited, and the crack growth rate is reduced.

Owner:国营芜湖机械厂

Anti-oxidation coating and preparation method thereof

ActiveCN105755423AImprove antioxidant capacityImproves ablation resistanceMolten spray coatingCarbon fibersOxidation resistant

The invention relates to anti-oxidation coating and a preparation method thereof.The anti-oxidation coating comprises an adhering layer and a ceramic layer which are sequentially prepared on a base, wherein the adhering layer is made of W, the ceramic layer is made of Yb2SiO4, the adhering layer is 0.05-0.15mm in thickness, and the ceramic layer is 0.15-0.3mm in thickness.The preparation method includes the steps of firstly, preheating the base, and controlling the temperature of the base to be 100-200 DEG C; secondly, using a plasma spraying method to sequentially prepare the adhering layer and the ceramic layer on the preheated base.The anti-oxidation coating and the preparation method thereof have the advantages that the coating is prepared by the single plasma spraying process; the preparation method is simple in process, low in cost and high in efficiency; the technical difficulties that traditional coating preparation technologies of carbon-fiber-reinforced ceramic-based composite materials are complex and the prepared coating is weak in steam corrosion resistance.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

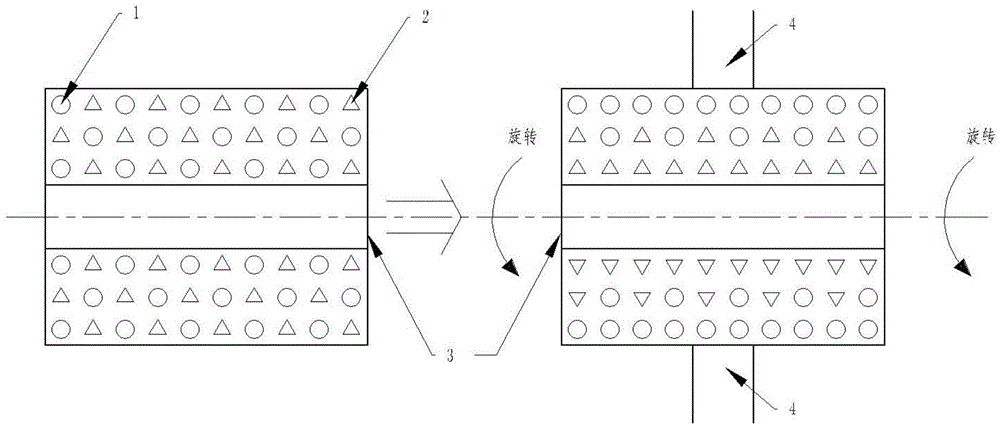

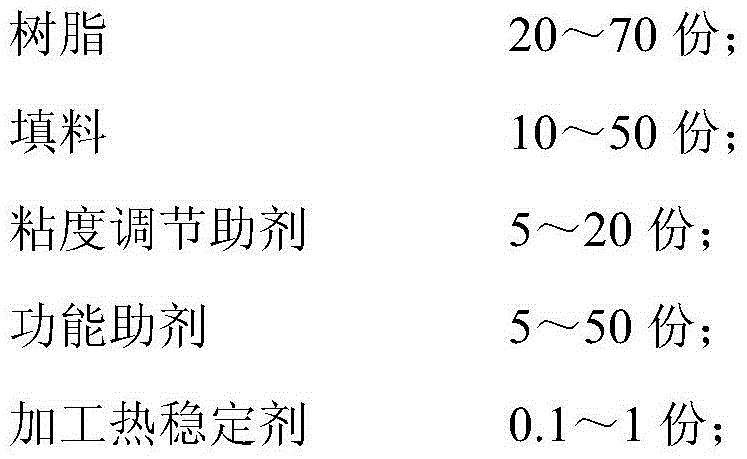

Super-light functional master batch, plastic product based on super-light functional master batch and method for preparing plastic product through rotational molding

The invention discloses a super-light functional master batch, which is prepared from the following components in ratio: 20-70 parts of resin, 10-50 parts of fillers, 5-20 parts of a viscosity adjusting auxiliary, 5-50 parts of a functional auxiliary, 0.1-1 part of a processing thermal stabilizer and 0.1-2 parts of a processing lubricant, wherein the resin is PP, ABS or PA; the fillers are hollow glass beads or phenolic beads; the invention further discloses a plastic product prepared from 40-60 parts of matrix plastic and 20-30 parts of super-light functional master batch; the invention further discloses a method for preparing the functional plastic through rotational molding after the matrix plastic and the functional master batch are heated to a molten / half molten state. According to the invention, after the matrix plastic and the functional master batch are heated to a certain temperature and the rotational molding is carried out, and under the effect of the centrifugal force, the matrix plastic moves towards an outer layer, so that the selective distribution of the functional auxiliary is achieved; the dosage of the functional auxiliary can be reduced and the performance of the products is improved.

Owner:重庆科聚孚新材料有限责任公司 +1

Ceramic and metal dissimilar material connecting method and ceramic surface treatment process

InactiveCN108794043AFirmly connectedHigh bonding strengthWelding/cutting media/materialsSoldering mediaChemical compatibilitySolder paste

The invention belongs to the field of connection of ceramic materials and dissimilar materials, and particularly relates to a ceramic and metal dissimilar material connecting method and a ceramic surface treatment process. The ceramic and metal dissimilar material connecting method includes the steps: S1 mixed solder paste preparation; S2 ceramic and metal surface treatment; S3 ceramic surface solder paste spraying and treating; S4 solder paste spraying and treated ceramic and the treated metal connection. According to the method, surfaces of ceramic parent materials are treated by grass-metalcomposite powder according to good physical and chemical compatibility between grass and ceramic, the bonding strength among surface treatment layers and the ceramic parent materials is improved, andthe surface treatment layers can be effectively moistened by metal solders, so that the ceramic is effectively connected with the ceramic / metal dissimilar materials by the metal solders.

Owner:哈尔滨赫捷科技有限公司

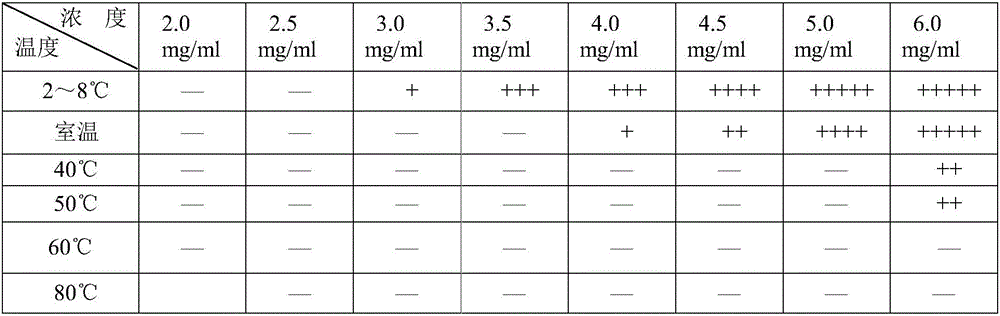

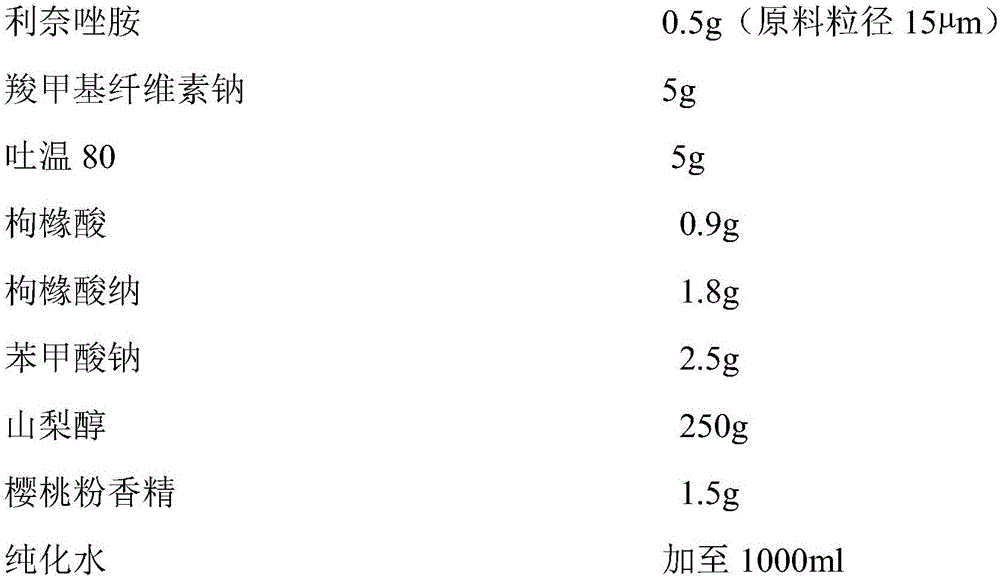

Linezolid oral suspension and preparation method theroef

ActiveCN105853351AEffective anti-corrosion effectGood physical and chemical compatibilityAntibacterial agentsOrganic active ingredientsCarboxymethyl cellulosePreservative

The invention belongs to the field of pharmaceutic preparation, and specifically a linezolid oral suspension and a preparation method thereof. The linezolid oral suspension comprises the following components by weight: 0.5-2.0 parts of linezolid, 0.5-5.0 parts of sodium carboxymethyl cellulose, 0.05-0.5 part of polysorbate 80, 0.15-0.20 part of sodium citrate, 0.08-0.10 part of citric acid, 0.22-0.28 part of a preservative, 22-28 parts of sweetener, 1.2-1.8 parts of a correctant and an aqueous medium. The present invention fills the market blank of only containing tablet or injection, and provides a novel dosage form choice. The linezolid oral suspension product has good quality, can be accurately divided into the dosage based on body weight, and is easy to swallow. The preparation process is simple, feasible and reproducible, and can consistently produce linezolid oral suspension with quality meeting the requirements.

Owner:CHONGQING HUAPONT PHARMA

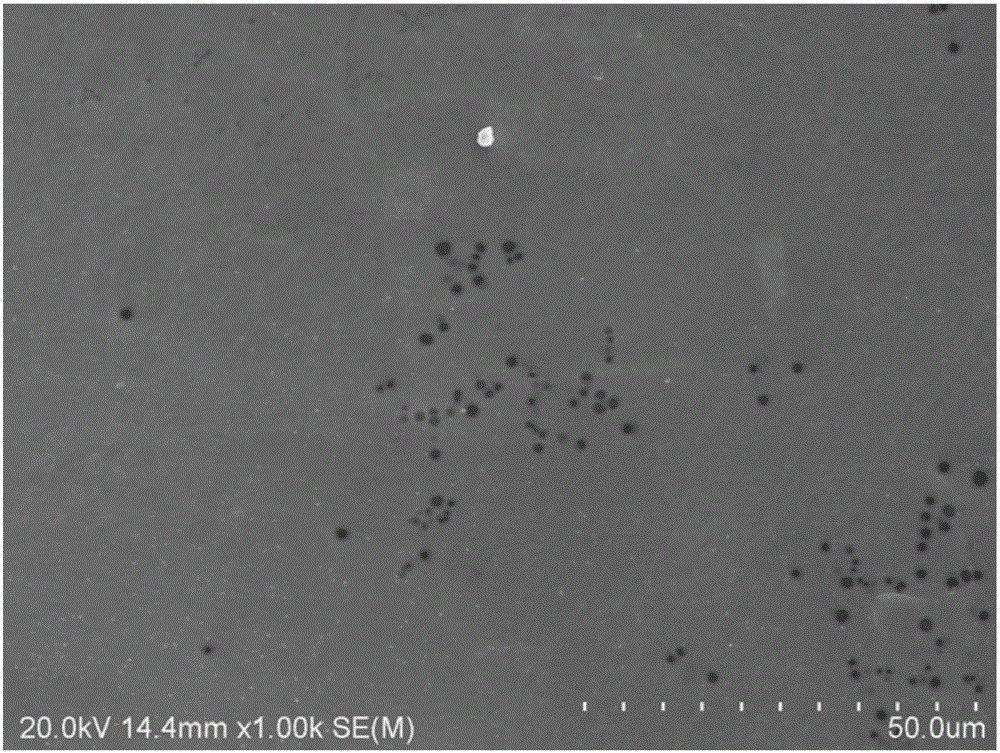

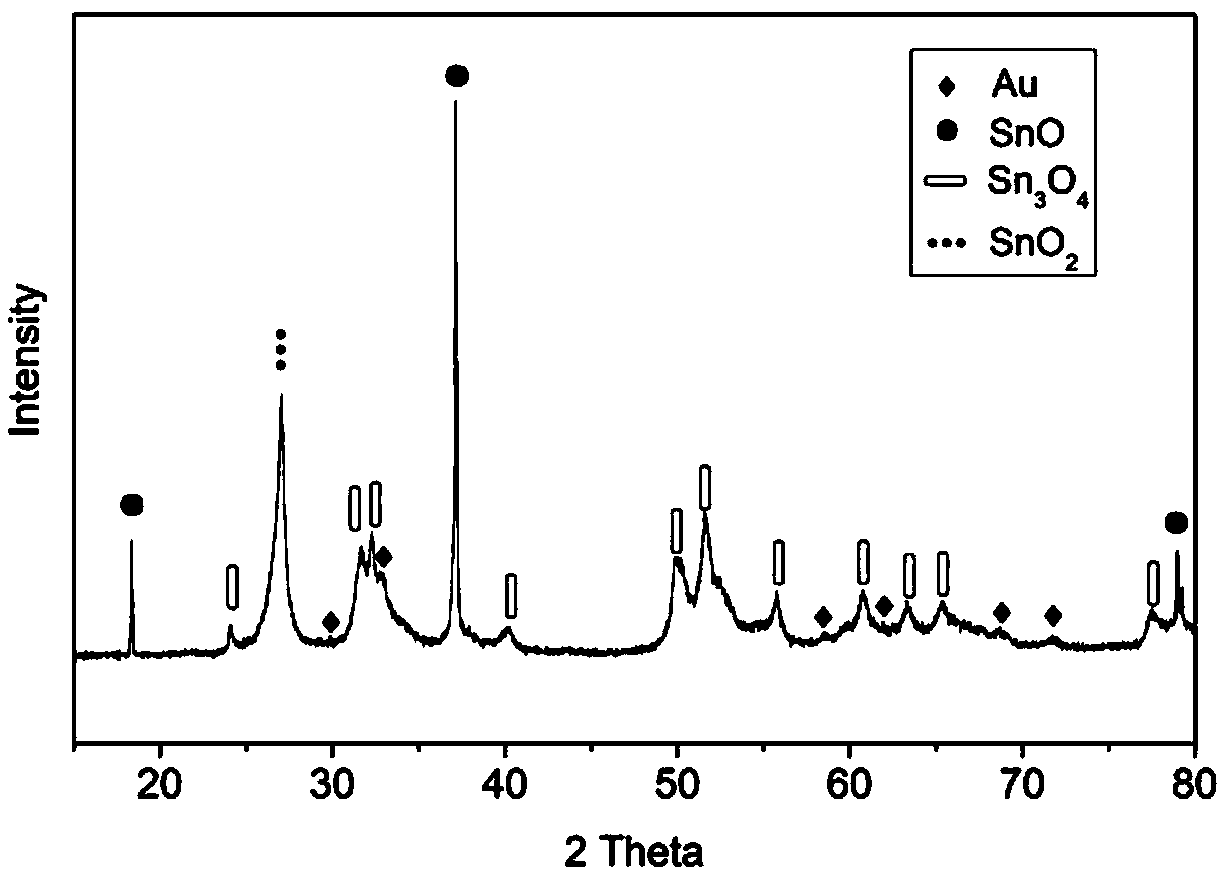

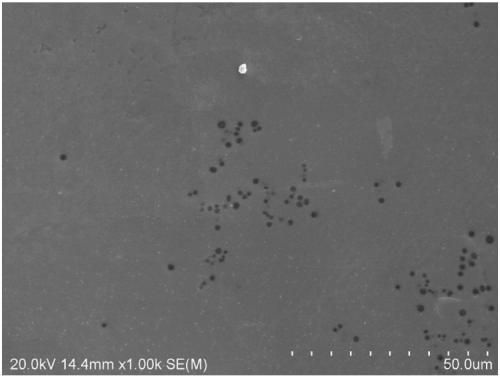

Preparation method of Au modified SnO/Sn3O4/SnO2 nano composite photocatalytic material

InactiveCN109092307AEnhanced light absorptionEasy to separateHydrogen productionHydrogen/synthetic gas productionHeterojunctionPhotocatalytic water splitting

The invention relates to a preparation method of an Au modified SnO / Sn3O4 / SnO2 nano composite photocatalytic material. The nano composite material is obtained by placing chloroauric acid and a tin source into a solvent, a surfactant and a reducing agent and forming chemical bond complexing among composite ingredients of the materials according to an ice salt bath and solvent combined hot wet chemical in-situ synthesis method. The composite material prepared by the invention utilizes a plasma resonance effect of Au metal nanoparticles, an excellent energy level matching heterojunction structureamong composite components of a tin oxide material and excellent electron conduction of Au metal nanoparticles, and implements rapid electron-hole separation in the process of cooperating photocatalytic oxidation and reduction degradation of pollutants with photocatalytic water splitting hydrogen production, thereby improving efficiency of photocatalytic water splitting and photocatalytic rhodamine B degradation of the Au modified SnO / Sn3O4 / SnO2 nano composite photocatalytic material.

Owner:PINGDINGSHAN UNIVERSITY

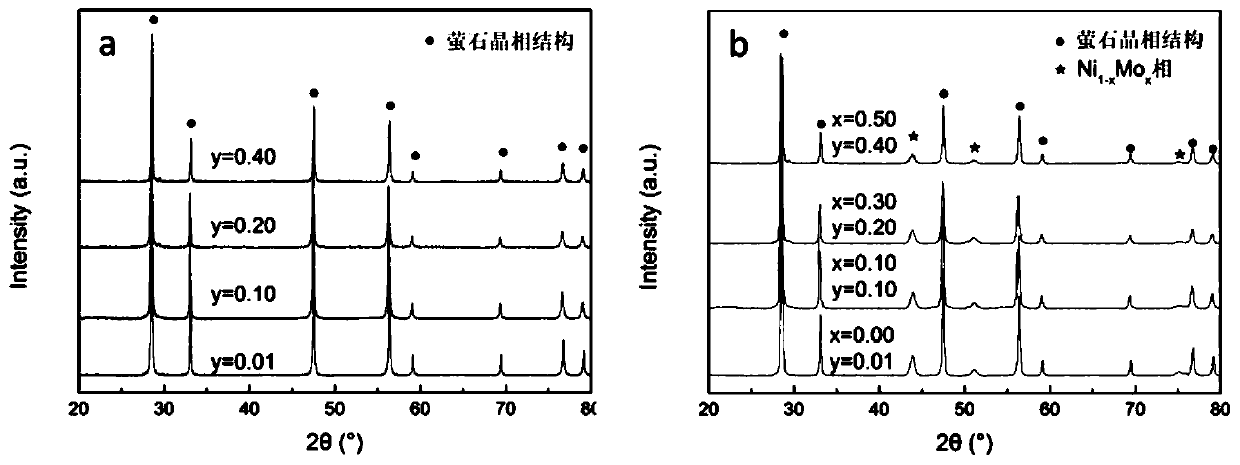

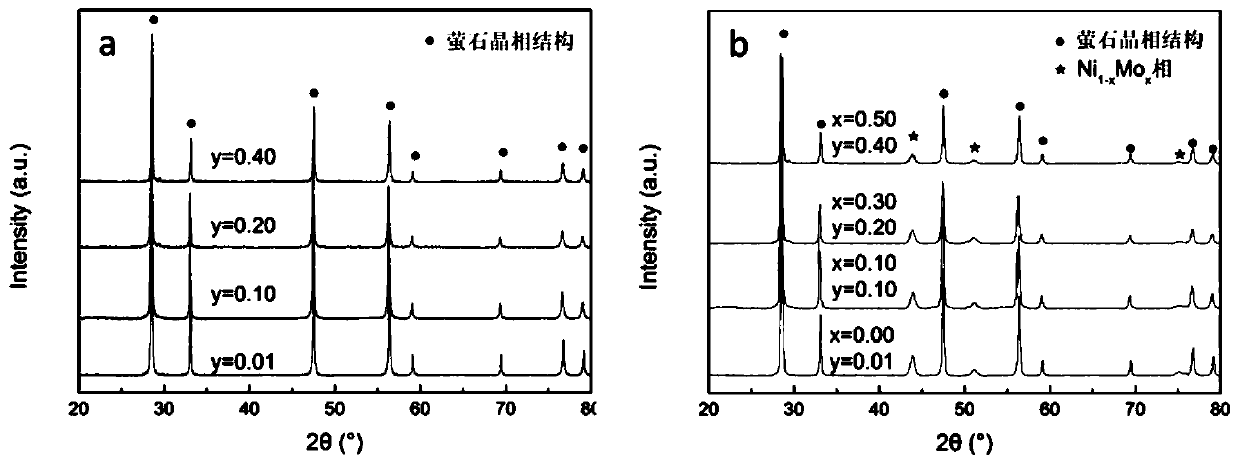

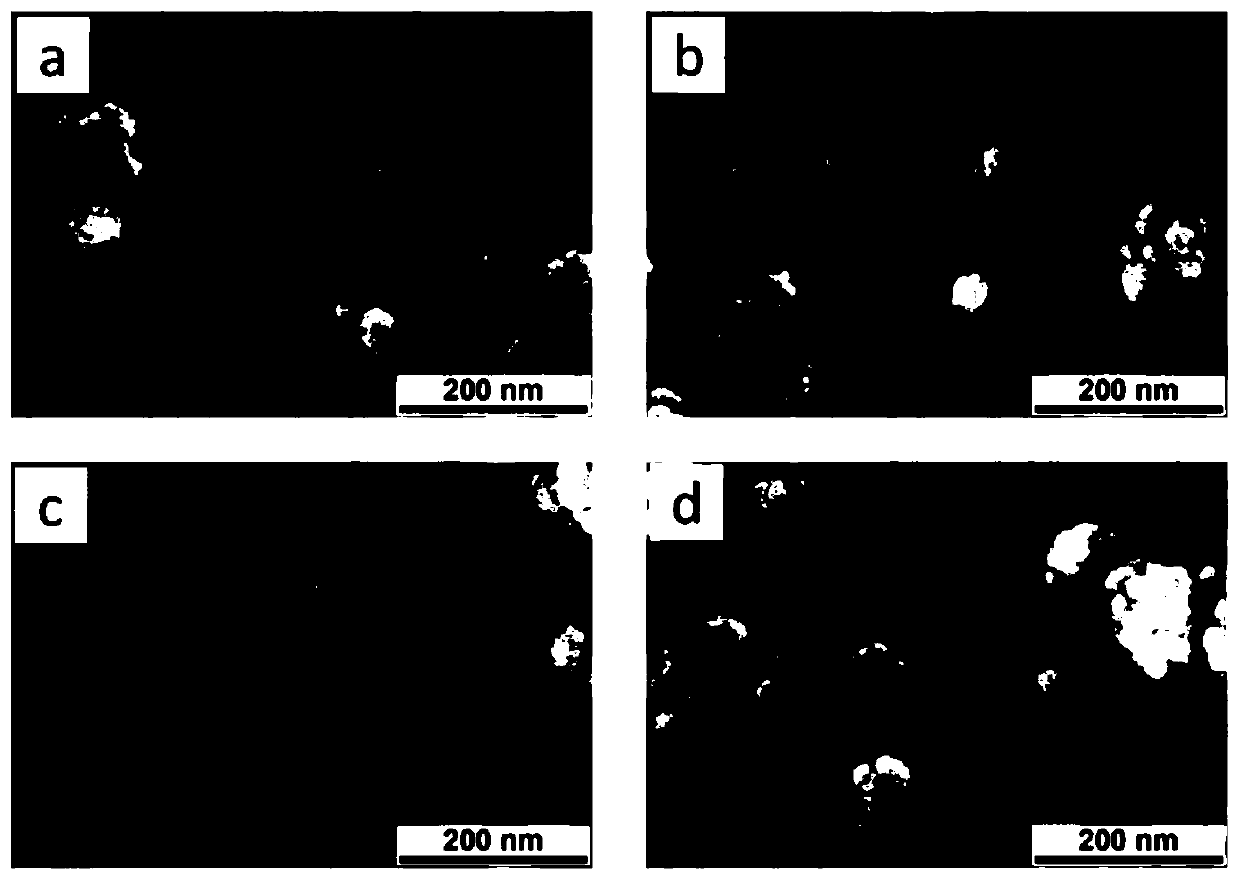

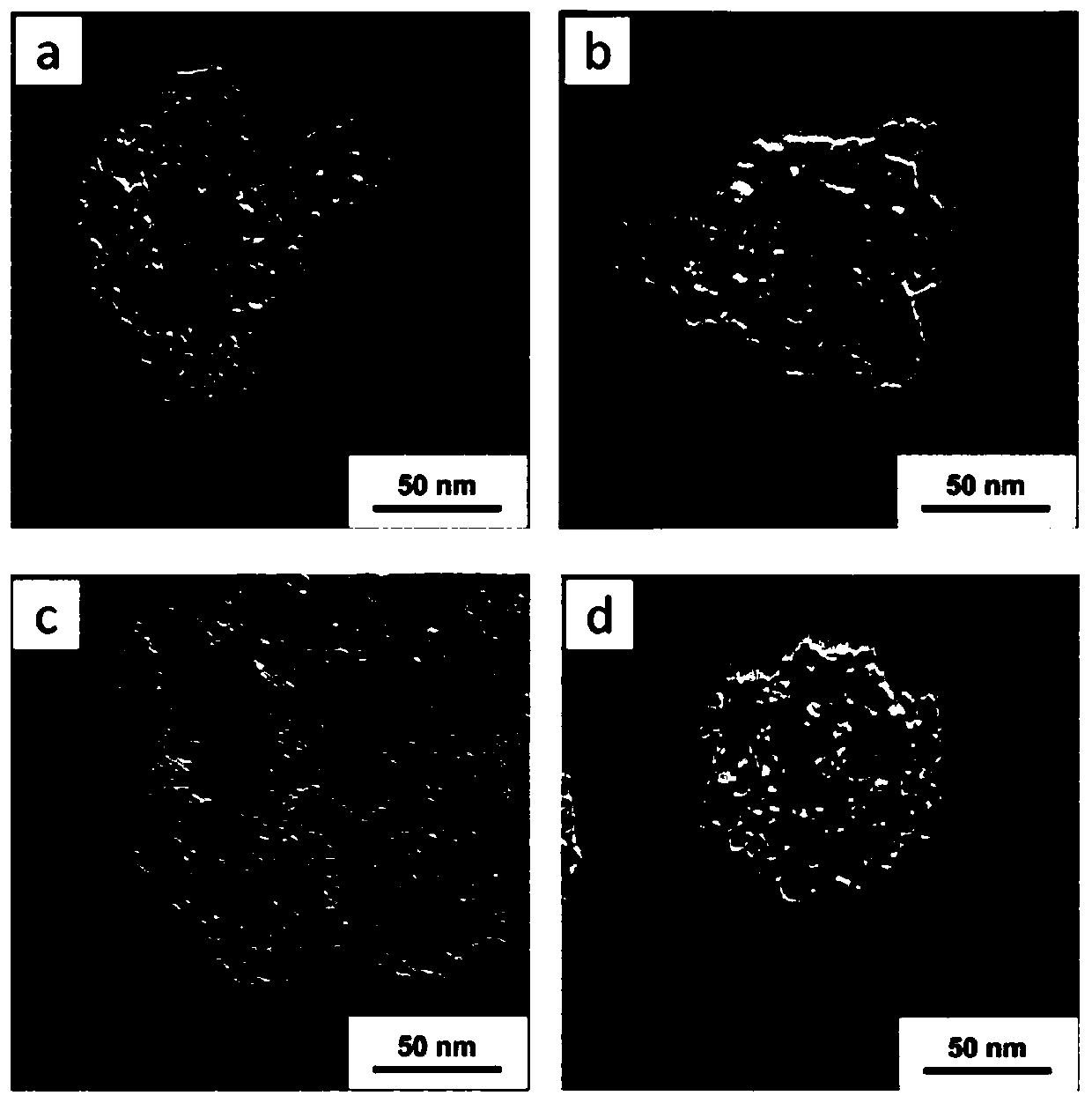

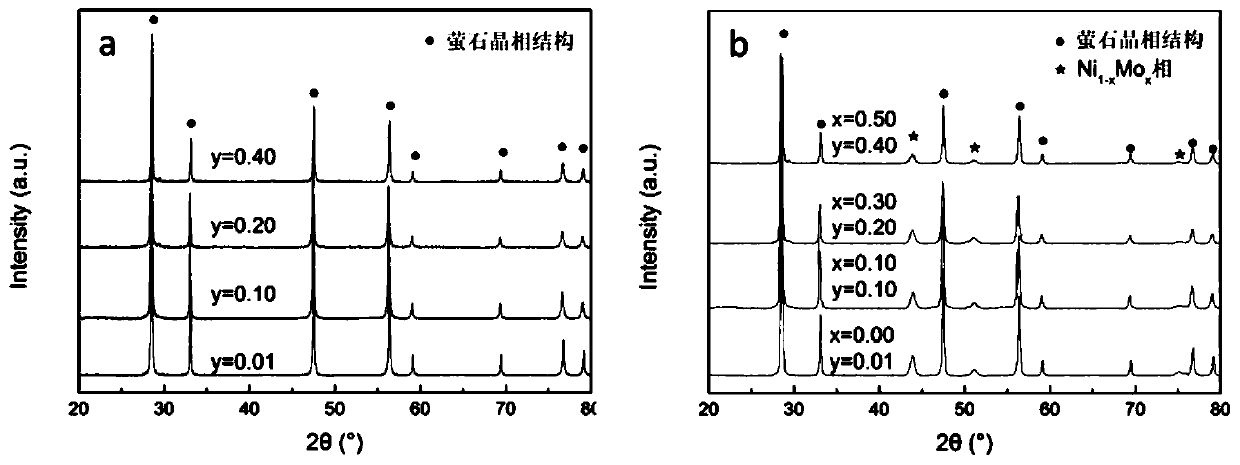

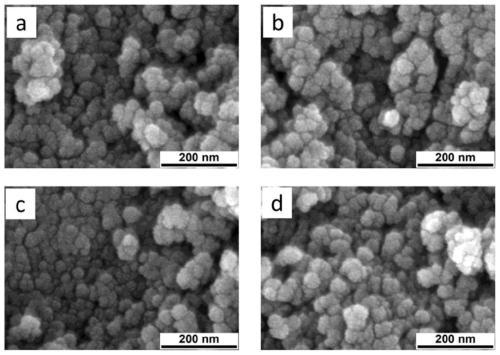

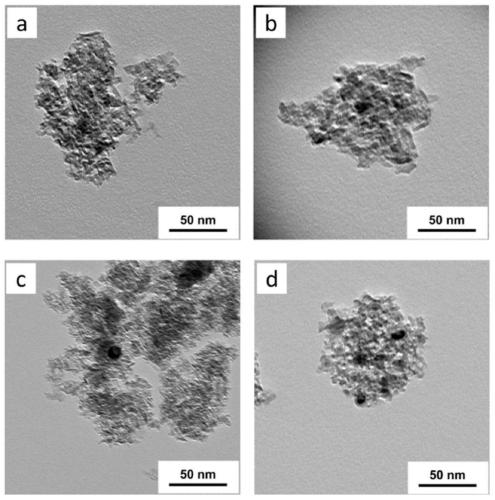

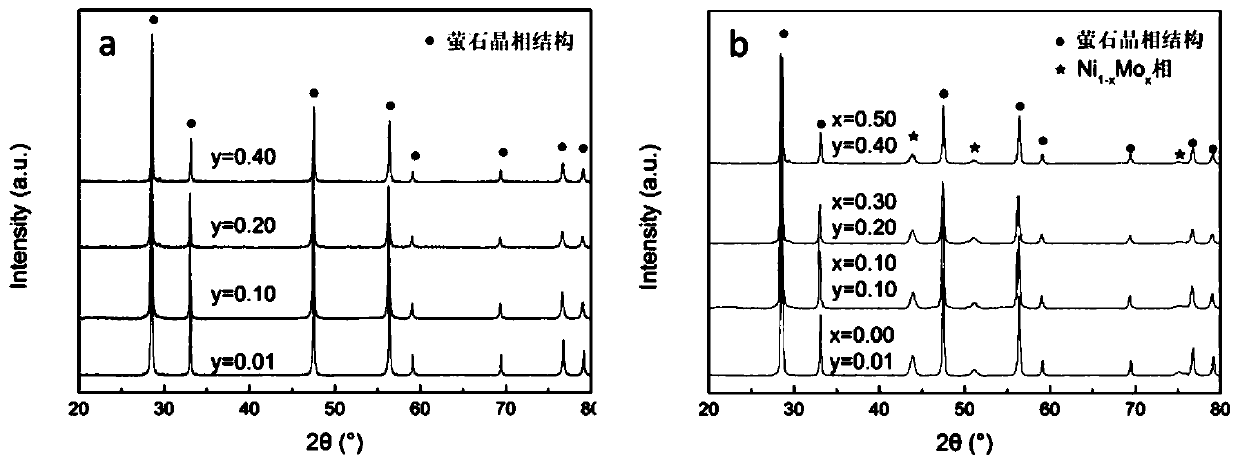

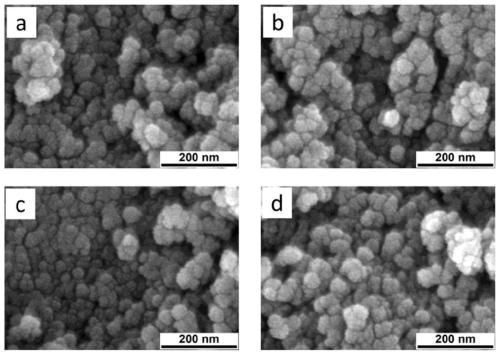

Preparation method of solid oxide fuel cell catalyst

InactiveCN111029595AImprove conversion rateProspects for commercial applicationCell electrodesSolid electrolyte fuel cellsElectrochemical responseAlkane

The invention relates to a preparation method of a solid oxide fuel cell catalyst, in particular to a preparation method of a metal-ceramic type Ni1-xMox / Ce1-yCayO2-delta SOFC anode catalyst taking nickel and molybdenum as metal components and taking high-performance nano Ce1-yCayO2-delta as a carrier. The anode catalyst has an excellent catalytic effect on complex hydrocarbon fuels (such as gaseous alkanes such as methane, methanol, ethanol, propane and the like and liquid alkanes such as gasoline and the like); hydrocarbons can be efficiently catalyzed and converted into fuel gas rich in H2and CO, H2 and CO reaction gas is provided for electrochemical reaction of an SOFC anode, the electrochemical reaction rate of the anode is increased, and the electrochemical performance of an SOFC monocell is improved.

Owner:FOSHAN UNIVERSITY

Alloy for braze welding of high-intensity graphite and titanium alloy and preparation method thereof

InactiveCN103173654AImprovement ingredientsIncrease temperatureWelding/cutting media/materialsSoldering mediaChemical reactionHigh intensity

The invention discloses an alloy for braze welding of high-intensity graphite and titanium alloy and a preparation method thereof. The alloy comprises the following elements in percentage by weight: 50%-65% of Ti, 30%-45% of Cu and 5%-10% of Si. The preparation method of the alloy comprises the following steps of: preparing materials according to the following elements in percentage by weight: 50%-65% of Ti, 30%-45% of Cu and 5%-10% of Si; performing vacuum electric arc smelting at a vacuum degree of 5*10<-3>-8*10<-3> Pa and at an electric arc current of 1100-1300 A; and electromagnetically stirring for 1-3 minutes, and then cooling. According to the invention, the alloy components are optimized, various chemical reaction products with good mechanical properties at high temperature are formed on the reaction interface, the braze welding temperature is effectively reduced, and the application temperature of a welded joint is increased.

Owner:CENT SOUTH UNIV

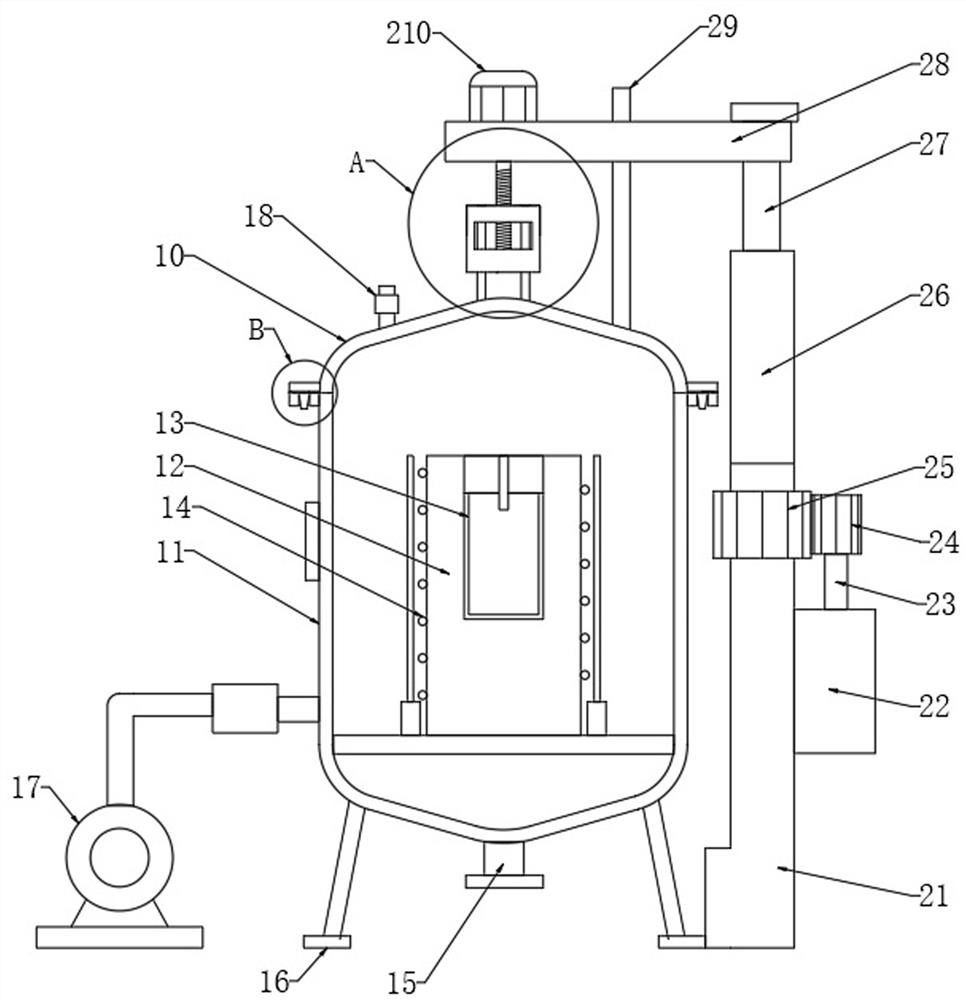

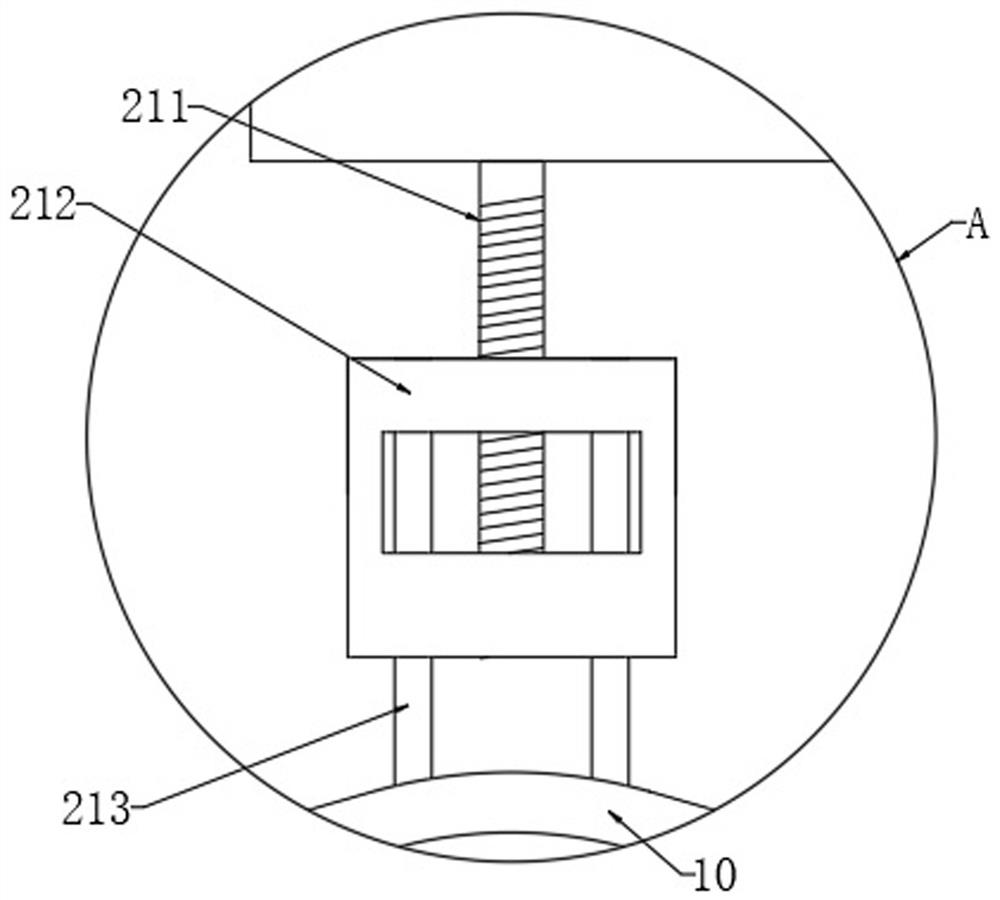

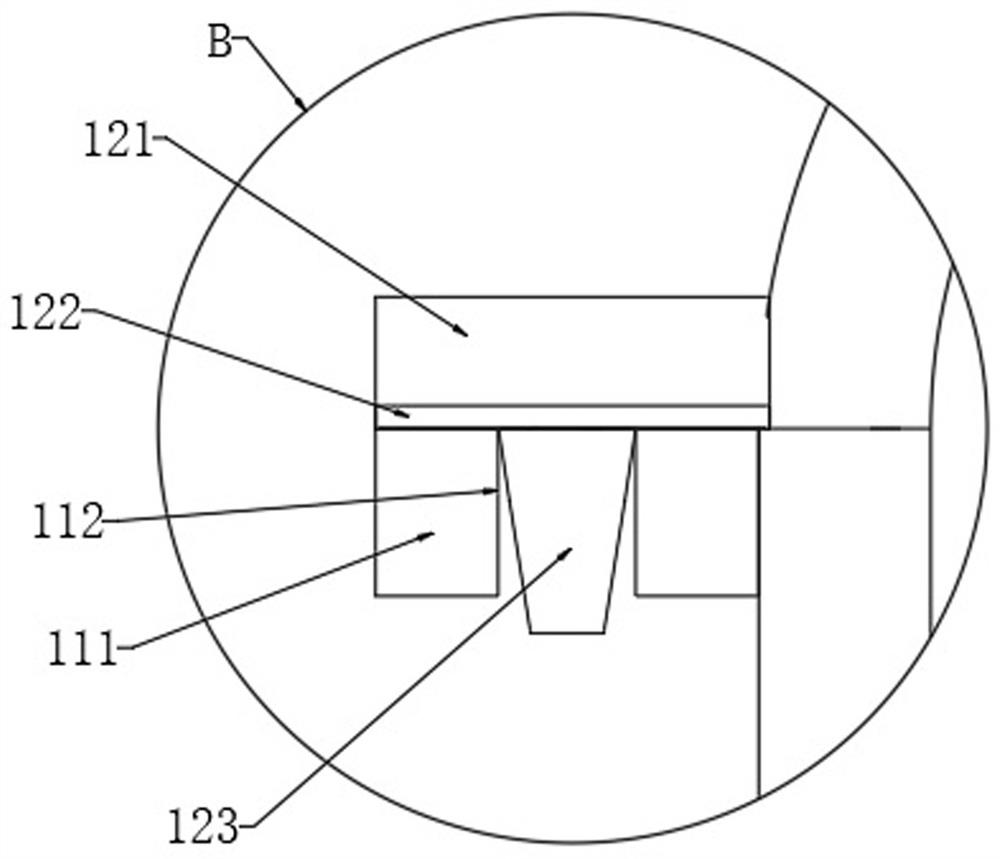

Improvement method and device for prolonging service life of graphite crucible

ActiveCN114105682AGood physical and chemical compatibilityPrevents oxidation and even breakageMolten spray coatingChemical industryPlasma sprayedGraphite crucible

The invention relates to the technical field of graphitization furnaces, in particular to an improvement method and device for prolonging the service life of a graphite crucible. The improvement method for prolonging the service life of the graphite crucible comprises the following steps that mixed powder is prepared, specifically, tungsten oxide, Si powder, C powder and chlorine salt are evenly mixed according to the mass part ratio of 45-60: 15-30: 10-25: 5-30, and the mixed powder is obtained; the graphite crucible base material is polished and pretreated, and an activated graphite crucible is obtained; primary bath: carrying out primary bath on the activated graphite crucible in the mixed powder to obtain a graphite crucible with a primary tungsten coating; and secondary spraying: spraying powder containing metal tungsten powder is subjected to plasma spraying on the surface of the graphite crucible with the primary tungsten coating, and the graphite crucible with the gradient tungsten coating is obtained. According to the method, the graphite crucible can be prevented from being oxidized and even fractured in the graphitization process; the service life is prolonged.

Owner:湖州启源金灿新能源科技有限公司

Titanium nitride reinforced zirconia toughened alumina ceramic powder and preparation method thereof

The invention provides titanium nitride reinforced zirconia toughened alumina ceramic powder and a preparation method thereof, and belongs to the technical field of ceramic materials. The preparationmethod comprises the following steps: mixing an aluminum salt, a zirconium salt, a yttrium salt, a titanium salt and water to obtain a mixed water solution, wherein the aluminum salt, the zirconium salt, the yttrium salt and the titanium salt are water-soluble inorganic salts; mixing the obtained mixed water solution with an alkaline precipitant for precipitation to obtain hydroxide precipitated powder; sequentially carrying out first calcining and second calcining on the obtained hydroxide precipitated powder to obtain oxide solid solution powder; and carrying out a selective nitriding reaction on the obtained oxide solid solution powder to obtain the titanium nitride reinforced zirconia toughened alumina ceramic powder. A ceramic material obtained by carrying out hot-pressing sintering on the titanium nitride reinforced zirconia toughened alumina ceramic powder provided by the invention is high in hardness and good in conductivity.

Owner:中国有色桂林矿产地质研究院有限公司

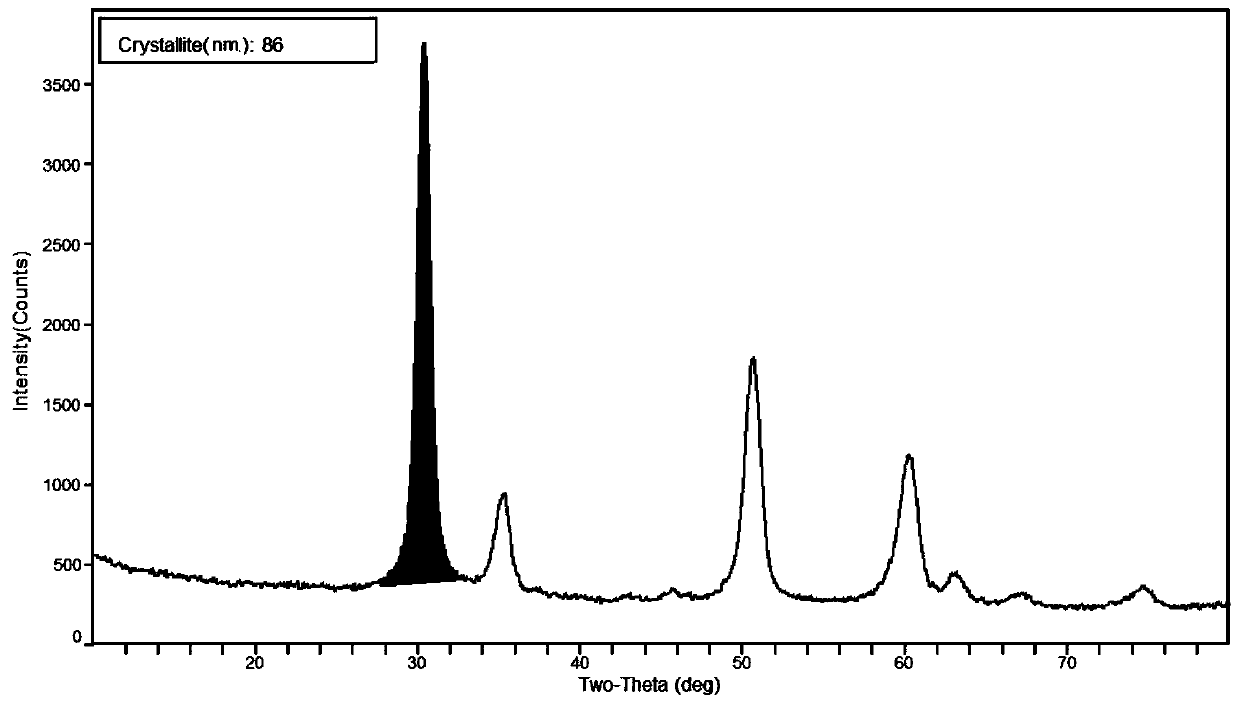

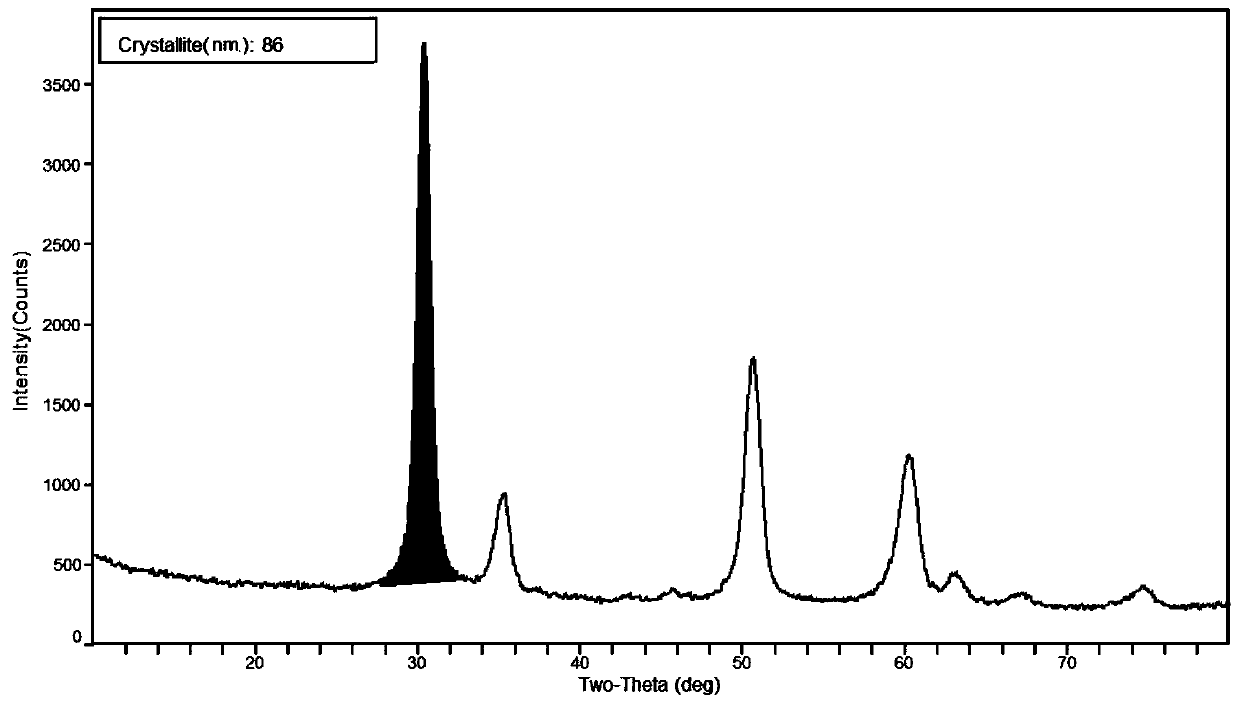

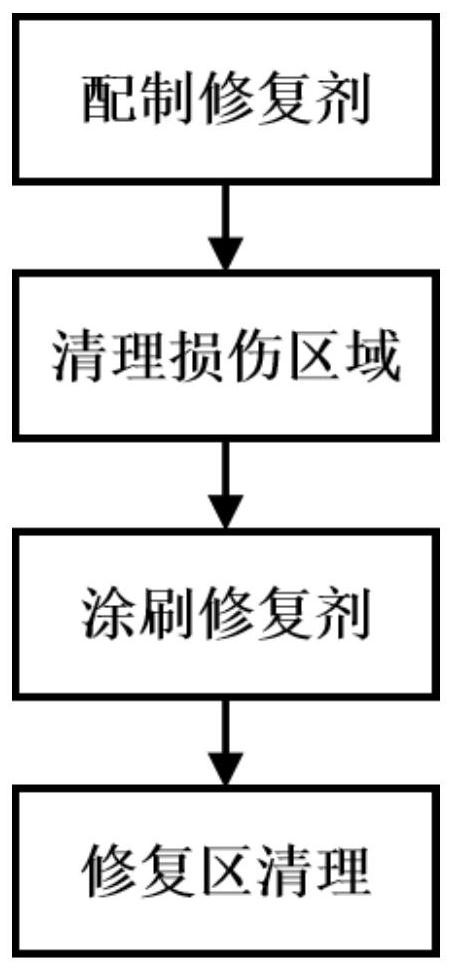

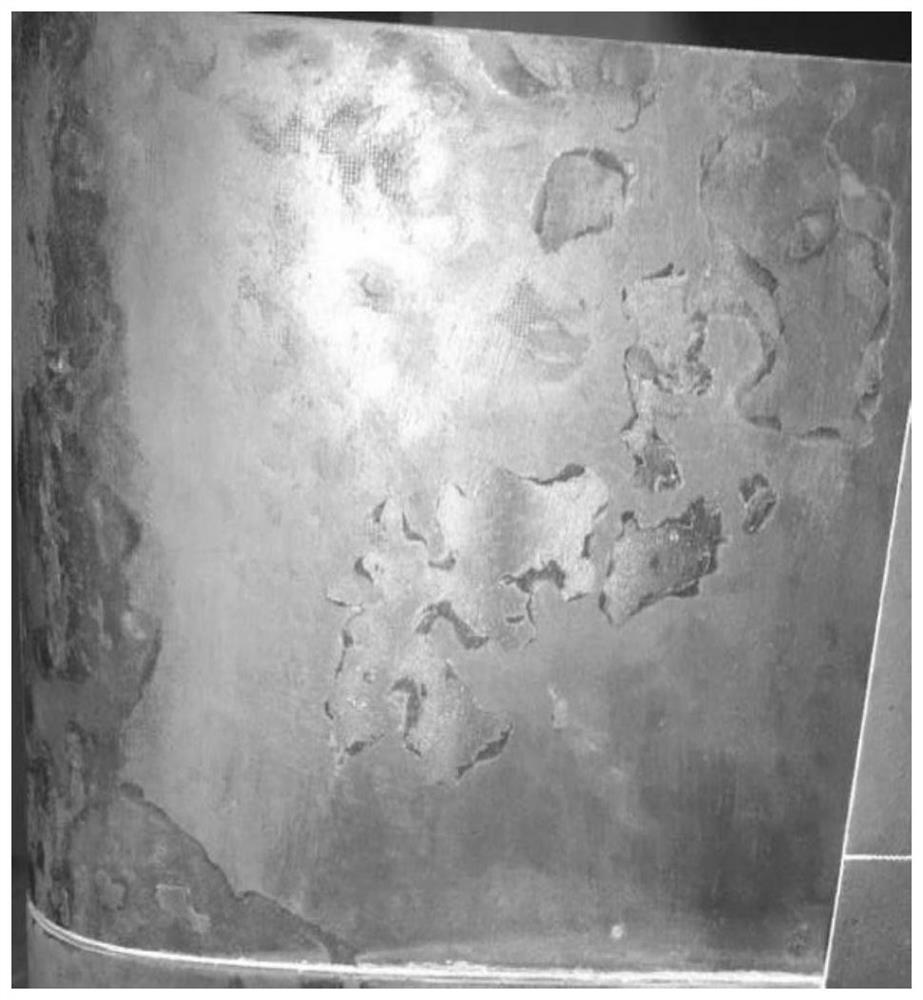

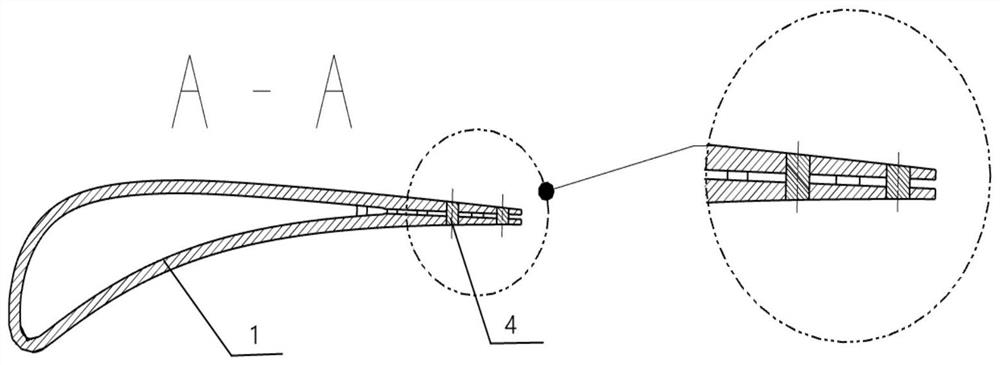

Repairing agent and repairing method for surface damage of silicon carbide ceramic matrix composite material

ActiveCN113402298AGood physical and chemical compatibilityLow costCarbide siliconChemical compatibility

The invention relates to a repairing agent and a repairing method for surface damage of a silicon carbide ceramic matrix composite material. According to the invention, solid polycarbosilane, dimethylbenzene, zirconium carbide powder, silicon carbide powder and silicon carbide whiskers in a reasonable ratio form a liquid substance with moderate viscosity. The chemical components of the repairing agent can quickly form a repairing layer having good physical and chemical compatibility with the silicon carbide ceramic matrix composite material in a natural environment. The preparation and construction processes of the repairing agent can be operated on line on the site of a damaged component. After the repairing agent is used for repairing surface damage, a repairing layer having good physical and chemical compatibility with a silicon carbide ceramic matrix composite body can be formed in a damaged area, and the repairing agent is high in bonding strength and high in temperature resistance. Through reasonable repair process parameters and matching of solid polycarbosilane, xylene, zirconium carbide powder, silicon carbide powder and silicon carbide whiskers in the reasonable ratio, the use temperature range of the repairing layer is -120 to 1400 DEG C, and the use temperature can reach 1650 DEG C in a short time.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

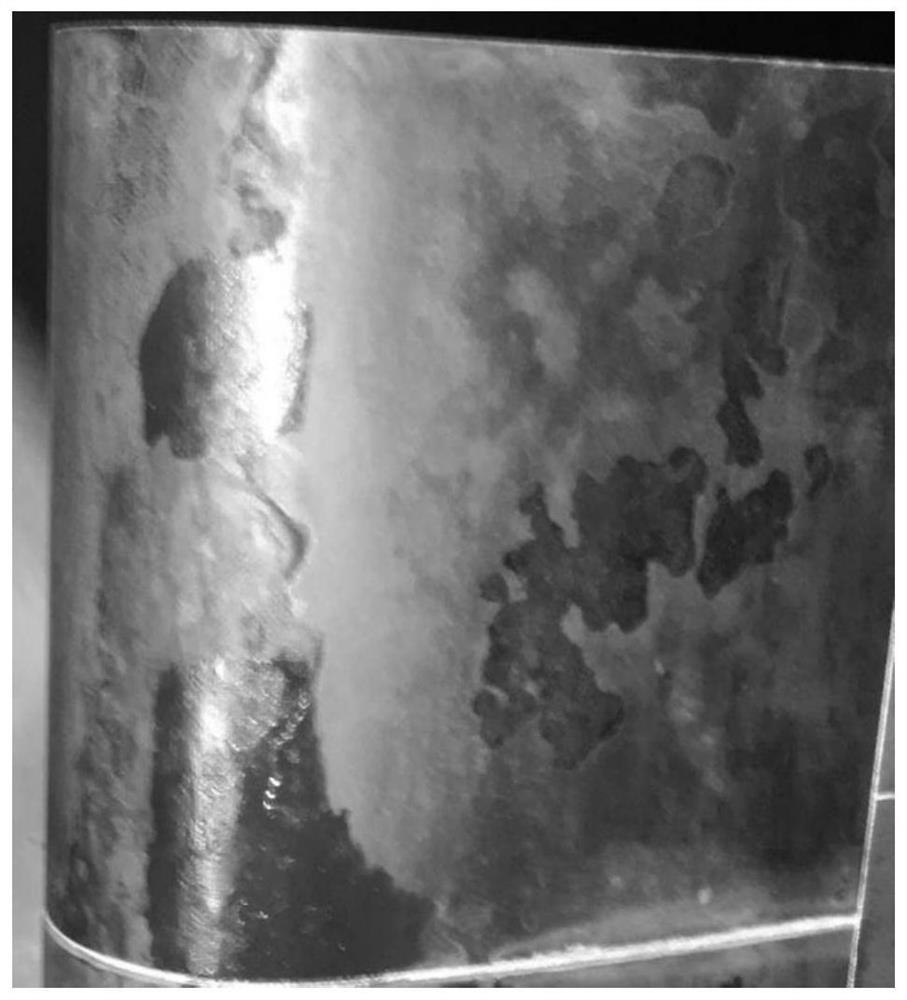

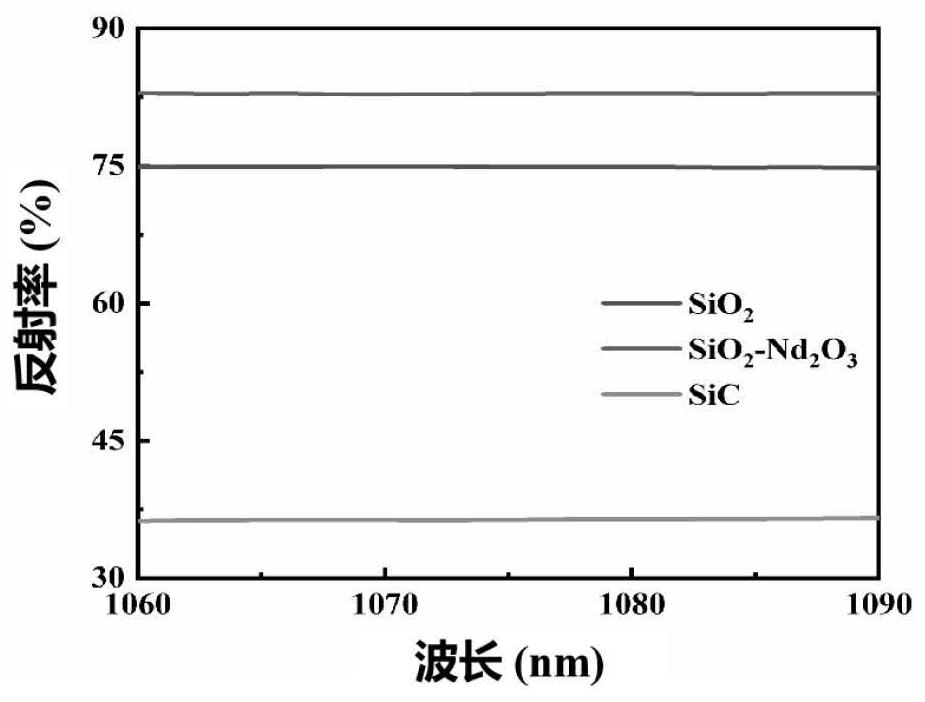

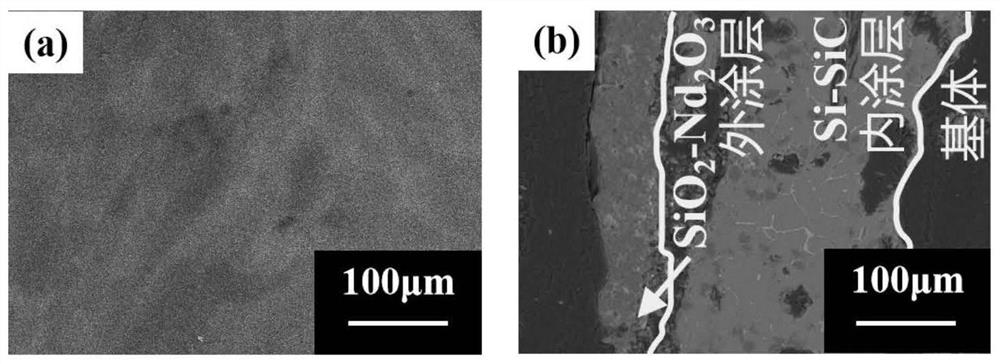

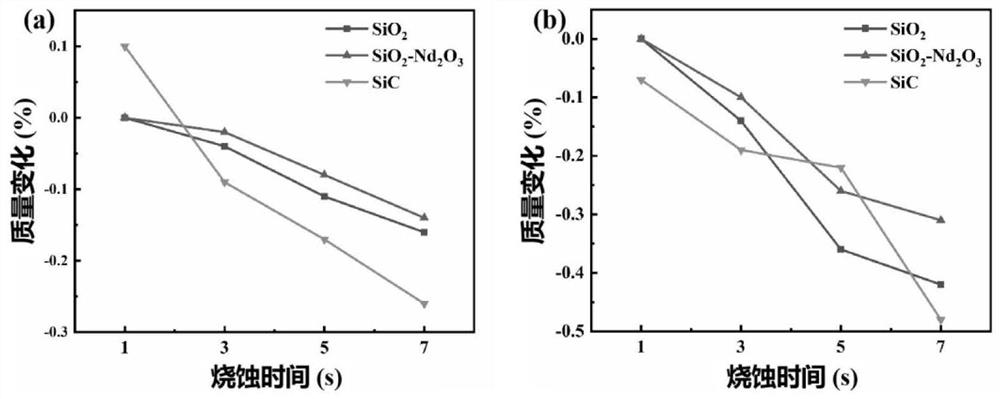

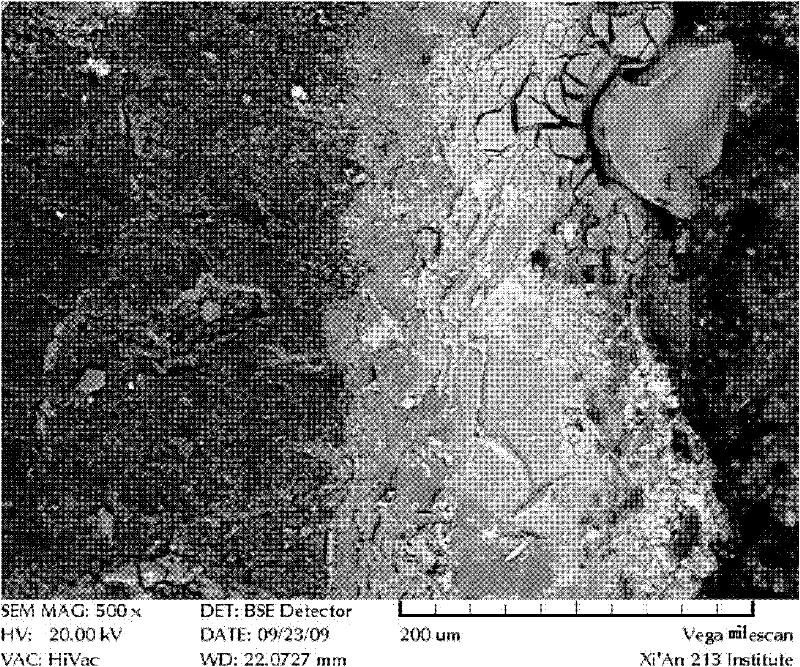

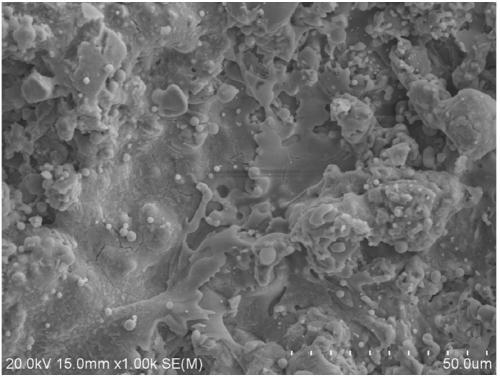

Repair method for damaged SiC coating carbon/carbon composite material

PendingCN113429223AProtection against secondary damageGood physical and chemical compatibilityCarbon compositesBi layer

The invention relates to a repairing method for a damaged SiC coating carbon / carbon composite material, in particular to a SiO2-Nd2O3 / Si-SiC repairing system for the damaged SiC coating carbon / carbon composite material and a preparation method of the SiO2-Nd2O3 / Si-SiC repairing system, and the damaged part of the SiC coating is locally repaired by adopting a SiO2-Nd2O3 / Si-SiC double-layer system based on a laser cladding technology. Wherein the Si-SiC inner coating has good physical and chemical compatibility with the C / C composite material matrix and the SiC coating at the undamaged part, and the recovery of the oxidation protection performance of the repaired sample is facilitated; and the SiO2-Nd2O3 outer coating has extremely strong reflection characteristics on laser with the wave band of about 1 [mu] m, and can effectively reduce the absorption of the material on laser energy and the generation of heat, so that the secondary damage of the laser on the SiC coating is effectively prevented.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

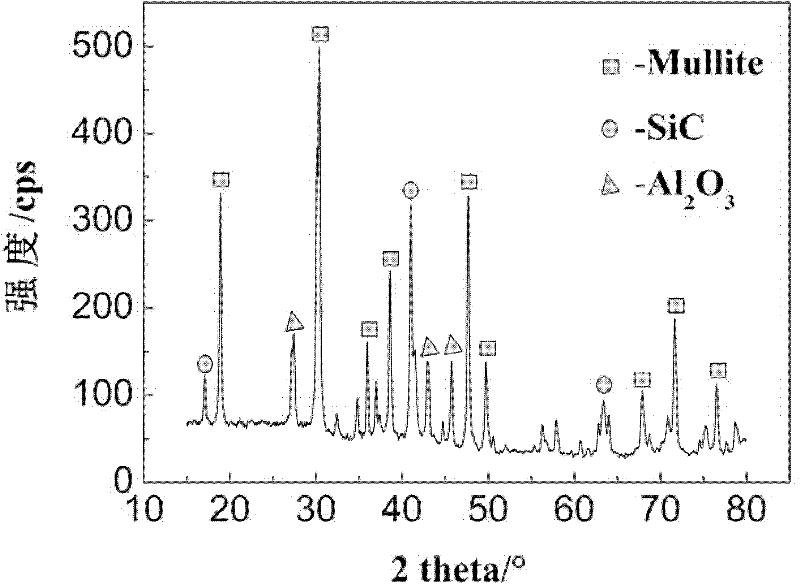

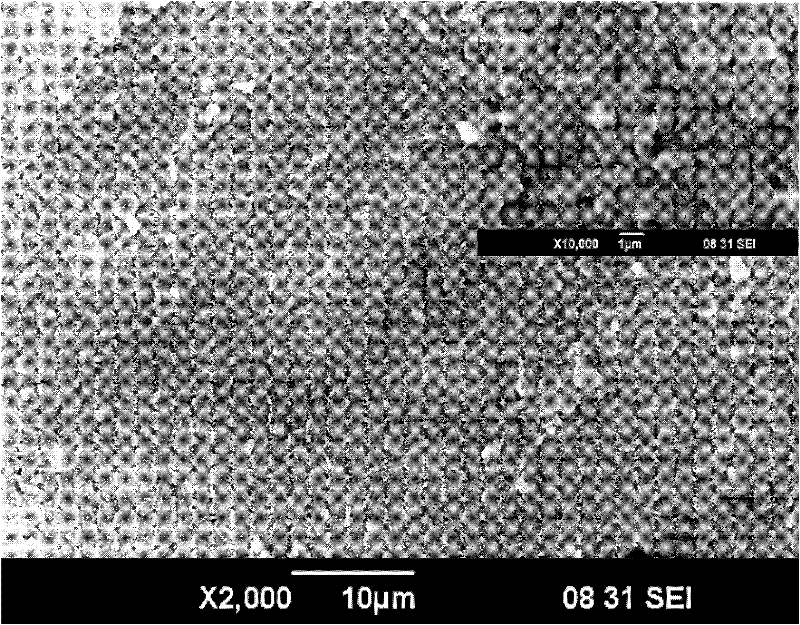

Method for preparing carbon/carbon composite material nanometer silicon carbide-mullite composite external coating

InactiveCN101838157BImprove high temperature oxidation resistanceImprove oxidation protection abilityCarbon compositesThermal dilatation

The invention provides a method for preparing carbon / carbon composite material nanometer silicon carbide-mullite composite external coating. The method comprises the following steps: adding mullite powder and nanometer silicon carbide powder into isopropanol for ultrasonic oscillation, adding iodine into the mixture for another ultrasonic oscillation, and placing the mixture in a hydrothermal reaction kettle; clamping the carbon / carbon composite material test sample with SiC internal coating on a cathode clip in the hydrothermal kettle for hydrothermal electrophoresis reaction, taking out anddrying the test sample to obtain the carbon / carbon composite material nanometer silicon carbide-mullite composite external coating. The mullite adopted as the C / C-SiC external coating has higher thermal stability and oxidation resistance, and has melting point more than 1,800 DEG C. The coefficient of thermal expansion of the mullite is close to that of the SiC, so the mullite cannot generate thermal stress at high temperature. The mullite can generate SiO2 and Al2O3 with low penetration and excellent high-temperature stability with oxygen at high temperature, additionally; nanometer silicon carbide particles can effectively overcome microcrack and other defects of the SiC internal coating, so that the high-temperature oxidation resistance of the coating can be greatly improved.

Owner:SHAANXI UNIV OF SCI & TECH

Connecting method for titanized Al2O3 ceramic and Ti ring in manmade retina

ActiveCN106270882AGood physical and chemical compatibilityImprove connection strengthSoldering apparatusTitaniumHeating furnace

The invention relates to a connecting method for titanized Al2O3 ceramic and a Ti ring in a manmade retina. The to-be-connected titanized Al2O3 ceramic and the to-be-connected Ti ring are placed in acetone to be subjected to ultrasonic cleaning for 5 min -10 min; then, a Ti foil piece is arranged between connecting faces of the to-be-connected titanized Al2O3 ceramic and the to-be-connected Ti ring, a titanized Al2O3 ceramic / Ti foil piece / Ti ring assembling piece is assembled, the obtained assembling piece is placed in a vacuum heating furnace, the exerted pressure ranges from 1 MPa to 10 MPa, when the vacuum degree reaches (1.3-2.0)*10-3 Pa, the temperature rise speed is controlled to range from 10 DEG C / min to 30 DEG C / min, the temperature is increased to range from 850 DEG C to 1,150 DEG C, then heat preservation is conducted for 30 min to 120 min, then the cooling speed is controlled to range from 3 DEG C / min to 10 DEG C / min, cooling is conducted to 300 DEG C, furnace cooling is conducted later, and then connection of the titanized Al2O3 ceramic with the Ti ring is finished. An obtained titanized Al2O3 ceramic / Ti ring connector is dense in structure, and air tightness is good.

Owner:HARBIN INST OF TECH AT WEIHAI

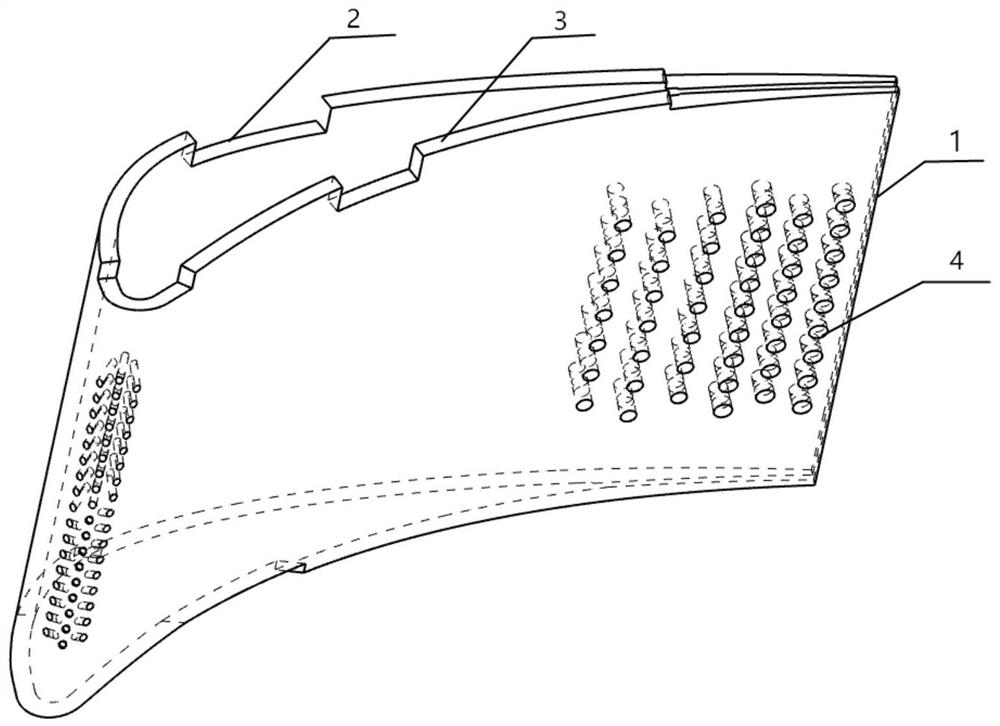

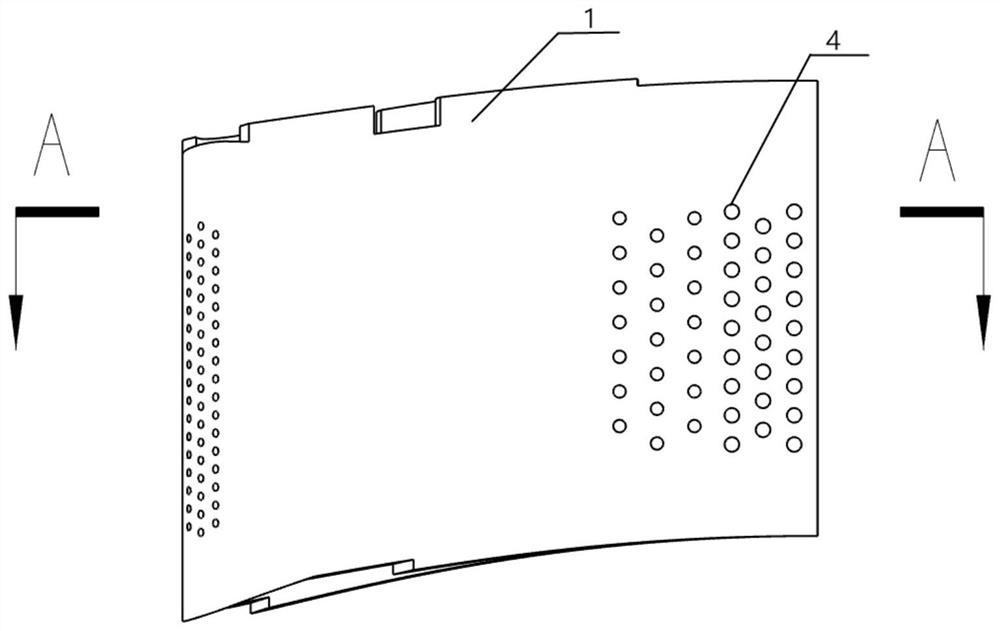

Ceramic matrix composite turbine guide blade with turbulent flow structures and preparation method thereof

ActiveCN113898417AReduce structural weightImprove temperature resistanceBlade accessoriesMachines/enginesCooling effectInterface layer

The invention discloses a ceramic matrix composite turbine guide blade with turbulent flow structures and a preparation method thereof. An inner cavity of the guide blade is provided with a plurality of columnar turbulent flow structures penetrating through a blade basin and a blade back, and the guide blade is made of a ceramic matrix composite. The invention further provides the preparation method of the blade. The preparation method comprises the following steps that a mold with vent holes is prepared firstly, then a fiber preform is prepared according to the mold, an interface layer and a ceramic matrix are sequentially deposited, after the mold is removed, the guide blade is machined to the design size, then through holes perpendicular to the blade profile are prepared in the turbulent flow column parts of a prepared blade body shell, then pins are inserted into the through holes, then a prepared assembly is connected in a homogeneous mode, and after machining and repairing, the ceramic matrix composite turbine guide blade with the turbulent flow structures is obtained. The temperature resistance of the guide blade prepared through the method is greatly improved, meanwhile, the structural weight is remarkably reduced, and the precision of the profile and the size and the cooling effect of the guide blade can be guaranteed.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

A kind of anti-oxidation coating and preparation method thereof

ActiveCN105755423BImprove antioxidant capacityImproves ablation resistanceMolten spray coatingCarbon fibersOxidation resistant

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Solid oxide fuel cell

InactiveCN111029593AImprove conversion rateProspects for commercial applicationCell electrodesSolid electrolyte fuel cellsElectrochemical responseAlkane

The invention relates to a solid oxide fuel cell, in particular to a solid oxide fuel cell containing a metal-ceramic type Ni1-xMox / Ce1-yCayO2-delta SOFC anode catalyst taking nickel and molybdenum asmetal components and taking high-performance nano Ce1-yCayO2-delta as a carrier. The catalyst has an excellent catalytic effect on complex hydrocarbon fuels (such as gaseous alkanes such as methane and propane and liquid alkanes such as gasoline), hydrocarbons can be efficiently catalyzed and converted into fuel gas rich in H2 and CO, H2 and CO reaction gas is provided for electrochemical reaction of an SOFC anode, the electrochemical reaction rate of the anode is increased, and the electrochemical performance of an SOFC monocell is improved.

Owner:FOSHAN UNIVERSITY

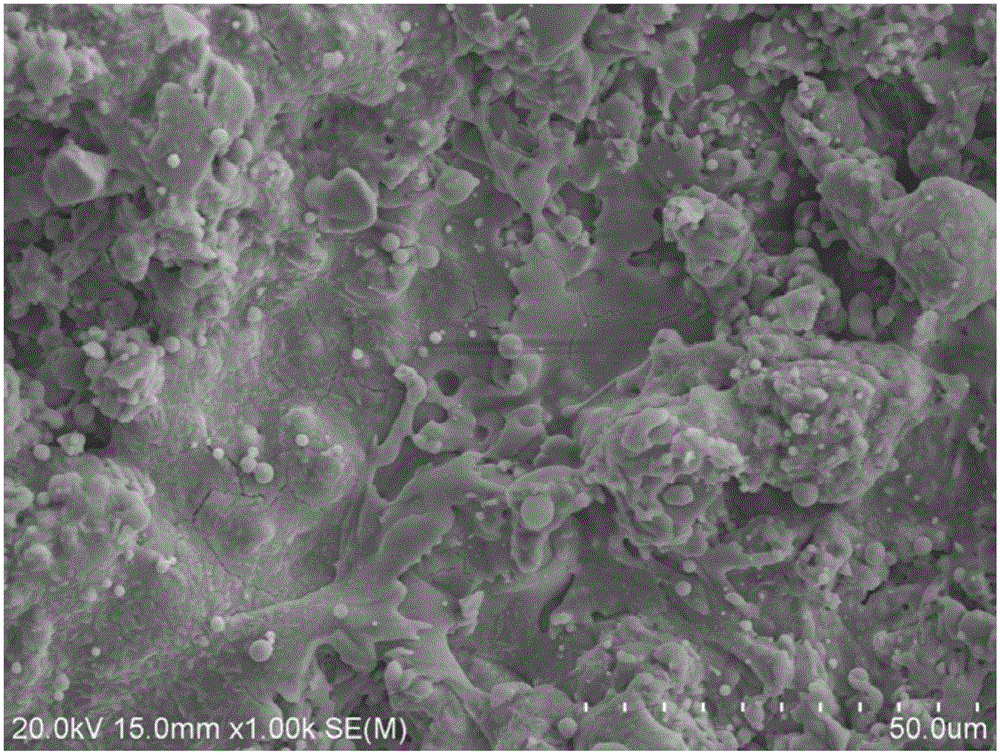

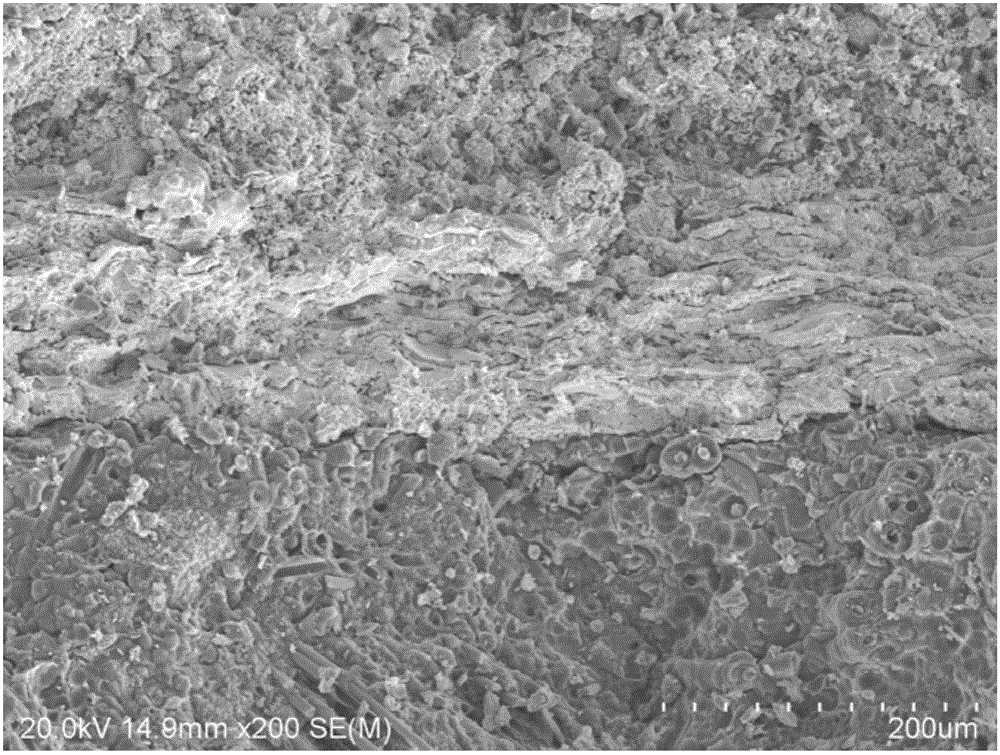

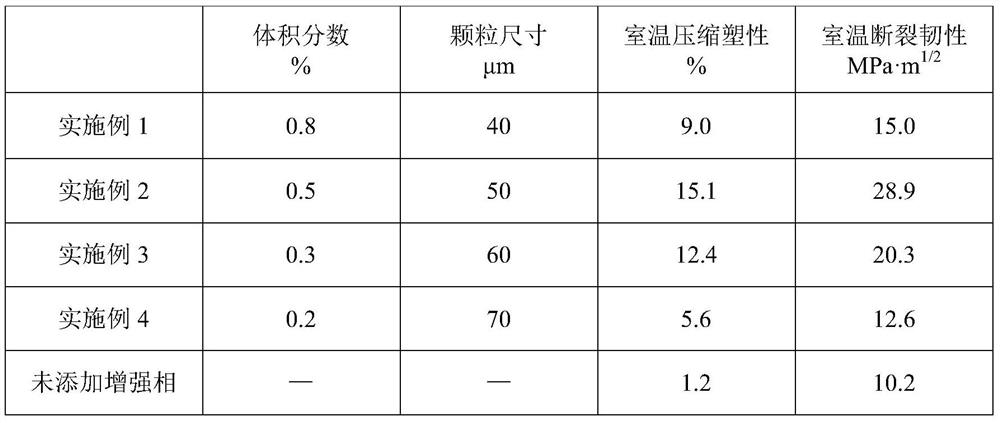

Method for preparing high-entropy reinforced amorphous alloy composite material

PendingCN113953528AGood physical and chemical compatibilityImprove plasticityAdditive manufacturing apparatusIncreasing energy efficiencyHigh entropy alloysPowder

The invention belongs to the technical field of amorphous alloy preparation, and relates to a method for preparing a high-entropy reinforced amorphous alloy composite material. The method comprises the following steps that amorphous alloy powder and high-melting-point high-entropy alloy powder with high toughness are evenly mixed according to a designed volume fraction, the mixed powder is conveyed out through airflow with supersonic speed, and the mixed powder and a laser focus are converged at a position 2-30mm above a deposition substrate; the amorphous alloy powder is heated to be in a molten state through laser suspension, meanwhile, the amorphous alloy powder is blown and cooled to be in a supercooled liquid state through supersonic airflow in the process of flying to the deposition substrate, an amorphous alloy matrix is deposited on the substrate, the high-entropy alloy powder is kept not molten all the time in the process, and finally, the high-entropy alloy powder is uniformly distributed in amorphous alloy formed by deposition in a reinforced phase form; the melting point of the high-entropy alloy powder is higher than that of the amorphous alloy powder; and an amorphous alloy composite material part without size constraint can be prepared, and the material has the performance advantages of high strength and high toughness.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

High-entropy reinforced amorphous alloy composite material and preparation method thereof

ActiveCN113981333AImprove brittlenessHigh strengthAdditive manufacturing apparatusIncreasing energy efficiencyHigh entropy alloysAlloy composite

The invention belongs to the technical field of composite materials and preparation thereof, and relates to a high-entropy reinforced amorphous alloy composite material and a preparation method thereof. The composite material is composed of a Cr-Fe-Ni-Ta-Mo-V high-entropy alloy phase reinforced Co-Fe-Ta-La-B amorphous alloy matrix, the volume of the high-entropy phase accounts for 0.1%-1% of the total volume of the composite material, and the size of the high-entropy alloy reinforced phase ranges from 30 micrometers to 80 [mu]m; the amorphous alloy matrix comprises the following components in percentage by atom: 15%-25% of Fe, 2%-10% of Ta, 11%-17% of La, 15%-25% of B and the balance of Co; the high-entropy alloy reinforcement phase comprises the following components in percentage by atom: 15%-25% of Fe, 10%-20% of Ni, 15%-25% of Ta, 7%-16% of Mo, 10%-20% of V and the balance of Cr; a laser additive manufacturing technology is adopted for preparation, the block high-entropy reinforced amorphous alloy composite material is finally obtained, and the plasticity and toughness of the composite material can be enhanced.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

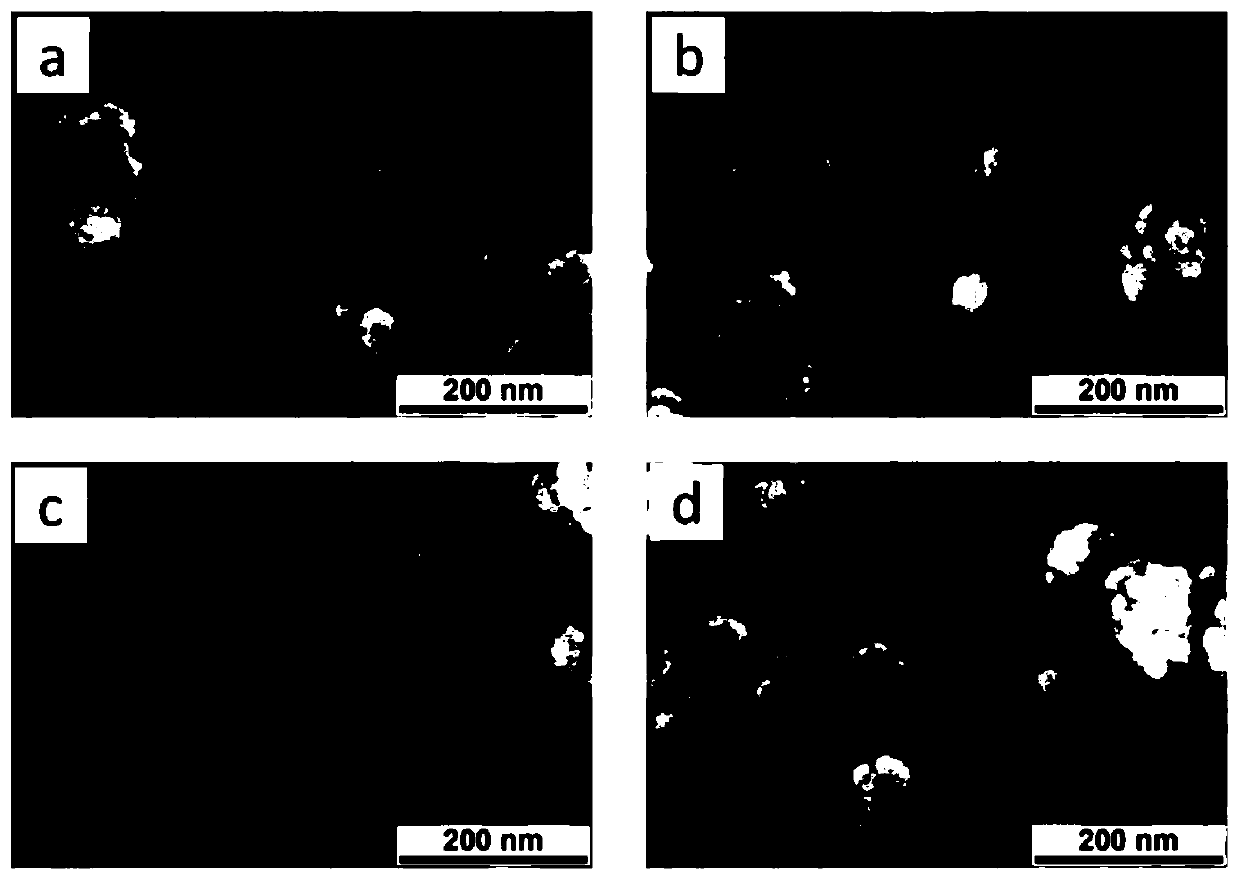

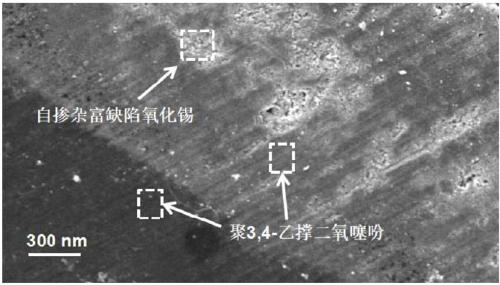

Preparation method of poly(3,4-ethylenedioxythiophene)/self-doped defect-rich tin oxide nano composite photocatalytic material

InactiveCN109107613AImprove separation rateResolve separabilityWater/sewage treatment by irradiationWater treatment compoundsHeterojunctionElectron hole

The invention relates to a preparation method of a poly(3,4-ethylenedioxythiophene) / self-doped defect-rich tin oxide nano composite photocatalytic material. A self-doped defect-rich tin oxide heterojunction material is loaded and dispersed on PETOT in a chemical bond complexing form to obtain the nano composite material; and the self-doped defect-rich tin oxide is selected from defect-rich tin oxide SnO2-x consisting of Sn-doped nonstoichiometric or mixed valent tin oxides. The electron-hole separation can be facilitated by utilizing the visible light responsive oxidation and reduction capacity of the self-doped defect-rich tin oxide heterojunction material, conductivity and hole transport capacity of PETOT as well as the chemical bonding heterojunction structure among different components, so that the excellent photocatalytic performance can be achieved. Meanwhile, the easy-to-mold characteristic of polypyrrole can effectively avoid the recycling difficulty of the powder material, sothat the poly(3,4-ethylenedioxythiophene) / self-doped defect-rich tin oxide heterojunction nano composite material is a novel environment-friendly photocatalytic material convenient to recycle.

Owner:PINGDINGSHAN UNIVERSITY

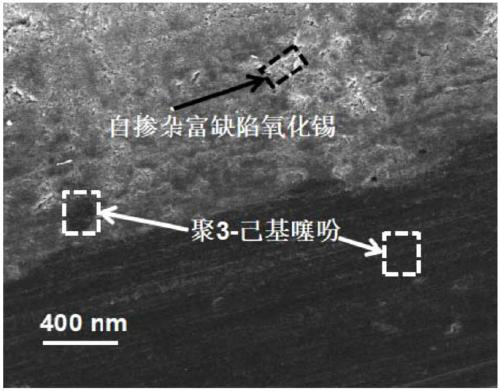

Preparation method of poly(3-hexylthiophene)/self-doped defect-riched tin oxide heterojunction nano composite photocatalytic material

InactiveCN109092368AHigh carrier mobilityEasy to process and prepareWater/sewage treatment by irradiationWater treatment compoundsElectron hole recombinationPollutant

The invention discloses a preparation method of poly(3-hexylthiophene) / self-doped defect-riched tin oxide heterojunction nano composite photocatalytic material. According to the method, a nano composite material is obtained by loading and dispersing a self-doped defect-riched tin oxide heterojunction material in P3HT in the form of chemical bond complexation; wherein the self-doped defect-riched tin oxide is selected from Sn-doped non-stoichiometric or defect-riched tin oxide SnO2-x composed of mixed valence state of tin oxide; according to the invention, the visible light photocatalytic redoxproperties of self-doped defect-riched tin oxide, the electrical conductivity of poly(3-hexylthiophene), the catalytic capacity of visible light and a heterojunction structure with chemical bonding among different components are utilized to fully inhibit photo-generated electrons-hole recombination of the nano composite photocatalytic material in a photocatalytic reaction, so that the improvements on the performance of photocatalytic redox degradation of pollutants and photocatalytic decomposition of hydrogen produced by water of the nano composite photocatalytic material are facilitated. Atthe same time, the characteristics of being easy to be molded of poly(3-hexylthiophene) can effectively avoid the problem of difficulty in recovery of powder materials.

Owner:PINGDINGSHAN UNIVERSITY

Anode of solid oxide fuel cell

InactiveCN111082070AEfficient CatalysisIncrease contentCell electrodesSolid electrolyte fuel cellsElectrochemical responseAlkane

The invention relates to an anode of a solid oxide fuel cell, and particular relates to an SOFC anode containing a metal-ceramic type Ni<1-x>Mox / Ce<1-y>CayO<2-delta> catalyst taking nickel and molybdenum as metal components and taking high-performance nano Ce<1-y>CayO<2-delta> as a carrier. According to the invention, an excellent catalytic effect is played on complex hydrocarbon fuels (for example, gaseous alkanes such as methane, methanol, ethanol and propane and liquid alkanes such as gasoline), hydrocarbons can be efficiently catalyzed and converted into fuel gas rich in H2 and CO, H2 andCO reaction gas is provided for electrochemical reaction of the SOFC anode, the electrochemical reaction rate of the anode is increased, and the electrochemical performance of the SOFC monocell is improved.

Owner:FOSHAN UNIVERSITY

Laser cladding powder for 30crmnsini2a steel and its preparation method

ActiveCN106480363BHigh bonding strengthLess metallurgical defectsTransportation and packagingMetal-working apparatusRare earthToughness

The invention relates to a laser cladding powder for 30CrMnSiNi2A steel and a preparation method. The amount of each component in the laser cladding powder is Cr 0.8%-1.0%, Mn 0.75%-1.10%, Si 0.65% by weight percentage ‑1.10%, Ni2.0%‑3.2%, C0.16%‑0.22%, Cu0.15%‑0.20%, P0.015%‑0.020%, S0.01%‑0.015%, Rare earth 0.001%‑0.015% , the remainder is iron. The present invention further proposes a preparation method of the cladding powder. The laser cladding powder is specially used in the laser cladding technology of 30CrMnSiNi2A steel, so as to ensure the excellent bonding strength of the cladding interface, lower metallurgical defects and reduced dilution rate, and improve the fusion rate. The toughness of the cladding layer improves the wettability of the cladding powder, inhibits the cracking of the cladding layer and delays the crack growth rate.

Owner:国营芜湖机械厂

Solid oxide fuel cell catalyst

PendingCN111048794AImprove conversion rateProspects for commercial applicationCell electrodesFuel cellsElectrochemical responseAlkane

The invention relates to a solid oxide fuel cell catalyst, in particular to a metal-ceramic type Ni < 1-x > Mo < x > / Ce < 1-y > Ca < y > O < 2-delta > SOFC anode catalyst taking nickel and molybdenumas metal components and taking high-performance nano Ce < 1-y > Ca < y > O < 2-delta > as a carrier. The catalyst has an excellent catalytic effect on complex hydrocarbon fuels (such as gaseous alkanes including methane, methanol, ethanol, propane and the like and liquid alkanes including gasoline and the like). The hydrocarbons can be efficiently catalyzed and converted into fuel gas rich in H2 and CO, H2 and CO reaction gas is provided for electrochemical reaction of the SOFC anode, the electrochemical reaction rate of the anode is increased, and the electrochemical performance of the SOFC monocell is improved.

Owner:FOSHAN UNIVERSITY

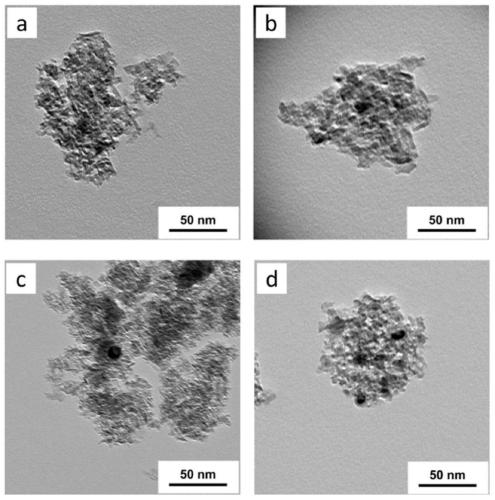

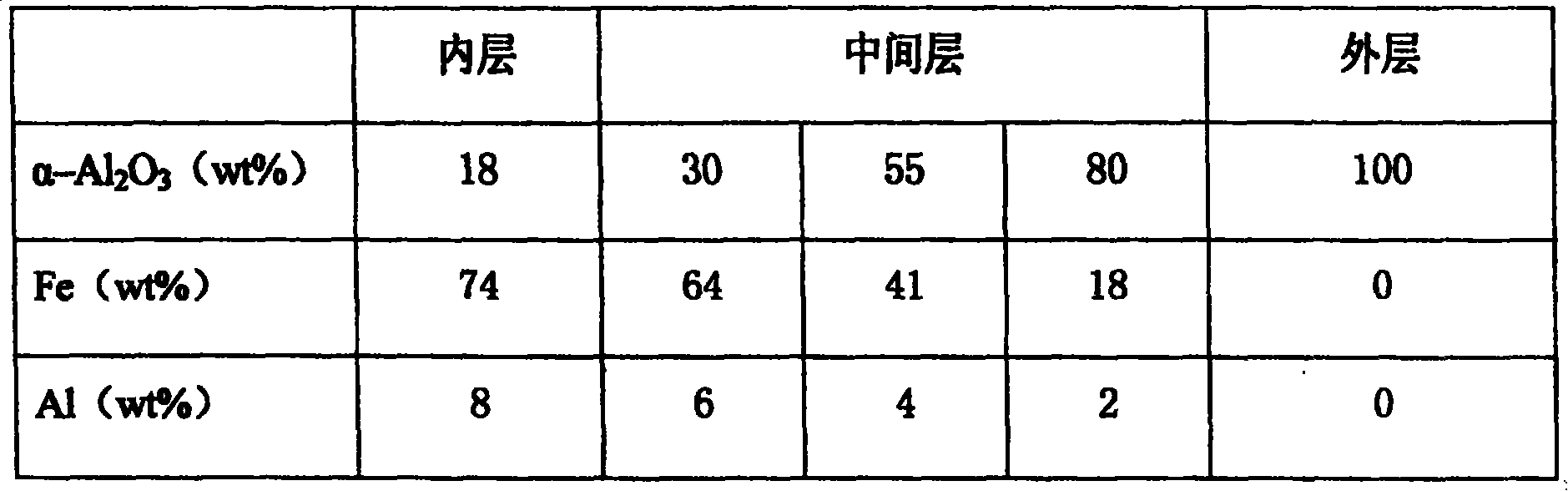

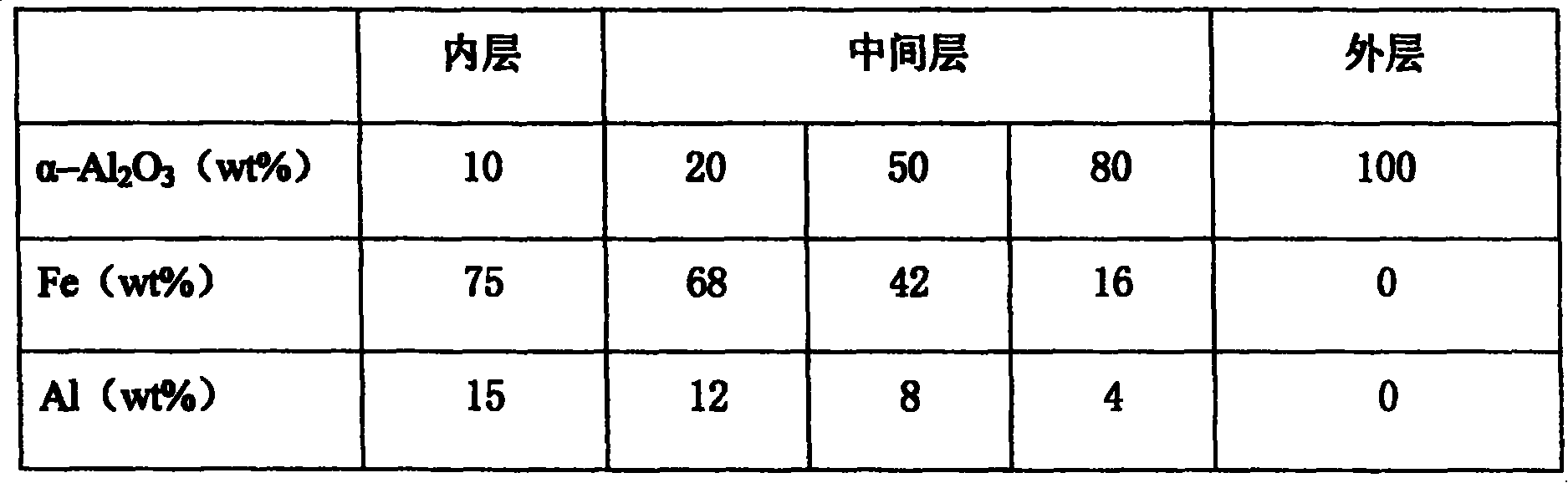

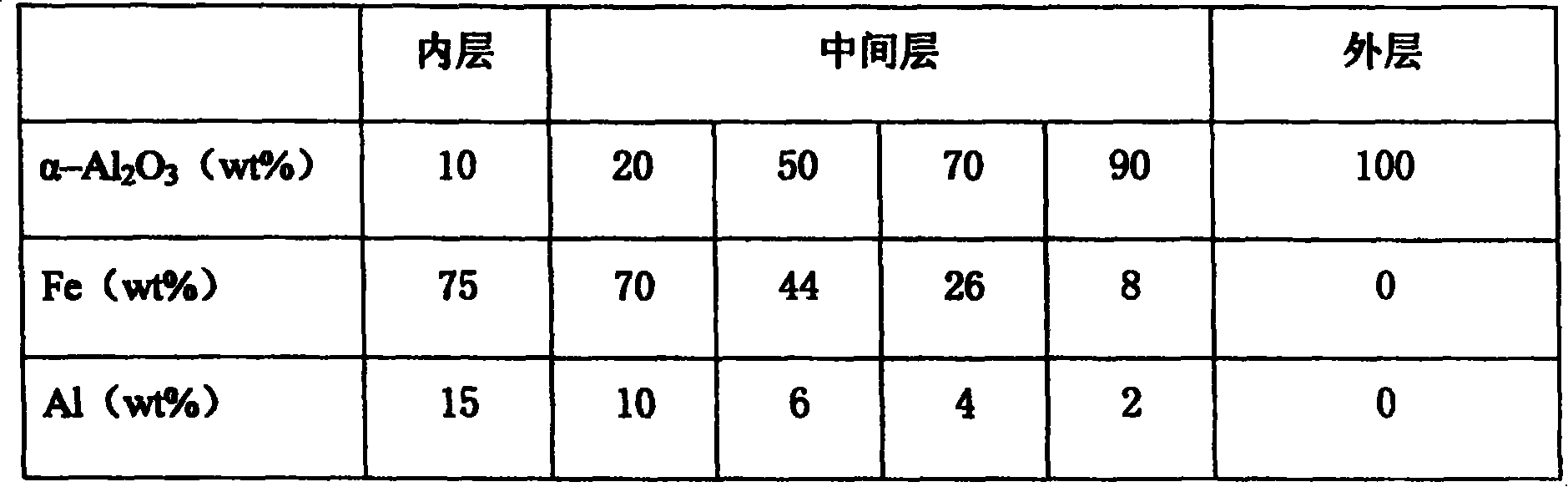

Gradient ceramic coating on steel substrate and its preparation process

Owner:UNIV OF JINAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com