Titanium nitride reinforced zirconia toughened alumina ceramic powder and preparation method thereof

A technology of alumina ceramic powder and zirconia, which is applied in chemical instruments and methods, zirconium compounds, inorganic chemistry, etc., can solve the problems of poor electrical conductivity, low hardness, etc., and achieve enhanced electrical conductivity, reduced inhomogeneity, and improved thermal conductivity. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

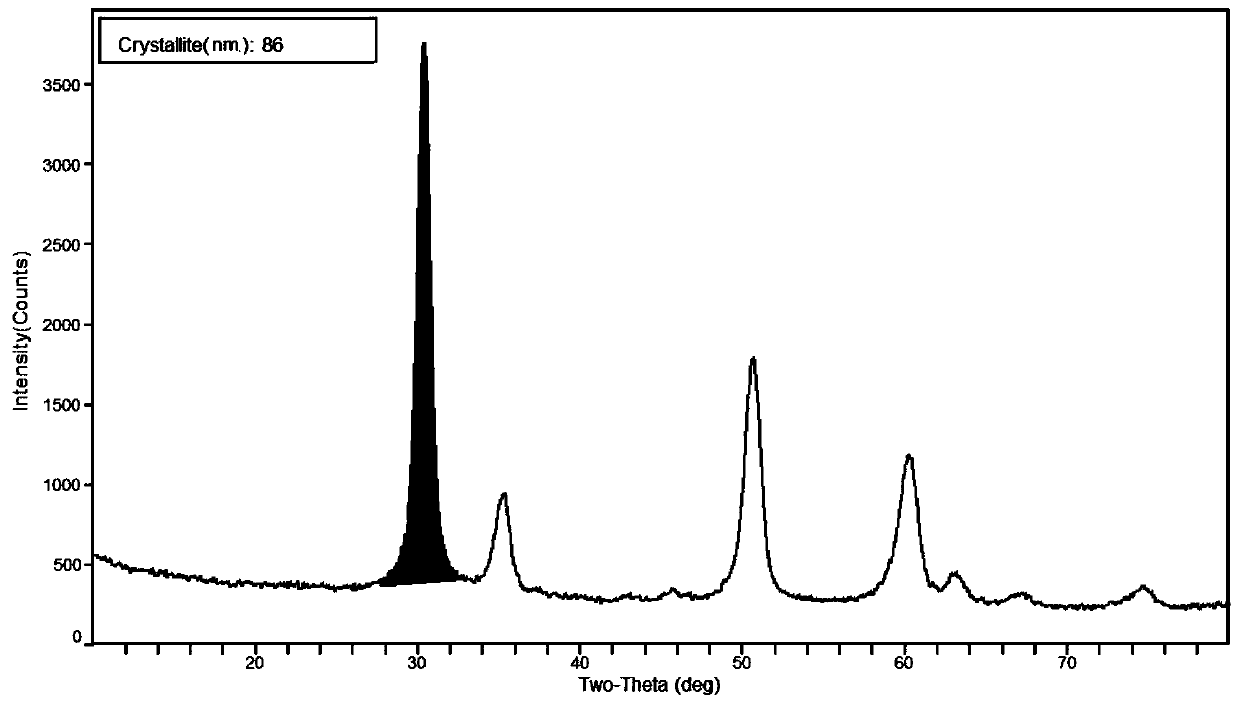

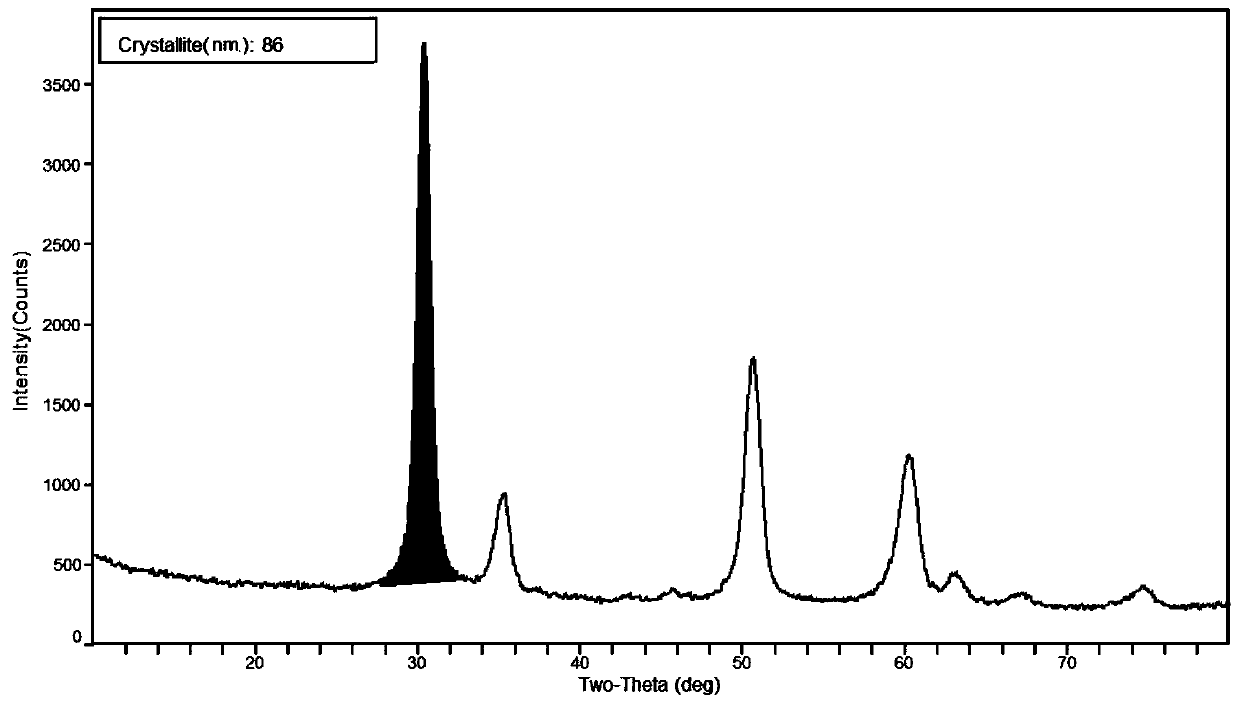

Image

Examples

preparation example Construction

[0020] The invention provides a method for preparing titanium nitride-reinforced zirconia-toughened alumina ceramic powder, which comprises the following steps:

[0021] 1) mixing aluminum salts, zirconium salts, yttrium salts, and titanium salts with water to obtain a mixed aqueous solution; the aluminum salts, zirconium salts, yttrium salts, and titanium salts are water-soluble inorganic salts;

[0022] 2) Precipitate by mixing the mixed aqueous solution obtained in step 1) with an alkaline precipitant to obtain a hydroxide precipitated powder;

[0023] 3) The hydroxide precipitated powder obtained in the step 2) is subjected to the first calcination and the second calcination in sequence to obtain the oxide solid solution powder; the temperature of the first calcination is 700-850°C, and the time is 6-6 12h; the temperature of the second calcination is 900-1000°C, and the time is 1-3h;

[0024] 4) The oxide solid solution powder obtained in the step 3) is subjected to a se...

Embodiment 1

[0048] Add zirconium oxychloride (ZrOCl) to water 2 ·8H 2 O), aluminum chloride (AlCl 3 ) and yttrium chloride (YCl 3 ), titanium sulfate (Ti(SO ) 4 ) 2 ) to prepare a mixed aqueous solution, the molar ratio of aluminum chloride, zirconium oxychloride and titanium sulfate is 60:25:15, and the molar ratio of zirconium oxychloride to yttrium chloride is 98.5:3. After mixing evenly, add ammonia water, fully stir and precipitate, filter, wash with water and absolute ethanol in sequence, and dry to obtain hydroxide precipitated powder. The obtained hydroxide precipitated powder was calcined in air at 700°C for 9 hours, and further calcined at 900°C for 1 hour to obtain oxide solid solution powder (Al 2 o 3 , ZrO 2 , Y 2 o 3 and TiO 2 ). Will Al 2 o 3 -ZrO 2 -Y 2 o 3 -TiO 2 Put the solid solution powder into a 99% alumina porcelain boat, then put the alumina porcelain boat into a vacuum tube-type high-temperature electric furnace, feed flowing high-purity ammonia ga...

Embodiment 2

[0052] Add zirconium oxychloride (ZrOCl) to water 2 ·8H 2 O), aluminum nitrate (AlNO 3 ) and yttrium nitrate (Y(No 3 ) 3 ), titanium sulfate (Ti(SO ) 4 ) 2 ) to prepare a mixed aqueous solution, the molar ratio of zirconium oxychloride, aluminum nitrate and titanium sulfate is 60:25:15, and the molar ratio of zirconium oxychloride to yttrium chloride is 97.5:3. After mixing evenly, add ammonia water, fully stir and precipitate, filter, wash with water and absolute ethanol in sequence, and dry to obtain hydroxide precipitated powder. The obtained hydroxide precipitated powder was calcined in air at 700°C for 9 hours, and further calcined at 900°C for 1 hour to obtain oxide solid solution powder (Al 2 o 3 , ZrO 2 , Y 2 o 3 and TiO 2 ). Will Al 2 o 3 -ZrO 2 -Y 2 o 3 -TiO 2 Put the solid solution powder into a 99% alumina porcelain boat, then put the alumina porcelain boat into a vacuum tube-type high-temperature electric furnace, feed flowing high-purity ammonia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com