Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Fully reuse" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for mineral processing of low-grade silicon calcium collophanite

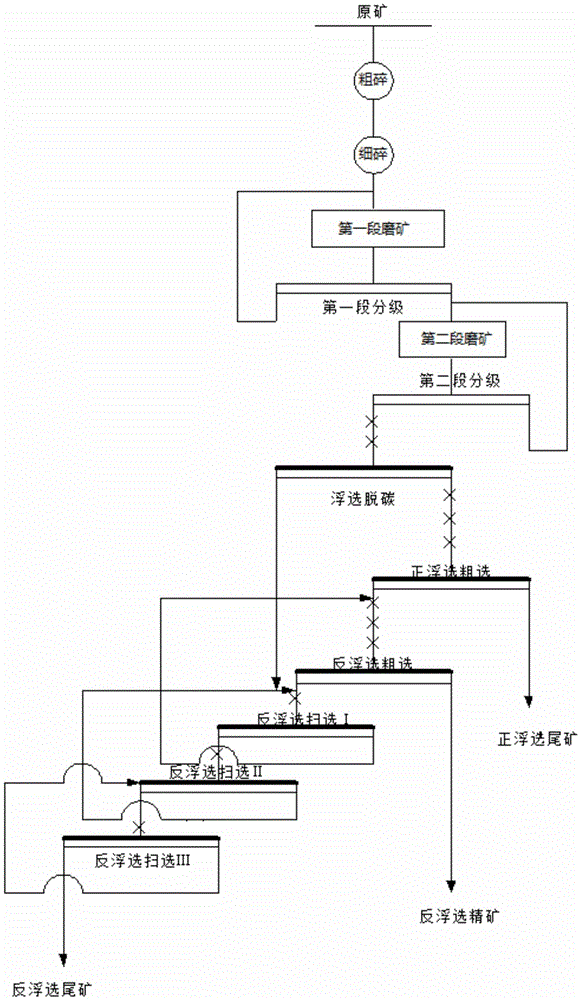

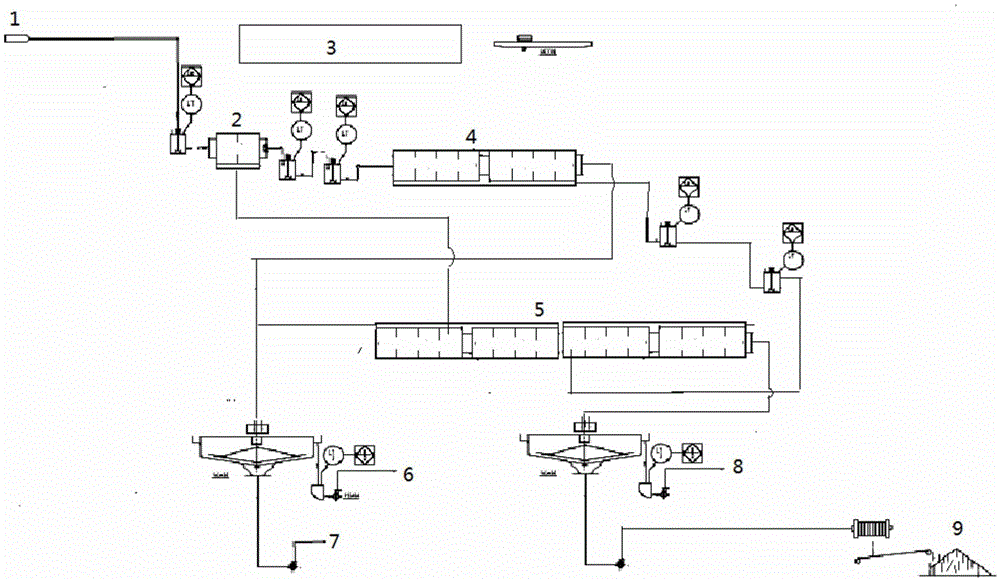

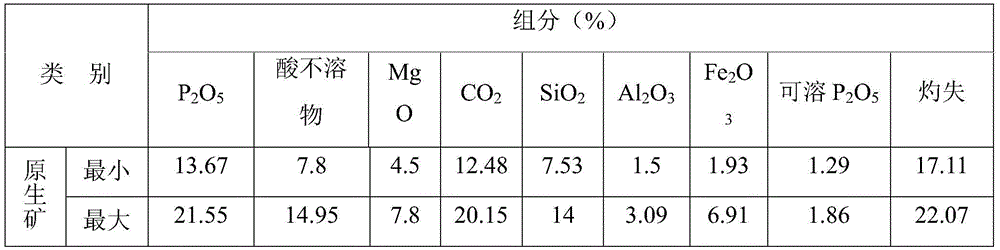

The invention discloses a process for mineral processing of low-grade silicon calcium collophanite. The process sequentially comprises smashing, ball milling, flotation decarburization, positive flotation roughing, reverse flotation roughing and reverse flotation scavenging. A specific collecting agent and a foaming agent are added into silicon calcium collophanite pulp in the flotation process. The process has the advantages that 1) high-grade phosphate concentrate can be obtained from low-grade phosphorite raw material, the influence of organic carbon on positive and reverse flotation is reduced, the effect of agent adsorption by organic carbon is eliminated, the production cost is reduced, and the grade of phosphate concentrate is improved; 2) the collecting agent is improved, so that the flotation efficiency is improved, the normal temperature flotation is achieved, and the flotation temperature is reduced from 35 DEG C to 17-25 DEG C; 3) due to the adoption of nonhazardous and efficient agent, concentrate water and tailing water are not treated, are subjected to closed cycle and are not discharged, and zero emission is achieved.

Owner:XIANGXI XINHUI EL CHRONIUM CO LTD

Biomass pyrolysis gasification method

ActiveCN105586091ARelaxed size requirementsReduce preprocessing power consumptionCombustible gas productionMicrowave pyrolysisTar

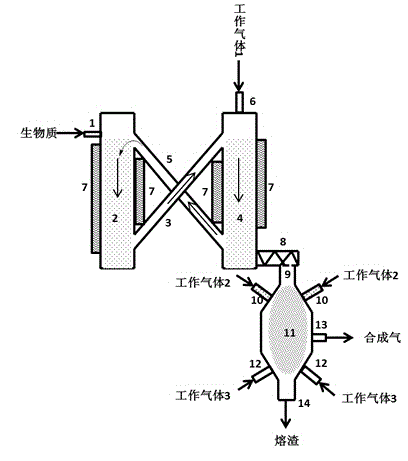

The invention discloses a biomass pyrolysis gasification method which includes the following steps: 1) feeding a biomass raw material into a microwave pyrolysis reaction section to perform pyrolysis under microwave to generate gas, tar and semicoke as pyrolysis products; 2) respectively feeding the pyrolysis products and a first working gas into a microwave oriented gasification section to perform a gasification reaction to obtain a gasification product; 3) in the gasification product, separating gasified semicoke into two parts, wherein one part is spirally transported to the upper part of a microwave pyrolysis reaction section from the bottom of the microwave oriented gasification section so that this part of semicoke is mixed with the biomass raw material to perform microwave pyrolysis, and the other part of the semicoke is spirally transported to a plasma reaction section with a gas-phase volatile component in the gasification product; 4) performing a plasma gasification reaction to the material fed into the plasma reaction section to obtain high-quality synthetic gas which then is discharged out from a gas outlet while solid residues are discharged from the bottom of the plasma reaction section. The method is high in biomass gasification rate and carbon conversion rate. The synthetic gas is high in quality, can satisfy demand on synthetic liquid fuels and has excellent application prospect.

Owner:SINOPEC DALIAN RES INST OF PETROLEUM & PETROCHEMICALS CO LTD +1

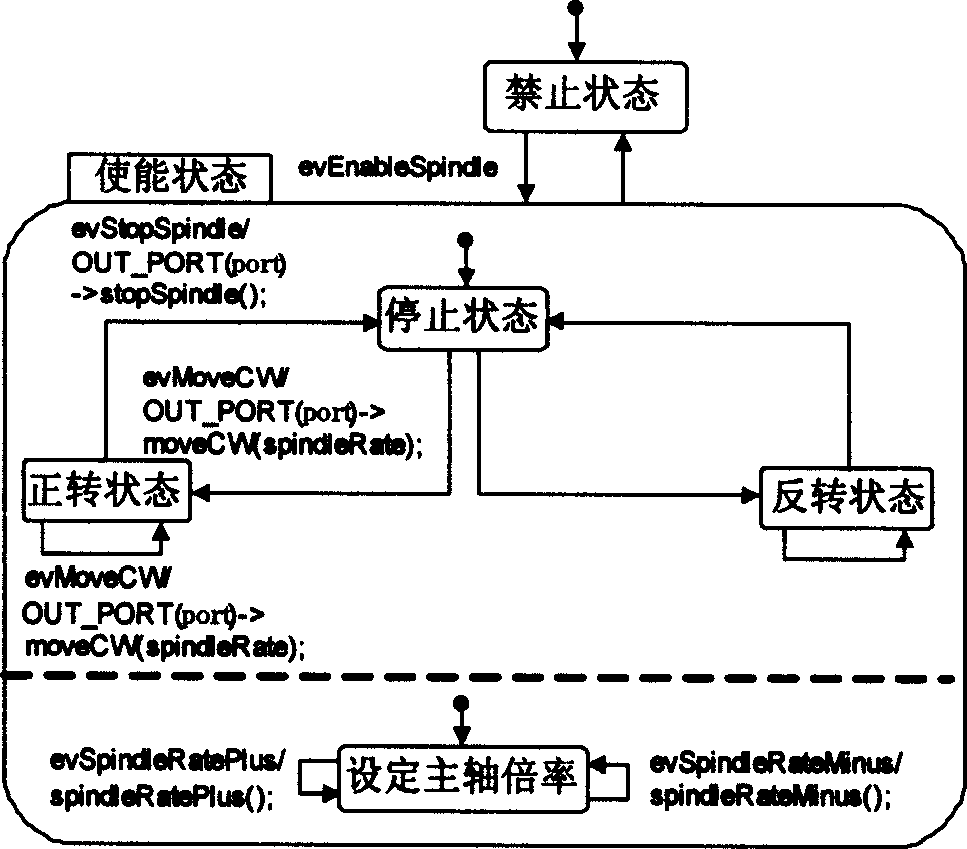

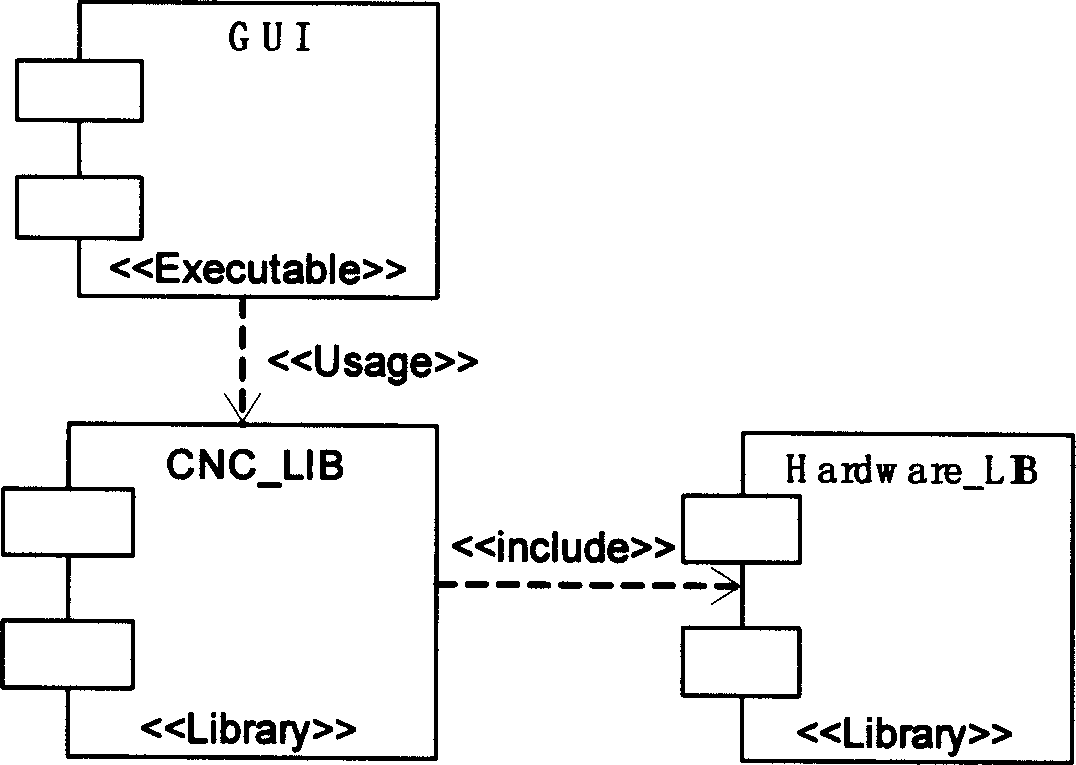

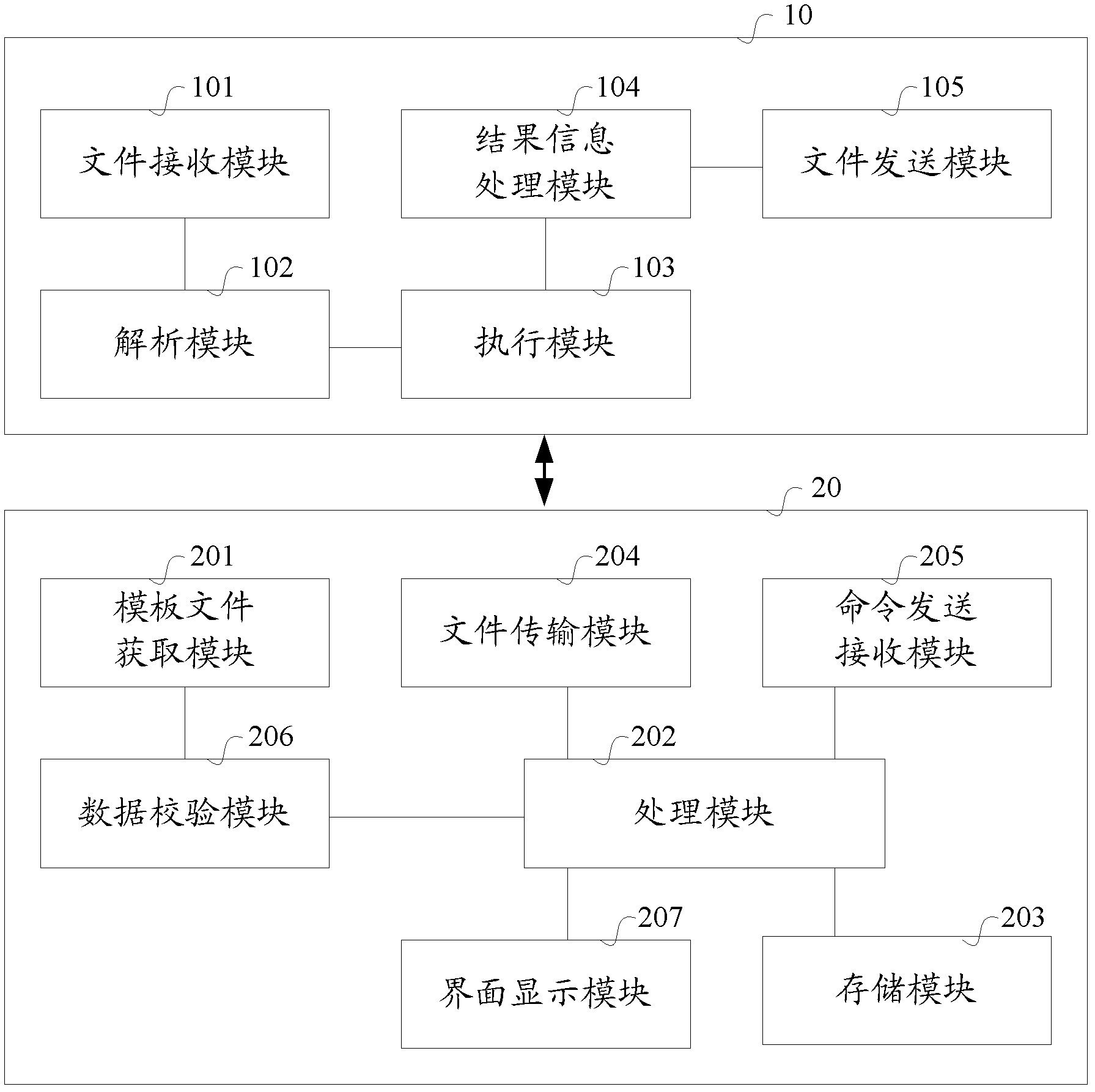

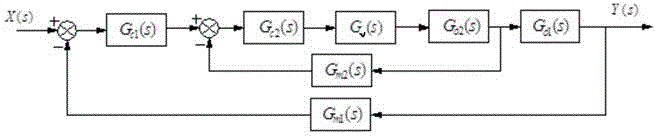

Opening structural computer digital control system able to re-configurate

InactiveCN1601416ARealize the control applicationGuaranteed robustnessComputer controlSimulator controlModel driven developmentHuman–machine interface

The invention is characterized by that making numerical system undergo the process of function module division, maknig model creation based on model drive development method, separating function of module from its behavious, utilizing change of state graph of correspondent module to despatch the the condition of its function execution so as to implement reuse of module function; using port to make communication between modules, said port can utilize its contract abstract interface to make interaction with man-machine interface and bottom layer hardware equipment so as to make related hardware application program meet the interface function requirement provided by system, and in the model layer increasing / reducing or replacing correspondent module so as to implement change of system functino. Said invention also provides the application of said numerical control system.

Owner:东莞市升力智能科技有限公司

Process for selectively extracting valuable metals in waste power lithium battery and repreparing ternary positive electrode material

InactiveCN110615486ANothing producedEasy to operatePositive electrodesWaste accumulators reclaimingResource utilizationManganese

The invention discloses a process for selectively extracting valuable metals in a waste power lithium battery and repreparing a ternary positive electrode material. The method comprises the followingsteps: (1) carrying out complete discharge, disassembly, ultrasonic stripping, calcination and grinding treatment on a recycled waste lithium battery to obtain a required LiNi1 / 3Mn1 / 3CoO2 positive electrode material; (2) leaching the LiNi1 / 3Mn1 / 3CoO2 positive electrode material through a wet metallurgy method by using mild acid and reducing agent, wherein the ratio of the positive electrode material to the added acid is controlled to be 20-60 mL / g, so as to obtain a leaching solution rich in lithium and a precipitate containing nickel-cobalt-manganese; (3) leaching the precipitate again by using a trace amount of acid and reducing agent, wherein the ratio of the precipitate to the added acid is controlled to be 20-60mL / g to obtain a metal-rich salt solution; and (4) carrying out coprecipitation on the metal salt solution to obtain a ternary precursor, adding excessive 3-10% of a lithium source according to the amount of substance of the precursor, and calcining the material at a selected temperature to obtain the ternary positive electrode material with good electrochemical performance. According to the method, metal resource utilization can be achieved, the problem of harmful garbage pollution is solved, and the cost is low.

Owner:SHAANXI UNIV OF SCI & TECH

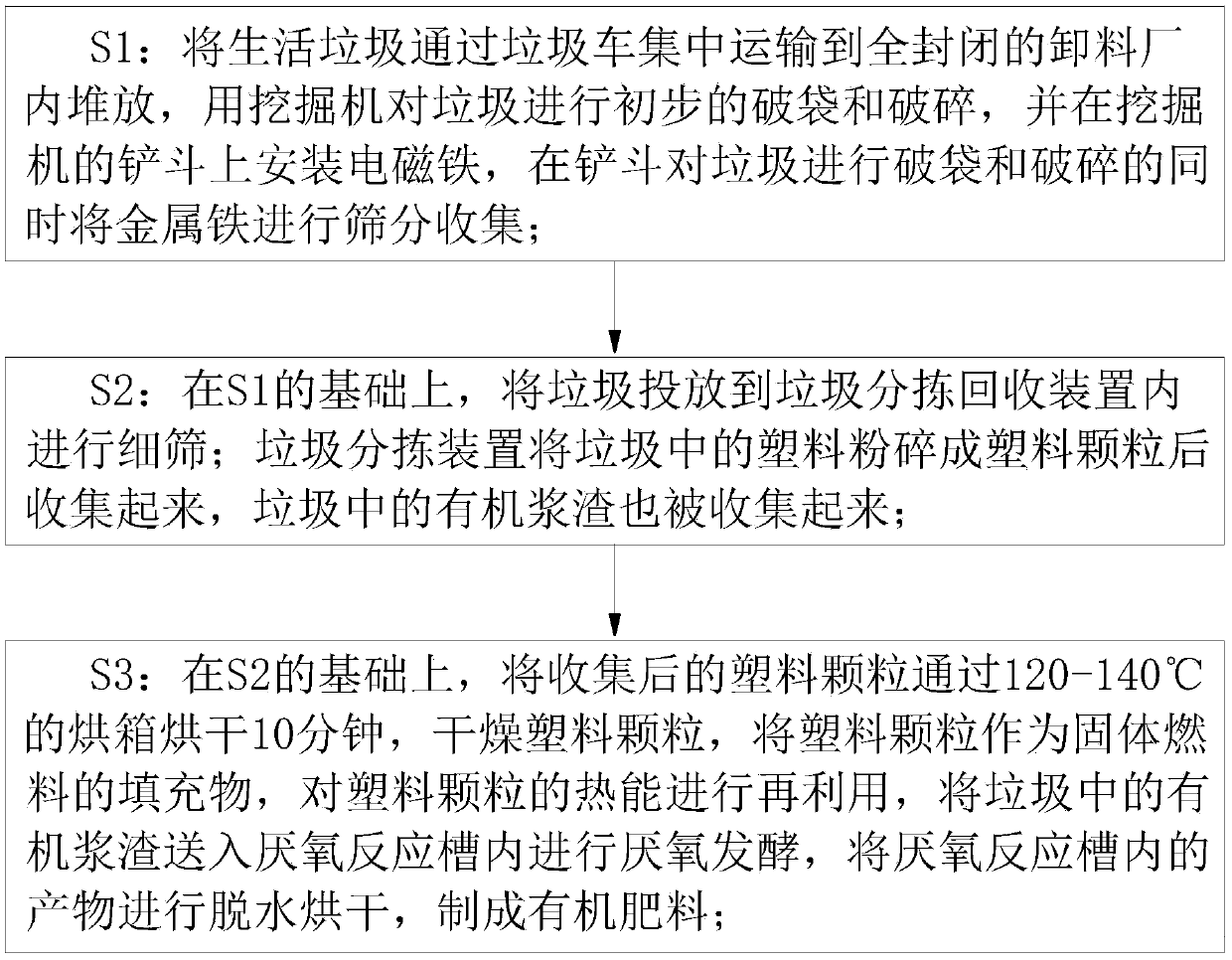

Household garbage recovery process

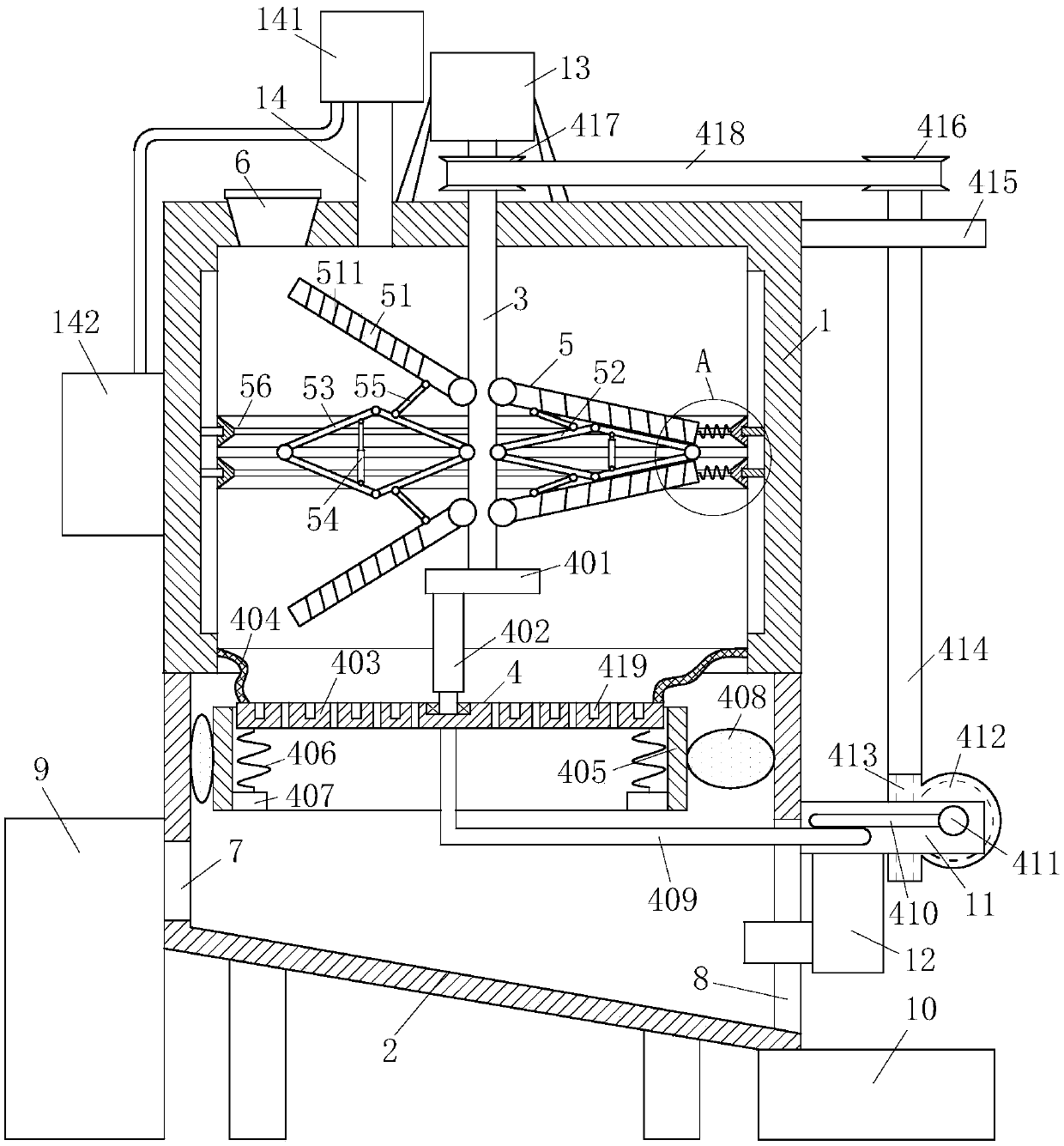

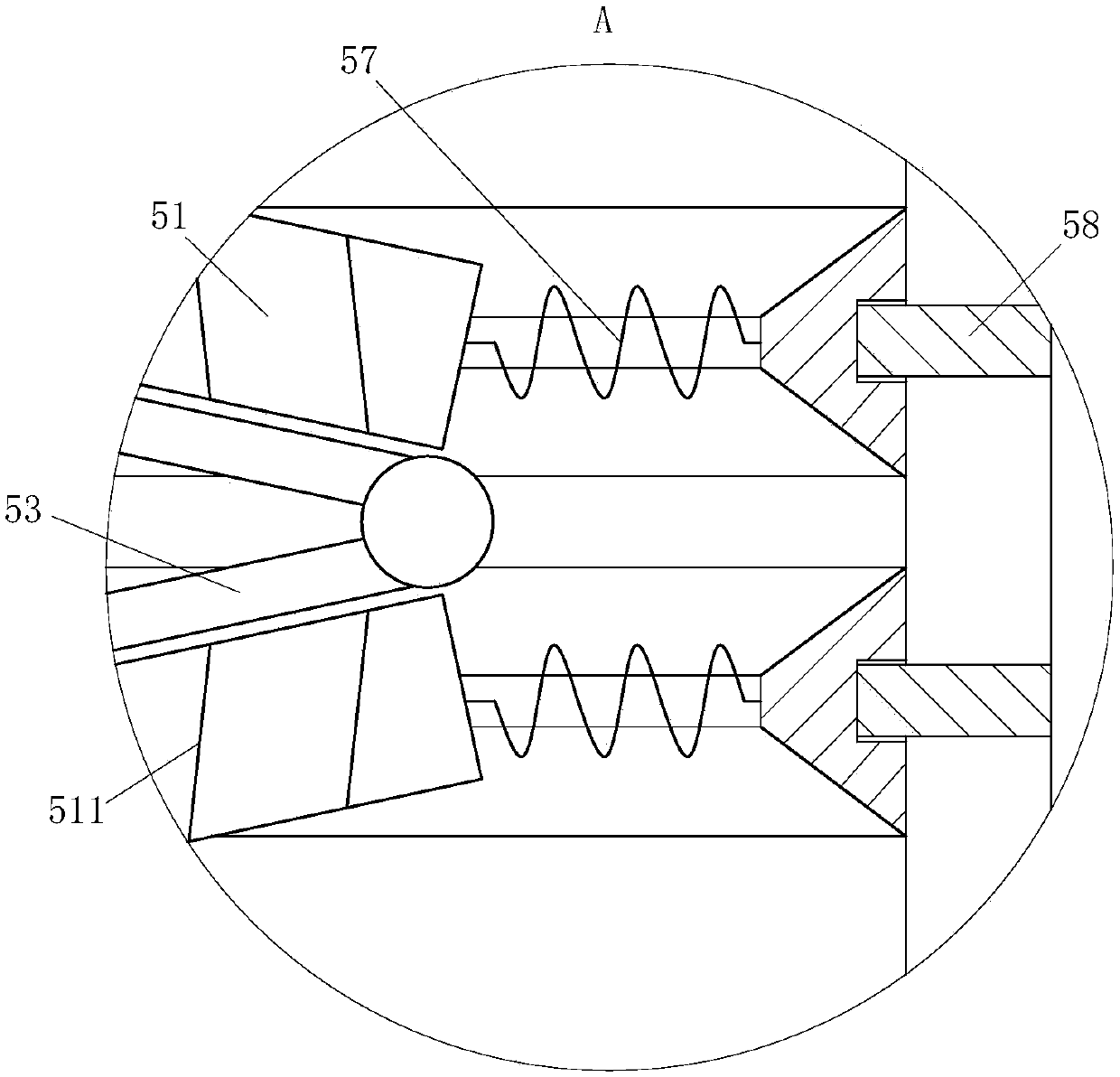

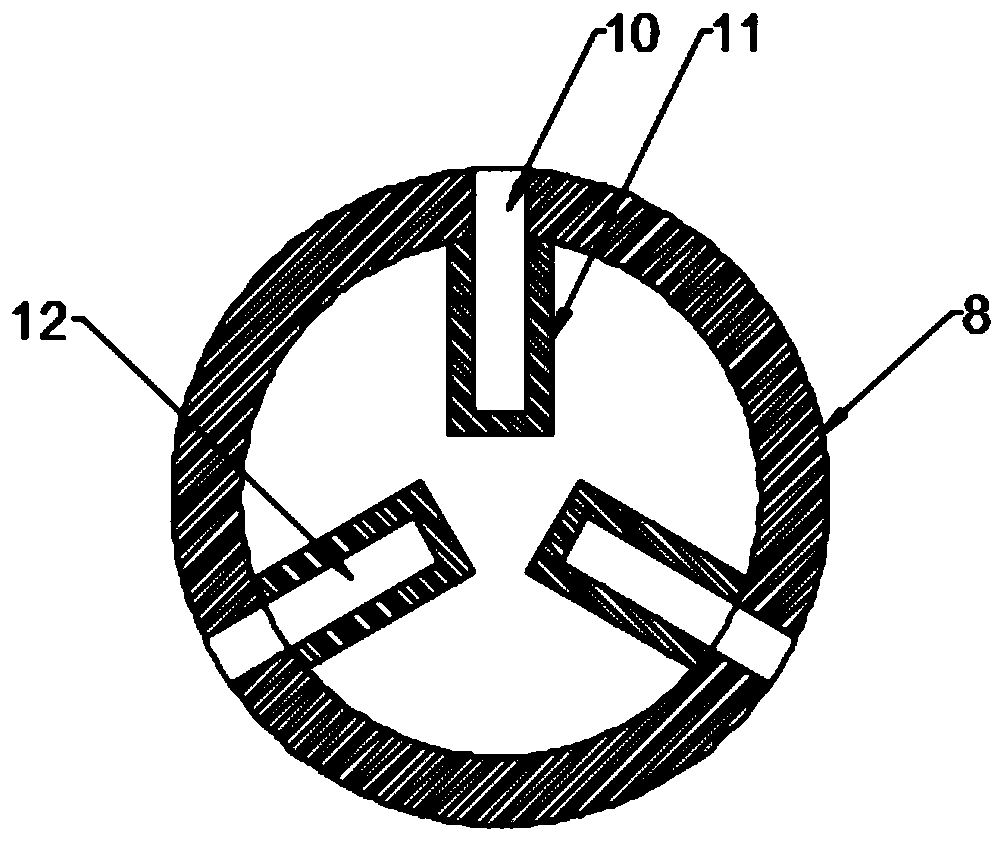

ActiveCN109513732AImprove crushing efficiencyImproves breakup effectSolid waste disposalClimate change adaptationSlagSolid fuel

The invention belongs to the technical field of garbage treatment, in particular to a household garbage recovery process. A sorting recovery device adopted by the process comprises a crushing chamber,and further comprises a sorting chamber, a stirring rotating shaft, a screening unit, a crushing unit, a feed port, a plastic outlet, a pulp slag outlet, a plastic collecting box, a pulp slag collecting barrel, a mounting plate, an air blower, a motor and a controller; the controller is used for controlling the work of the sorting recovery device; the crushing chamber is a of a cylindrical structure vertically arranged and opened at the bottom; the sorting chamber is arranged on the lower side of the crushing chamber, and communicates with the crushing chamber; as an electromagnet is mountedon a bucket of an excavator, metal iron is screened and collected when garbage is broken and crushed by the bucket, and the sorting efficiency is improved; and meanwhile, plastic particles are used asfillers of solid fuels, and organic pulp slag in the garbage is fed in an anaerobic reaction tank for anaerobic fermentation, so that the garbage is fully reutilized.

Owner:臣功环境科技有限公司

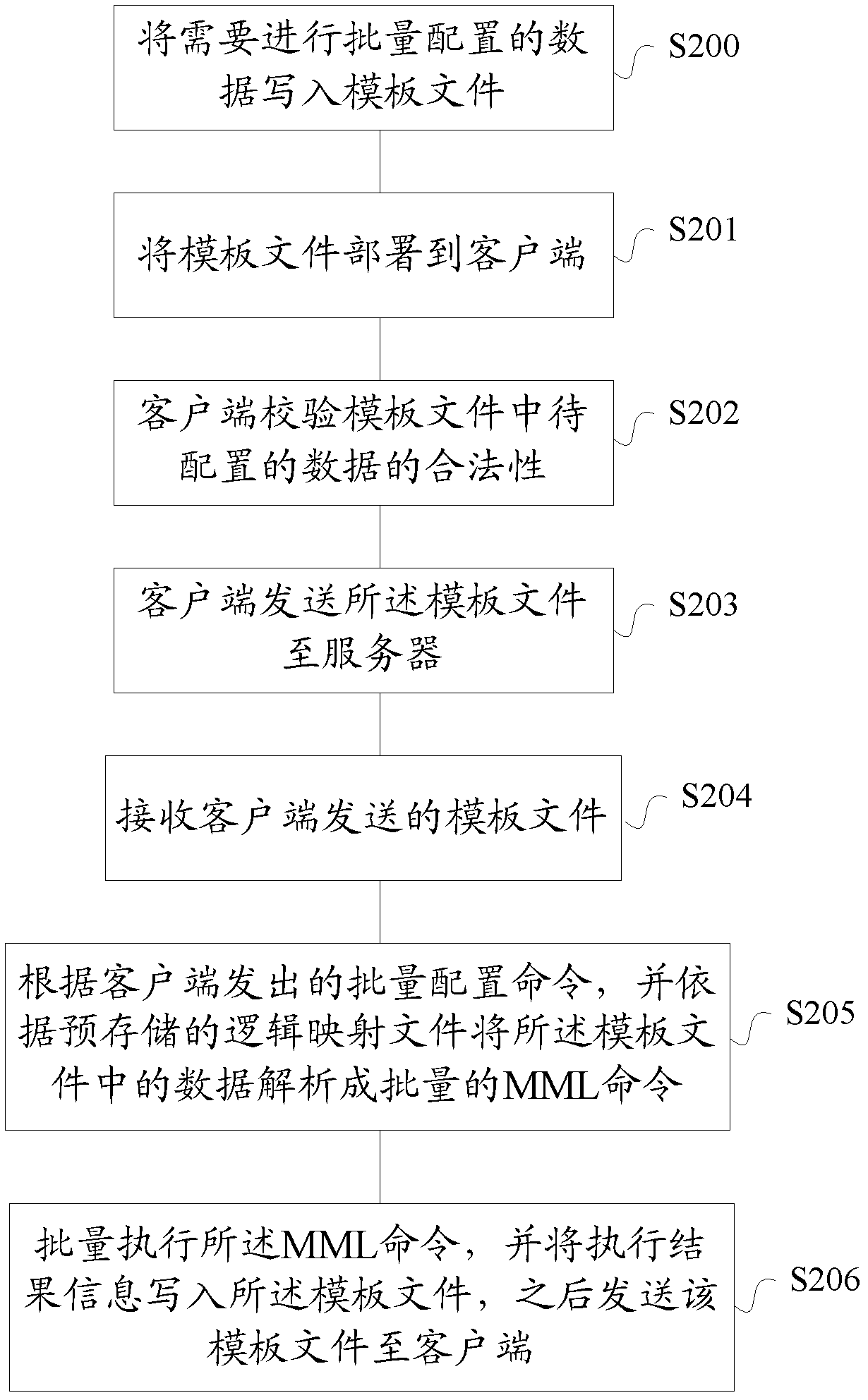

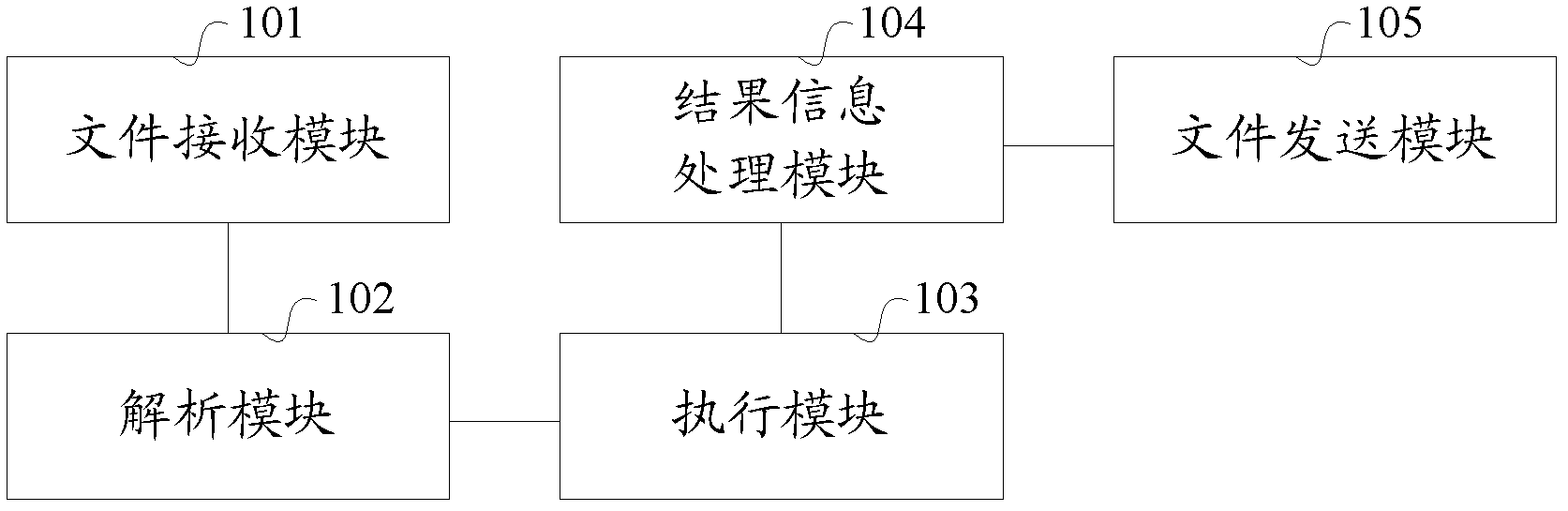

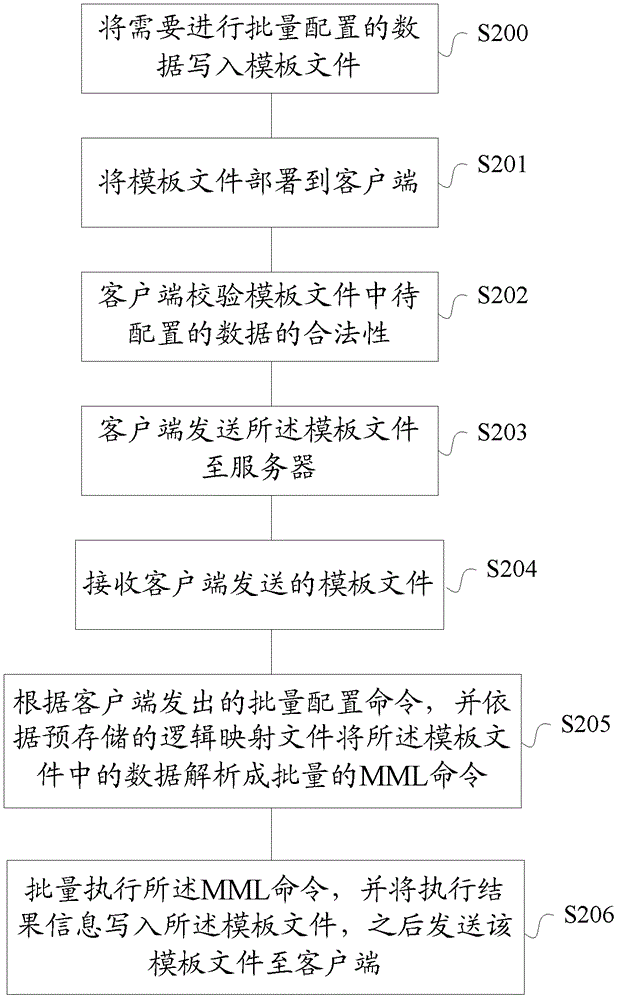

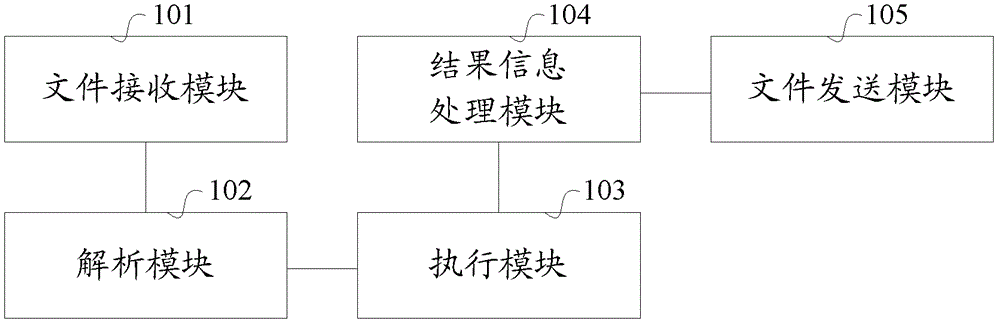

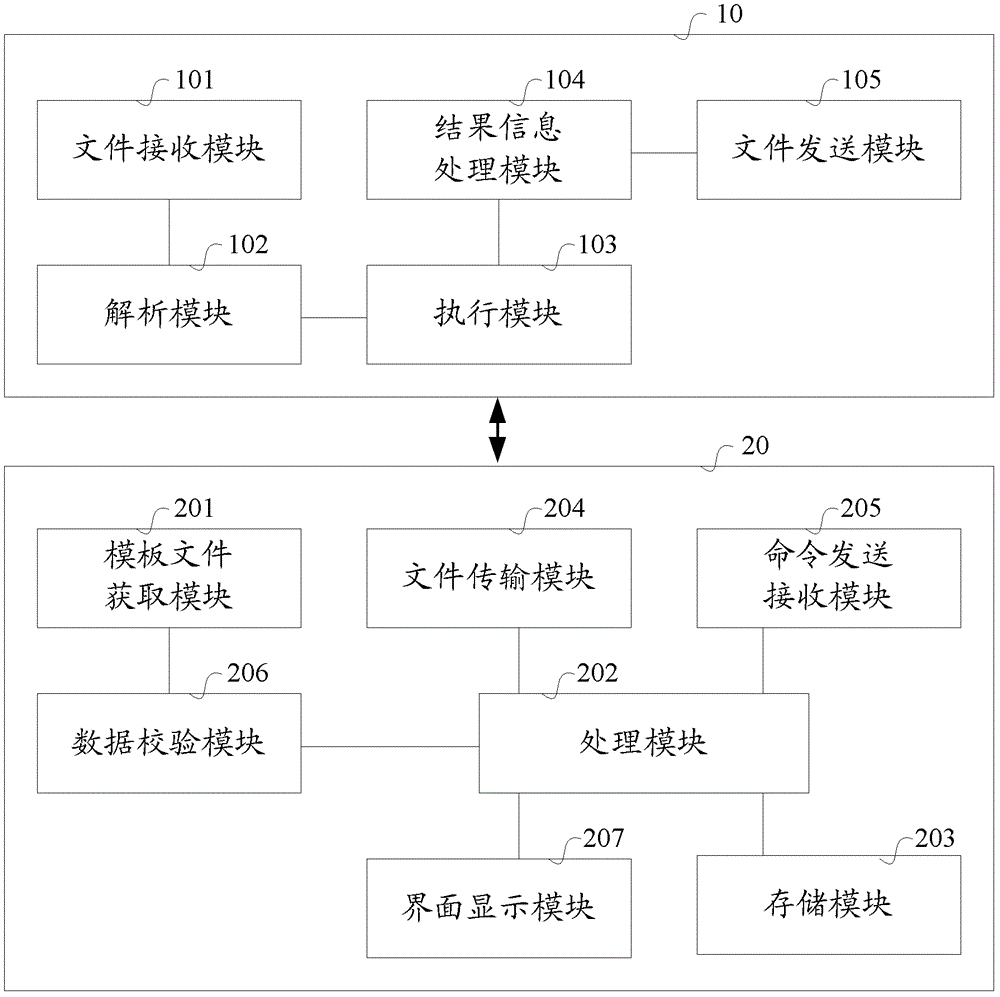

MML-based (man-machine-language-based) method, server and system for configuring large volume data

ActiveCN103001786AFully reuseImprove development efficiencyData switching networksMan machinePaper document

The invention discloses an MML-based (man-machine-language-based) method, server and system for configuring large volume data. The method includes: receiving template document transmitted by a client; analyzing data in the template document into batch MML commands according to a batch configuration command given by the client and prestored logic mapping document; executing the MML commands in batch, writing execution result information into the template document, and transmitting the template document to the client. The template document with written to-be-configured data is analyzed into MML commands for execution according to the prestored logic mapping document, original codes can be fully utilized, development efficiency is improved, and complexity is reduced.

Owner:ZTE CORP

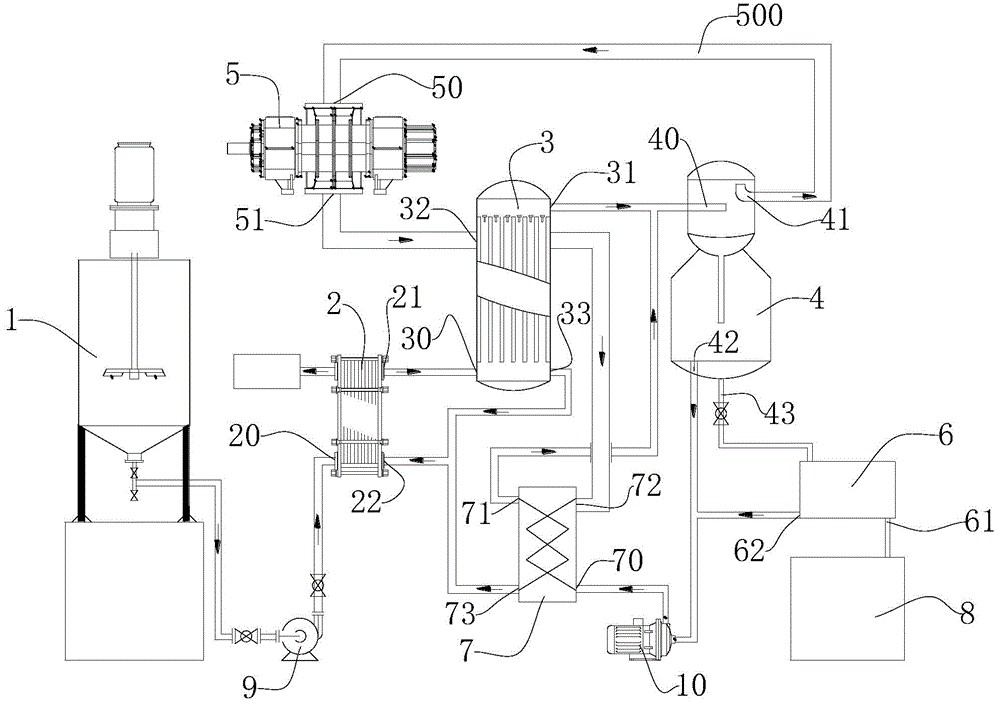

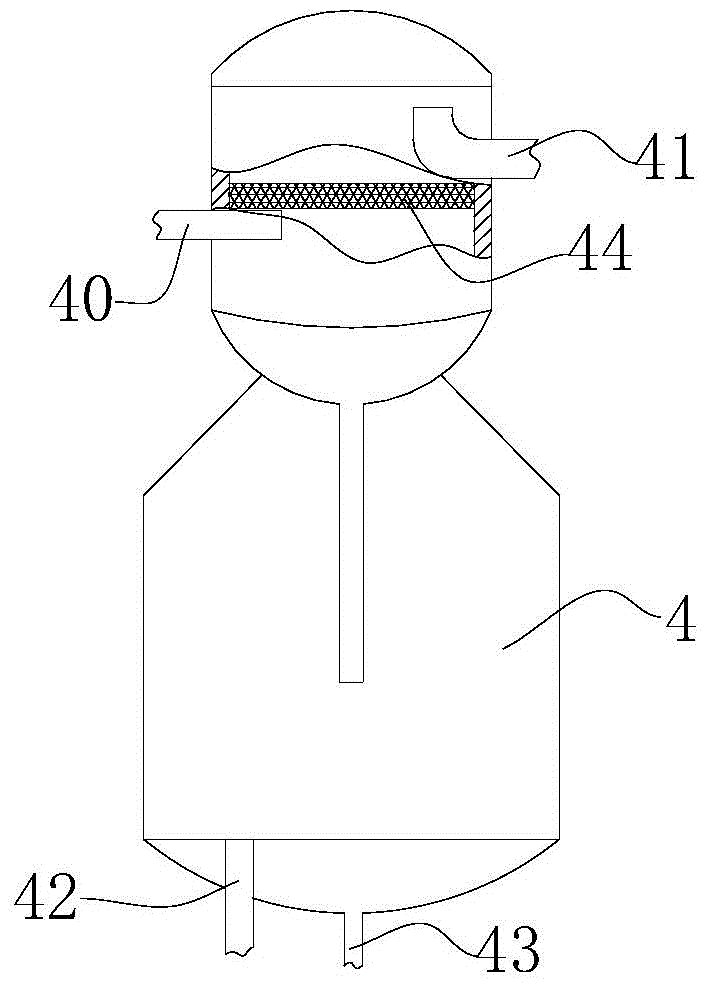

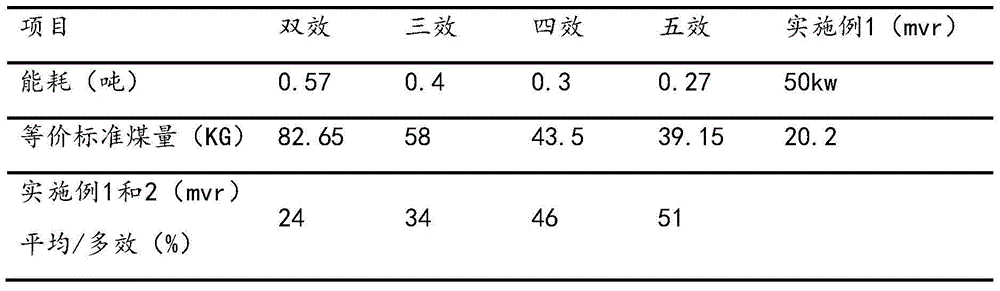

Continuous evaporative crystallization method

InactiveCN104548650ALow costTake advantage ofDispersed particle filtrationEvaporationVapor–liquid separatorEvaporation

The invention relates to a continuous evaporative crystallization method for saving energy by virtue of mechanical steam recompression. The method comprises the following steps: (a), adding raw materials into a tank, and stirring to obtain a solution; (b), pumping the solution to a first heater, and heating to a bubble point temperature by virtue of the first heater; (c), feeding the hot solution in the step (b) into a climbing film evaporator for heating, so that the climbing film evaporator generates lots of secondary steam, spraying the solution into a gas-liquid separator at the speed of 25-50m / s by virtue of the secondary steam; (d), separating by virtue of the gas-liquid separator, discharging one part of the concentrated solution by virtue of the gas-liquid separator, performing forced-circulation evaporation, feeding the solution back to the gas-liquid separator after forced-circulation evaporation, and discharging and crystallizing the other part of the solution; and (e), recompressing the steam discharged by the gas-liquid separator into superheated steam by virtue of a compressor, feeding the steam serving as a heating source of the climbing film evaporator back to the climbing film evaporator, so that the hot solution in the step (c) can be heated by the superheated steam. The continuous evaporative crystallization method is low in cost, multi-level recovery of the energy and raw materials is realized, and the energy consumption is low.

Owner:丁武轩

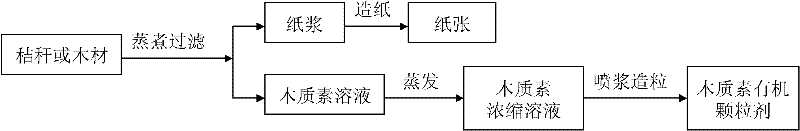

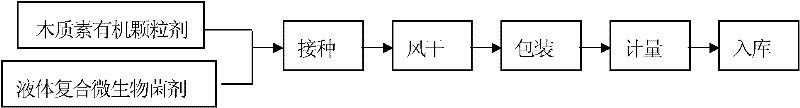

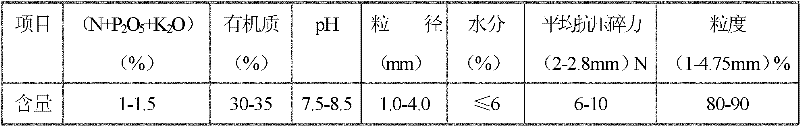

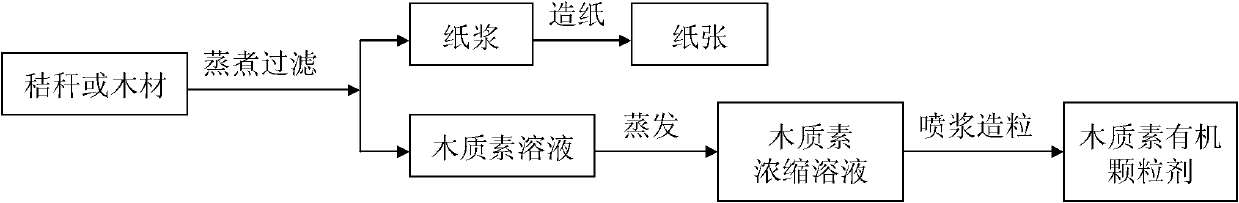

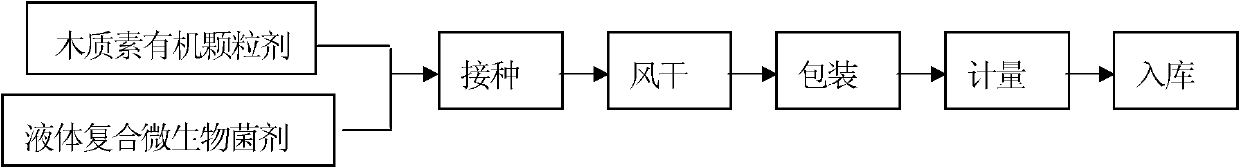

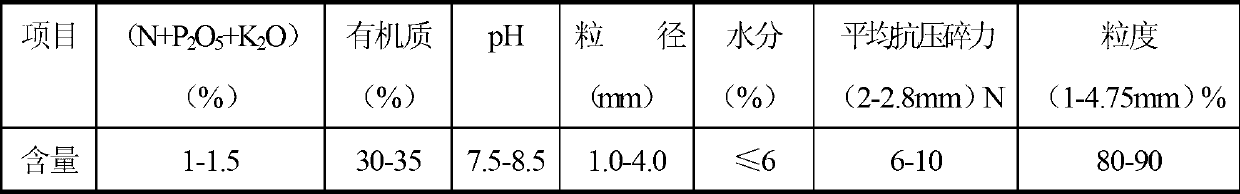

Method for producing bio-organic fertilizer by using lignin organic granules

InactiveCN102442847AFully reuseEliminate emission pollutionOrganic fertilisersFertilizer mixturesParticulatesSpray Granulation

The invention provides a method for producing a bio-organic fertilizer by using lignin organic granules. The method provided by the invention comprises steps of: preparing a liquid inoculant, preparing a lignin black liquor into an organic particulate agent by spraying granulation, and compounding the organic granules and the liquid composite inoculant, wherein the liquid composite inoculant which accounts for 0.5-1.5% of the weight of the finished product composite microbial fertilizer is added. The production of the bio-organic fertilizer can be completed by bacterial liquid permeation intoorganic particles and the technical requirement of the product can be reached without drying. According to the invention, routines are broken by creative introduction of the spraying granulation method into the biological fertilizer granulation technology. The production method of the particulate bio-organic fertilizer is divided into two steps of spraying granulation of the organic granules and organic granule wrapping or inoculant adsorption. In the meanwhile, a certain activity of the bio-organic fertilizer is maintained. According to the bio-organic fertilizer product, the breakthrough from a powder form to spray particles is realized, thus laying a foundation for the extensive popularization of the bio-organic fertilizer.

Owner:北京世纪大德环保科技有限公司

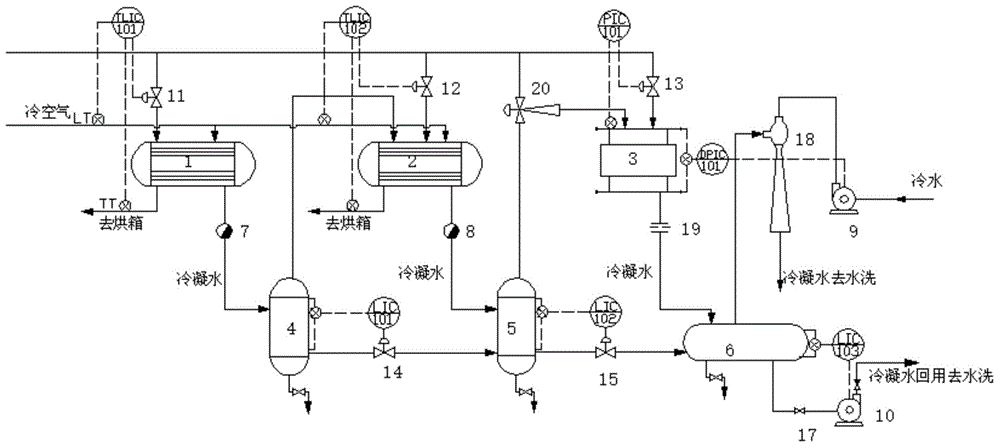

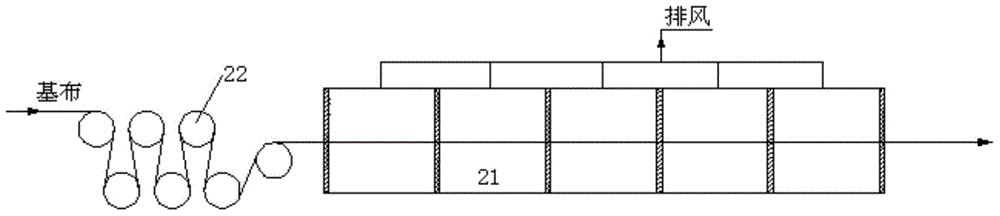

Control method and system for wet method leather manufacturing

ActiveCN104913624AImprove surface qualityRealize automated productionDrying gas arrangementsTextile/flexible product manufactureControl systemProcess engineering

The invention discloses a control method and a system for wet method leather manufacturing. By means of combination of hot air dying and drying-cylinder drying, base cloth is subjected to hot pressing and ironing at low temperature to improve surface quality of the base cloth; by means of three-section steam supply, trapezoidal utilization of energy is realized, fresh steam consumption is reduced while base cloth is dried, so that energy saving and consumption reduction are realized; the problem of safety in heating of conduction oil is solved by adoption of steam; by a multi-section heat supply control system, heat of steam condensate can be recycled completely, so that energy saving and consumption reduction are realized; owing to design of the control system, automatic production of a drying section is realized; in addition, adjustment of steam quantity according to operating conditions is realized so as to meet production requirements of different synthetic leather techniques.

Owner:SHAANXI UNIV OF SCI & TECH

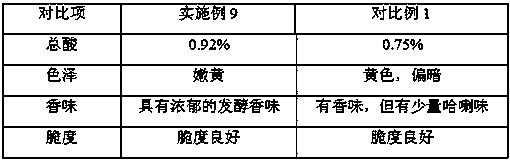

Production process for preparing pickled cowpeas through fermentation with pickle water

The invention discloses a production process for preparing pickled cowpeas through fermentation with pickle water. The production process is a process for adding cowpeas, edible salt, pickle water anda lactic acid preparation in a fermentation tank and performing sealed heat preservation and fermentation to prepare the pickled cowpeas. The pickle water is obtained by pretreating pickle curing water. According to the production process disclosed by the invention, through the adoption of a sealed heat preservation and fermentation mode, the edible salt, the pickle water and the lactic acid preparation are added into the fermentation tank to process the cowpeas; the pickle water is obtained by pretreating the pickle curing water; under the cooperation with the lactic acid preparation, the defects that conventional pickled cowpeas have light flavor and are high in content of edible salt and nitrite are overcome; and the production process has good economical benefits.

Owner:SICHUAN FUXIN FOOD CO LTD

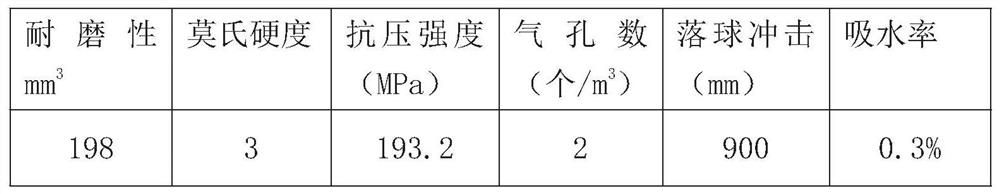

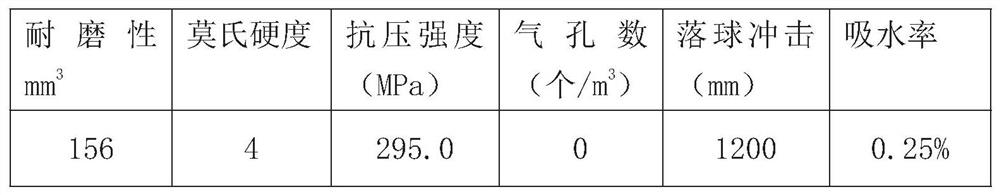

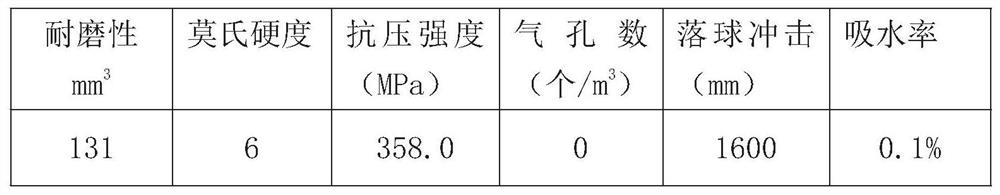

Method for preparing artificial decorative stone by using manganese-silicon alloy hot melting slag

The invention belongs to the field of manganese-silicon alloy hot-melt slag treatment, and particularly discloses a method for preparing artificial decorative stone by using manganese-silicon alloy hot-melt slag, which comprises the following steps: S1, synchronously adding the manganese-silicon alloy hot-melt slag and a clarifying agent into a tempering electrolytic furnace to obtain mixed slag, keeping the temperature in the tempering electrolytic furnace at 1100-1600 DEG C, and uniformly mixing and heating for 1-4 hours; s2, pouring the mixed slag into a mold, then transferring the mold rapidly into a crystallization furnace, controlling the temperature of the crystallization furnace to range from 800 DEG C to 1300 DEG C, carrying out heat preservation for 1-3 h, and obtaining crystals; s3, after heat preservation is finished, stopping heating of the crystallization furnace kiln, and after the temperature of the crystallization furnace kiln is naturally cooled to the room temperature, withdrawing the mold from the crystallization furnace kiln; and S4, taking out the cooled crystal from the mold, cutting and polishing to obtain the artificial decorative stone. The method has the advantages that resources are effectively saved, the compressive strength of the artificial decorative stone is improved, and the porosity of the artificial decorative stone is reduced.

Owner:NINGXIA JIYUAN JUNTAI NEW MATERIAL TECH CO LTD +2

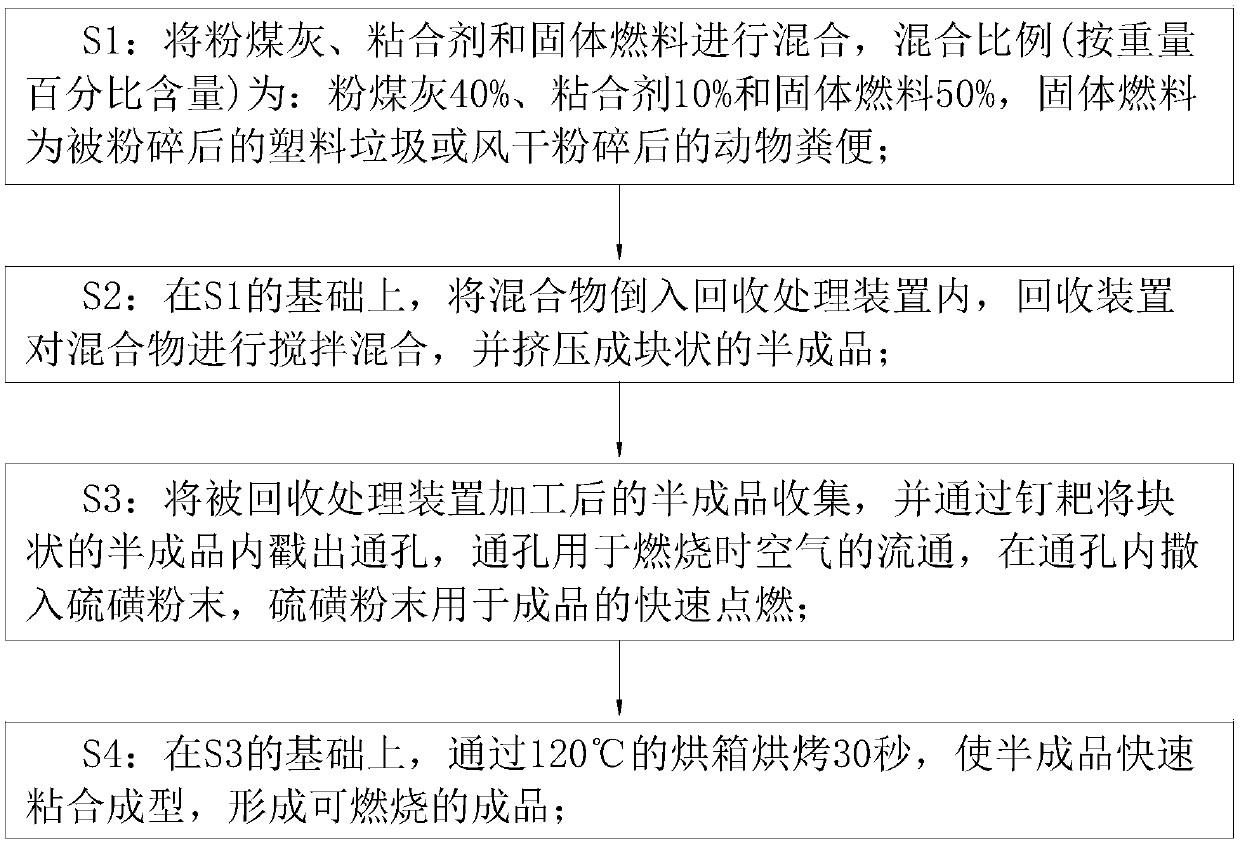

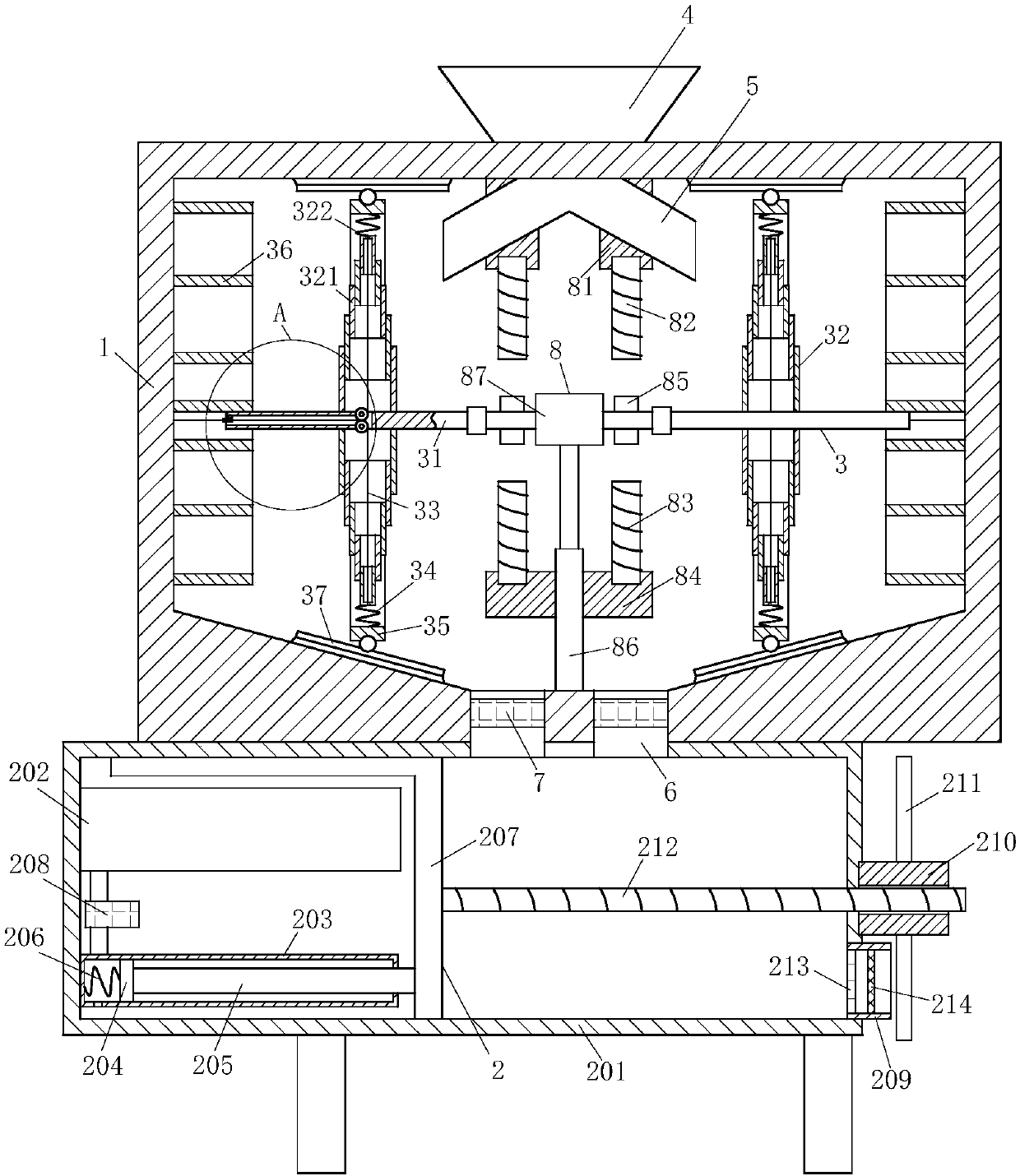

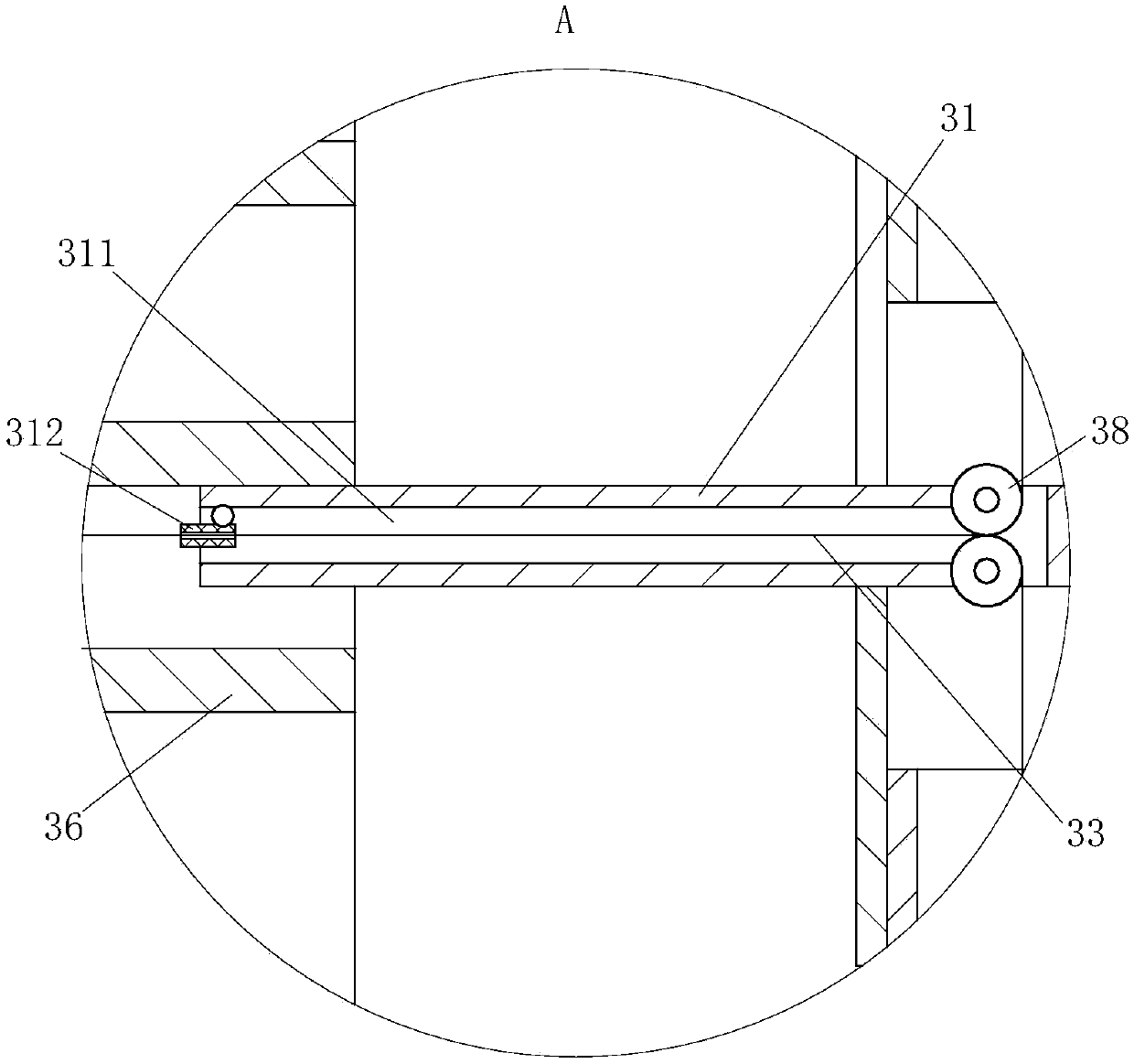

Recycling process of pulverized coal ash

The invention belongs to the technical field of environment protection and particularly relates to a recycling process of pulverized coal ash. A recycling device used by the recycling process comprises a shell and also comprises an extruding mechanism, a mixing mechanism, a feeding opening, a feeding pipe, a conveying channel, a first electromagnetic switch, a driving device and a controller, wherein the controller is used for controlling operation of equipment; the shell is of a horizontally arranged cylindrical structure; an inner bottom wall of the shell is conical; the pulverized coal ashis bonded with solid fuels through adhesives and is treated by the recycling device; about 1-25% of effective heat value in the pulverized coal ash can be fully reused, so that the coal energy can bereused; meanwhile, plastic wastes and animal wastes can be used as the solid fuels, so that the wastes are further used, and the resources are saved; through holes are poked on finished blocks, and sulfur powder are sprinkled into the through holes; the ignition points of finished products are reduced; the finished products can be rapidly ignited; meanwhile, the combustion of the finished productsis more complete.

Owner:石宏扬

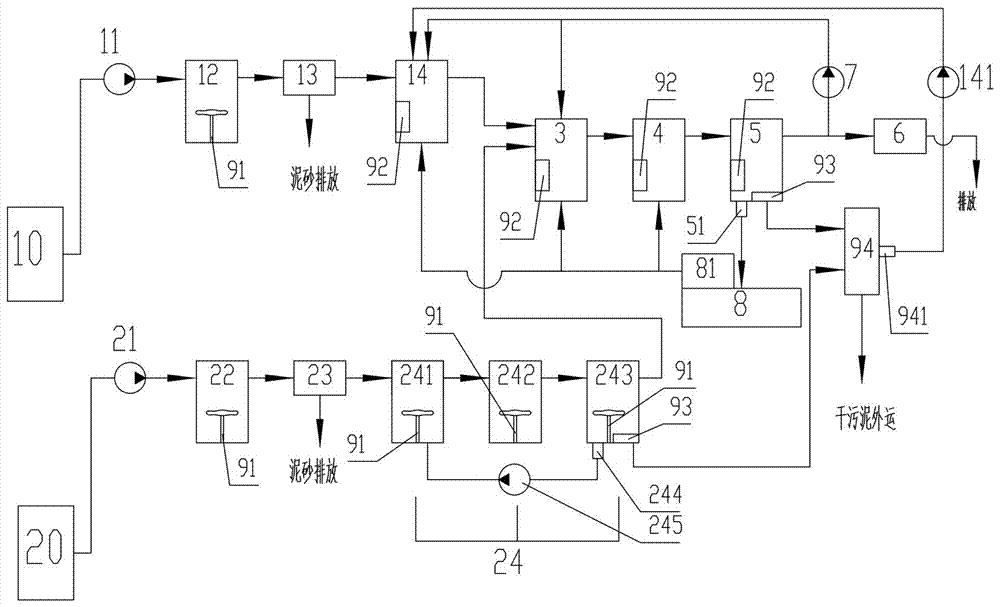

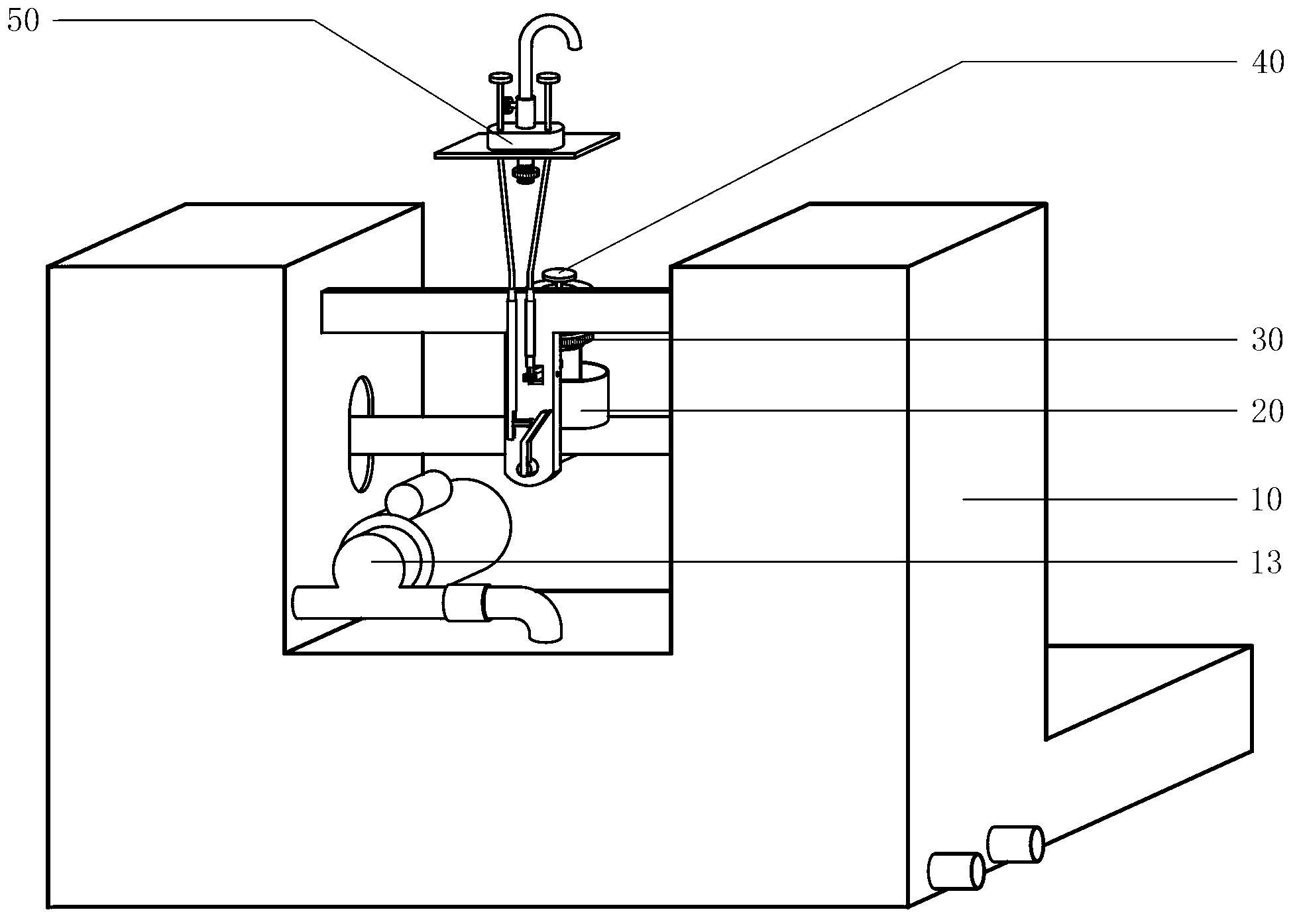

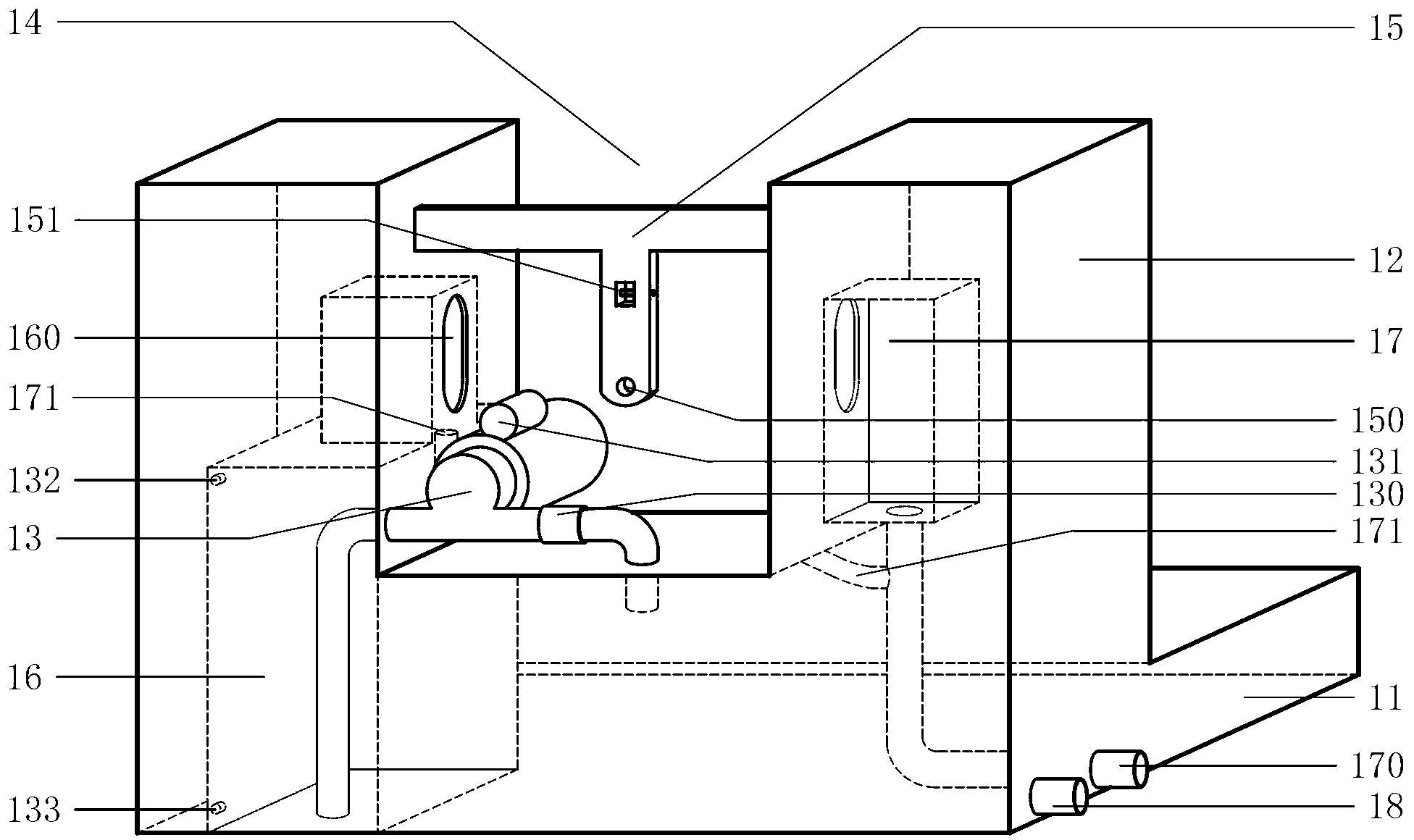

Treatment system of isopropanol sewage generated in monocrystalline silicon battery manufacturing

InactiveCN108002658AEmission reductionFully reuseWater contaminantsTreatment with anaerobic digestion processesSewage treatmentSewage

The invention discloses a treatment system of isopropanol sewage generated in monocrystalline silicon battery manufacturing. The system comprises a concentrated isopropanol alkali waste liquid storagetank, a fluorine-containing diluted isopropanol waste water storage pool, a first lifting pump, a second lifting pump, a first pH regulating pool, a second pH regulating pool, a first floating removal primary precipitation pool, a second floating removal primary precipitation pool, an anaerobic pool, a defluorination flocculating sedimentation device, a hydrolytic acidification pool, an active sludge pool, a secondary sedimentation tank, a clean water discharging pool, a mud scraping and sucking machine and a sludge pump station. The concentrated isopropanol alkali waste liquid generated after the use of the isopropanol in the wool making stage in the monocrystalline silicon battery production and the fluorine-containing diluted isopropanol waste water are subjected to comprehensive treatment; through the respective pretreatment, the flow is merged for biotreatment; outlet water and active sludge after the simultaneous biological treatment are subjected to sufficient multi-aspect reuse; the waste reuse rate is improved; the discharge of waste liquid and waste materials is greatly reduced.

Owner:HUHOU FUYOUDE MEMBRANE SEPARATION TECH CO LTD

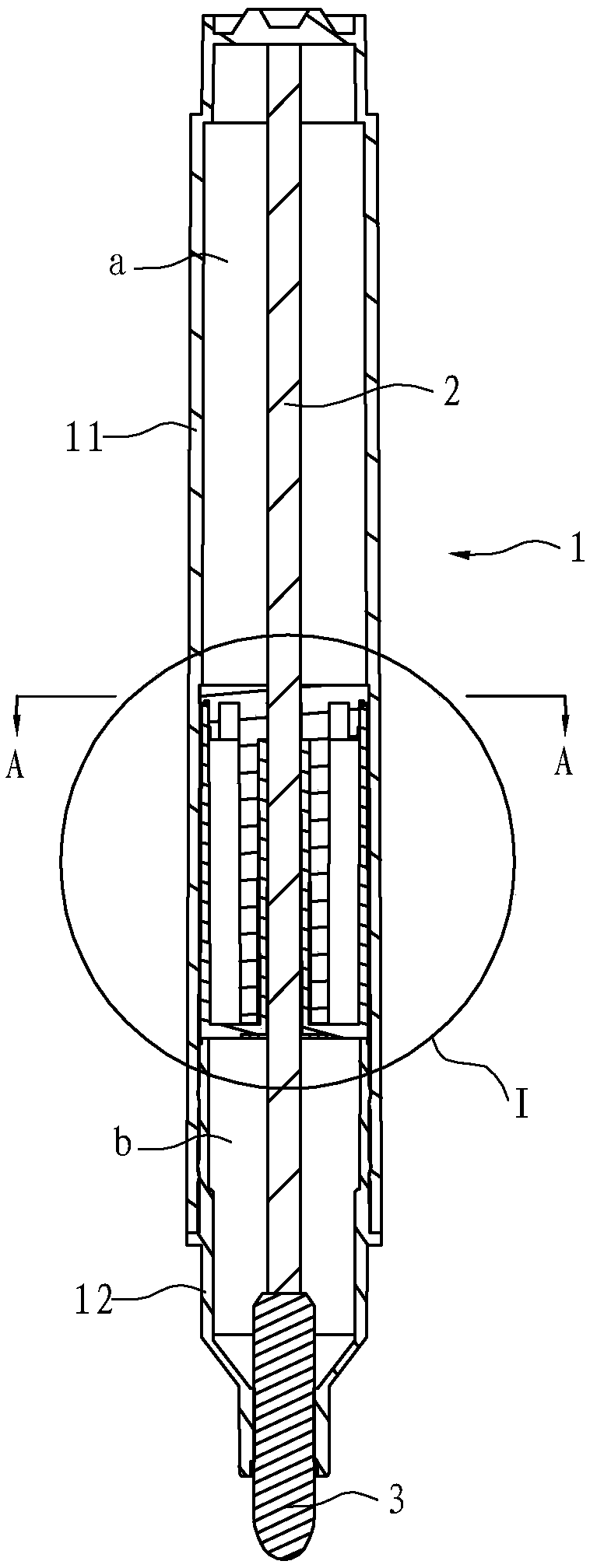

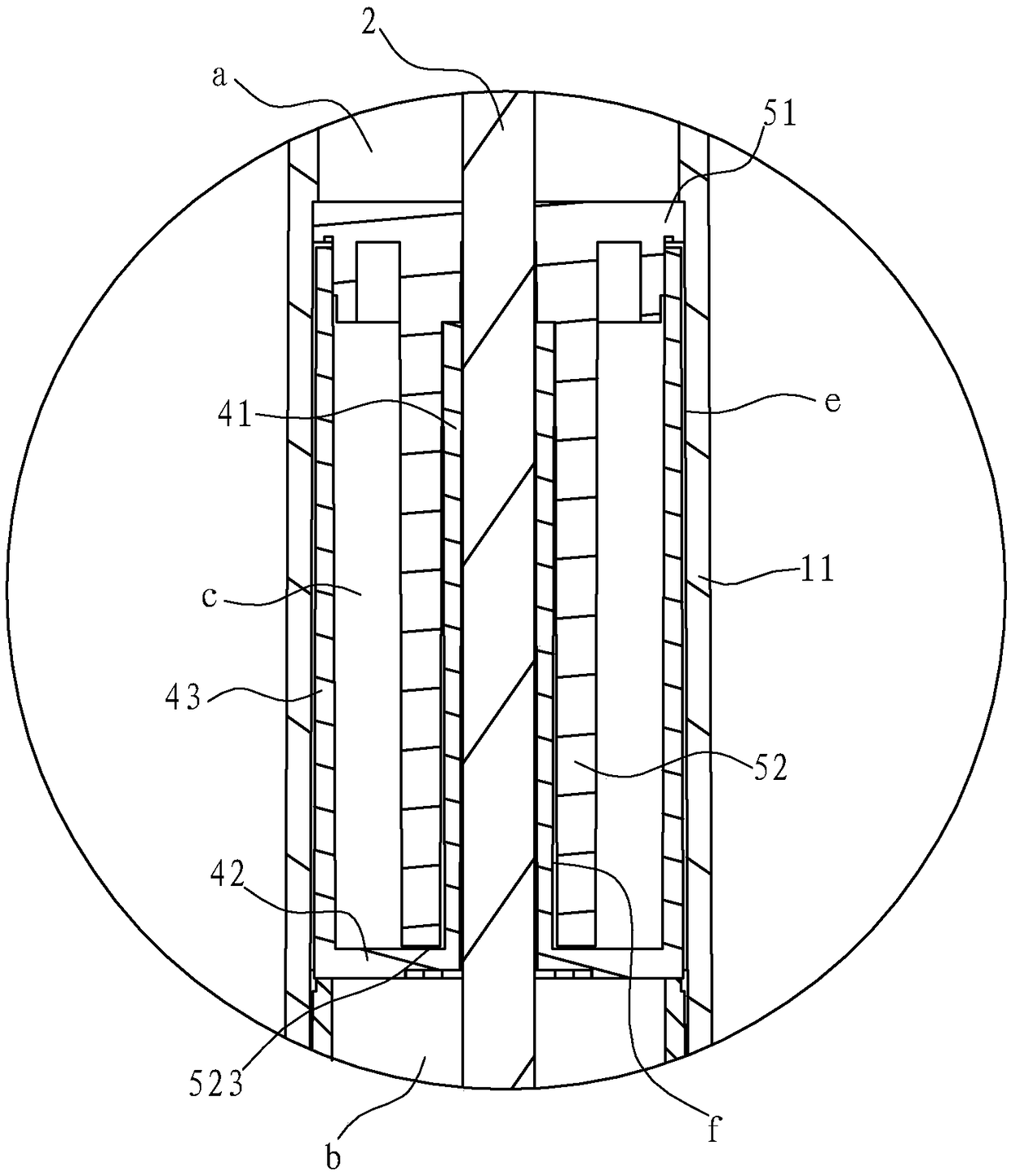

Capillary system type writing tool

The invention relates to a capillary system type writing tool. The capillary system type writing tool is improved on the basis of an existing pen shell, an ink feeder, a pen point and an ink storing part, namely, a temporary ink storing channel which reciprocates in the length direction of the ink feeder is arranged in the ink storing part; the temporary ink storing channel comprises an ink returning channel of which an upper end port communicates with an ink supplying chamber through a liquid sealing port, an air guide channel of which a lower end port communicates with an atmosphere communication chamber, an a temporary ink storing chamber which is connected between a lower end port of the ink returning channel and an upper end port of the air guide channel; and the ink returning channelis a narrow and long channel which can realize capillary effect. According to the capillary system type writing tool adopting the abovementioned structure, ink stored in the temporary ink storing chamber can be fully recycled by double effects of air pressure and capillary suction force under each negative pressure of the ink supplying chamber. Therefore, sufficient space is ensured for storing ink after the air pressure of the temporary ink storing chamber changes in a plurality of times, and as a result, the problem of ink leaking can be effectively prevented.

Owner:宁波华丰文具有限公司

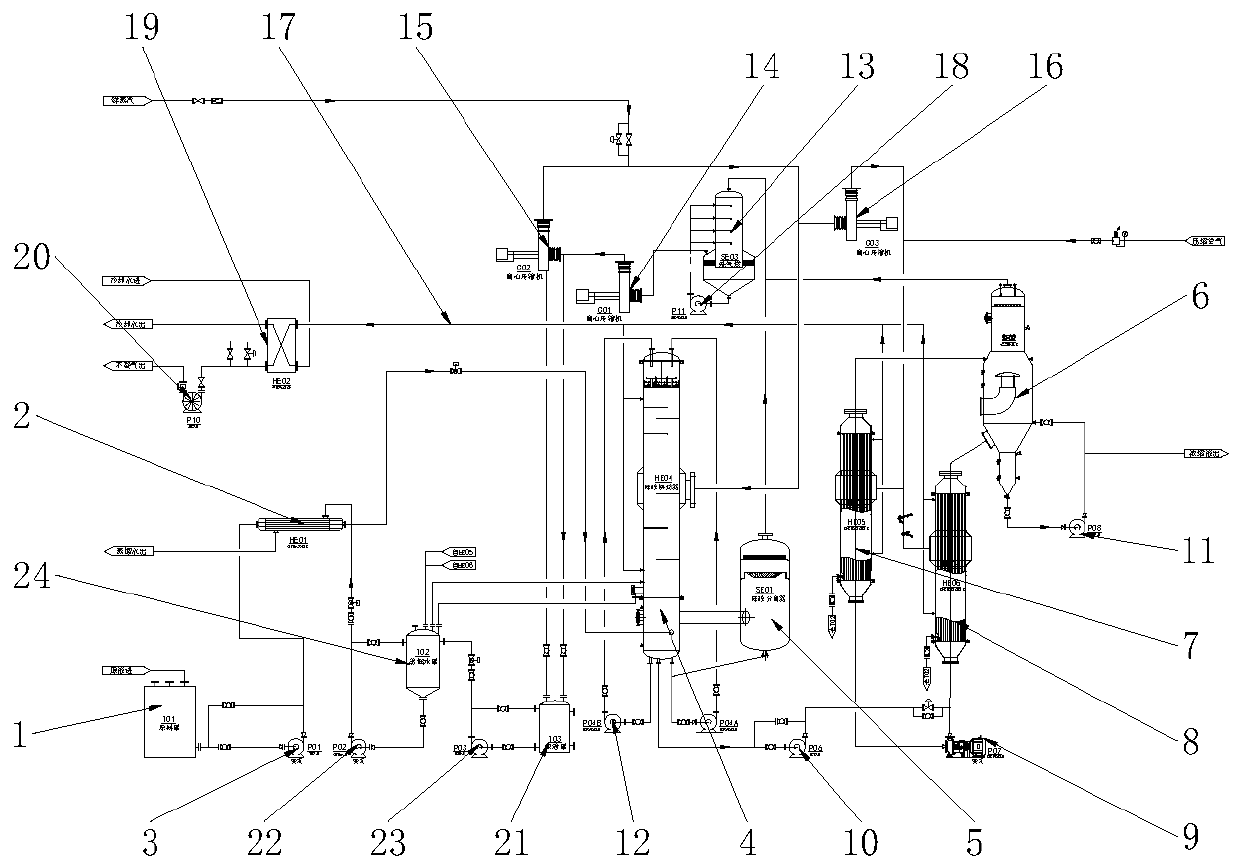

Potassium permanganate electrolyte evaporation concentration system

PendingCN107744669AReduce consumptionIncrease concentrationEvaporator accessoriesSolution crystallizationEvaporationDistilled water

The invention discloses a potassium permanganate electrolyte evaporation concentration system. The potassium permanganate electrolyte evaporation concentration system comprises a raw material tank, atubular heat exchanger, a falling film heat exchanger, a forced circulation heat exchanger, a crystallization separator, an MVR compression system and a distilled water system, wherein the lower partof the falling film heat exchanger is provided with a falling film separator; the MVR compression system comprises a scrubber tower and a noncondensable gas pipe, a gas outlet of the scrubber tower isconnected with a first centrifugal compressor, a steam outlet of the first centrifugal compressor is connected with a second centrifugal compressor, a steam outlet of the second centrifugal compressor is connected with a third centrifugal compressor, and a steam outlet of the second centrifugal compressor is also connected with a fresh steam pipe; and a steam inlet of the falling film heat exchanger is connected with a steam outlet of the second centrifugal compressor, a steam inlet of the forced circulation heat exchanger is connected with a steam outlet of the third centrifugal compressor,and the noncondensable gas outlet of the falling film separator and the noncondensable gas outlet of the forced circulation heat exchanger are connected with the noncondensable gas pipe.

Owner:重庆昌元化工集团有限公司

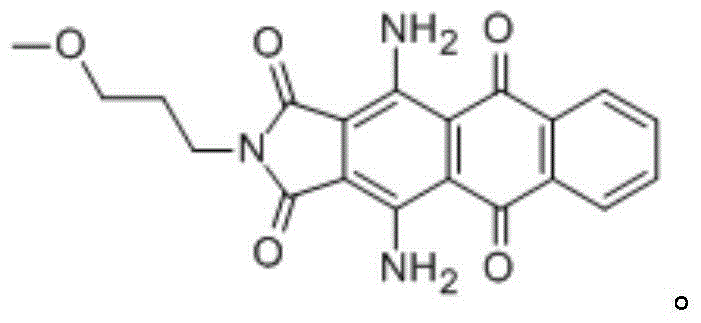

Clean production process of 1,4-diaminoanthraquinone-2-sulfonic acid

The invention discloses a clean production process of 1,4-diaminoanthraquinone-2-sulfonic acid. The process comprises the following steps of in the presence of o-dichlorobenzene as a solvent, oxidizing and sulfonating a 1,4-diaminoanthraquinone leuco compound by virtue of chlorosulfonic acid; after the reaction is completed, neutralizing, removing the solvent and filtering to obtain waste residue; pulping the waste residue and water, filtering to obtain a filter cake and drying the filter cake for reuse; acidifying filtrate, filtering and washing the filter cake which is 1,4-diaminoanthraquinone-2-sulfonic acid; carrying out extraction and reverse extraction on the filtrate to obtain low-COD wastewater and recycling the solvent. After the implementation of the method disclosed by the invention, the waste residue is fully reused and the emissions of waste residue are greatly reduced; meanwhile, the conversion rate of the 1,4-diaminoanthraquinone leuco compound is increased and the cost of sulfonic acid is decreased. The difficult problems of high COD and dark chromaticity of acidified wastewater are solved, the obtained wastewater can be directly subjected to subsequent treatment, and discoloration and COD removal treatment are not needed.

Owner:ZHEJIANG RUNTU INST

Kitchen garbage decomposing box

ActiveCN111346906AFully decomposedFully reuseSolid waste disposalClimate change adaptationFertilizerAgricultural engineering

The invention discloses a kitchen garbage decomposing box. The kitchen garbage decomposing box comprises a box body and a turnover cover mounted on the box body and rotatably connected with the box body through a turnover shaft, a placing cavity upwards opened is formed in the box body, the inner rear end wall of the placing cavity is rotatably connected with six engaging grinding wheels, a grinding wheel cavity is formed in the front side of the placing cavity, a stirring mechanism is mounted in the placing cavity, a first transmission cavity is formed in the lower side of the placing cavity,a door closing cavity is formed in the left side of the first transmission cavity, a door closing mechanism is mounted in the door closing cavity, kitchen garbage can be automatically treated, a series of garbage decomposing flows can be strictly monitored, useful oil and fertilizer can be separated while the kitchen garbage is decomposed, and sufficient decomposing and recycling of the garbage can be ensured.

Owner:嘉兴圣斯顿金属制品有限公司

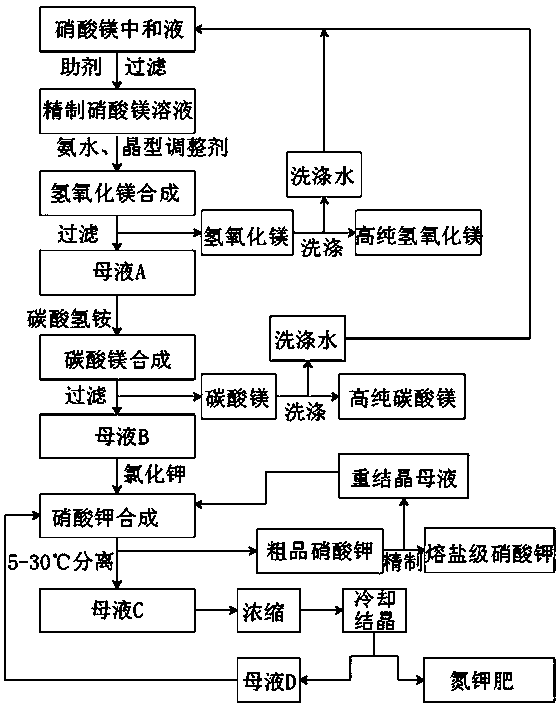

Molten salt production method for co-producing high-purity magnesium hydroxide, magnesium carbonate and nitrogen-potassium fertilizer

InactiveCN111204779AIncrease profitReduce wasteMagnesium carbonatesAlkali metal nitrate preparationPotassium nitrateMolten salt

The invention discloses a molten salt production method for co-producing high-purity magnesium hydroxide, magnesium carbonate and a nitrogen-potassium fertilizer, and relates to the technical field ofchemical product production. The method comprises the following steps: refining magnesium nitrate, adding ammonia water for reacting to obtain a magnesium hydroxide product, reacting a mother solution with ammonium carbonate, performing precipitating to obtain a basic magnesium carbonate product, reacting the mother solution with potassium chloride to obtain crude potassium nitrate, performing refining to obtain molten-salt-grade potassium nitrate, and finally concentrating and crystallizing the mother solution to obtain the nitrogen-potassium fertilizer. The method disclosed by the inventionhas the beneficial effects that a co-production process and a magnesium hydroxide production process supplement each other, existing resources are utilized at the maximum efficiency to obtain the maximum yield, the waste of raw materials is reduced, the commodity additional value is improved, the process raw material utilization rate is high, the product purity is high, and the economic benefit is considerable.

Owner:余荣华

Device for extracting gasoline and diesel oil from used lubricating oil

ActiveCN104611007AFully reuseEmission reductionTreatment with plural serial refining stagesHydrocarbon oils treatment productsChemical industryResource utilization

The invention relates to the technical field of chemical industry and particularly rates to a device for extracting gasoline and diesel oil from used lubricating oil. The device comprises a settling tank, a high-temperature oil pump, a flash tank, a gasifying kettle, a gasifying kettle filter tower, an induced draft fan, a smoke purifying device, a fixed bed catalyzing tower, a fractionating tower, a water cooler for gasoline, a diesel oil intermediate tank, a gear oil pump, a diesel oil storage tank, as well as a vacuum pump set, an oil-gas separation tank, a reflux pump, a gasoline storage tank, a dry gas buffering tank, a dry gas desulfurating / dechlorinating tower, a dry gas holder, a fused salt heating furnace, a fused salt pump and a fused salt tank, wherein the settling tank, the high-temperature oil pump, the flash tank, the gasifying kettle, the gasifying kettle filter tower, the fixed bed catalyzing tower and the fractionating tower are connected in sequence, the fractionating tower is respectively connected with a gasoline extracting device and a diesel extracting device, and the fused salt heating furnace is used for providing a heat source for the whole set of device. The device is full automatic, pollution-free, zero-energy-consumption, environmentally friendly, low-consumption and easy to operate and can be used for treating used lubricating oil without causing any harm or pollution and realizing the best resource utilization of the used lubricating oil.

Owner:YANTAI RONGSHENG PRESSURE VESSEL MFG

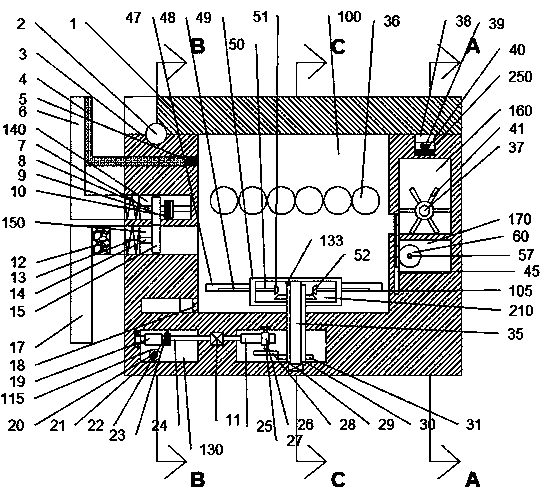

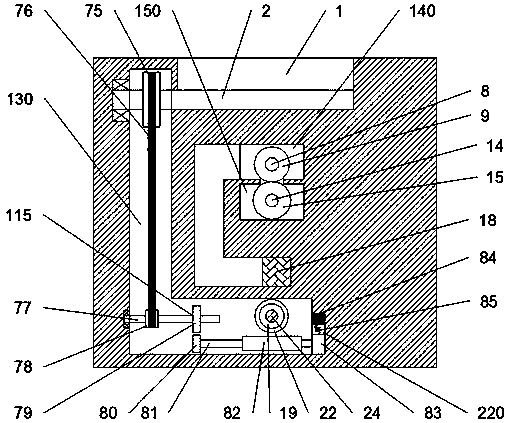

Opening structural computer digital control system able to re-configurate

InactiveCN100370381CMeet different processing requirementsRealize the control applicationComputer controlSimulator controlModel driven developmentHuman–machine interface

The invention is characterized by that making numerical system undergo the process of function module division, maknig model creation based on model drive development method, separating function of module from its behavious, utilizing change of state graph of correspondent module to despatch the the condition of its function execution so as to implement reuse of module function; using port to make communication between modules, said port can utilize its contract abstract interface to make interaction with man-machine interface and bottom layer hardware equipment so as to make related hardware application program meet the interface function requirement provided by system, and in the model layer increasing / reducing or replacing correspondent module so as to implement change of system functino. Said invention also provides the application of said numerical control system.

Owner:东莞市升力智能科技有限公司

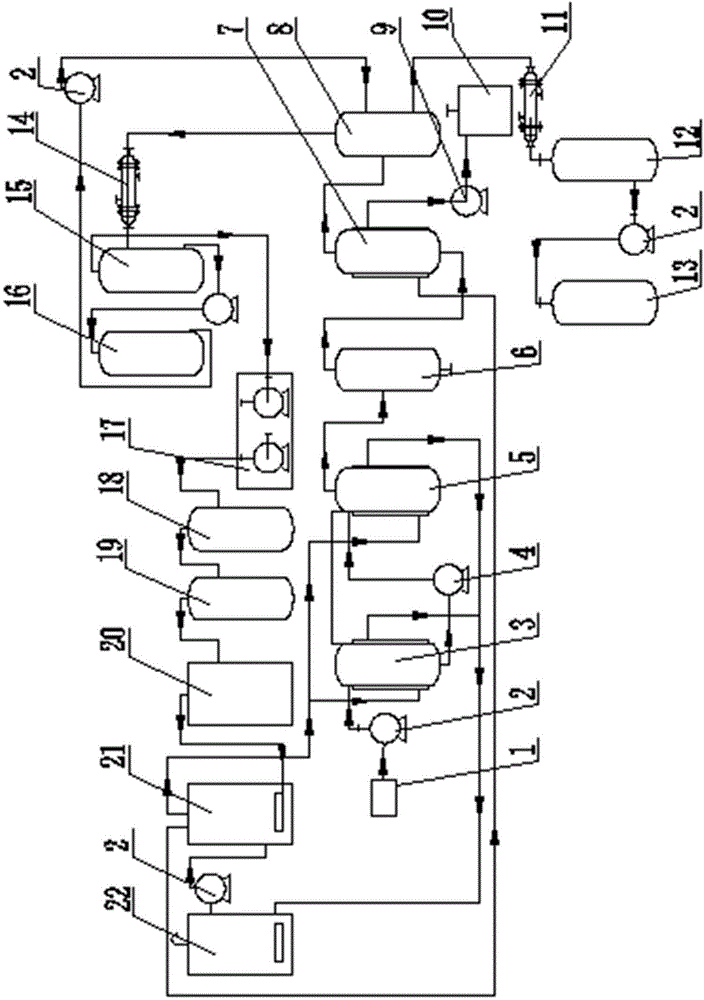

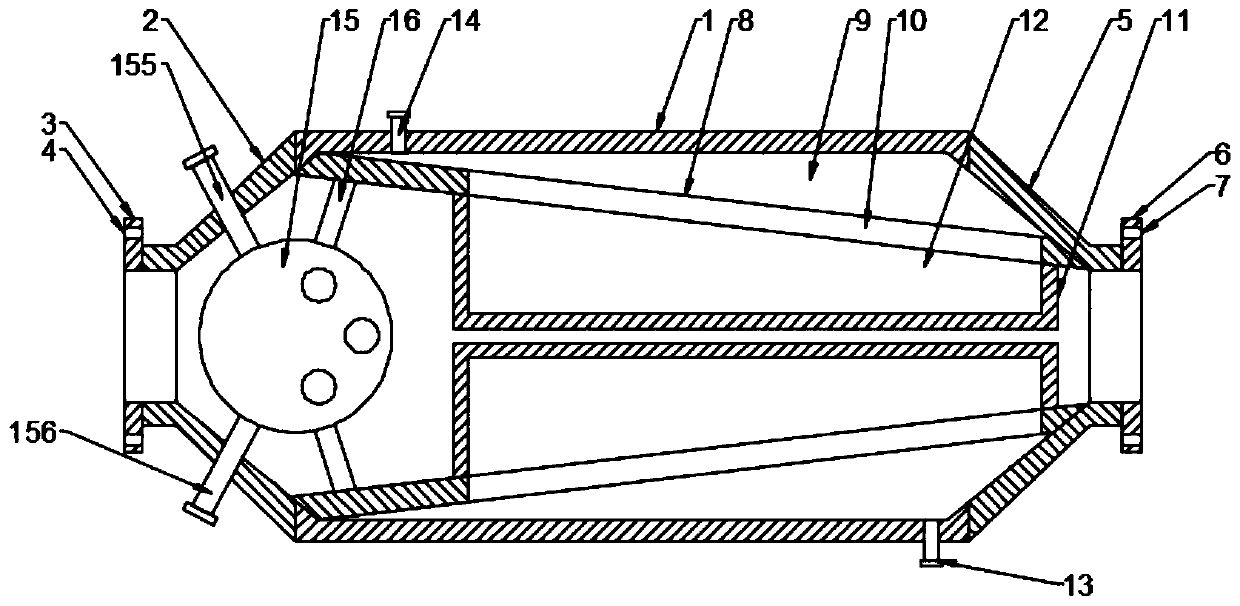

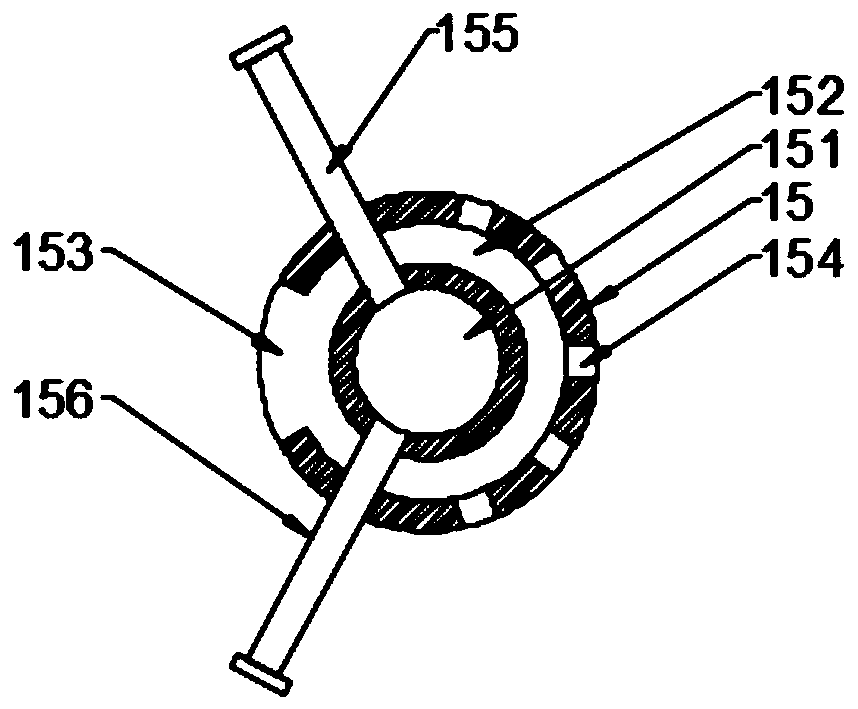

A resource-saving industrial waste gas heat energy secondary utilization device

InactiveCN108458596BFully reuseReduce consumptionHeat recovery systemsIncreasing energy efficiencyResource savingEngineering

The invention discloses a resource-saving industrial waste gas heat energy secondary utilization device. The device comprises a cylinder; the left side end of the cylinder communicates with an intakepipe; the right side end of the cylinder communicates with an exhaust pipe; a heat exchange cylinder is arranged in an inner cavity of the cylinder; the heat exchange cylinder and the inner wall of the cylinder form a first water cavity; multiple groove holes are uniformly formed in the inner side wall of the first water cavity; heat exchange fins sleeve openings on the inner sides of the groove holes; and a heat exchange ball is arranged on the side, near the intake pipe, of the inner cavity of the cylinder. High-temperature industrial waste gas enters a second heat exchange cavity from an intake hole for heat exchange with water in a second water cavity; heat in high-temperature industrial waste gas is absorbed at the first time; the heat-absorbed industrial waste gas directly enters theheat exchange cylinder for heat exchange with the water through the heat exchange fins; and the secondary heat exchange reaction is performed for further absorbing the heat in the industrial waste gas, so that the heat in the industrial waste gas is fully reutilized, the heat utilization rate is increased, the energy consumption is reduced, and the energy is greatly saved.

Owner:广东净尘环保设备有限公司

Method for producing bio-organic fertilizer by using lignin organic granules

InactiveCN102442847BFully reuseEliminate emission pollutionOrganic fertilisersFertilizer mixturesSpray GranulationParticulates

The invention provides a method for producing a bio-organic fertilizer by using lignin organic granules. The method provided by the invention comprises steps of: preparing a liquid inoculant, preparing a lignin black liquor into an organic particulate agent by spraying granulation, and compounding the organic granules and the liquid composite inoculant, wherein the liquid composite inoculant which accounts for 0.5-1.5% of the weight of the finished product composite microbial fertilizer is added. The production of the bio-organic fertilizer can be completed by bacterial liquid permeation intoorganic particles and the technical requirement of the product can be reached without drying. According to the invention, routines are broken by creative introduction of the spraying granulation method into the biological fertilizer granulation technology. The production method of the particulate bio-organic fertilizer is divided into two steps of spraying granulation of the organic granules and organic granule wrapping or inoculant adsorption. In the meanwhile, a certain activity of the bio-organic fertilizer is maintained. According to the bio-organic fertilizer product, the breakthrough from a powder form to spray particles is realized, thus laying a foundation for the extensive popularization of the bio-organic fertilizer.

Owner:北京世纪大德环保科技有限公司

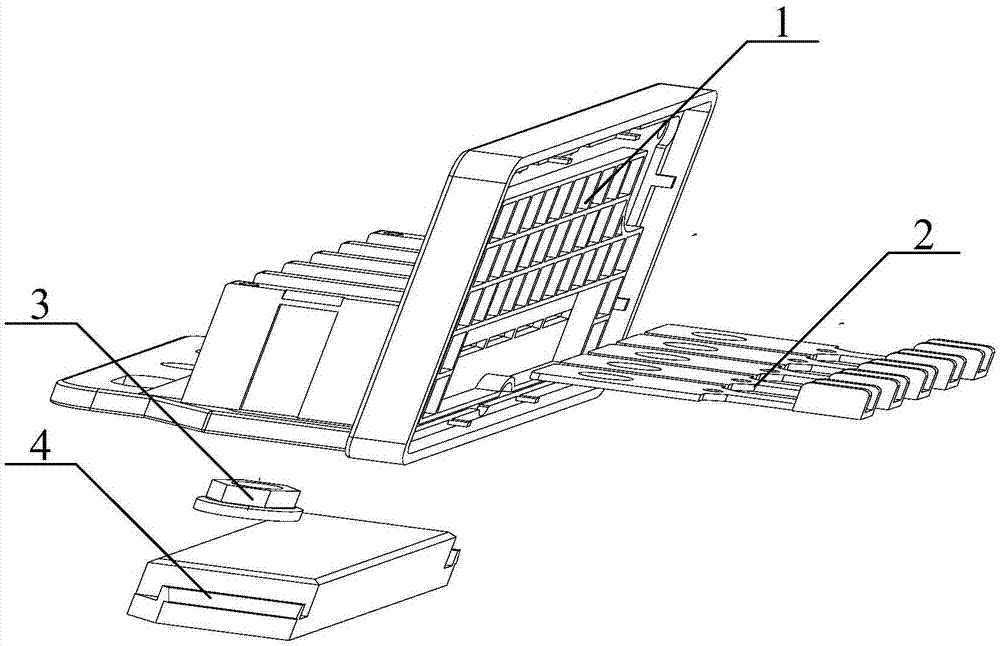

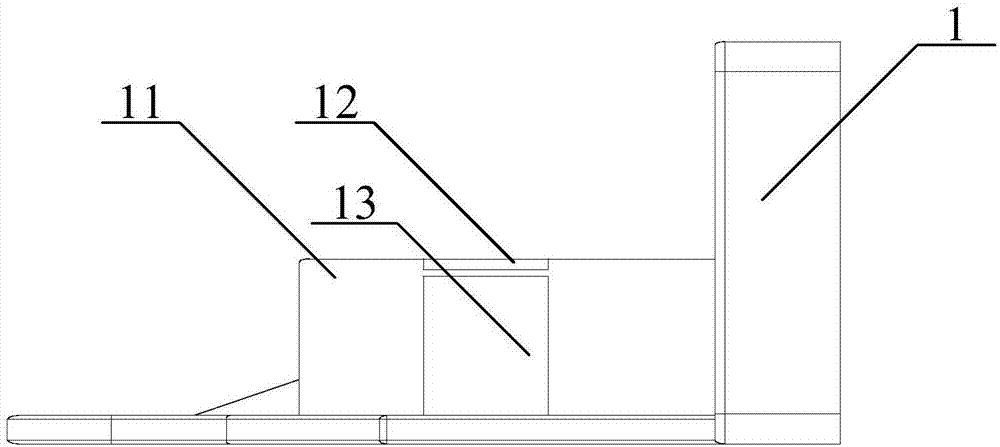

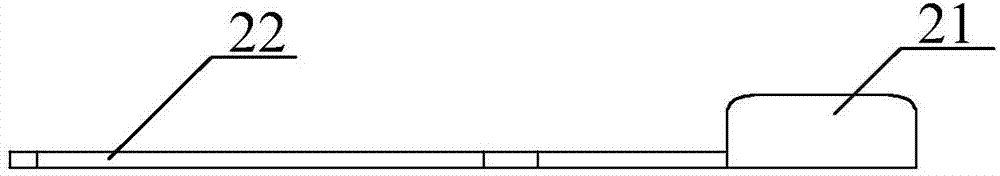

Vehicle controller wiring end shield

PendingCN107369972AFully reuseChange complexityCouplings bases/casesElectric/fluid circuitStructural engineeringBatch manufacturing

The invention provides a vehicle controller wiring end shield which comprises connector lugs, wiring insertion sheets, M6 nuts with cap and rear pressing plates, wherein the wiring insertion sheets are inserted in the inner lower portions of the connector lugs, the M6 nuts with caps are sequentially disposed in the nut holes vertically arranged in the central tops of the second gradient heads of the connector lugs, bolt holes are arranged vertically in the lower portions of the second gradient heads, and the rear pressure plates are in clamp connection with the bottom of the connector lugs. Connector lugs, wiring insertion sheets, and M6 nuts with caps and rear pressing plates are provided, low production efficiency of original design can be changed, the problems of complex structure and not environmental friendly can be solved. The design is simple and reasonable, and installation is facilitated. Some components can be reused to save energy and ensure environmental friendliness. Batch production is possible, and subsequent maintenance and replacement are facilitated. Since second gradient heads, nut holes and bolt holes are provided, rapid positioning and installation are facilitated.

Owner:江苏万聚电气有限公司

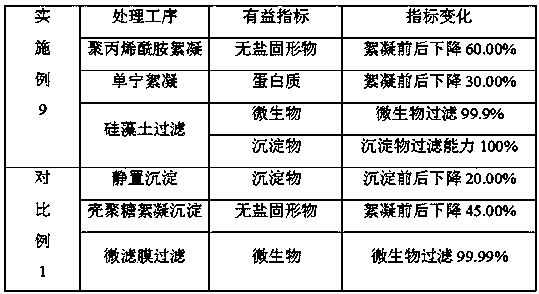

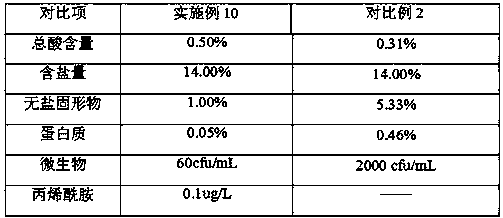

A recovery and treatment process of pickled pepper pickled brine

ActiveCN108164035BPreserve the flavorRetain colorTreatment involving filtrationMultistage water/sewage treatmentBiotechnologyFlocculation

Owner:SICHUAN FUXIN FOOD CO LTD

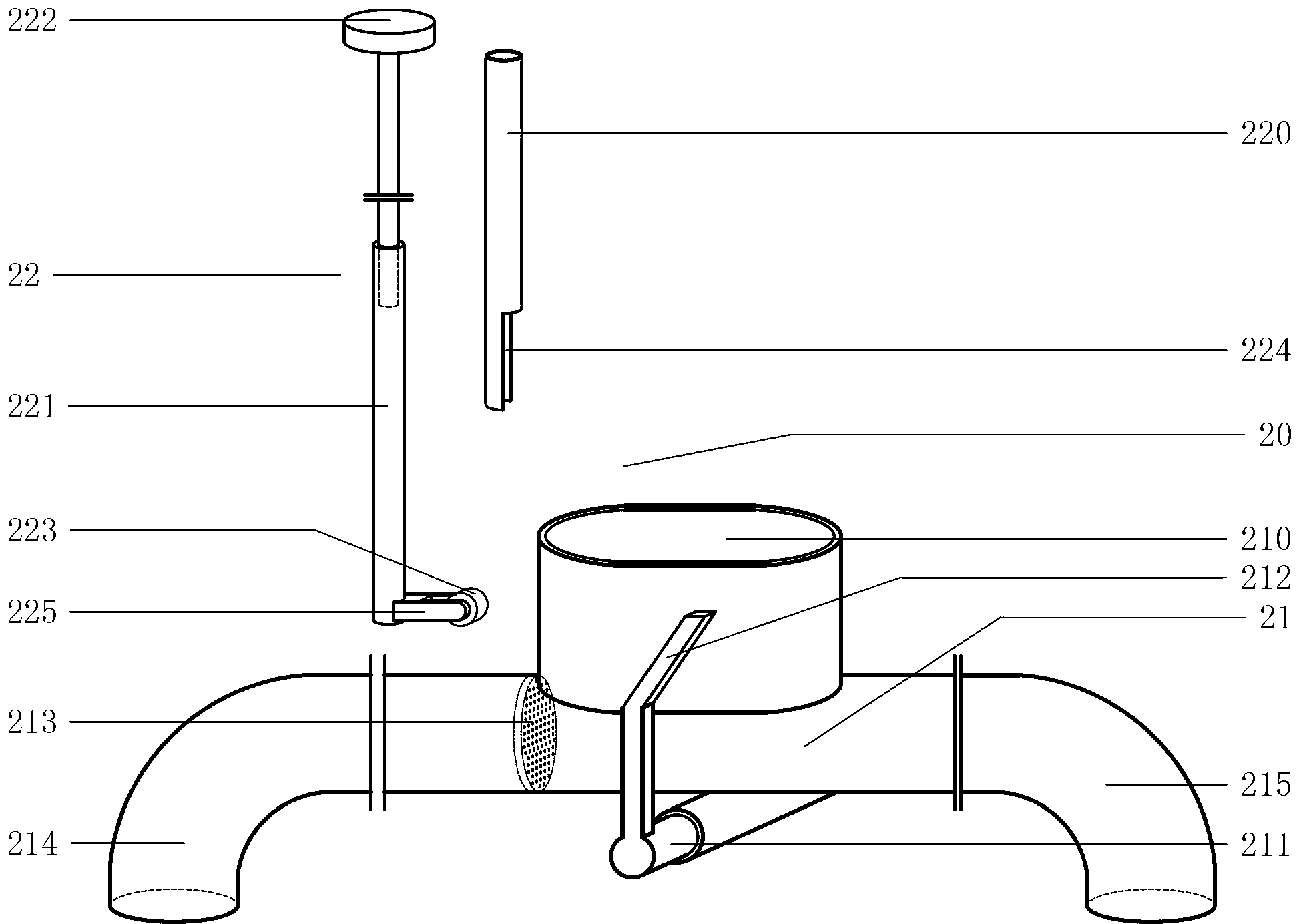

Flow splitting type washing cabin water-saving device

ActiveCN103306341AFully reuseReasonable structureDomestic plumbingWater supply installationWater savingWater channel

The invention provides a flow splitting type washing cabin water-saving device. The flow splitting type washing cabin water-saving device comprises a basic frame type water storage tank, a flow splitting pipe valve, a sleeve valve head and a water discharging valve core, wherein the basic frame type water storage tank is a mounting basic frame of a washing cabinet and is also the water storage tank and structurally comprises a cabinet bottom tank body, a backrest tank body and a pressurizing water conveying pump; the flow splitting pipe valve is mounted on the basic frame type water storage tank and structurally comprises a swinging flow splitting pipe and a pressurized flow splitting valve rod; the sleeve valve head is mounted on a washing water channel; and the water discharging valve core is mounted on the basic frame type water storage tank and structurally comprises a valve core slide pipe and a pressurized water discharging valve rod. According to the embodiment of the invention, spaces of the bottom face and the back part of the washing cabinet, which are difficult to use, are arranged into the water storage tank, so that the water storage tank can be conveniently combined and mounted with the washing cabinet, and sufficient washing water can be stored and reutilized; and a washing worker only needs to lift a flow splitting pressurizing handle, and the cleaner washing water can be collected into the basic frame type water storage tank to be stored and reutilized. Therefore, the flow splitting type washing cabin water-saving device is reasonable in structure, is simple to operate and control, and is convenient for people to save the water.

Owner:淮安市清江浦区市场监管综合服务中心

Production process of waterproof leakage-repairing adhesive

InactiveCN1309796CFully reuseWill not polluteOther chemical processesHydrocarbon polymer adhesivesCalcium hydroxideSludge

The production process of waterproof leakage-repairing adhesive features that calcium hydroxide is added into acid sludge to obtain the depolymerizing acid sludge paste, waste polymer foam is dissolved with benzene or acetate solvent to obtain ropy liquid, and the depolymerizing acid sludge paste and the ropy liquid are then mixed to form the waterproof leakage-repairing adhesive. It has acid sludge / calcium hydroxide weight ratio of 1-1.67, waste polymer foam content in the ropy liquid of 20-50 wt%, and the weight ratio between the depolymerizing acid sludge paste and the ropy liquid of 1-5. The present invention has the advantages of best utilization of acid sludge, environment friendship, low production cost and good product use effect.

Owner:叶贤忠

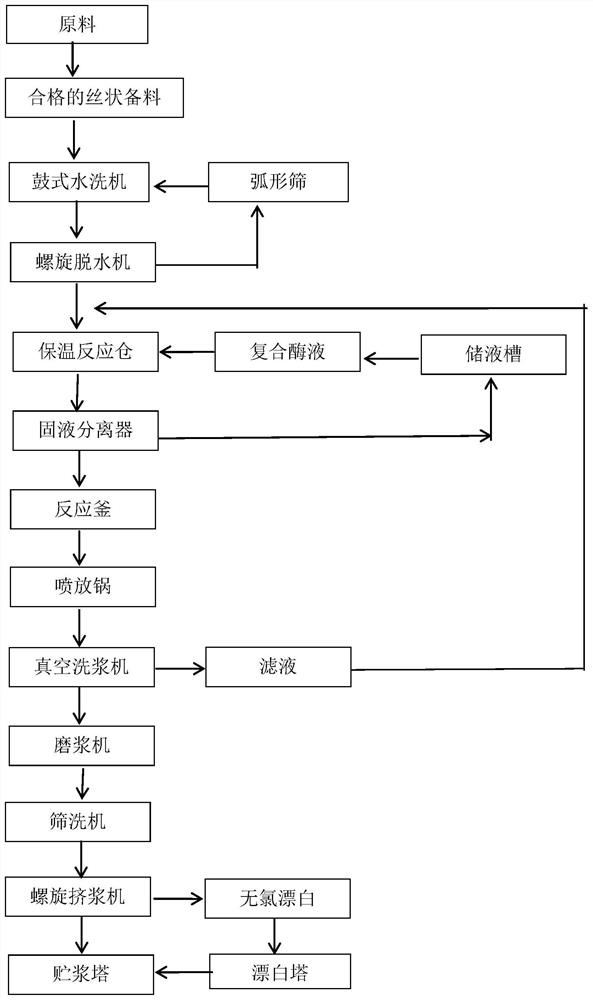

A kind of compound enzyme preparation and the technology for preparing paper pulp

ActiveCN108978305BHigh porosityImprove bleachabilityCellulose treatment using microorganisms/enzymesPectinaseMicroorganism

The invention discloses a complex enzyme preparation. The complex enzyme preparation is prepared from 10-20 parts of laccase, 10-15 parts of xylanase, 3-5 parts of pectinase and 1 part of mannose. According to the complex enzyme preparation, the problem that in the prior art, the period for treating plant fiber raw materials by adopting microorganisms is too long is solved. The invention further discloses a process for preparing paper pulp by adopting the above complex enzyme preparation, and a bio-enzyme method is adopted to combine with mechanical pulping.

Owner:陈五岭

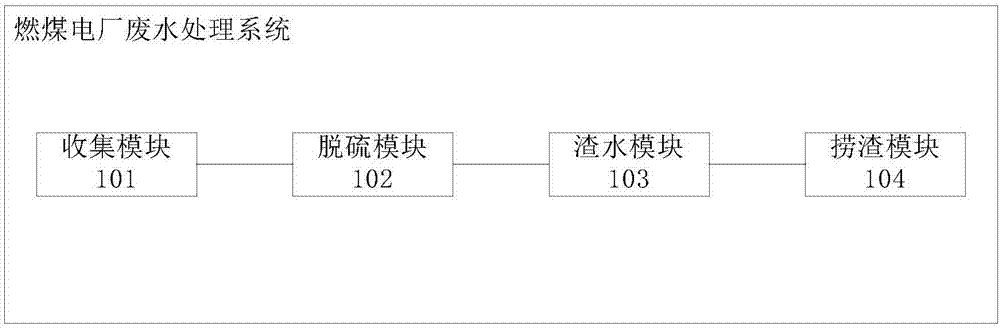

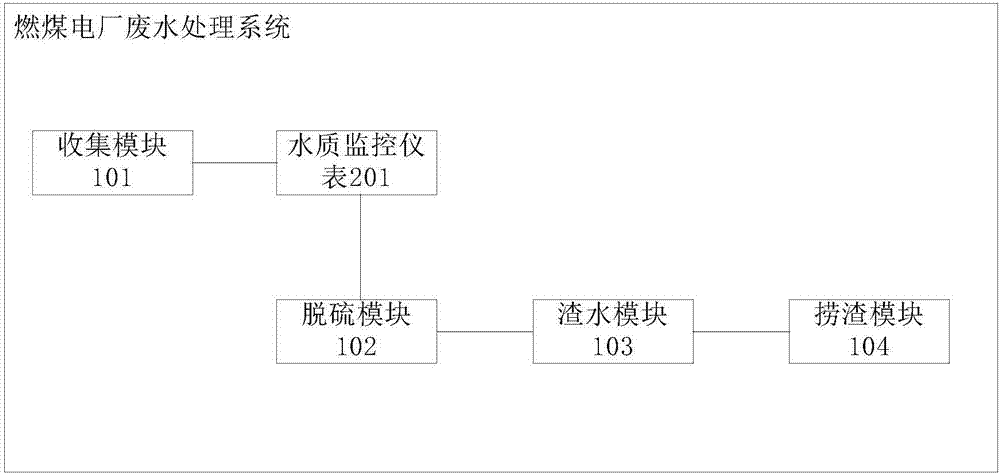

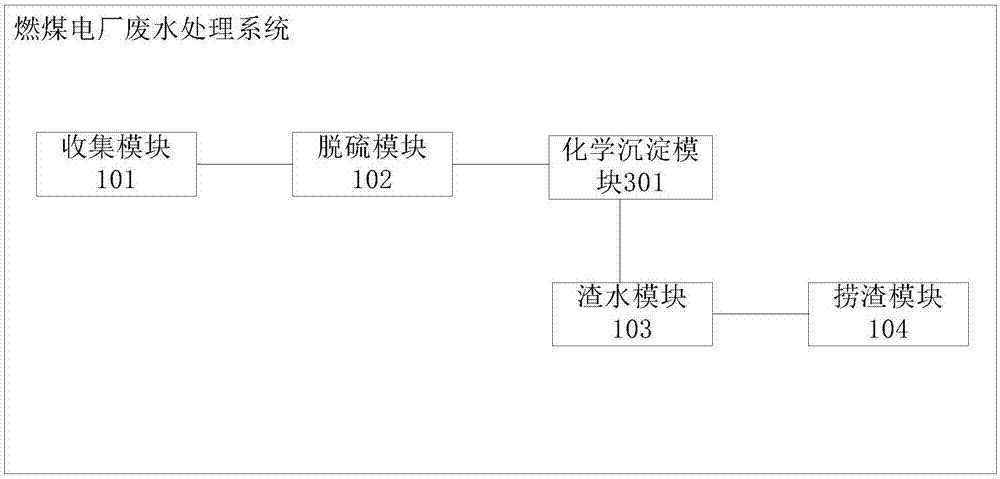

Waste water treatment system for coal-fired power plant

PendingCN107311384AAchieving zero emissionsFully reuseWater treatment parameter controlMultistage water/sewage treatmentWater treatment systemSlag

The invention discloses a waste water treatment system for a coal-fired power plant. The system comprises a collecting module, a desulfurization module, a slag water module and a slag fishing module, wherein a water draining tube of the collecting module is connected with a water inlet tube of the desulfurization module; a water draining tube of the desulfurization module is connected with a water inlet tube of the slag water module; the slag water module is connected with the slag fishing module; the collecting module is used for acquiring first waste water generated during running of the coal-fired power plant and delivering the first waste water to the desulfurization module; the desulfurization module is used for carrying out desulfurization treatment on the first waste water; the slag water module is used for washing waste slag by second waste water discharged from the desulfurization module and evaporating the second waste water; and the slag fishing module is used for fishing the waste slag in the slag water module. Thus, the waste water treatment system for the coal-fired power plant takes the waste water as replenished water of the desulfurization module and the slag water module, and by modes of desulfurization, slag washing, evaporating, slag fishing and the like, zero emission of the waste water of the coal-fired power plant is realized simply and really.

Owner:GUODIAN ENVIRONMENTAL PROTECTION RES INST CO LTD

A MML-based large-capacity data configuration method, server and system

ActiveCN103001786BFully reuseImprove development efficiencyData switching networksSource codeLogic mapping

Disclosed are an MML-based large volume data configuration method, server and system. The method includes receiving a template file sent by a client; parsing data in the template file into batched MML commands according to a batch configuration command sent by the client and on the basis of a pre-stored logic mapping file; and executing the MML commands in batches, and writing execution result information into the template file, and then sending the template file to the client. The present invention can parse the template file into which data to be configured is written into MML commands based on a pre-stored logic mapping file and execute same, which could fully reuse the original source code and improve development efficiency and reduce complexity.

Owner:ZTE CORP

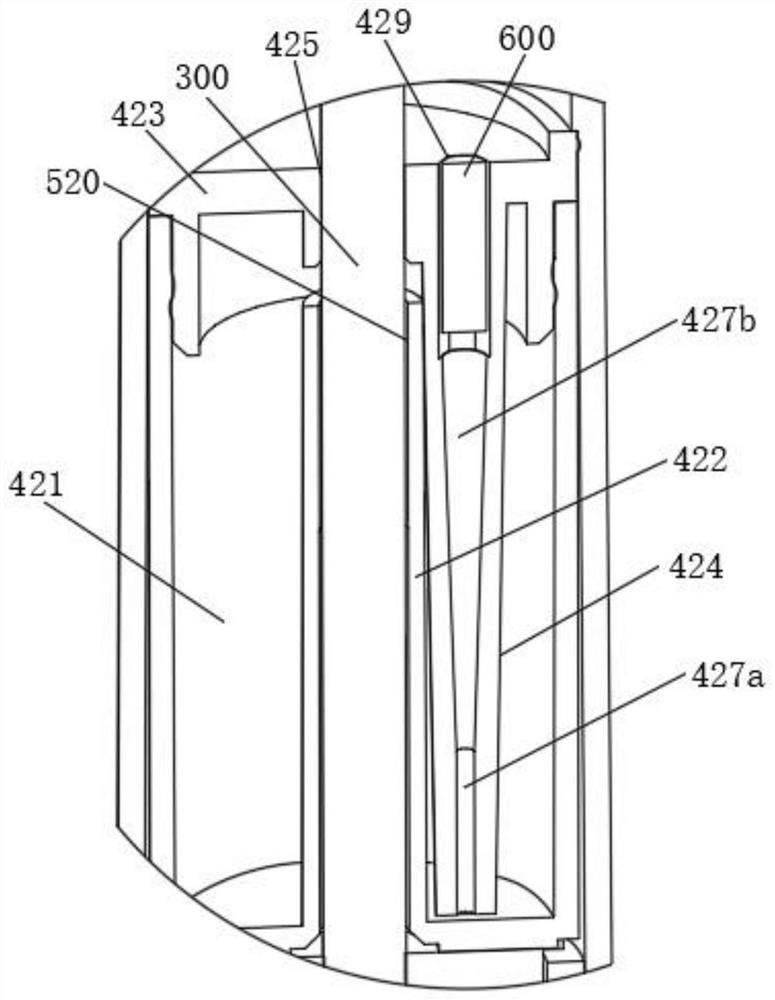

Direct liquid type writing tool

InactiveCN113212031AFully reuseInk leakage will not occurInk reservoir pensEngineeringMechanical engineering

The invention relates to a direct liquid type writing tool which comprises a pen body, a writing element, a water leading core and an ink storage assembly, wherein the ink storage assembly is arranged in the pen body and divides the pen body into an ink supply cavity located on the upper portion and an atmosphere communication cavity located on the lower portion, and the ink storage assembly comprises a first ink storage part and a second ink storage part; the outer wall of the first ink storage part and the inner wall of the pen body are provided with a first air guide flow channel in communication with the atmosphere communication cavity, the inner wall of the second ink storage part and the outer wall of the ink leading core are provided with a second air guide flow channel in communication with the first air guide flow channel, the second ink storage part comprises a second ink storage part and an ink storage base which are connected, and the second ink storage part comprises an ink storage cavity; the ink storage base comprises an ink return device, the ink return device is arranged in the ink storage cavity and comprises an ink return flow channel, and the second air guide flow channel communicates with the ink supply cavity through the ink return flow channel. The ink stored in the ink storage cavity can flow back to the ink supply cavity through the air guide flow channel and the ink return flow channel, so that the ink can be fully recycled, and the phenomenon of ink leakage is avoided.

Owner:苏州雄鹰笔墨新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com