Treatment system of isopropanol sewage generated in monocrystalline silicon battery manufacturing

A sewage treatment system and monocrystalline silicon battery technology, applied in biological water/sewage treatment, neutralized water/sewage treatment, water/sewage multi-stage treatment, etc., can solve external environmental pollution and do not meet solar energy "cleaning products themselves Image and other issues to achieve the effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

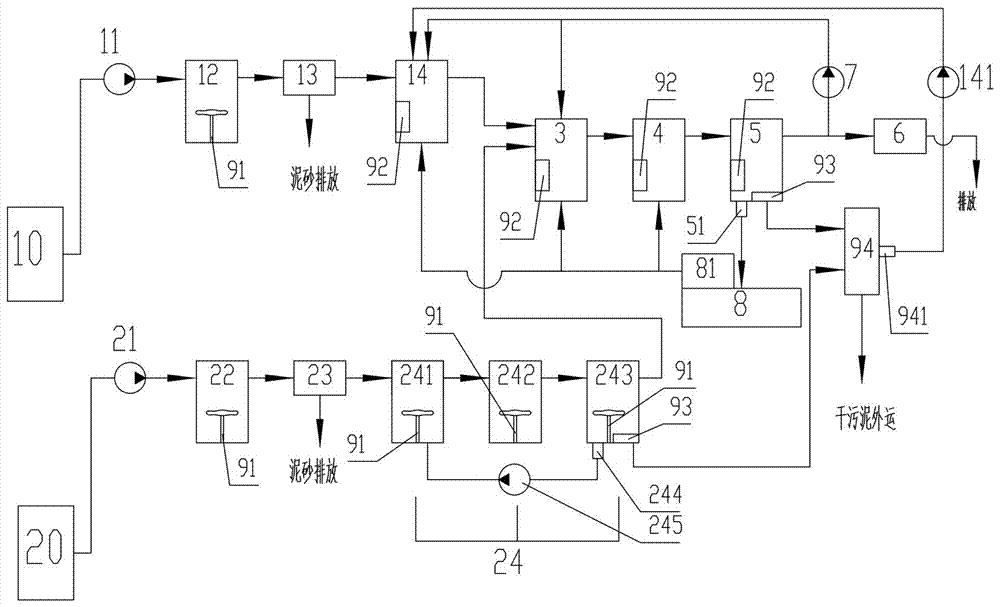

[0021] Example: such as figure 1 As shown, a kind of isopropanol sewage treatment system that monocrystalline silicon cell manufacture produces, comprises concentrated isopropanol alkali waste liquid storage tank 10, fluorine-containing dilute isopropanol waste water storage tank 20, the first lifting pump 11, the second Lift pump 21, first pH adjustment tank 12, second pH adjustment tank 22, first floatation and primary sedimentation tank 13, second floatation and primary sedimentation tank 23, anaerobic tank 14, fluorine removal flocculation sedimentation device 24, hydrolysis acidification Pool 3, activated sludge pool 4, secondary settling pool 5, clear water discharge pool 6; described concentrated isopropanol alkali waste liquid storage tank 10, first lift pump 11, first pH adjustment pool 12, first floatation Settling tank 13 and anaerobic tank 14 are piped in series in sequence, and the fluorine-containing dilute isopropanol wastewater storage tank 20, the second lift ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com