Continuous evaporative crystallization method

An evaporative crystallization and crystallization technology, applied in evaporation, solution crystallization, separation methods, etc., can solve the problems of unsatisfactory energy saving effect, complex structure, high energy consumption of compressors, overcome the lack of heat supply for crystallization, improve crystallization effect, energy and energy consumption. The effect of resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

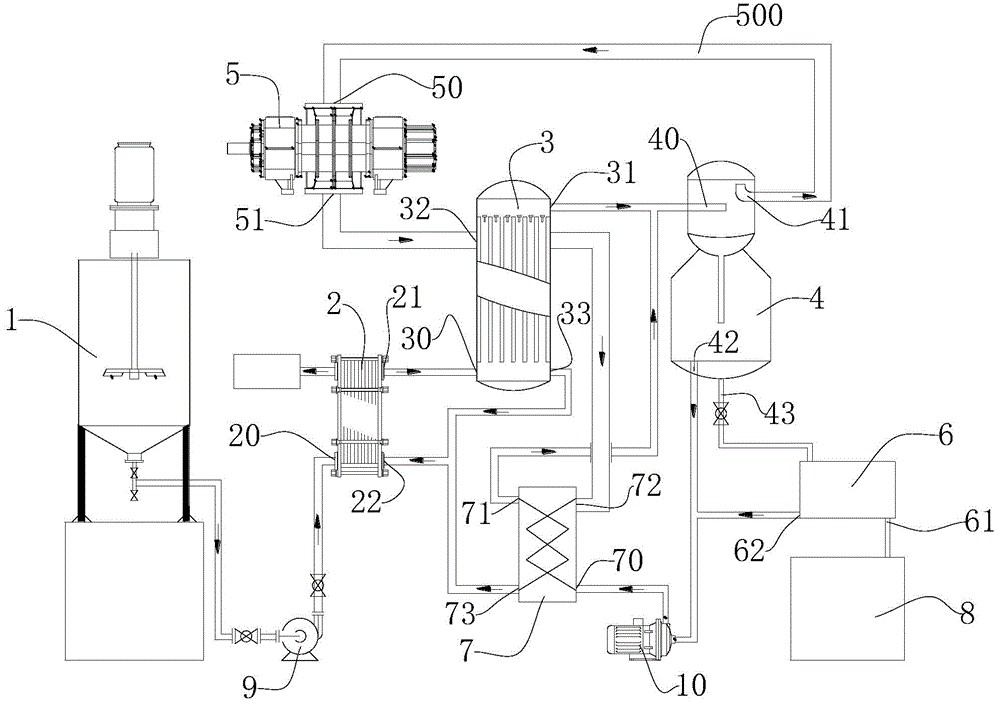

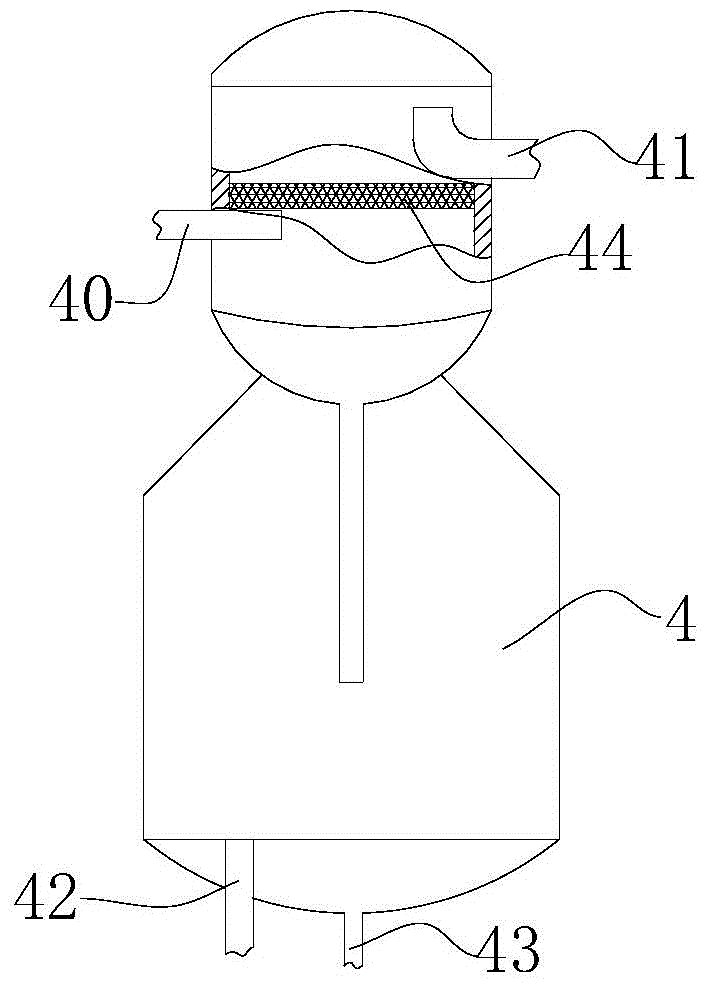

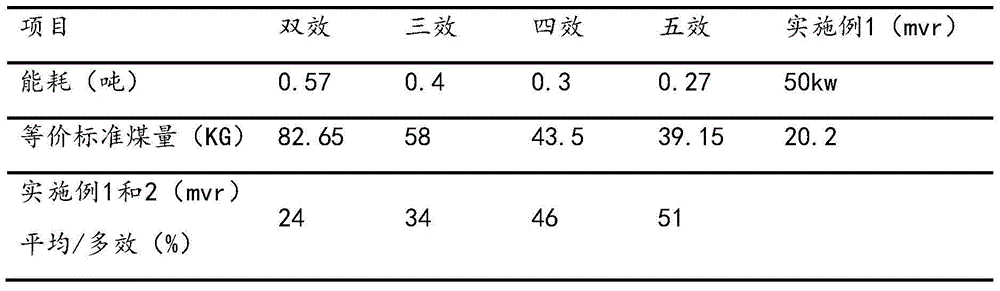

[0026] In order to better illustrate the continuous evaporation crystallization method of the present invention, the present embodiment first describes in detail the equipment it adopts, as figure 1 Shown is a mechanical vapor recompression continuous evaporative crystallization device, the evaporative crystallization device is mainly composed of a raw material tank 1 for feeding materials to be crystallized, a first heater, a rising film evaporator 3, a mechanical vapor compressor 5, The forced circulation evaporator 7, the gas-liquid separator 4 and the crystallization separator 6 are composed. Wherein, the first heater, the rising film evaporator 3 and the forced circulation evaporator 7 in this embodiment are all heat exchanger structures. The first heater is the heat exchanger 2 with an electric heater, which is mainly used for preheating the material solution, and the heat exchanger 2 with an electric heater has an electric heater in addition to the heat exchanger struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com