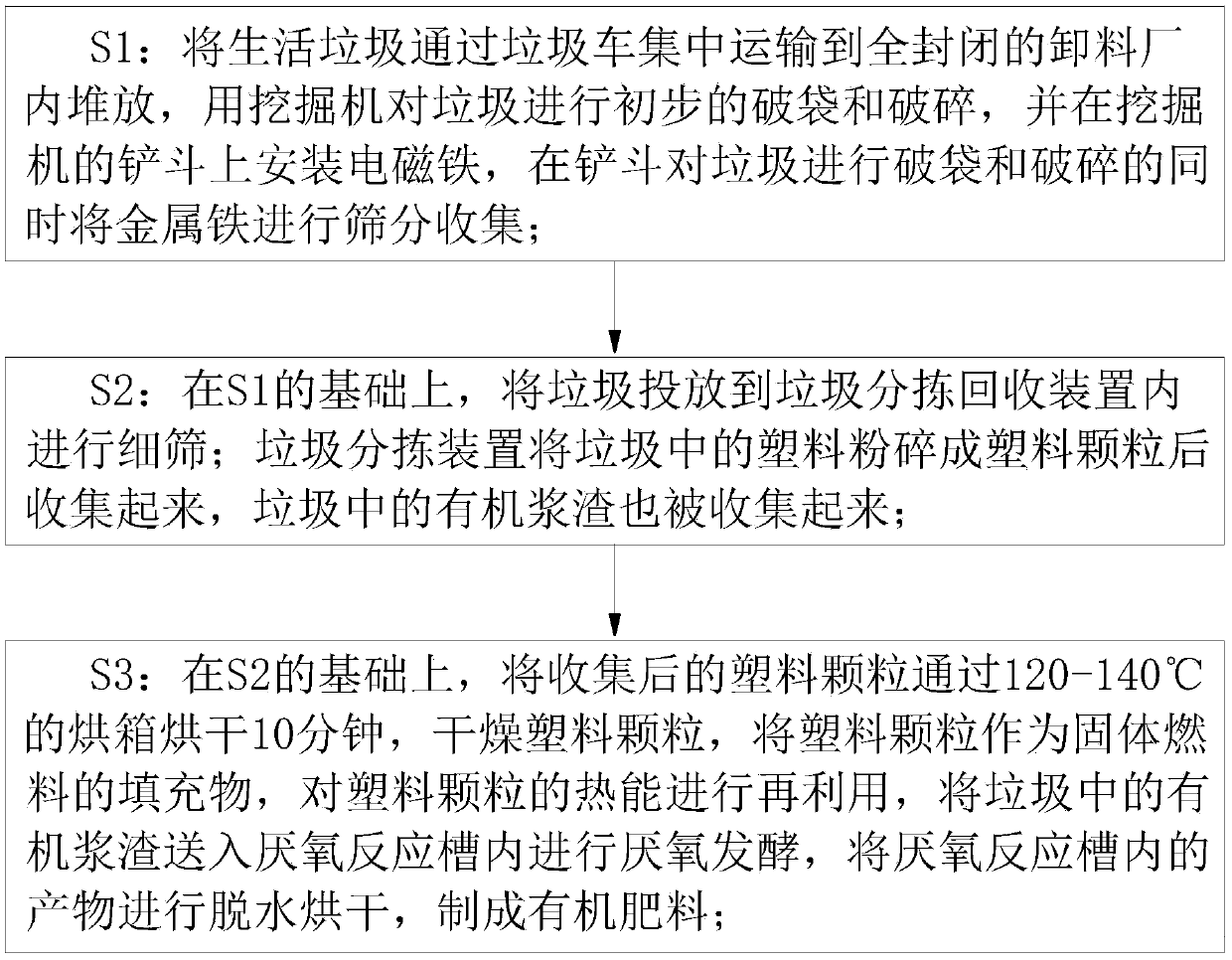

Household garbage recovery process

A domestic garbage and recycling technology, applied in plastic recycling, grain processing, mechanical material recycling, etc., can solve problems such as insufficient resource utilization, low sorting efficiency, natural gas leakage, etc., to improve the breaking effect and crushing efficiency , the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

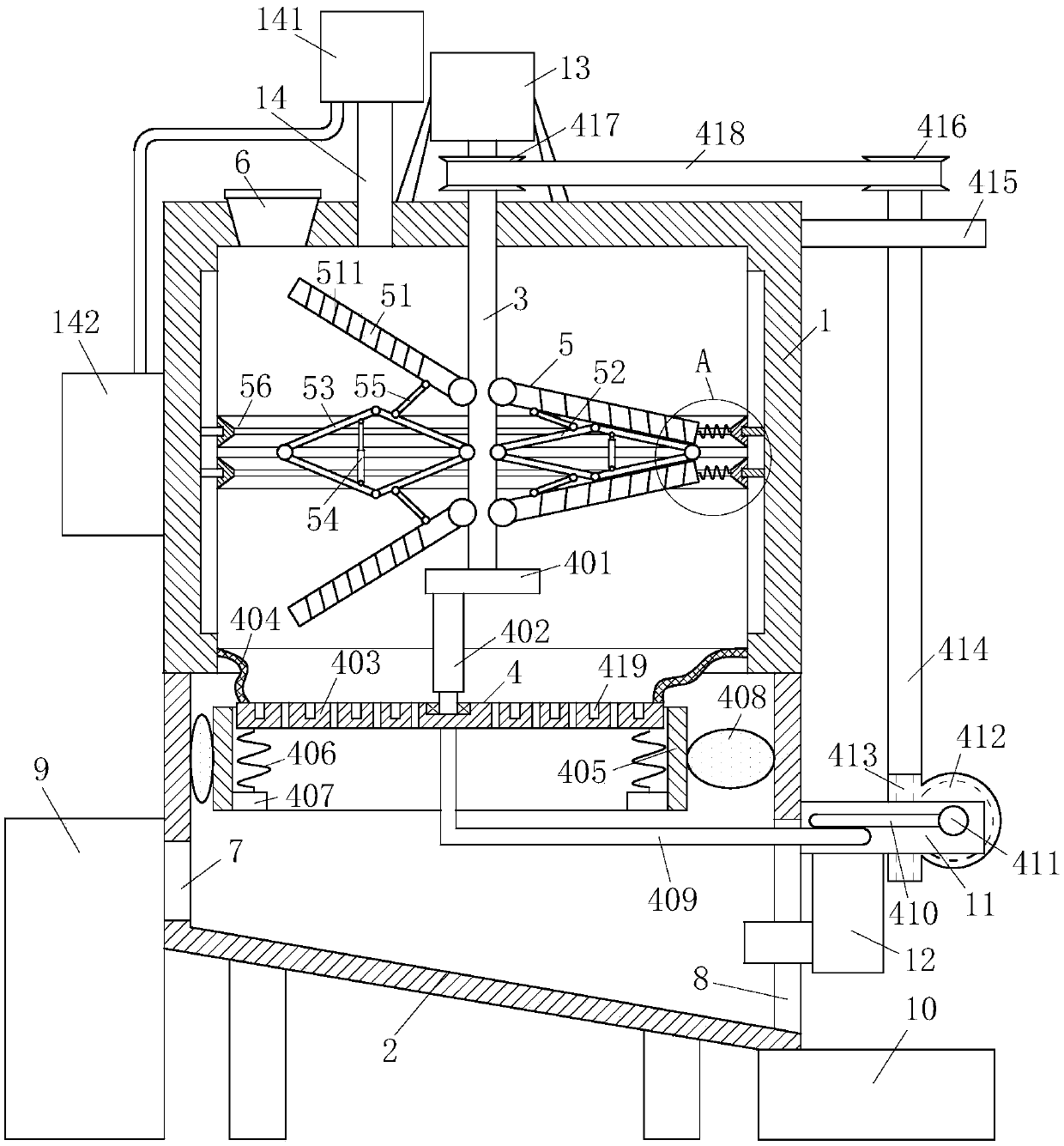

Examples

Embodiment approach

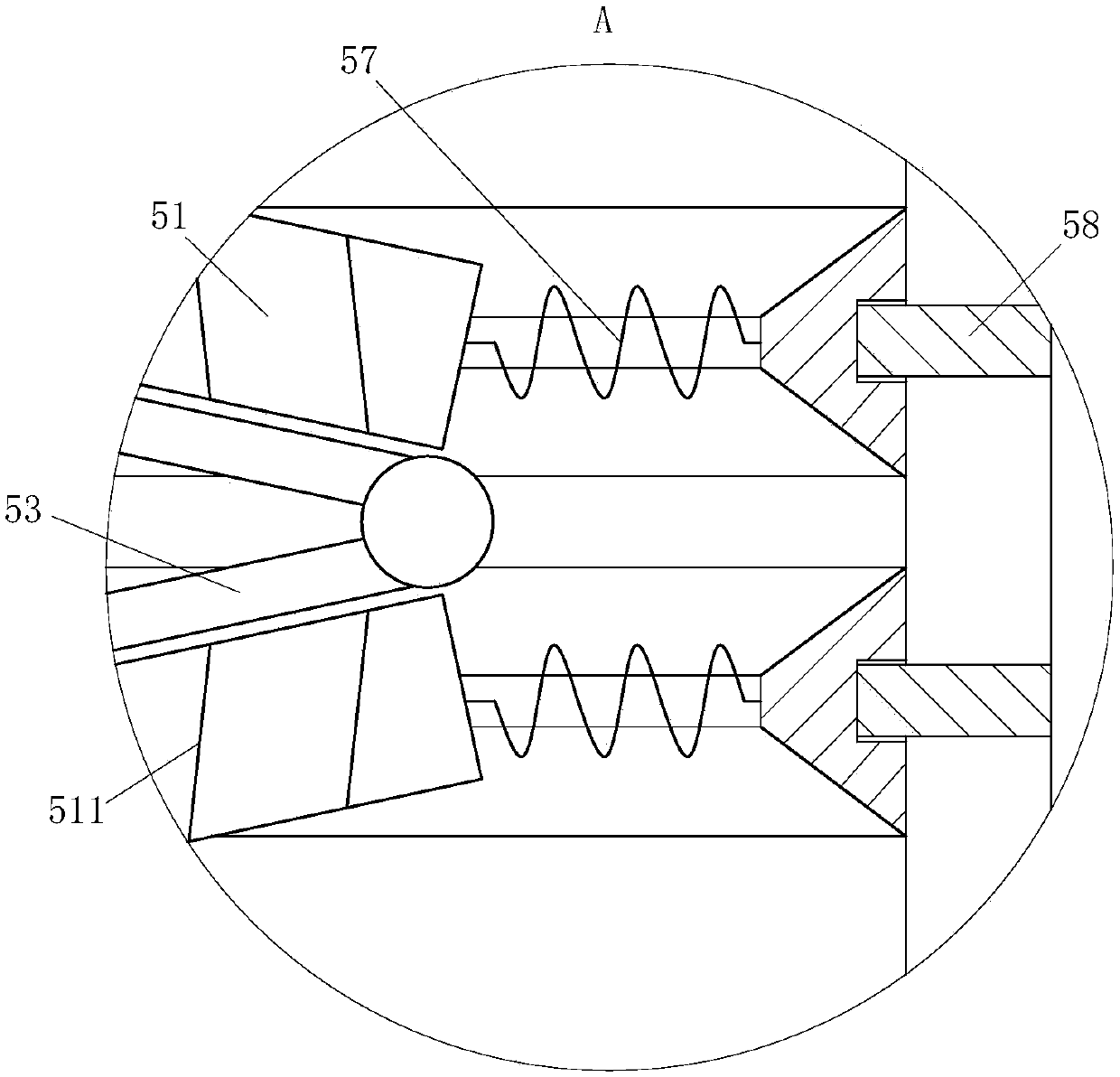

[0037] As an embodiment of the present invention, two wall scraping rings 56 are slidably arranged on the inner wall of the crushing chamber 1; the wall scraping rings 56 are connected to the end of the crushing rod 51 through a No. The section of 56 is trapezoidal structure, scraping ring 56 is used for scraping off the rubbish attached on the inner wall of crushing chamber 1, is provided with annular chute on the scraping ring 56; One end of slide block 58 is slidably installed on the said annular chute, The other end of the slide block 58 is slidably installed in the strip chute provided on the inner wall of the crushing chamber 1, and through the cooperation between the wall scraping ring 56, No. 2 spring 57, slide block 58 and crushing rod 51, the wall scraping ring 56 is Sliding up and down under the drive of crushing rod 51. The crushing rod 51 drives the wall-scraping ring 56 to slide up and down while rotating through the No. 2 spring 57. Since the cross-section of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com