Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37 results about "Numerical system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

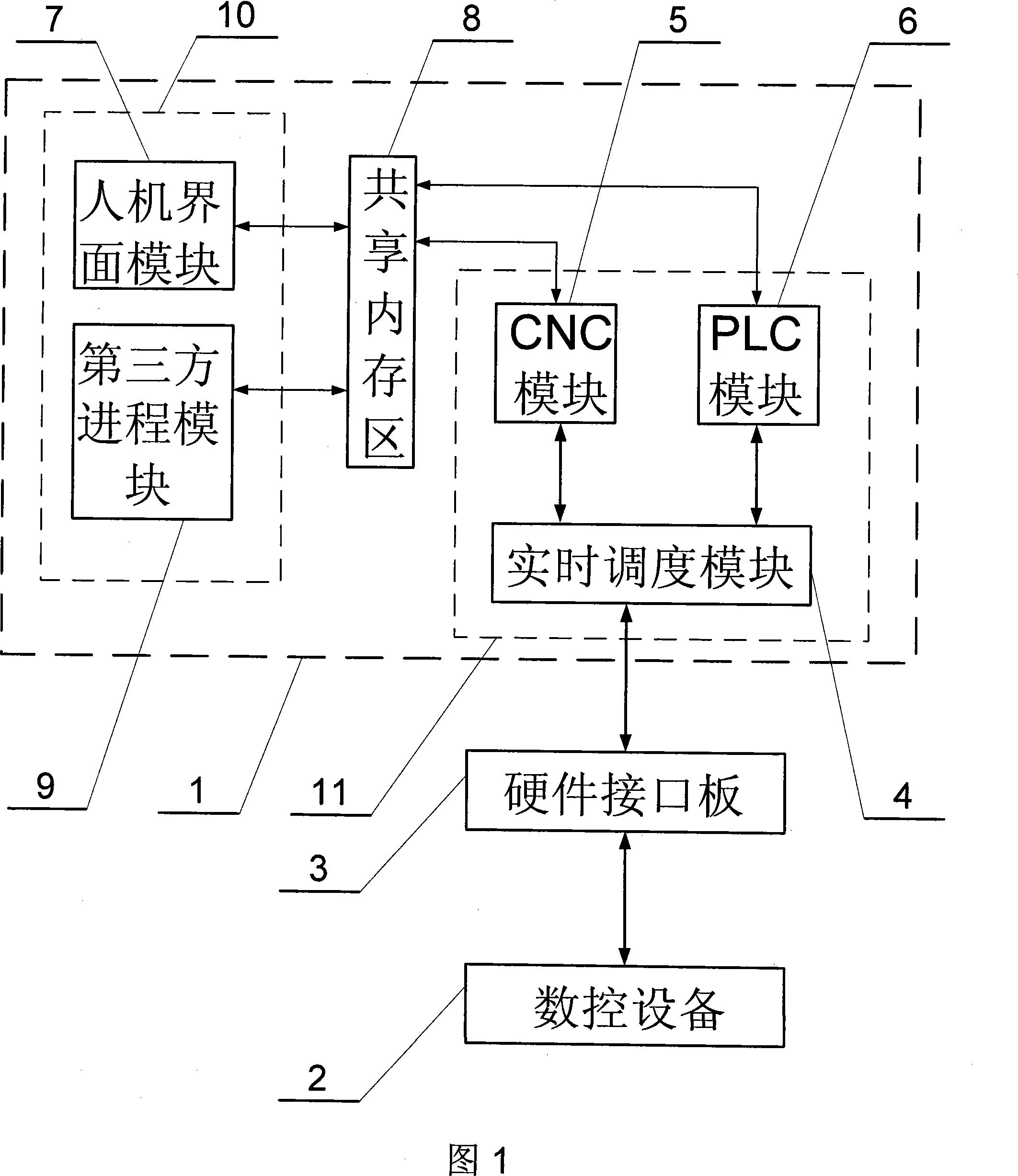

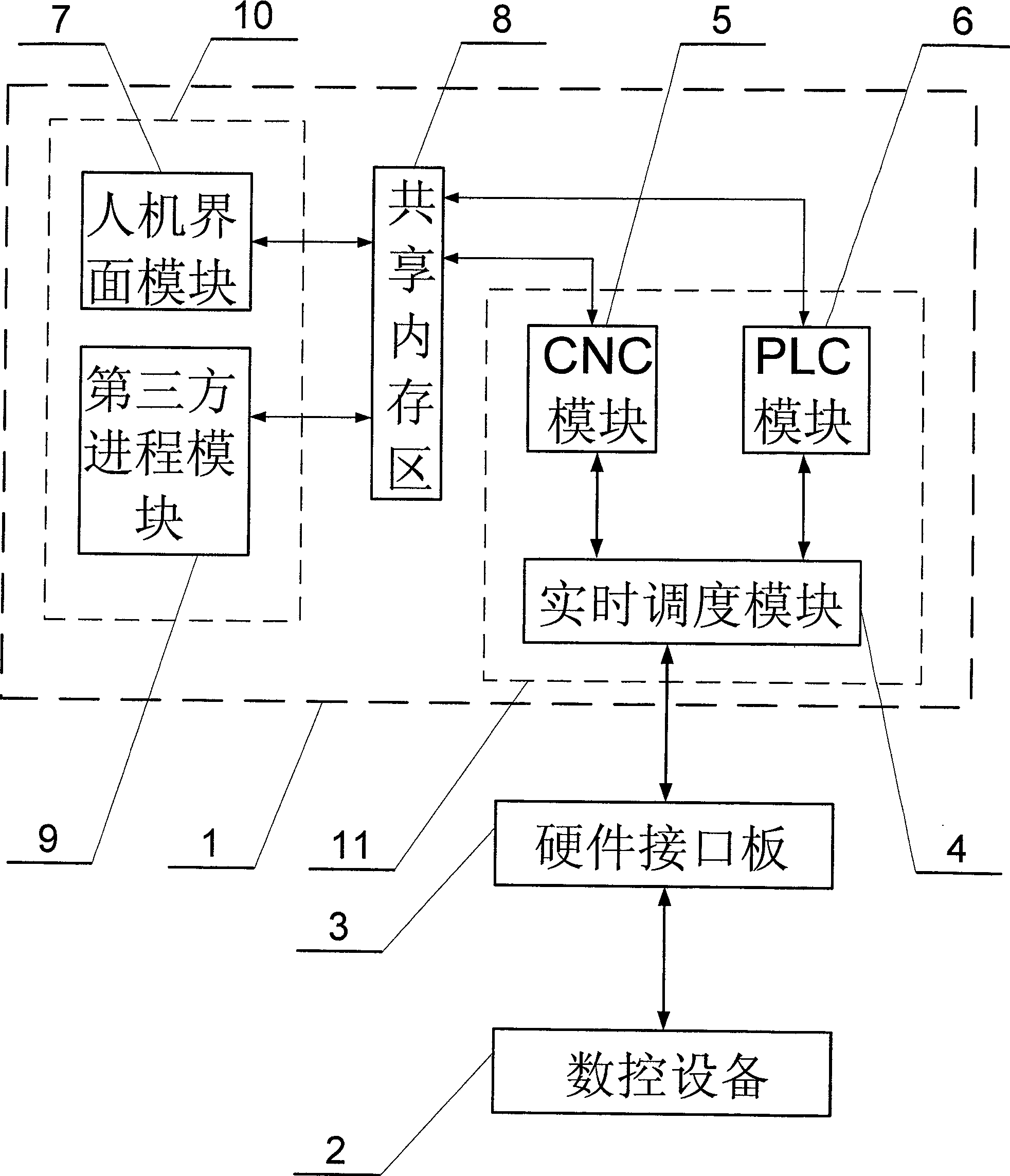

Open type numerical control system based on PC

An open numerical control system base on PC machine is provided, which relates to a numerical system base on Windows, and is used for solving the problems in the existing numerical system based on Windows, such as poor real-time performance and high development cost, as well as the problem in a numerical system based on WINCE of poor compatibility between hardware and software. A real-time scheduling module of the invention is used for establishing connections between PC machine and a hardware interface board and scheduling real-time tasks; a CNC module is used for establishing sharing memory area in the memory of PC machine and connecting with the real-time scheduling module, as well as realizing position controlling function through the real-time scheduling module schedules real-time tasks; a PLC module realizes a logical controlling function through the real-time scheduling module schedules real-time tasks; a man-machine interface module transfers input path procedure, set operation mode and data collocation of operating system to real-time task and displays execution result of real-time task to user; the real-time scheduling module, the CNC module and the PLC module are all embedded in the Windows operating system, the man-machine interface module is a universal Windows procedure.

Owner:HARBIN INST OF TECH

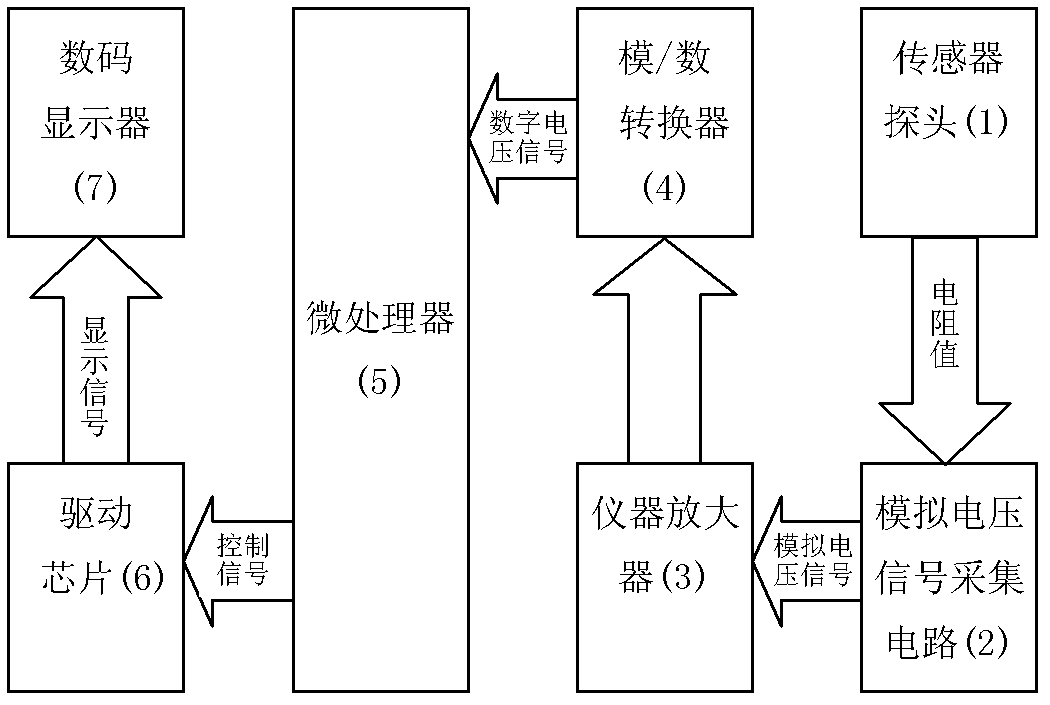

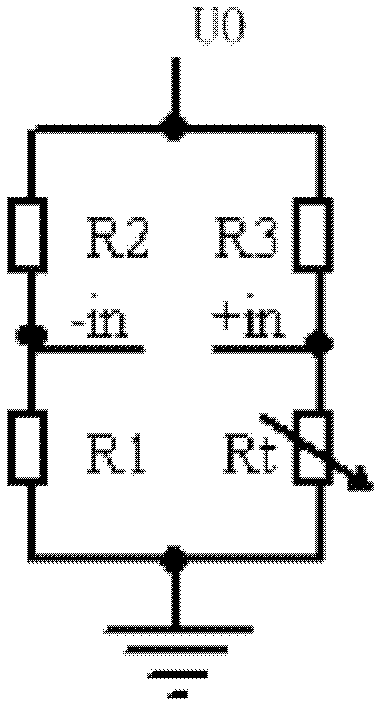

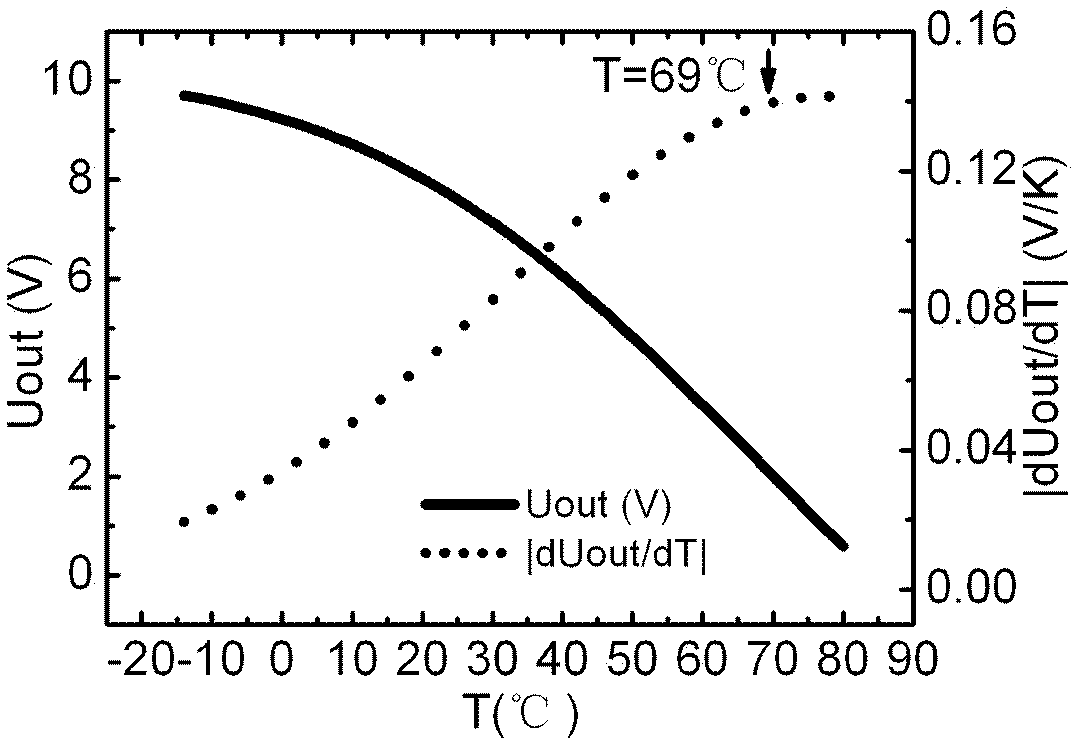

Digital display temperature detection system and digital display temperature detection method

ActiveCN102589743AEasy to chooseImprove utilization efficiencyThermometers using electric/magnetic elementsUsing electrical meansInstrumentation amplifierImage resolution

The invention relates to a high-resolution, wide-measurement range and low-cost digital display temperature detection system and a digital display temperature detection method. The digital display temperature detection system consists of a sensor probe, an analogue voltage signal acquisition circuit, an instrumentation amplifier, an analogue / digital converter, a processor, a drive chip and a digital display. The digital display temperature detection method comprises the following steps of: calling a signal acquisition module to perform voltage value sampling; calling an extreme value eliminating, filtering and averaging module to solve an average value; calling a table searching and temperature value converting module to convert the voltage value into a temperature value; calling a temperature value numerical system conversion module to convert a binary temperature value into a decimal temperature value; and calling a scanning drive module to perform dynamic scanning display. By the system and the method, the resolution of 0.1 DEG C and the measurement range of -15 to +80 DEG C are realized; and the problem that the conventional temperature gauge difficultly balances high resolution, wide measurement range and low cost is solved.

Owner:西安广芯电子科技有限公司

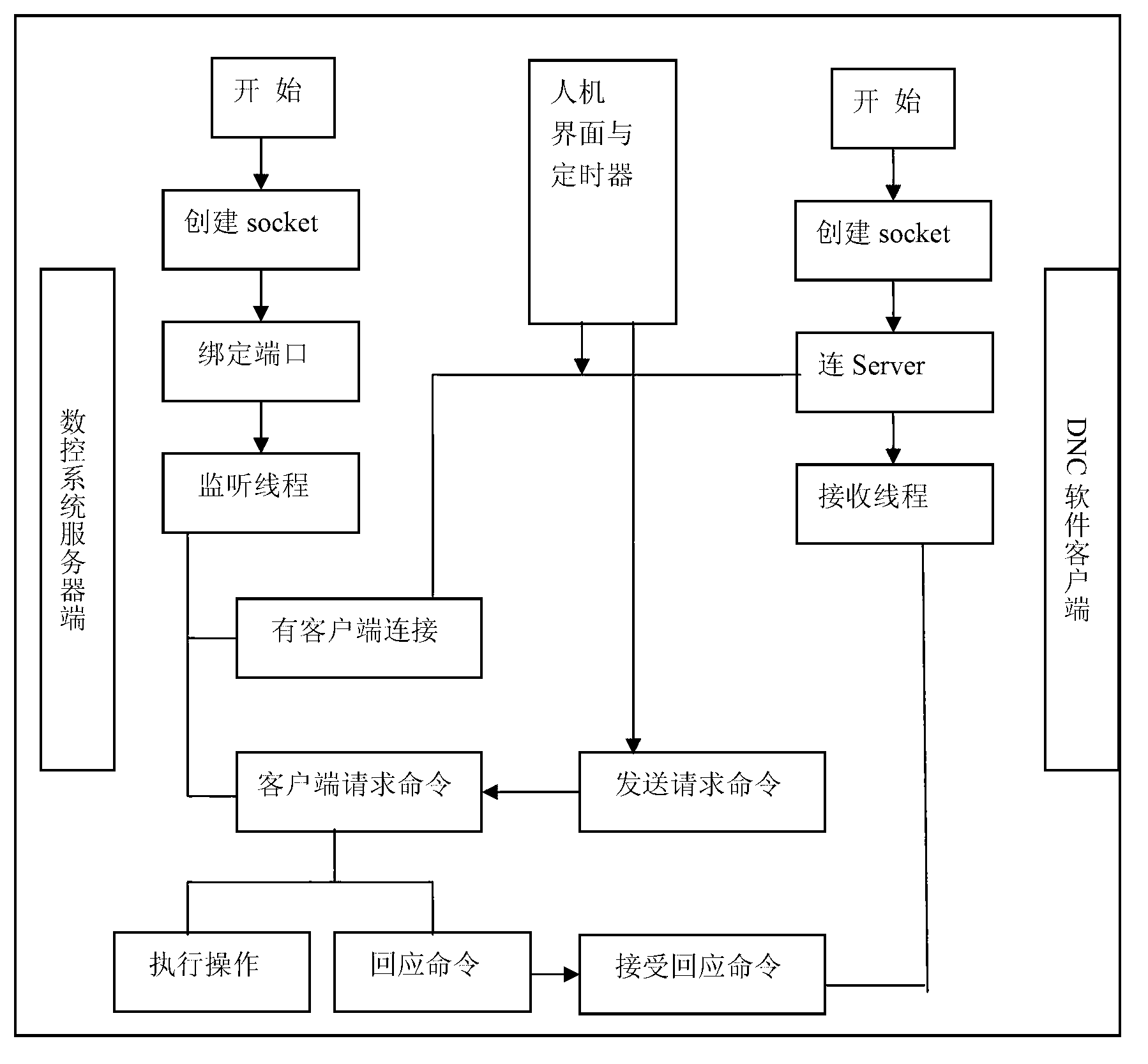

Numerical control system long-distance direct numerical control (DNC) control method based on transmission control protocol (TCP) / internet protocol (IP) and linux network program

ActiveCN103064391AImprove transmission distanceAchieve sharingTotal factory controlProgramme total factory controlCommunications mediaTimer

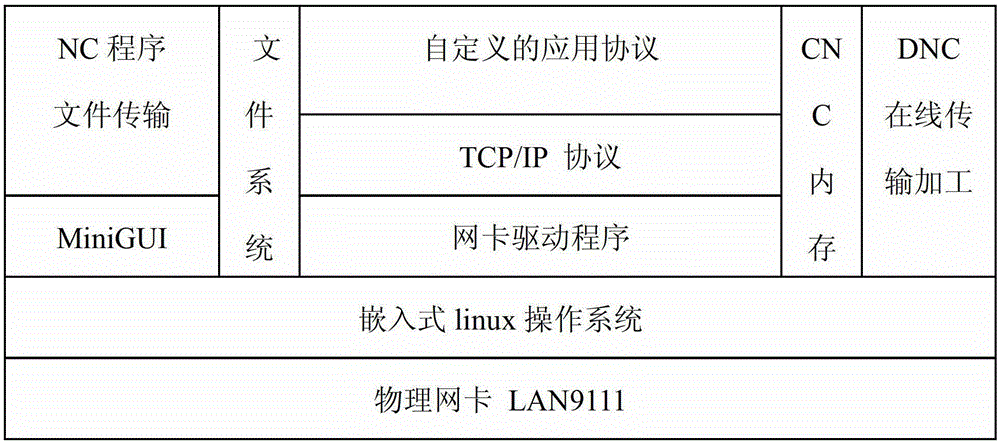

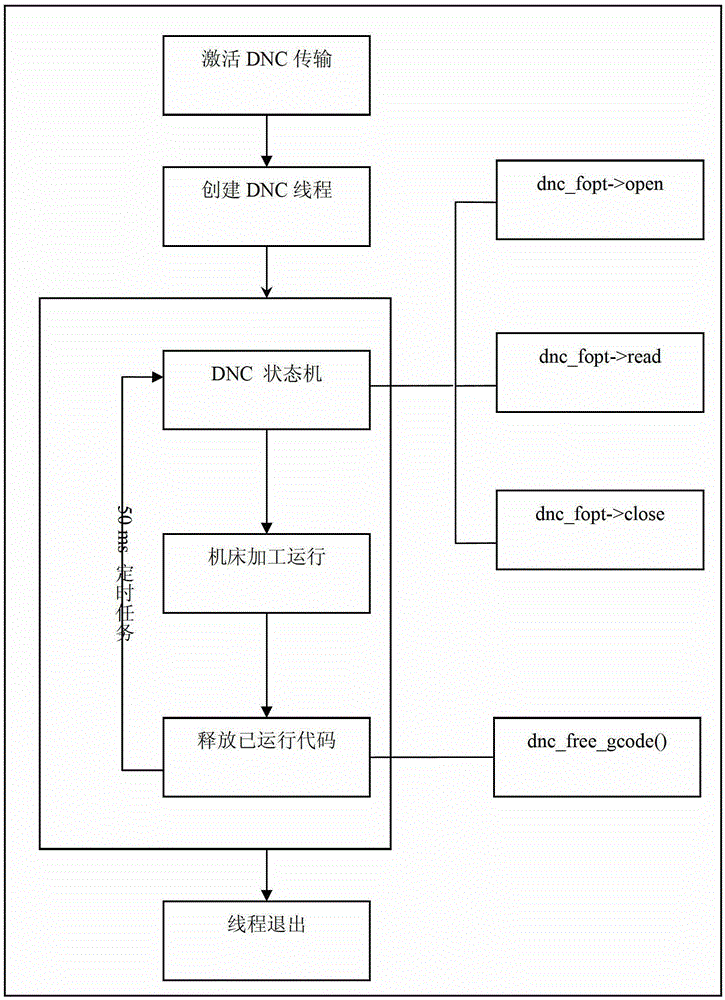

The invention discloses a numerical control system long-distance direct numerical control (DNC) method based on a transmission control protocol (TCP) / internet protocol (IP) and a linux network program. The method includes the following steps: (1) starting a numerical system, creating a network thread, and binding a port and an IP; (2) monitoring all the time to know whether a client side is connected after the port and the IP are bound; (3) starting a timer and sending user-defined heartbeat packets to the numerical control system after the client side and the numerical control system are connected; and (4) a user listing network computer (NC) files, uploading NC programs, downloading the NC programs, deleting the NC programs, carrying out DNC transmission fabrication and stopping transmission fabrication on a user interface after the client side and the numerical system are connected. According to the method, the numerical system is used as a server, a user computer serving as the client side constructs a network environment with the TCP / IP as a bottom layer protocol and a twisted pair line as a communication medium, the TPC / IP is used as a communication protocol for sending information, data transmission rates and anti-interference capacity are improved, connection with an internet is convenient, and data sharing is achieved.

Owner:GSK CNC EQUIP

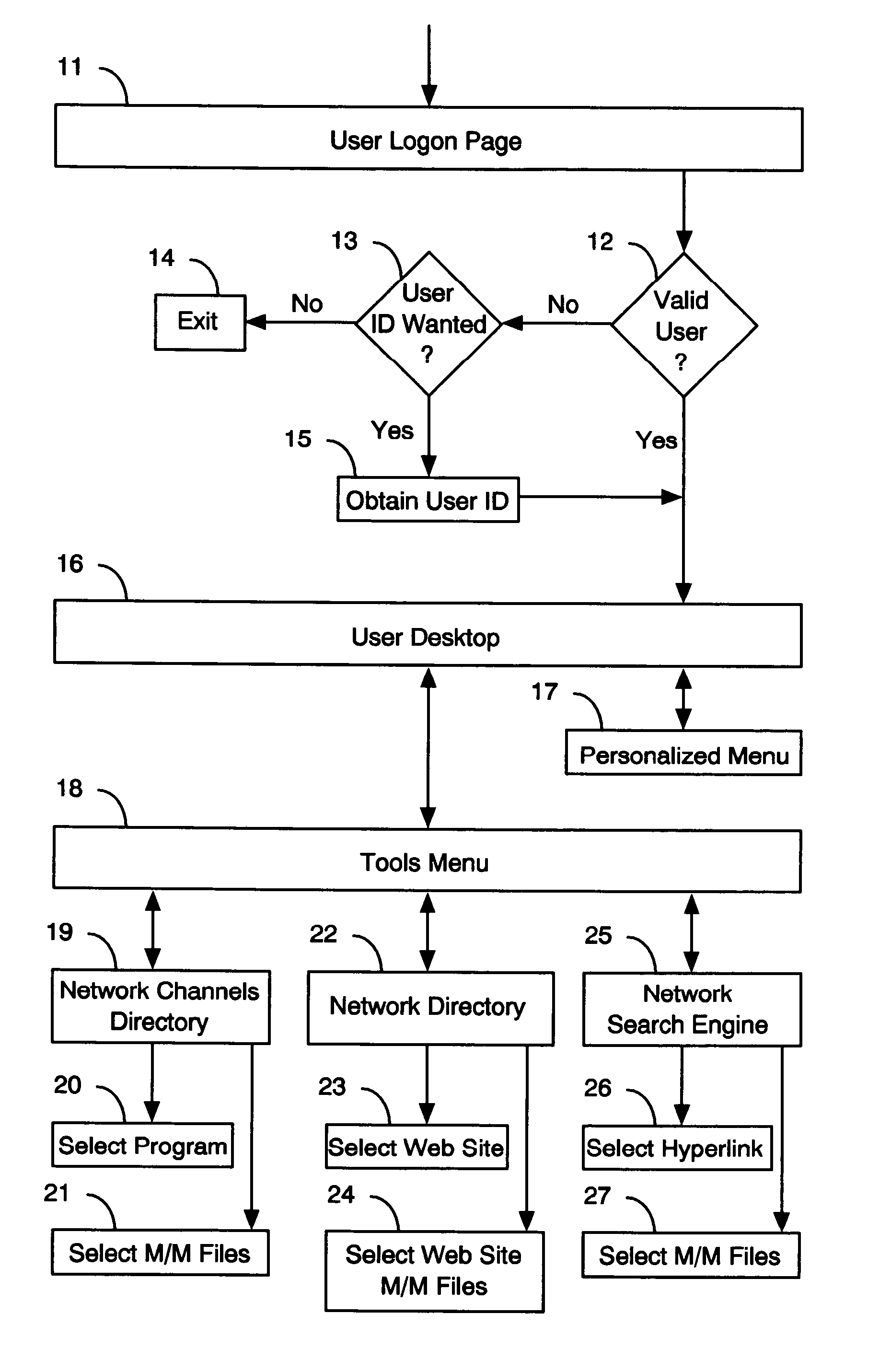

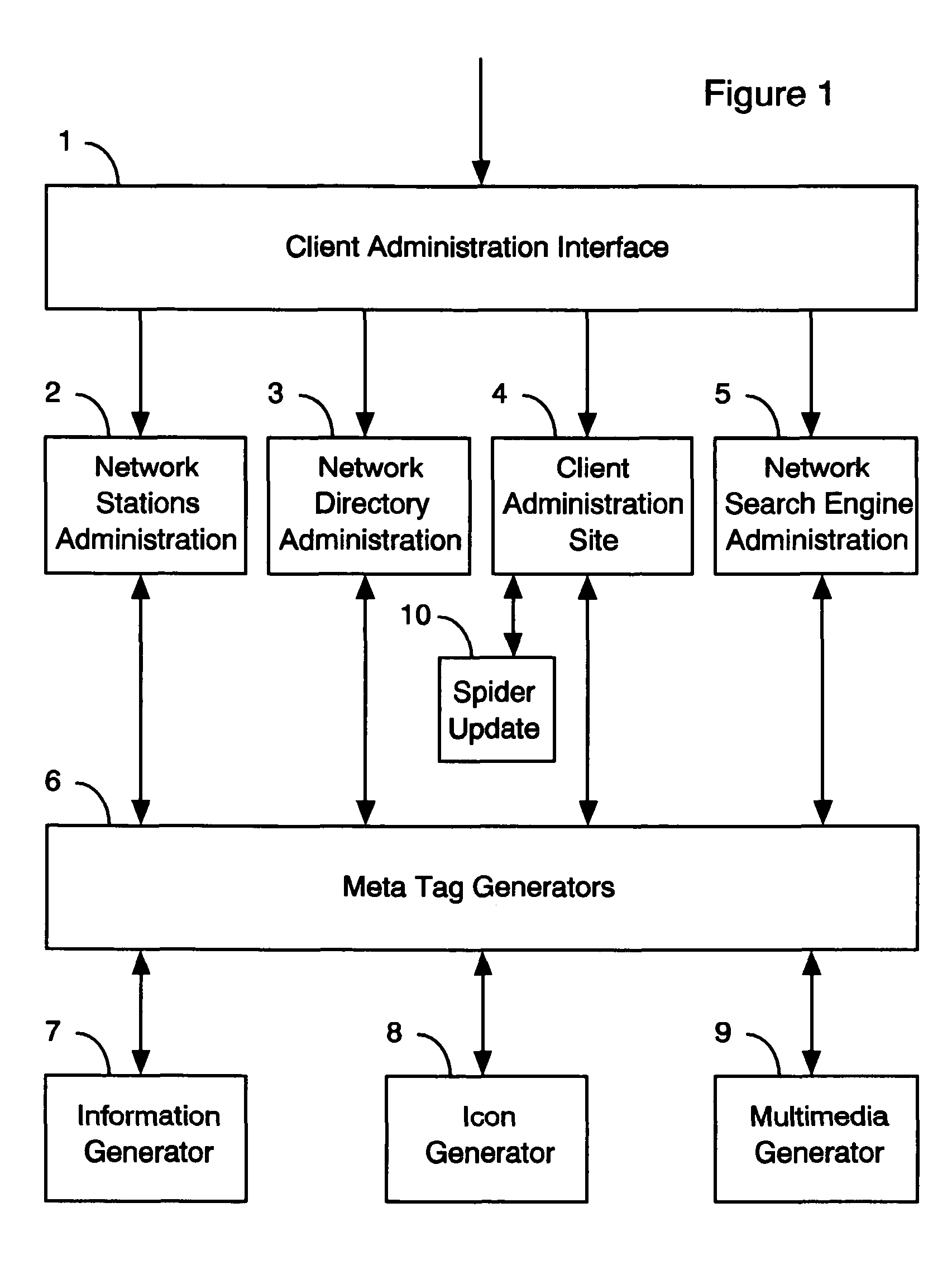

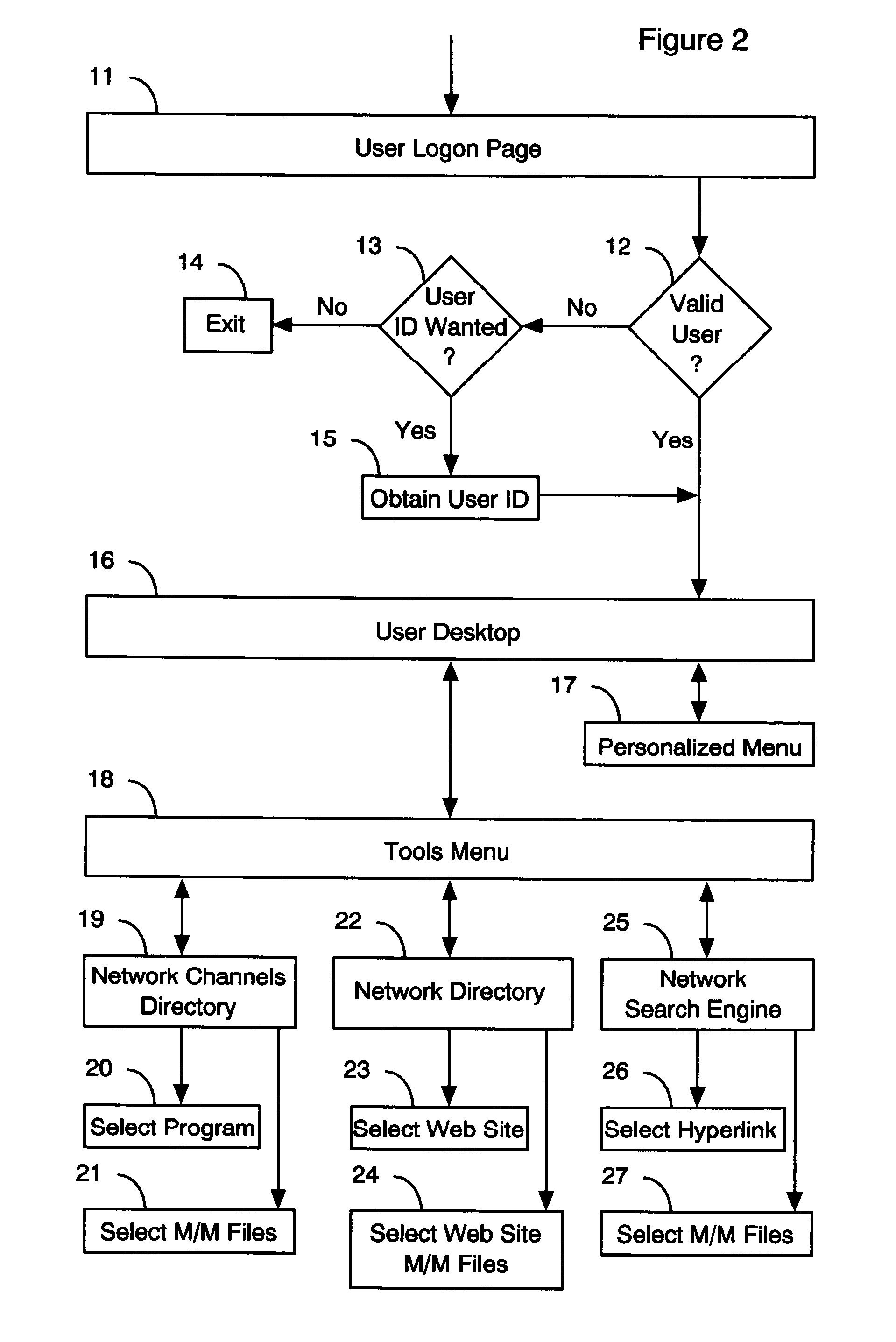

Broadcast network platform system

InactiveUS7865498B2The result is accurateWeb data indexingDigital data processing detailsWeb siteMultimedia search

A multimedia search system that provides search results which may be in the form of multiple data types, including text, icon, audio, video, and / or multimedia. The system also provides the ability to preview data video associated with a potentially linkable Web site listed in the search results screen, without linking directly to the Web site, by previewing a video file from that linkable Web site on the search results screen. The searcher then has the option of linking to that Web site based on information delivered by the previewed video file. The user also has the ability to search using the numerical system in which a numerical index is used to access data which is hierarchically categorized and sub categorized in a station / channel / program structured environment. The user can directly access stations, channels, or programs using predefined numerical index numbers.

Owner:FIERO ALEXIOUS MR +1

Computing formula for processing rocker shaft eccentric toothed sector of numerical control gear shaping machine and processing method

ActiveCN101412129AHigh precisionConvenient and flexible processingGear teethEngineeringCooling fluid

The invention discloses a computing formula for a numerical control gear sector gear slotting machine to process an eccentric gear sector of a rock arm shaft, and a method for processing the same. The computing formula comprises a computing formula of the hobbing radial radius rho of the eccentric gear sector of the rock arm shaft, a computing formula of the corresponding arc length of the revolution angle of the eccentric gear sector of the rock arm shaft and a computing formula for processing the contour curve of a reference circle of the eccentric gear sector of the rock arm shaft. The processing method comprises the following steps: 1) starting a program; 2) computing the initial position of the eccentric gear sector of the rock arm shaft; 3) starting auxiliary actions; 4) starting to cut the position; 5) inputting the cutting parameter into a numerical control register; 6) computing the displacement at three coordinate axes by a numerical control system; 7) cutting the contour line of the eccentric gear sector through the linkage of the three coordinate axes; 8) extending the Z axis to a retracting position; 9) extending the Y axis and the X axis to the retracting position; 10) stopping a cooling fluid and stopping a slotting cutter; and 11) ending the program. The computing formula and the method have the advantages that a parameterized programming can finish the computation and processing of the contour curve of the whole workpiece, and the parameter can be input into the numerical system in a short time to achieve the requirement of processing an eccentric distance gear sector.

Owner:通用技术集团天津第一机床有限公司

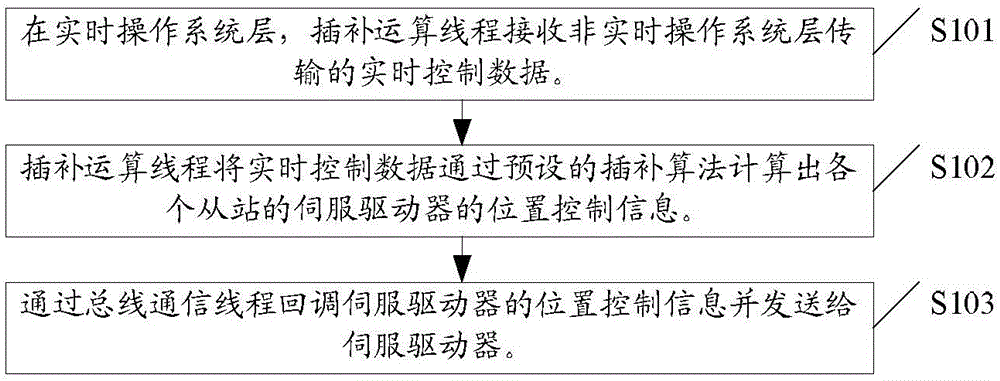

Numerical control system interpolation algorithm and numerical control system

ActiveCN106406227ASimple structureEasy wiringProgramme controlComputer controlNon real timeTime control

The invention discloses a numerical control system interpolation algorithm and a numerical control system. The algorithm comprises: in a real-time operation system layer, an interpolation operation thread receives real-time control data transmitted by a non-real-time operation system layer; the interpolation operation thread uses a preset interpolation algorithm to calculate position control information of a servo driver of each sub-station from the real-time control data; and a bus communication thread is used for calling back the position control information of the servo driver and sending the position control information to the servo driver. According to the technical scheme, the numerical system interpolation algorithm is performed on the basis of real-time Ethernet bus technology. The structure and wiring are simple; the algorithm is high in real-time degree and transmission efficiency, long in transmission distance, good in anti-interference capability and stability, and easy for expansion and maintenance.

Owner:CHINA ELECTRONICS HARVEST TECH CO LTD

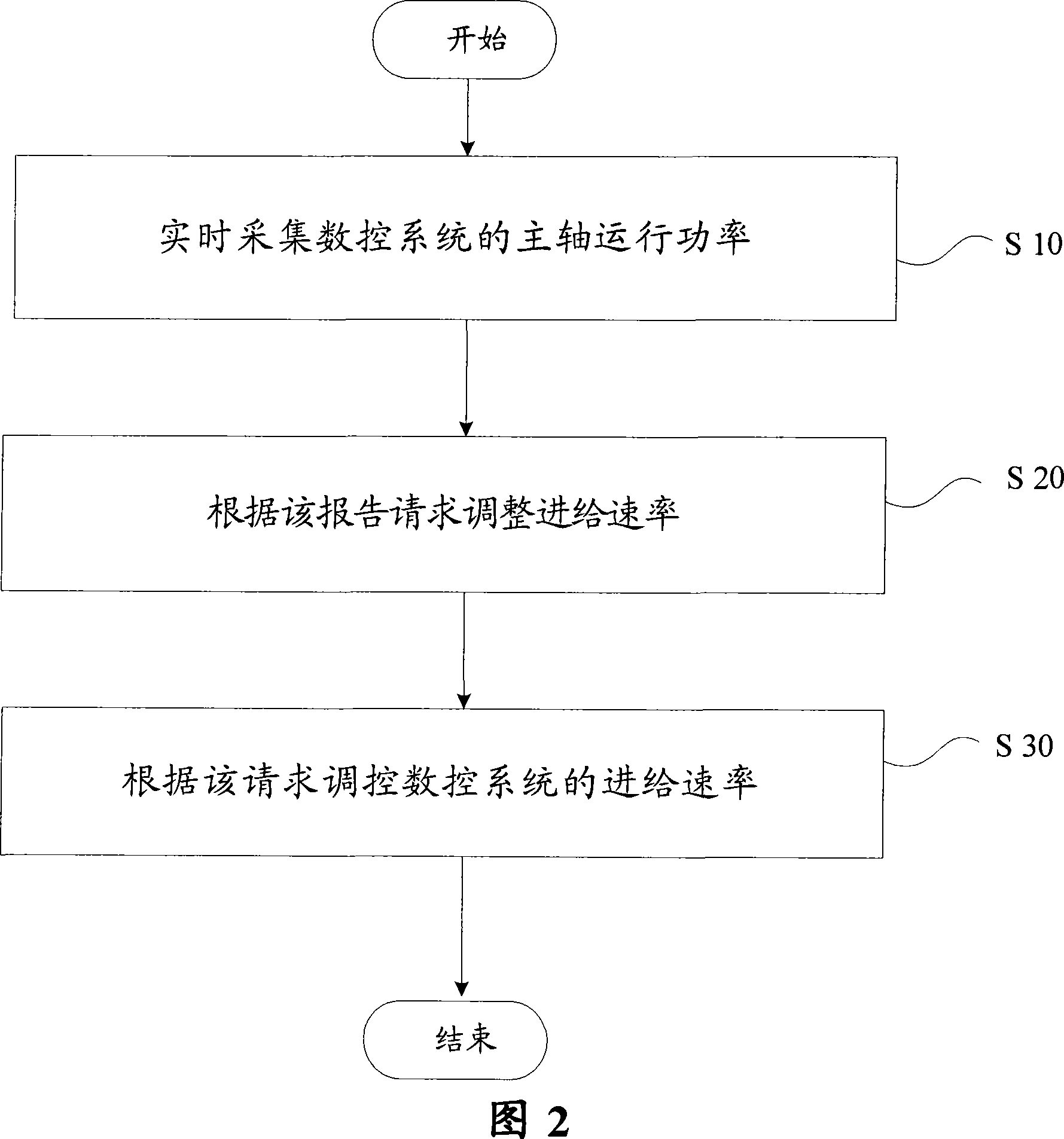

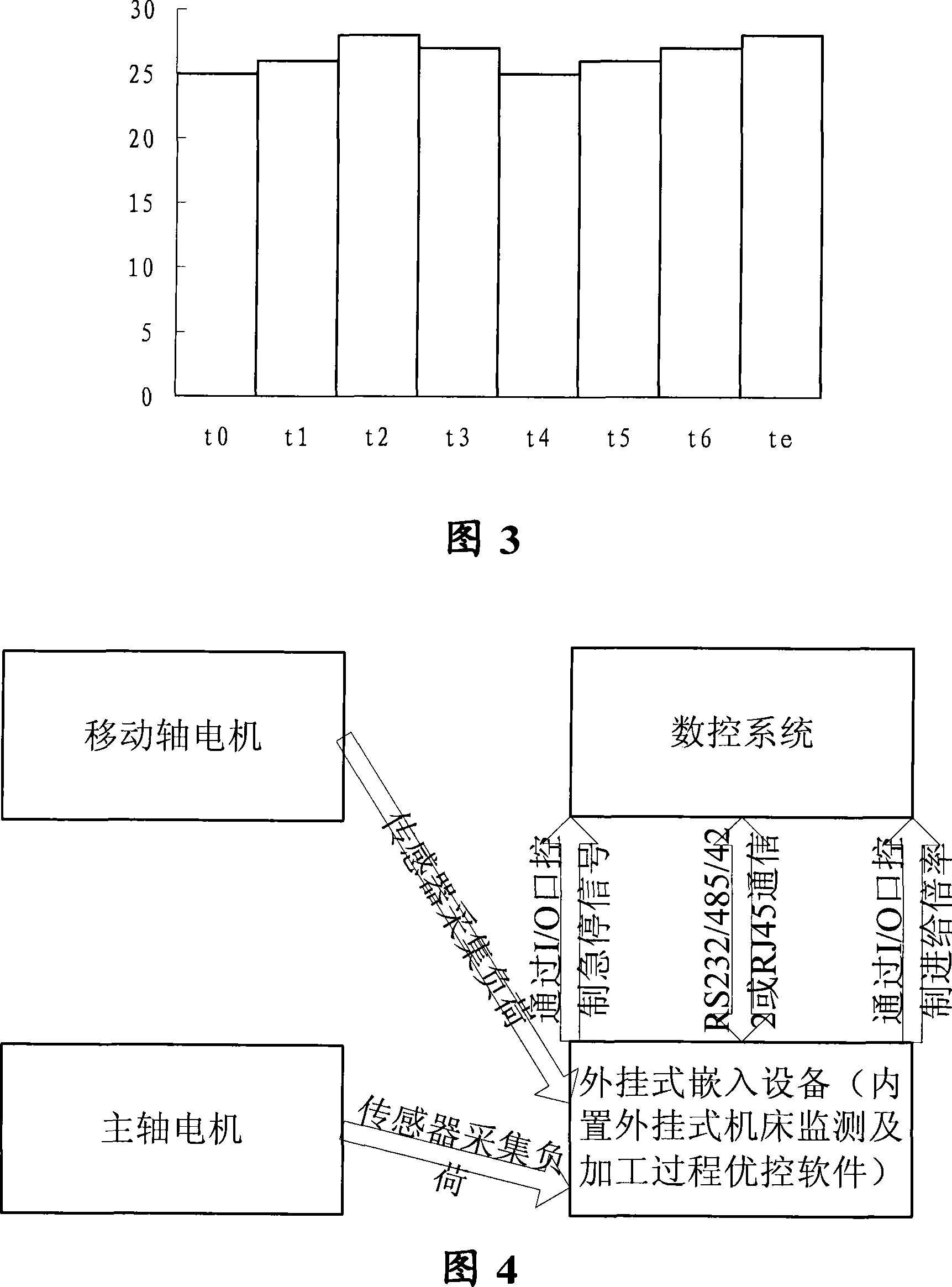

External hanging type optimization method and device for numerical control system

InactiveCN101201612AImprove processing efficiencyNumerical controlEngineeringNumerical control system

The invention provides an outside hanging pattern optimization method and a device used in a numerical control system. The steps of the method are as follows: the operation power of the spindle of the numerical system is gathered in real time; when the operation power of the spindle is lower than a preset load rate, a feed rate is requested to improve; when the operation power of the spindle is higher than the preset load rate, the feed rate is requested to reduce; the feed rate of the numerical system is adjusted and controlled according to the request. The invention improves the working efficiency of the numerical system and improves the safety of the work.

Owner:CAXA TECH

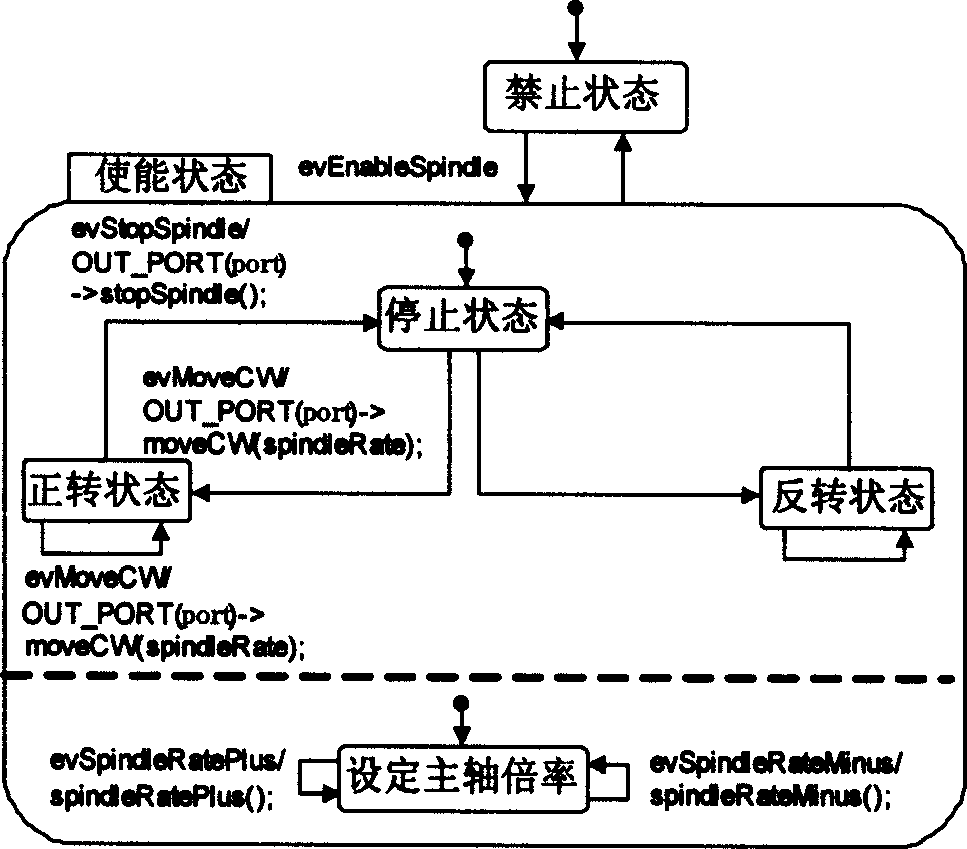

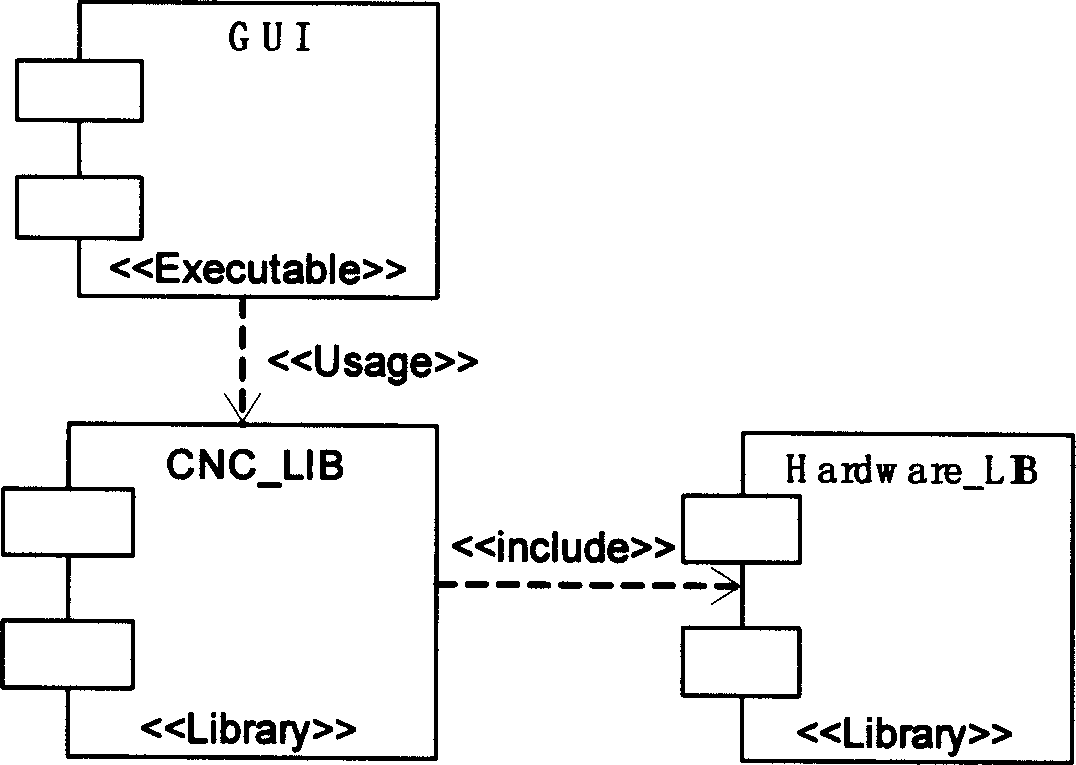

Opening structural computer digital control system able to re-configurate

InactiveCN1601416ARealize the control applicationGuaranteed robustnessComputer controlSimulator controlModel driven developmentHuman–machine interface

The invention is characterized by that making numerical system undergo the process of function module division, maknig model creation based on model drive development method, separating function of module from its behavious, utilizing change of state graph of correspondent module to despatch the the condition of its function execution so as to implement reuse of module function; using port to make communication between modules, said port can utilize its contract abstract interface to make interaction with man-machine interface and bottom layer hardware equipment so as to make related hardware application program meet the interface function requirement provided by system, and in the model layer increasing / reducing or replacing correspondent module so as to implement change of system functino. Said invention also provides the application of said numerical control system.

Owner:东莞市升力智能科技有限公司

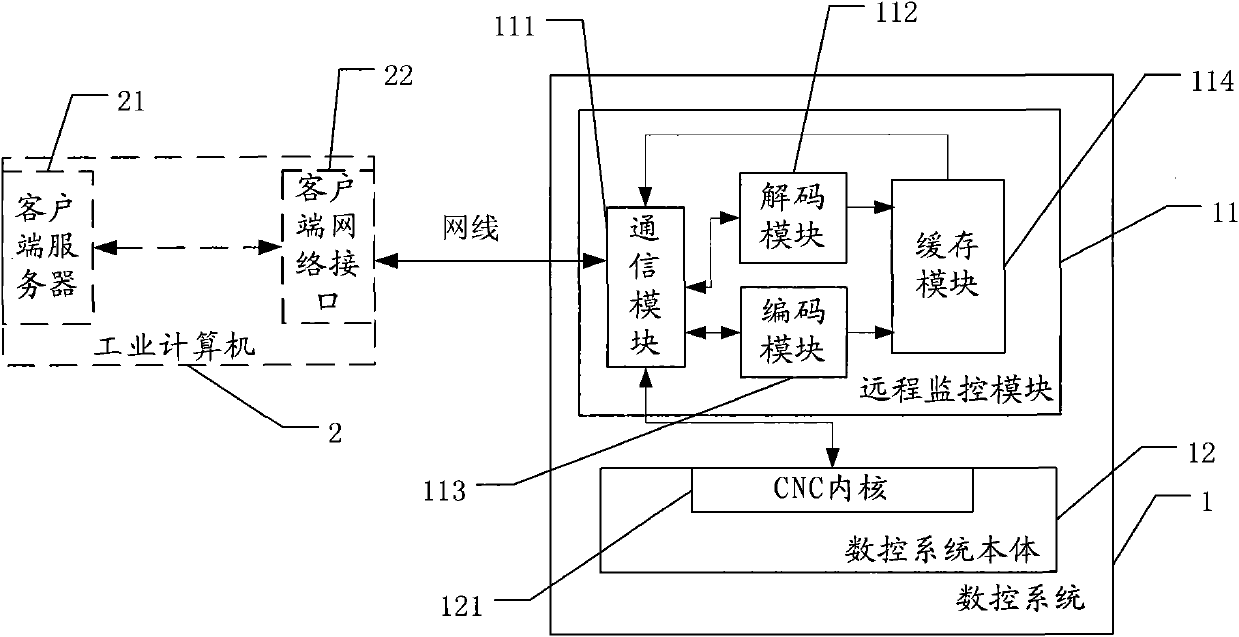

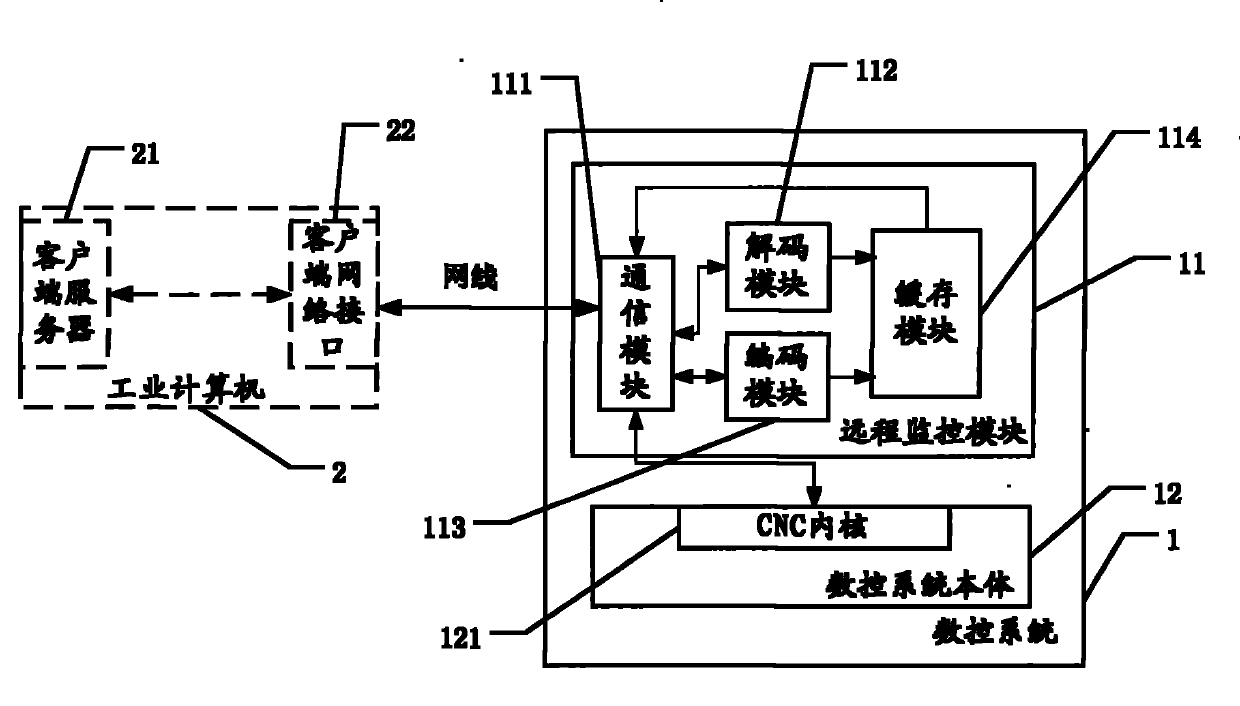

Numerical control system with remote monitoring function and control method thereof

ActiveCN102087515ARealize the communication functionKeep abreast of processabilityProgramme controlComputer controlMachine toolEmbedded system

The invention discloses a numerical control system with a remote monitoring function and a control method thereof. The system comprises a numerical control system body including a CNC (computer numerical control) kernel, and a remote monitor module connected with the CNC kernel, wherein the remote monitor module includes a communication module, as well as a decoding module and an encoding module respectively connected with the communication module. The method comprises: an industrial computer is started, and an external monitor instruction is transmitted to the numerical control system; the remote monitor module monitors an external request, decodes the external request and transmits the decoded external request to the CNC kernel; the CNC kernel executes corresponding commands after receiving the decoded instruction, and feeds back the information; and the remote monitor module monitors the feedback information of the CNC kernel, encodes the information, and transmits the encoded information to the industrial computer. The numerical control system can be communicated with the outside, and read / write various internal parameters of the numerical system in real time to achieve the remote monitoring of the numerical control machine tool, thereby improving the use safety and the efficiency of the numerical control machine tool.

Owner:SHANGHAI ELECTRICGROUP CORP

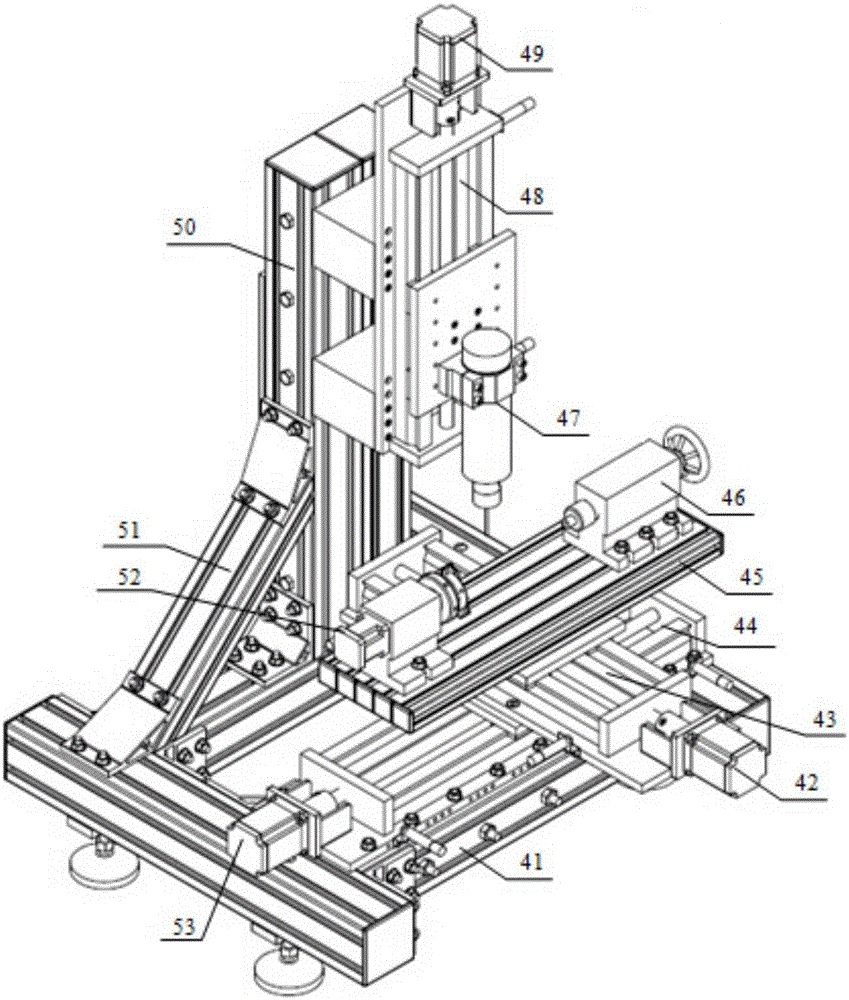

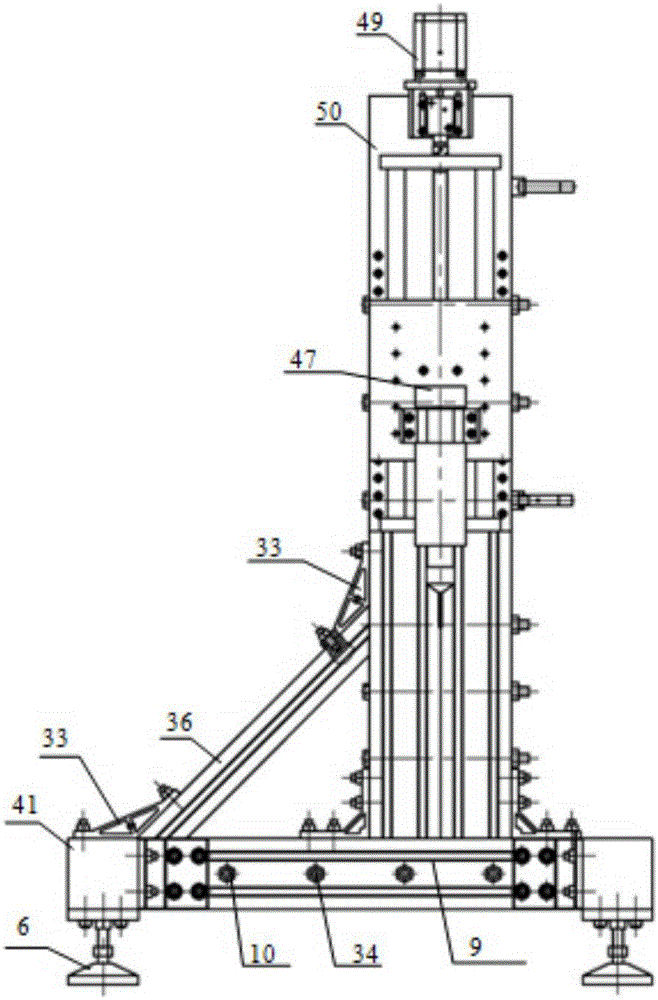

Assembly-type numerical control carving machine based on open-type numerical control system

InactiveCN105785923AMaster structureMastery featuresNumerical controlCommunication interfaceComputer module

The invention discloses a numerical control carving machine, and the carving machine comprises a machine tool body, a numerical control system and a servo system and employs an open-type numerical control system and an assembly-type structure. The open-type numerical control system comprises a universal PC module and a high-speed motion control card module. The universal PC module serves as an upper computer, and the high-speed motion control card module serves as a lower computer. The universal PC module and the high-speed motion control card module are connected through employing the USB technology to form a master-slave type numerical system. The universal PC module achieves the functions of application program, communication interface, coding and decoding, file management and man-machine interaction. The high-speed motion control card module achieves the functions of track interpolation, speed adjustment, pulse output and signal collection. The carving machine is low in cost, is convenient to assemble and disassemble, is suitable to be popularized in colleges, serves as a numerical control practical training teaching carrier of major of machinery, is suitable for a DIY amateur, especially for the training of the operating capability of a learner and the learning of the structure and characteristics of a numerical control machine tool. Meanwhile, the carving machine also can be used for the processing of wood, plastics, stone and aluminium alloy.

Owner:JINGGANGSHAN UNIVERSITY

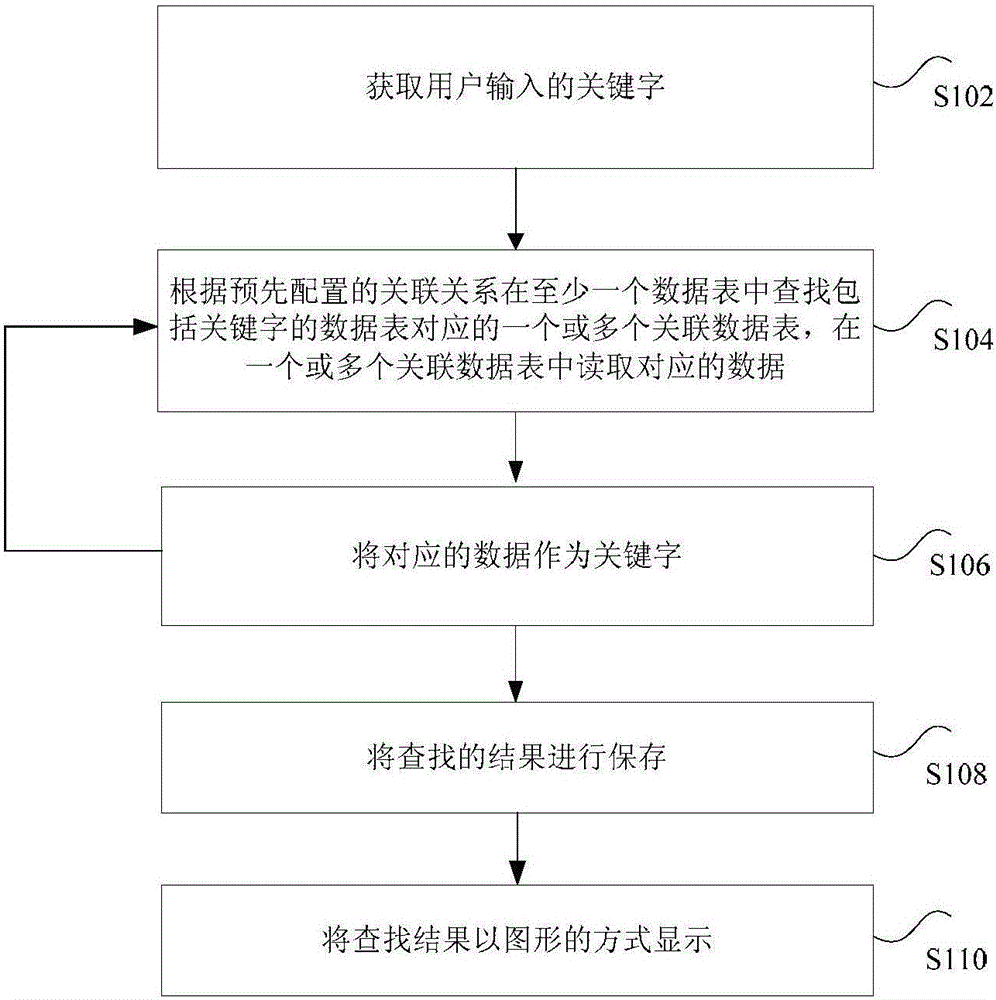

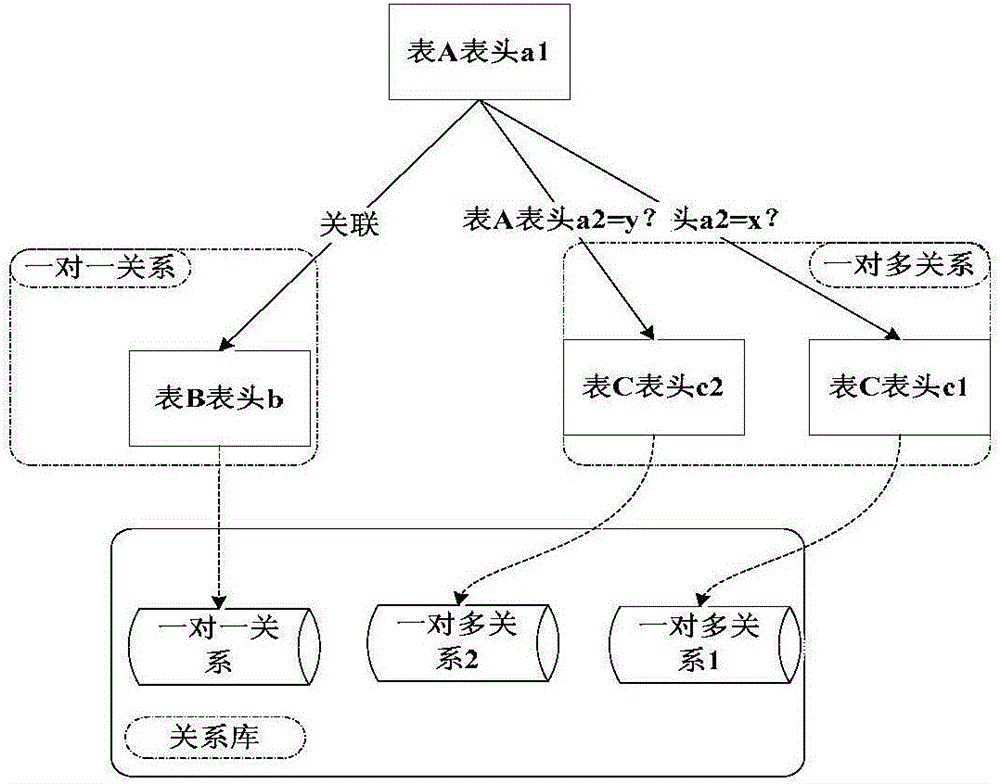

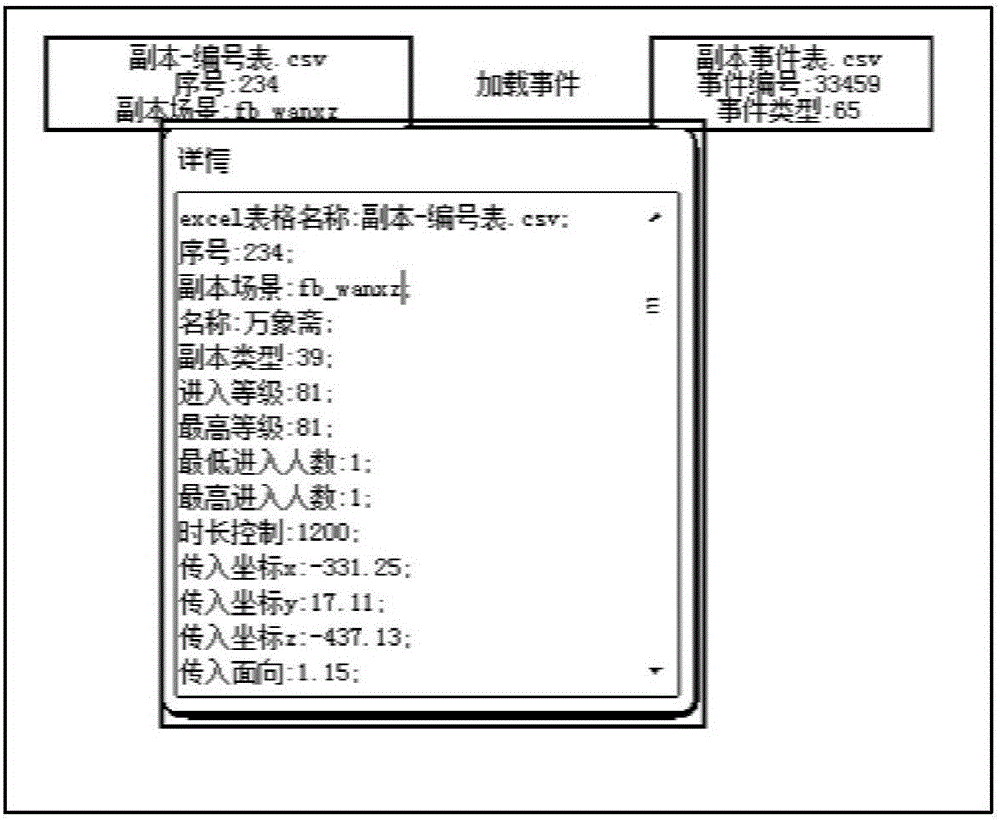

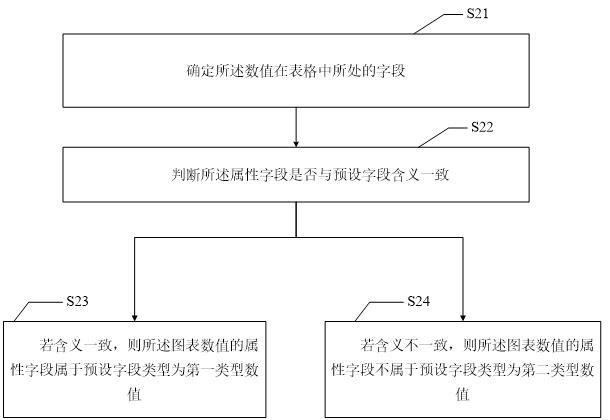

Table display processing method and device

ActiveCN106095961AFast and accurate generationImprove production efficiencySpecial data processing applicationsGraphicsUser input

The invention discloses a table display processing method and device. The method comprises the obtaining step, the search step, the cycle step, the preservation step and the display step; in the obtaining step, a keyword input by a user is obtained; in the search step, one or more associated data tables corresponding to a data table containing the keyword are found in at least one data table according to a pre-configured association relationship, and corresponding data is read in the one or more associated data tables; in the cycle step, the corresponding data serves as the keyword for repeating the search step; in the preservation step, search results are preserved in the search step and the cycle step or after the search step and the cycle step; in the display step, the search results are displayed in a graphic mode. The table display processing method and device solve the technical problems that in the prior art, a generated game numerical value system is low in efficiency, and display of the search results is not visual.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

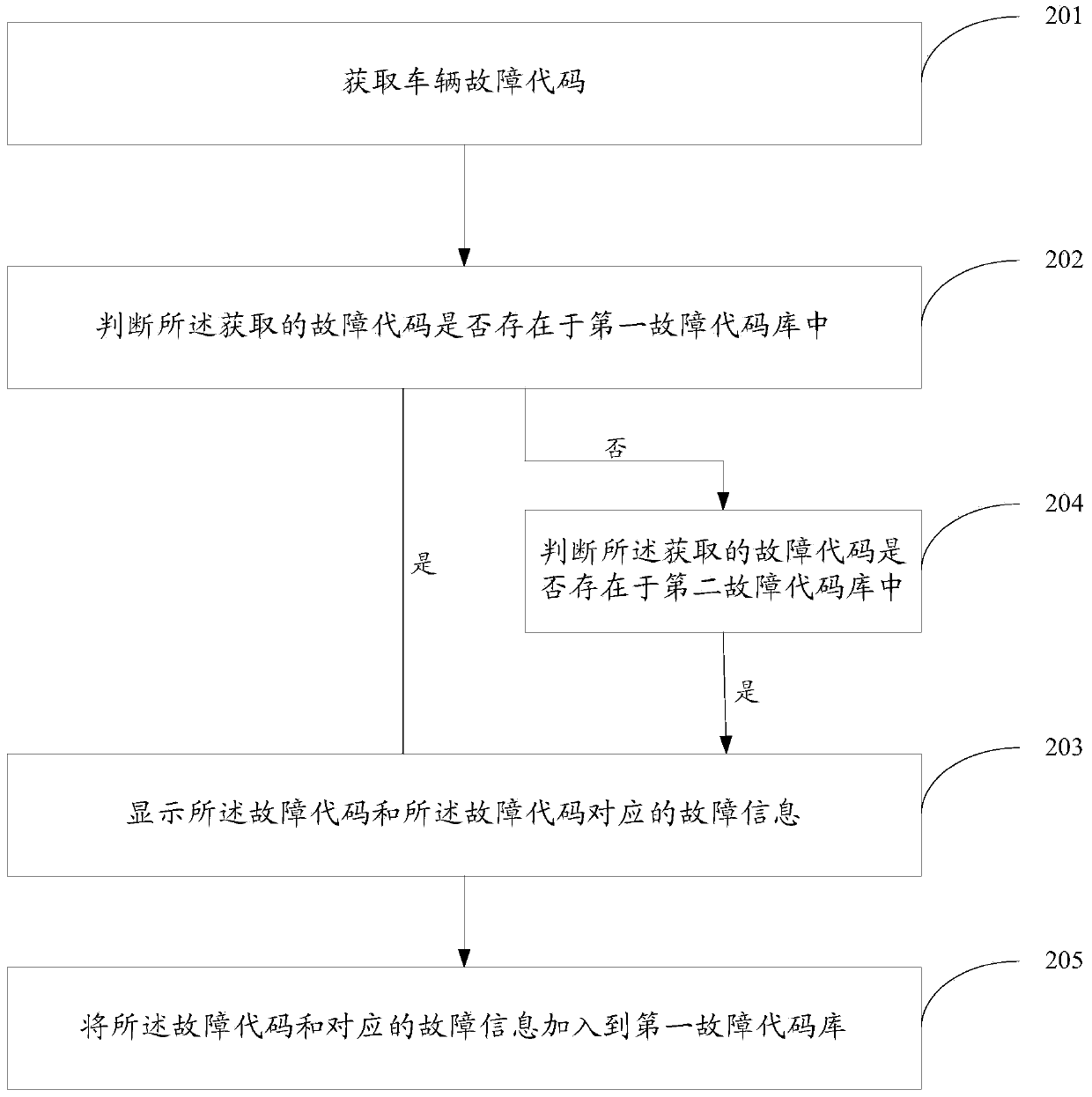

Vehicle fault code displaying method and device

InactiveCN104008183AReduce failure efficiencyImprove processing efficiencySpecial data processing applicationsSpecific program execution arrangementsComputer scienceFault handling

The embodiment of the invention discloses a vehicle fault code displaying method. The method comprises the steps of acquiring a vehicle fault code; judging whether the acquired fault code exists in a first fault code library, and displaying the fault code and the fault information corresponding to the fault code if yes, wherein the numerical system of fault codes in the first fault code library is consistent with the numerical system of the acquired fault code, and the fault codes and fault information in the first fault code library are mapped in the programming language. Correspondingly, the embodiment of the invention discloses a vehicle fault code displaying device. According to the vehicle fault code displaying method and device, the purposes of improving vehicle fault handling efficiency and reducing potential safety hazards are realized.

Owner:XUZHOU HEAVY MASCH CO LTD

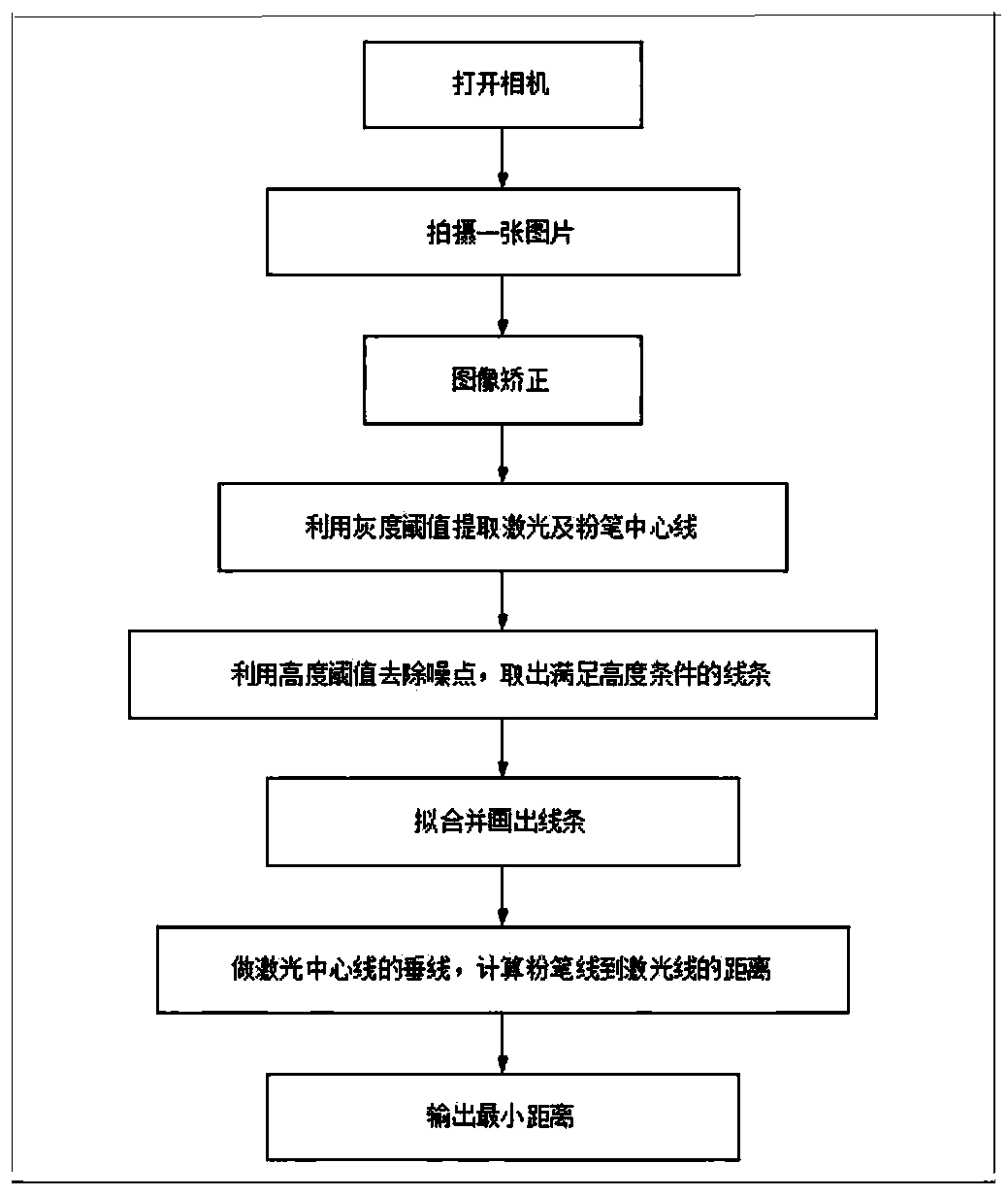

Bidirectional feeding multi-knife bending automatic alignment process method for numerical control bending machine

InactiveCN110773656ARealize the automation of bending and formingEliminate the detection processMetal-working feeding devicesMetal working apparatusDisplay deviceImage detection

The invention discloses a bidirectional feeding multi-knife bending automatic alignment process method for a numerical control bending machine. According to the bidirectional feeding multi-knife bending automatic alignment process method for the numerical control bending machine, a multi-axis composite feeding device, a bending machine workbench and a numerical control system are provided. The process method comprises the following steps: S1, mounting one area-array camera at each of the left end and the right end of the bending machine workbench; S2, controlling by a numerical control systemto trigger the area-array camera to take photos, acquiring an image of a to-be-detected workpiece in real time, uploading and feeding back the image information to the numerical system, processing byimage detection software, displaying curve fitting result on a display and replacing artificial sample plate measuring; and S3, when a back half arc is bended, detecting the error of a bending line and machine tool line laser cluster on the workpiece in real time, controlling operation of the multi-axis composite feeding device and completing automatic positioning of the back half arc bending. Theartificial sample plate detection process is omitted, automatic positioning of the whole feeding process is realized, automatic acquisition of bending forming shape is completed and the industrial automation degree is high.

Owner:HUALI BRANCH CORP HUBEI SANHUAN METALFORMING EQUIP

Programming method of numerical control system

InactiveCN108334035AImprove coding efficiencyImprove compatibilityProgramme controlComputer controlEmbedded systemData buffer

The invention discloses a programming method of a numerical control system. The programming method comprises the following steps: micropython codes are written in the user state; the micropython codeswritten in the user state are packed in the non-compression mode by using the zip format; the micropython codes are transmitted to a data buffer area in the kernel mode through an I / O interface; theCPU of the numerical control system receives a timing interrupt signal and then calls the micropython codes stored in the data buffer area. According to the programming method of the numerical controlsystem, the programming of the numerical control system can be simplified, and the operation efficiency of the numerical control system is improved.

Owner:SUZHOU GFD AUTOMATION TECH

Digital display temperature detection system and digital display temperature detection method

ActiveCN102589743BEasy to chooseImprove utilization efficiencyThermometers using electric/magnetic elementsUsing electrical meansInstrumentation amplifierImage resolution

The invention relates to a high-resolution, wide-measurement range and low-cost digital display temperature detection system and a digital display temperature detection method. The digital display temperature detection system consists of a sensor probe, an analogue voltage signal acquisition circuit, an instrumentation amplifier, an analogue / digital converter, a processor, a drive chip and a digital display. The digital display temperature detection method comprises the following steps of: calling a signal acquisition module to perform voltage value sampling; calling an extreme value eliminating, filtering and averaging module to solve an average value; calling a table searching and temperature value converting module to convert the voltage value into a temperature value; calling a temperature value numerical system conversion module to convert a binary temperature value into a decimal temperature value; and calling a scanning drive module to perform dynamic scanning display. By the system and the method, the resolution of 0.1 DEG C and the measurement range of -15 to +80 DEG C are realized; and the problem that the conventional temperature gauge difficultly balances high resolution, wide measurement range and low cost is solved.

Owner:西安广芯电子科技有限公司

Open type numerical control system based on PC

InactiveCN100514234CQuick responseImprove compatibilityNumerical controlOperational systemHuman–machine interface

An open numerical control system base on PC machine is provided, which relates to a numerical system base on Windows, and is used for solving the problems in the existing numerical system based on Windows, such as poor real-time performance and high development cost, as well as the problem in a numerical system based on WINCE of poor compatibility between hardware and software. A real-time scheduling module of the invention is used for establishing connections between PC machine and a hardware interface board and scheduling real-time tasks; a CNC module is used for establishing sharing memory area in the memory of PC machine and connecting with the real-time scheduling module, as well as realizing position controlling function through the real-time scheduling module schedules real-time tasks; a PLC module realizes a logical controlling function through the real-time scheduling module schedules real-time tasks; a man-machine interface module transfers input path procedure, set operation mode and data collocation of operating system to real-time task and displays execution result of real-time task to user; the real-time scheduling module, the CNC module and the PLC module are all embedded in the Windows operating system, the man-machine interface module is a universal Windows procedure.

Owner:HARBIN INST OF TECH

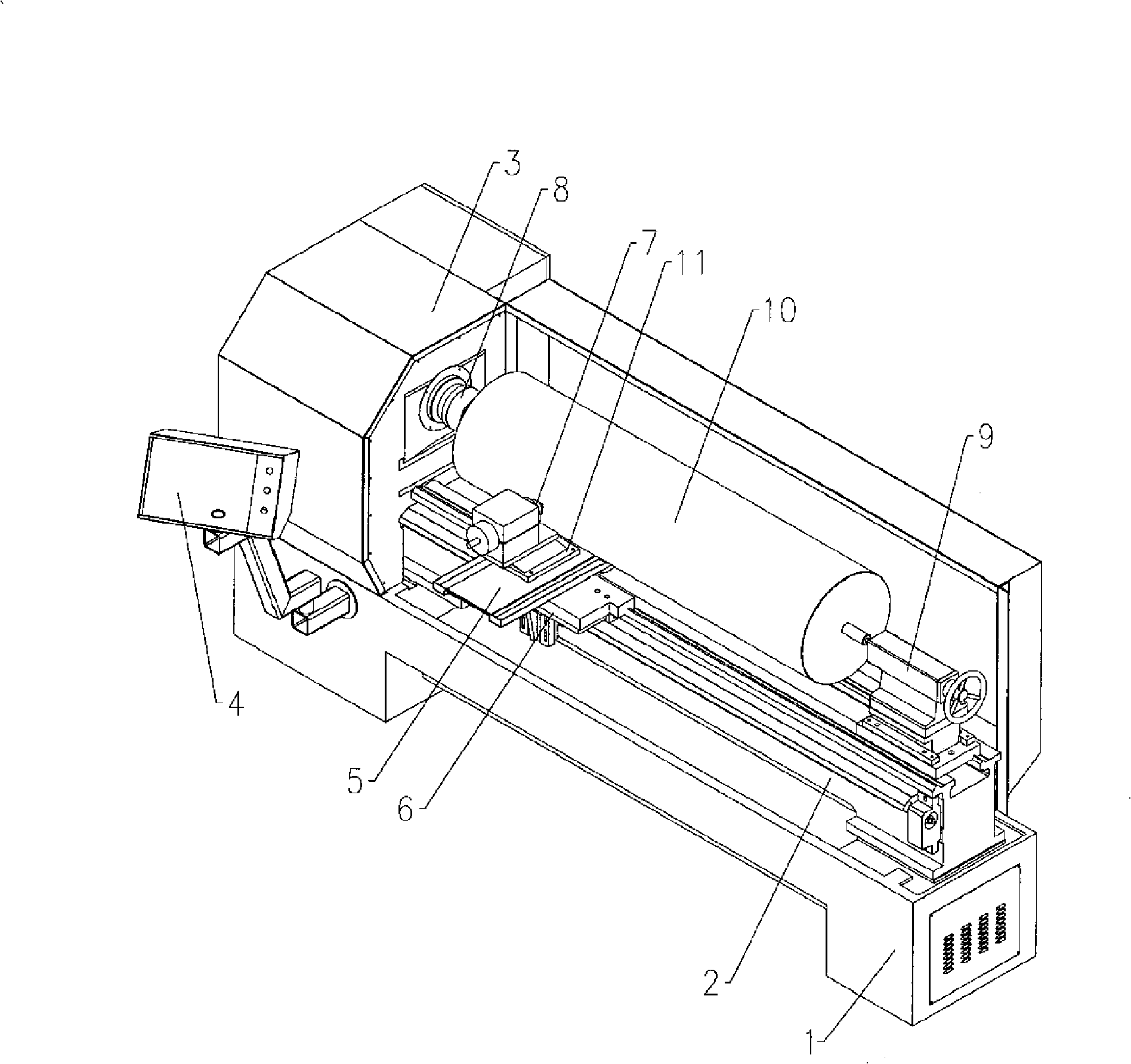

Numerical control horizontal machine tool

InactiveCN101537508AHigh indexing accuracyLow powerMilling equipment detailsDriving apparatusEngineeringMoment of inertia

The invention relates to a numerical control horizontal machine tool which is horizontally arranged. A base is provided with a machine tool body. One side of the machine tool body is provided with a headstock. A numerical system controls the work of a servo system which is provided with a high-speed drilling head. A spinner needle roll is positioned between a driving spindle and a tailstock. The driving spindle is provided with a numerical control dividing head for continuous division and random position locking. The great speed ratio 1:90 of the numerical control dividing head steplessly decelerates the driving spindle. As the great speed ratio 1:90 of the numerical control dividing head is used for steplessly decelerating the driving spindle, the numerical control horizontal machine tool realizes the continuous division and the random position locking, solves the key technical problem that reliable braking and positioning cannot be realized due to large and long processed workpieces and great moment of inertia, improves the workpiece division accuracy, reduces the power of a main motor and realizes low power consumption. The machine tool can meet the requirement on maximum processing diameter of 600 mm and maximum processing length of 2000 mm, and the mechanical structure of a main transmission system of the numerical control machine tool is simplified.

Owner:应高峰

Method and device for testing numerical system

ActiveCN110109842AAchieve common managementImprove synchronicitySoftware testing/debuggingManufacturing computing systemsTest efficiencyComputer science

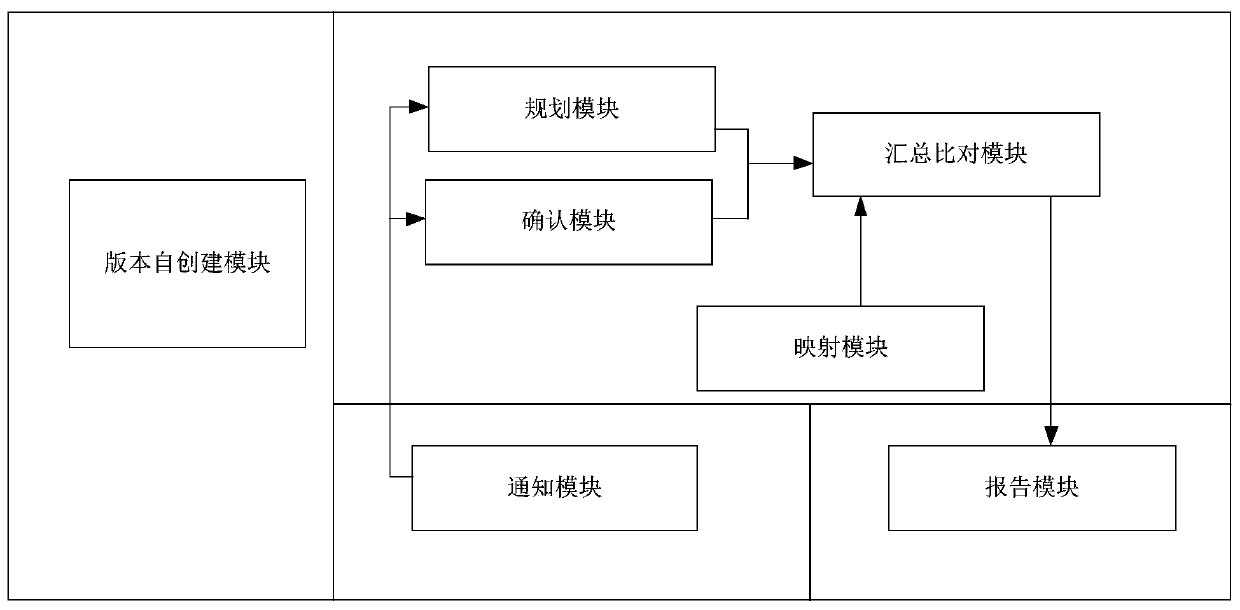

The embodiment of the invention provides a method and device for testing a numerical system. The method comprises the steps of according to a preset creation cycle, creating a test version of the numerical system automatically, wherein the test version comprises a planning template and a confirmation template, the planning template is used for inputting the planning information of the numerical system, and the confirmation template is used for inputting the actual information generated in the numerical system according to the planning information. After the first information filled by a firstobject according to the planning template and the second information filled by a second object according to the confirmation template are obtained, the test result of the numerical system can be determined according to the first information and the second information, and during the process, the planning template does not need to be distributed manually, and the test result does not need to be checked manually, so that the test omission can be reduced, and the test synchronism, stability and test efficiency are improved.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

Division operation method and device

ActiveCN102063284BFast operationCompute cycle optimizationComputation using non-contact making devicesDevice materialControl engineering

The invention relates to a nonlinear combined number division operation method applied to a semiconductor device by utilizing numerical system expression and a division device for realizing the operation method, in particular to a division operation method and an operation device adopting the same. The division operation method achieves the purposes of reducing the operation period of the whole division operation method and optimizing the whole division operation method in a 'shifting and subtraction' method by simultaneously executing shifting and subtraction in one period. The invention also provides the division device adopting the division operation method. By adopting the technical scheme, the invention provides a division operation method with high operation speed and high operationefficiency and optimized calculating period and a division operation device adopting the division operation method.

Owner:HISENSE VISUAL TECH CO LTD

Remote dnc control method of numerical control system based on tcp/ip protocol and linux network programming

ActiveCN103064391BImprove transmission distanceAchieve sharingTotal factory controlProgramme total factory controlEngineeringCommunications media

The invention discloses a numerical control system long-distance direct numerical control (DNC) method based on a transmission control protocol (TCP) / internet protocol (IP) and a linux network program. The method includes the following steps: (1) starting a numerical system, creating a network thread, and binding a port and an IP; (2) monitoring all the time to know whether a client side is connected after the port and the IP are bound; (3) starting a timer and sending user-defined heartbeat packets to the numerical control system after the client side and the numerical control system are connected; and (4) a user listing network computer (NC) files, uploading NC programs, downloading the NC programs, deleting the NC programs, carrying out DNC transmission fabrication and stopping transmission fabrication on a user interface after the client side and the numerical system are connected. According to the method, the numerical system is used as a server, a user computer serving as the client side constructs a network environment with the TCP / IP as a bottom layer protocol and a twisted pair line as a communication medium, the TPC / IP is used as a communication protocol for sending information, data transmission rates and anti-interference capacity are improved, connection with an internet is convenient, and data sharing is achieved.

Owner:GSK CNC EQUIP

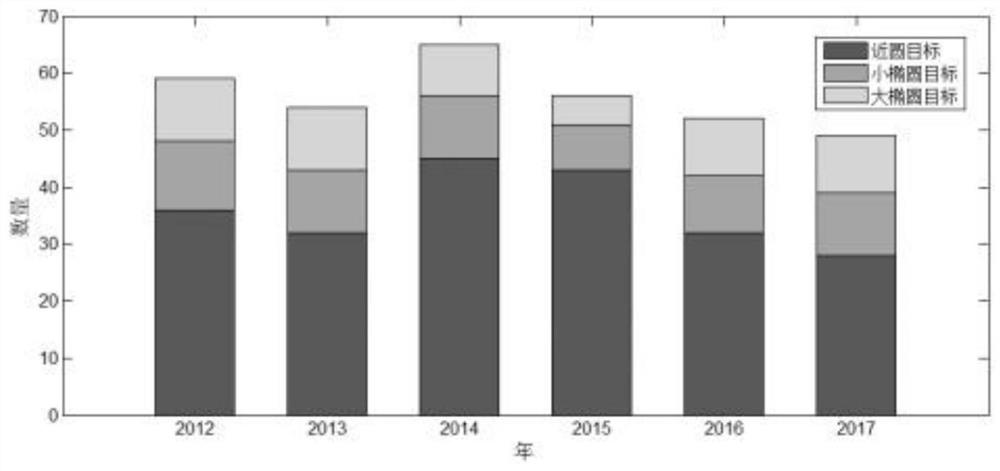

A Reentry Prediction Method for Small Ellipse Targets in Sparse Data

ActiveCN109992927BDesign optimisation/simulationSelf-propelled projectilesNumerical methodologyKepler

The invention discloses a re-entry prediction method for a small elliptical target under the condition of sparse data, which processes N-circle data collected in the past 5 days, uses a numerical method to determine the orbit of the single-circle data respectively, and uses the Kepler square root as the root. Compared with the prior art, the present invention proposes a numerical system based on the characteristics of sparse data and small elliptical orbits, and uses the semi-numerical method for orbit integration, and uses the least squares method to fit the ballistic coefficient of the re-entry target. A reentry forecasting method combining the method with the semi-numerical method. It effectively solves the problems that the residual error of joint orbit determination of multi-turn data is too large or does not converge in the case of sparse data, and it is difficult to determine the ballistic coefficient of orbit determination of single-turn data.

Owner:中国人民解放军32035部队

Opening structural computer digital control system able to re-configurate

InactiveCN100370381CMeet different processing requirementsRealize the control applicationComputer controlSimulator controlModel driven developmentHuman–machine interface

The invention is characterized by that making numerical system undergo the process of function module division, maknig model creation based on model drive development method, separating function of module from its behavious, utilizing change of state graph of correspondent module to despatch the the condition of its function execution so as to implement reuse of module function; using port to make communication between modules, said port can utilize its contract abstract interface to make interaction with man-machine interface and bottom layer hardware equipment so as to make related hardware application program meet the interface function requirement provided by system, and in the model layer increasing / reducing or replacing correspondent module so as to implement change of system functino. Said invention also provides the application of said numerical control system.

Owner:东莞市升力智能科技有限公司

Numerical format intelligent display method, device terminal and computer-readable storage medium

ActiveCN113420538BMeet personalized display needsImprove user experienceData processing applicationsText processingComputer hardwarePersonalization

The invention discloses a numerical format intelligent display method, a device terminal and a computer-readable storage medium. The numerical format intelligent display method includes: in the real estate BI field, the BI system makes the BI The system can intelligently identify whether there is a corresponding fixed format for the value of this field, and then use the corresponding fixed format to display it; for values without a fixed format, the BI system uses an adaptive format scheme so that the value without a fixed format is displayed in the report The digits maintain a suitable number of references. It meets the personalized display needs of special field values in the industry, and also improves the experience of different users when viewing reports.

Owner:深圳市明源云科技有限公司

Method to represent the nucleotide elements of a DNA sequence as numerical elements to include cytosine being assigned the value zero, thymine being assigned the value one, adenine being assigned the value two and guanine being assigned the value three

Current study of the genomes of species is conducted by examining the nucleotides as represented by the first letter of the name that has by convention been arbitrarily given to the nitrogenous base that comprises each of the four different nucleotides that comprise deoxyribonucleic acids. Representing the four nucleotides that comprise DNA by a specific number, rather than a letter, facilitates study of a numerical system and command instructions embedded in a sequence of DNA. Studying genomes by converting the nucleotides to a numerical system assists in the identification of certain genes that cannot be discovered by conventional means. The method presented consists of describing a DNA sequence by representing each cytosine with the number zero, representing each thymine with the number one, representing each adenine with the number two and each guanine with the number three.

Owner:SCHEIBER LANE BERNARD +1

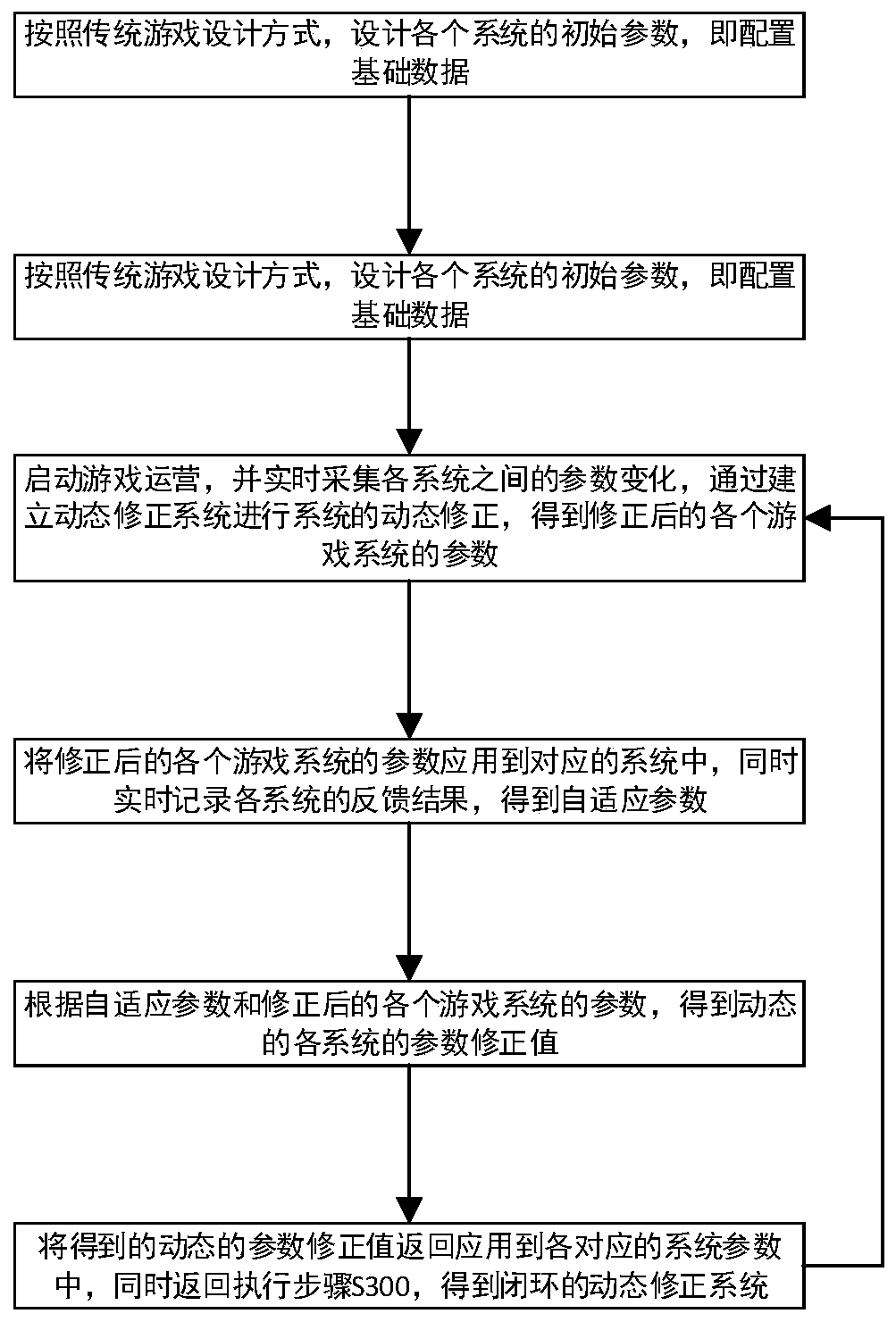

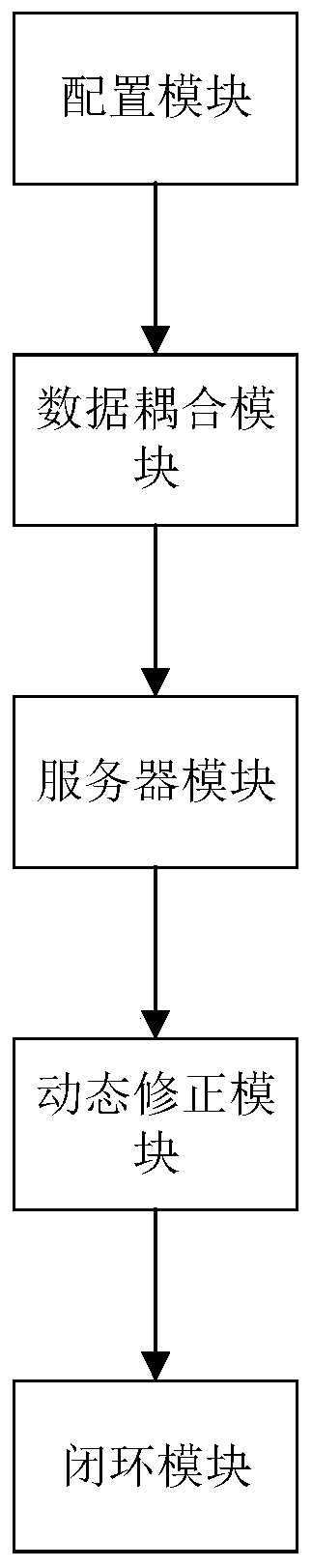

Dynamic correction method and system for game

The invention discloses a dynamic correction method and system for a game. The dynamic correction method for the game comprises the implementation steps that according to a system design of the game,basic data is configured, data couplers are arranged, correctors conduct data adjustment for the dependency couplers, dynamic correctors which mainly depend on an economic model and a mathematical model are arranged, and real user expectations and deviations are established to achieve dynamic balance; user data is collected during a game test, and the system dynamically generates self-adaptive parameters based on game data. The dynamic correction method and system for the game have the advantages that planned data is only basic data or is called reference data, and the dynamic correction system carries out correction based on the reference data; a numerical system has polymorphism, and the dynamic correction system dynamically adjusts the data according to the level of a player to reach the expectations of the player for the game; the numerical system has fault tolerance, for a data system design failure of a single module, the dynamic correction system can carry out correction according to threshold values, and therefore the avalanche effect is mitigated.

Owner:ZHUHAI KINGSOFT ONLINE GAME TECH CO LTD +1

Method to represent the nucleotide elements of a DNA sequence as numerical elements to include adenine being assigned the value one, guanine being assigned the value two, cytosine being assigned the value three, and thymine being assigned the value four

InactiveUS20150227678A1Help studyComputation using non-denominational number representationSequence analysisCytosineNucleotide

Current study of the genomes of species is conducted by examining the nucleotides as represented by the first letter of the name that has by convention been arbitrarily given to the nitrogenous base that comprises each of the four different nucleotides that comprise deoxyribonucleic acids. Representing the four nucleotides that comprise DNA by a specific number, rather than a letter, facilitates study of a numerical system and command instructions embedded in a sequence of DNA. Studying genomes by converting the nucleotides to a numerical system assists in the identification of certain genes that cannot be discovered by conventional means. The method presented consists of describing a DNA sequence by representing each adenine with the number one, representing each guanine with the number two, representing each cytosine with the number three and each thymine with the number four.

Owner:SCHEIBER LANE BERNARD +1

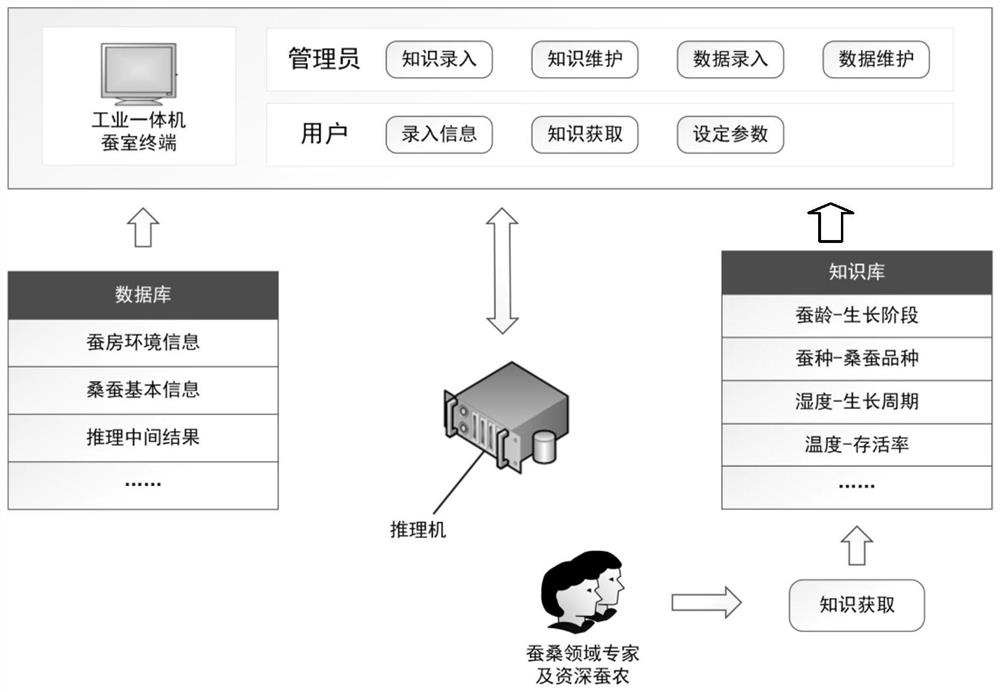

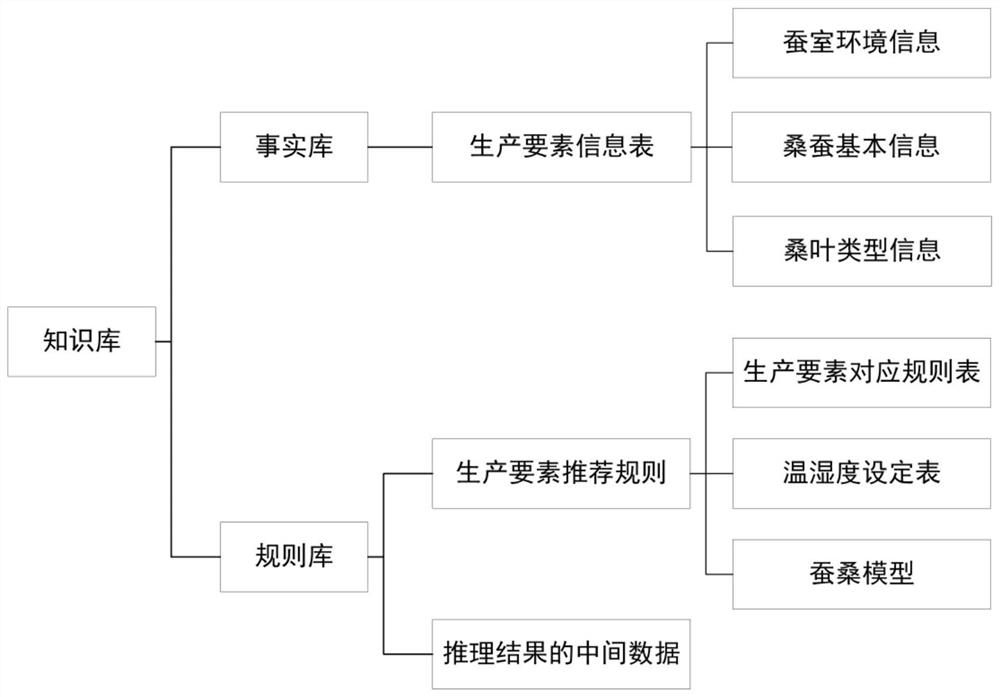

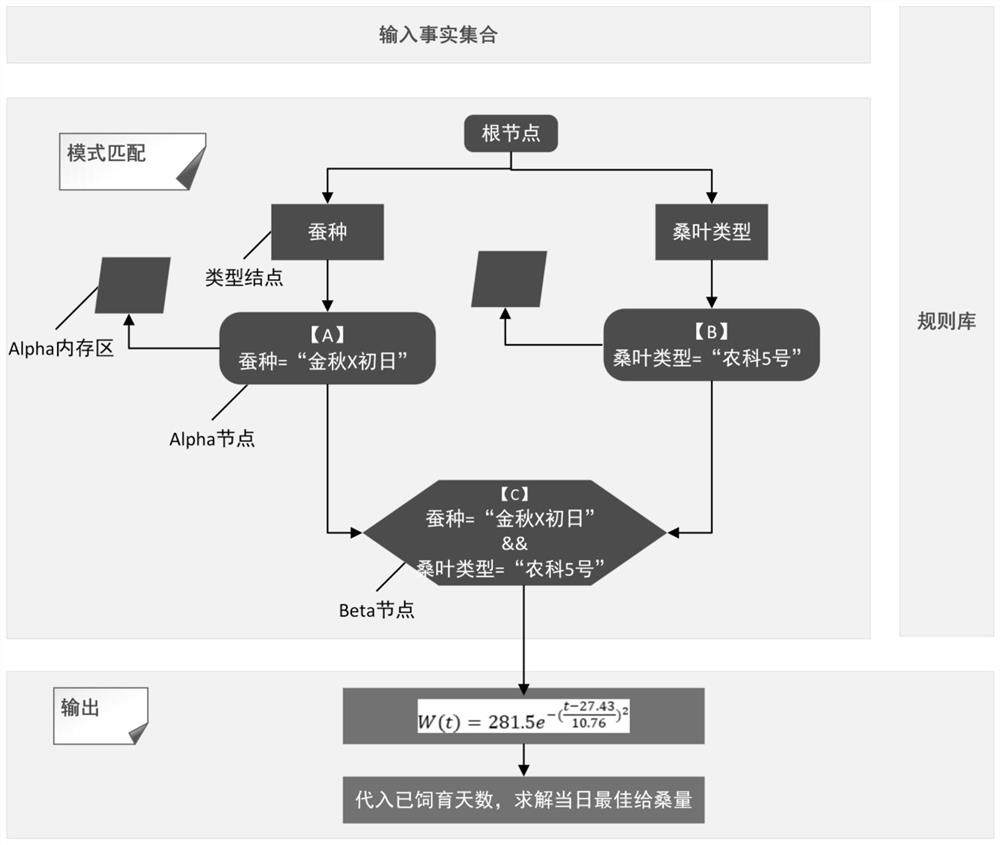

Silkworm production element recommendation system and method based on knowledge base

PendingCN113016727AAble to learnAchieve optimizationDatabase management systemsDesign optimisation/simulationEconomic benefitsData bank

The invention discloses a silkworm production element recommendation system and method based on a knowledge base. The system comprises a database, the knowledge base, a terminal and an inference machine, wherein the database stores production element information; the knowledge base stores relevant knowledge in the silkworm breeding field, integrates the knowledge into knowledge data and performs mathematical modeling to form a numerical system; the terminal is used for man-machine interaction, receives information transmitted by the database and the knowledge base and transmits the information to the inference machine; and the inference machine generates and pushes a production element setting scheme to the terminal. Through the technical scheme, the problem that at present, silkworm breeding has an excessively high requirement for personnel quality can be effectively solved, therefore, the working threshold and production risk can be lowered, the silkworm survival rate and silkworm cocoon quality are further improved, and more economic benefits are brought to the silkworm industry.

Owner:ZHEJIANG SCI-TECH UNIV

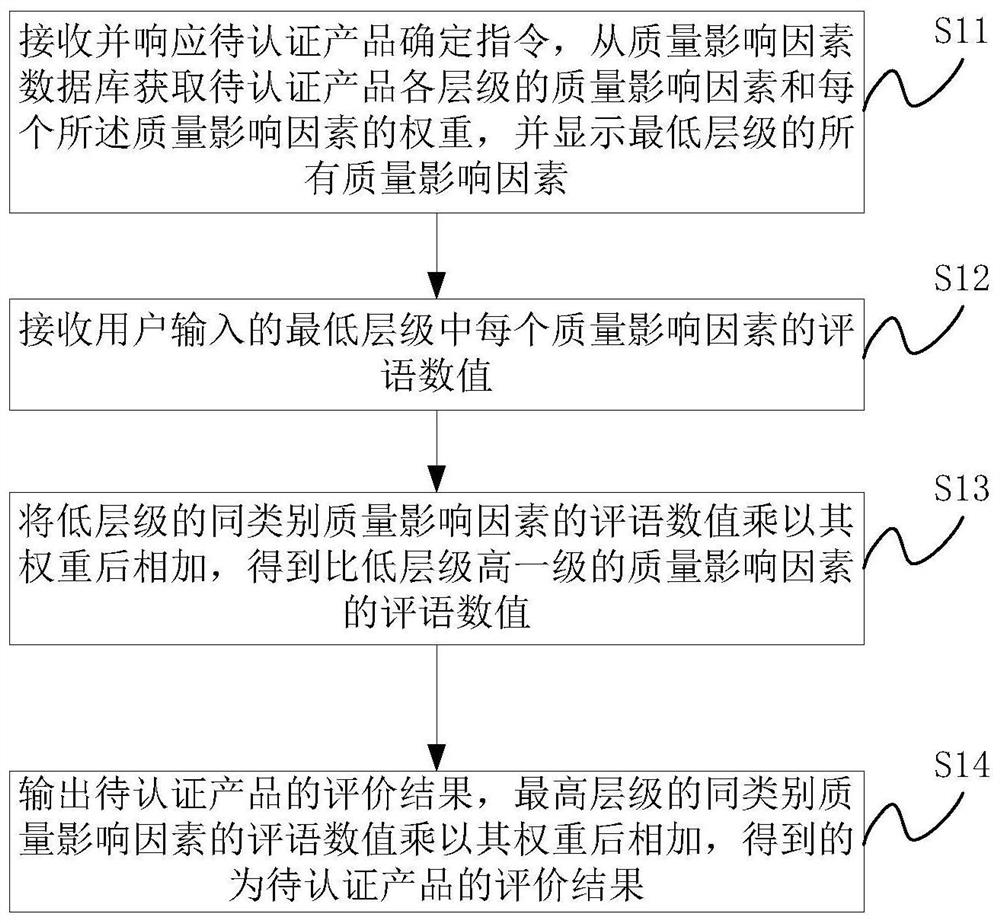

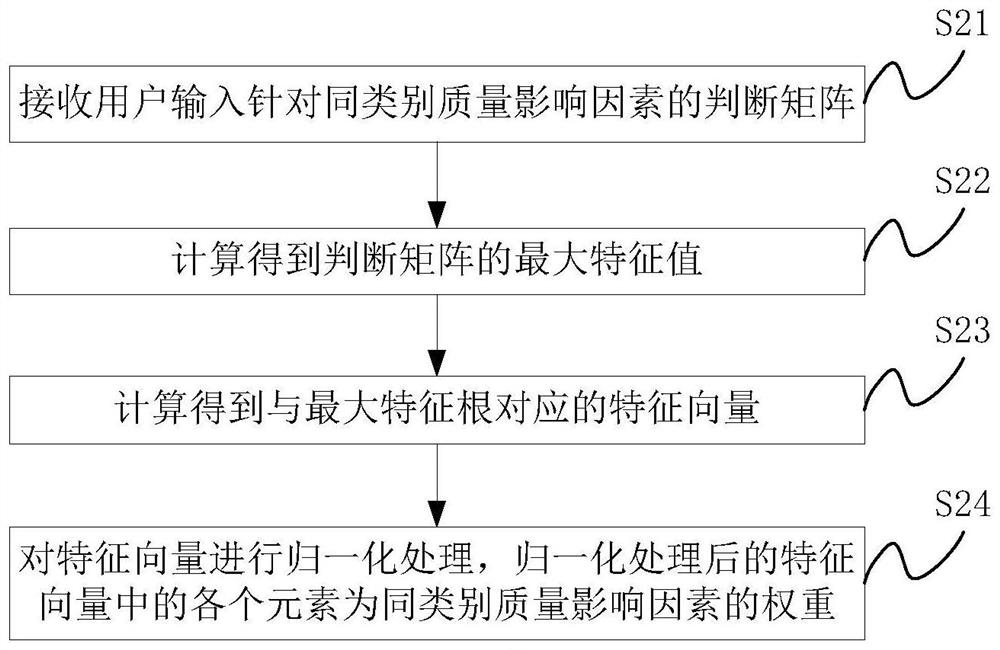

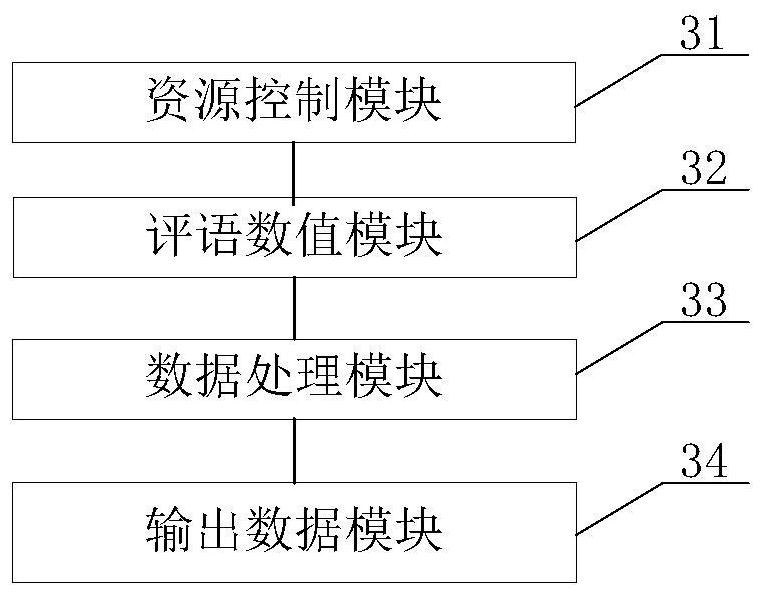

Product authentication method and related device

PendingCN112488727AImprove authentication efficiencyEvaluation results are objectiveCommerceEvaluation resultData mining

The invention discloses a product authentication method and system, a readable storage medium and electronic equipment, and belongs to the field of data processing, and the method comprises the steps:building a quality influence factor database in advance, storing a factor set having an influence on the quality of a product for each type of product according to the classification of the product,and storing the weight of each quality influence factor; in the authentication process, enabling a user to select a to-be-authenticated product from a system and inputting a comment numerical value ofeach quality influence factor in the bottommost level corresponding to the to-be-authenticated product; and enabling the system to automatically calculate an evaluation result of the to-be-authenticated product according to the comment numerical value of each quality influence factor in the bottommost level and the weight of each quality influence factor. The automatic calculation is performed bythe system, so that the product authentication efficiency is improved, and the evaluation result is more objective.

Owner:XIAN HIGH VOLTAGE APP RES INST CO LTD

Numerical format intelligent display method, equipment terminal and computer readable storage medium

ActiveCN113420538AMeet personalized display needsImprove user experienceData processing applicationsText processingComputer graphics (images)Theoretical computer science

The invention discloses a numerical format intelligent display method, a device terminal and a computer readable storage medium, the numerical format intelligent display method comprises the following steps: in the real estate BI field, a BI system can intelligently identify whether a numerical value of a field has a corresponding fixed format or not by building a binary classifier of the special field in a report, therefore, a corresponding fixed format is used for displaying; for the numerical values without the fixed format, the BI system uses an adaptive format scheme to enable the numerical values without the fixed format to keep a proper lookup number in the digits displayed in the report. The personalized display requirement for special field numerical values in the industry is met, and the use experience when different users look up the report is also improved.

Owner:深圳市明源云科技有限公司

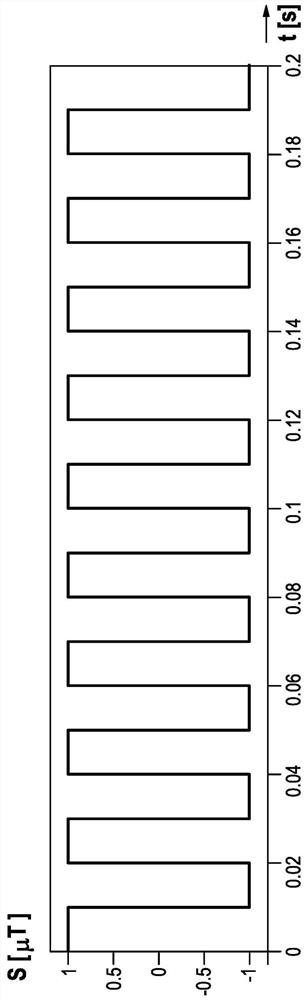

Magnetic parking sensor

PendingCN113167839ASupport energy-saving operationExtended run timeIndication of parksing free spacesElectric/magnetic detectionParking sensorsParking space

The invention relates to a magnetic parking sensor (100), having: a detection device (10) for detecting geomagnetic measured values (M) in the region of a parking space in three coordinates; a first-in-first-out storage device (20), into which the geomagnetic measured values (M) can be loaded; and a determination device (30) which is set up: to depict the X and Y components of the geomagnetic measured values (M) in complex numbers (b), wherein the complex numbers (b) can be determined as a function of the variability (V) of the defined number of geomagnetic measured values (M), and to define a numerical system (b, F) having a defined number of elements (n) corresponding to the variability (V) of the geomagnetic measured value (M) and the complex numbers; and to determine an availability state of the parking space by determining a root [lambda]n of the polynomial: [lambda]3-(2n-1)[lambda]2-(n-1)2[lambda]-(n2+1) with: n... variability of the geomagnetic measured values; [lambda]... auxiliary variable of the numerical theory ('Ito variable') wherein 2xlog([lambda]n) / log (n2+1)>a points to an occupancy state of the parking space and 2*log([lambda]n) / log(n2+1)< indicates a free state of the parking space with: a... defined threshold value.

Owner:ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com