Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

69results about How to "Meet different processing requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

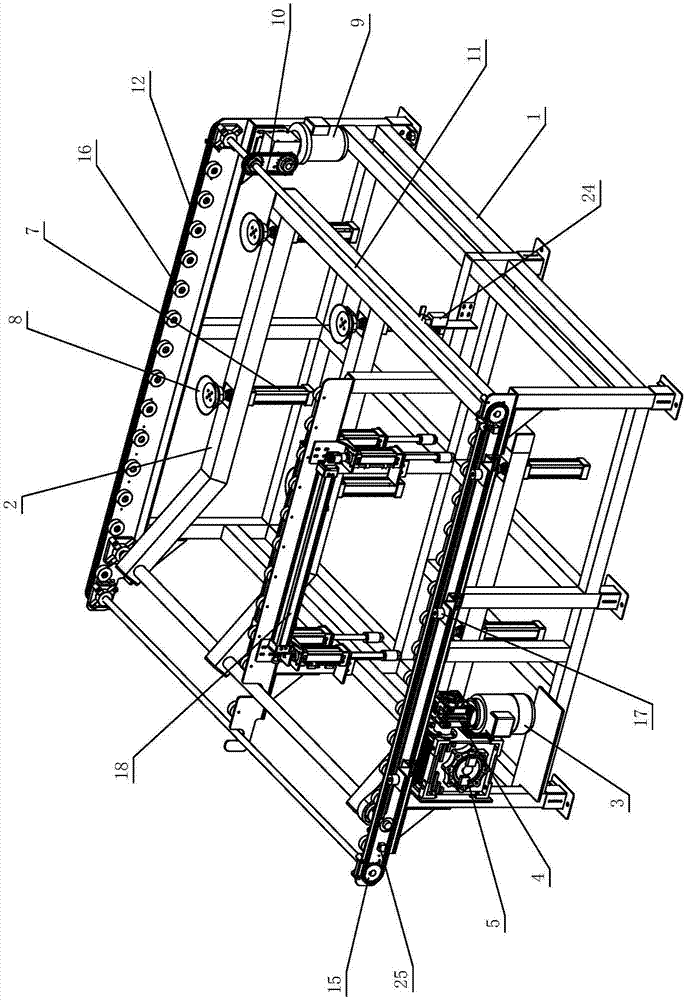

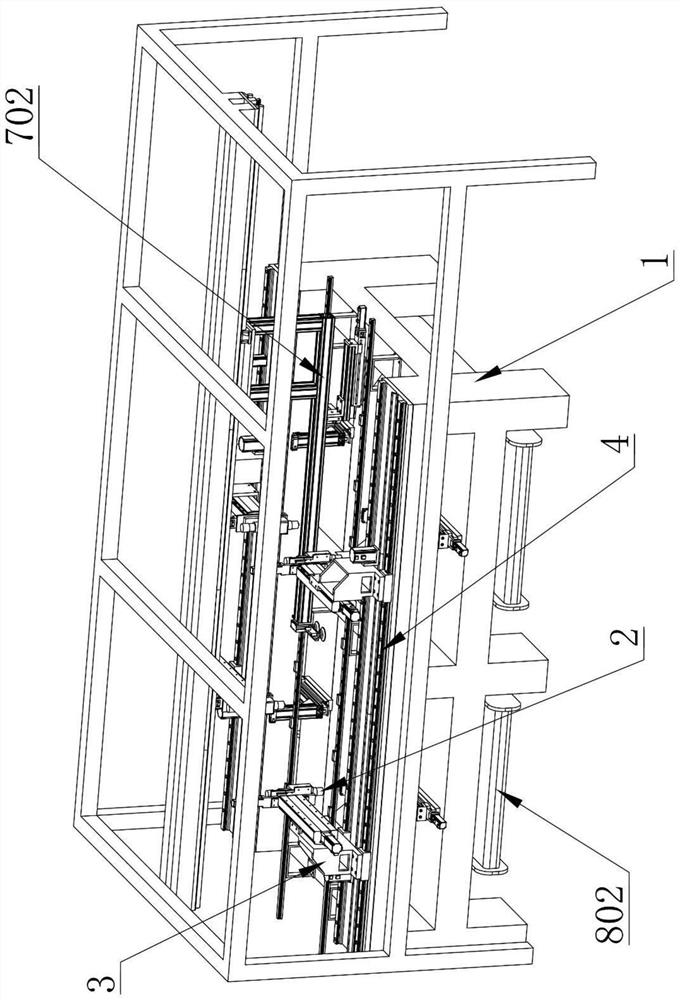

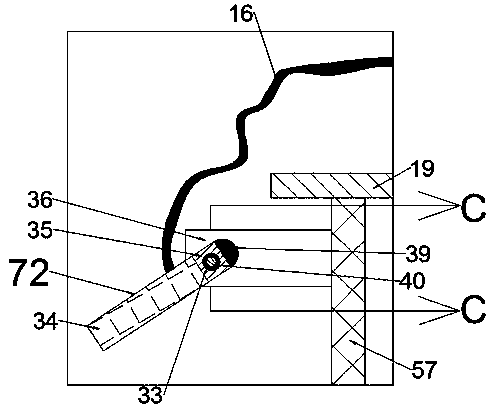

Plate overturning machine and numerical-control cutting production line thereof

PendingCN107954185ASimple structureReduce manufacturing costConveyorsConveyor partsHigh turnoverProduction line

A plate overturning machine comprises an equipment machine frame. An overturning mechanism and a conveying mechanism are arranged on the equipment machine frame. The overturning mechanism comprises anoverturning arm, one or more suction disk assemblies and an overturning drive assembly. One side of the overturning arm is rotationally connected with the equipment machine frame. The suction disk assemblies are assembled on the overturning arm. The overturning drive assembly is arranged on the equipment machine frame and drives the overturning arm to conduct reciprocating overturning between thecorresponding numerical-control cutting machine and the equipment machine frame where the overturning arm is located so that a plate-shaped workpiece on the numerical-control cutting machine can be overturned and placed on a feeding area of the equipment machine frame. The conveying mechanism is located in the feeding area of the equipment machine frame and comprises a conveying chain and a conveying drive assembly, wherein the conveying chain is provided with a stop block, the conveying drive assembly is arranged on the equipment machine frame and drives the conveying chain to operate, and the stop block moves along with the conveying chain and drives the plate-shaped workpiece in the feeding area to be conveyed in the direction of the corresponding numerical-control cutting machine. Theplate overturning machine has the advantages of being reliable and stable in performance, high in overturning efficiency, low in labor intensity and capable of achieving multi-machine combination.

Owner:FOSHAN HAOYANG WOODWORK MACHINERY MFR

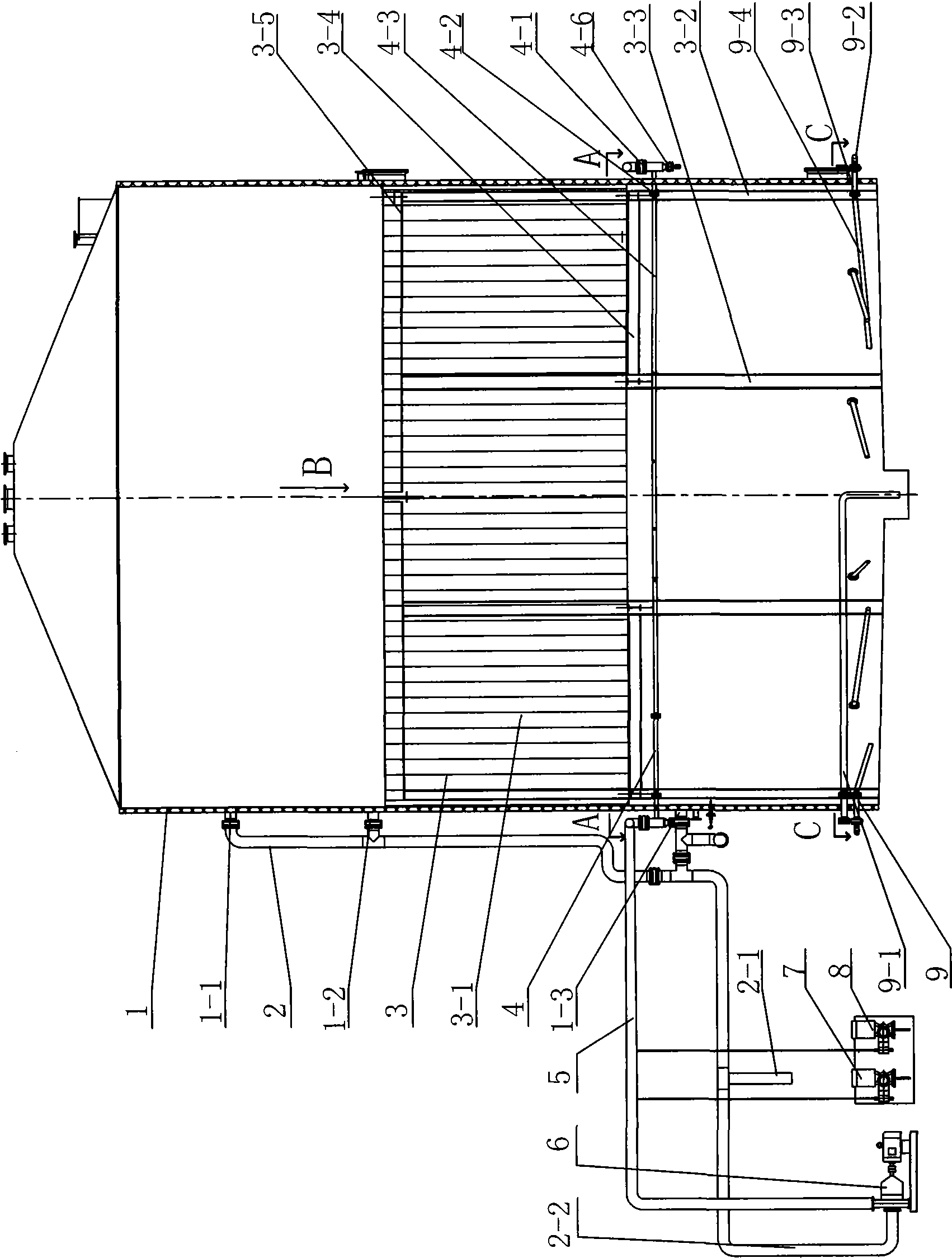

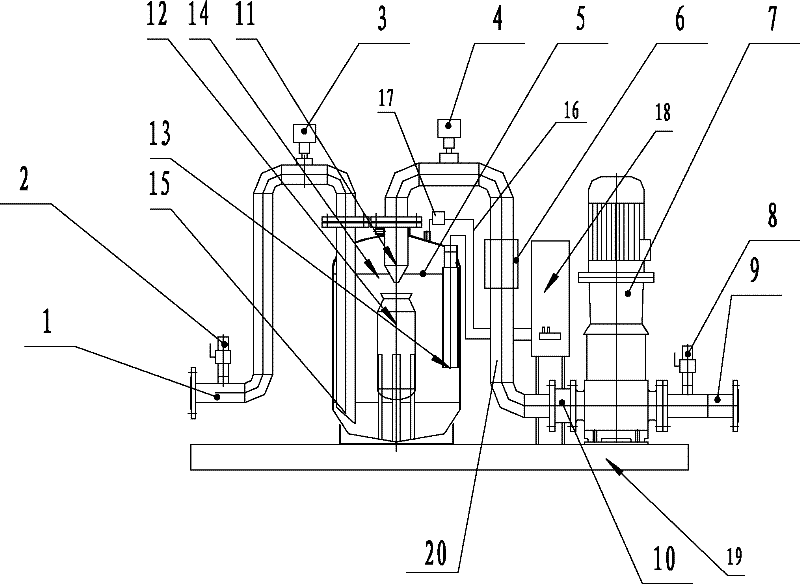

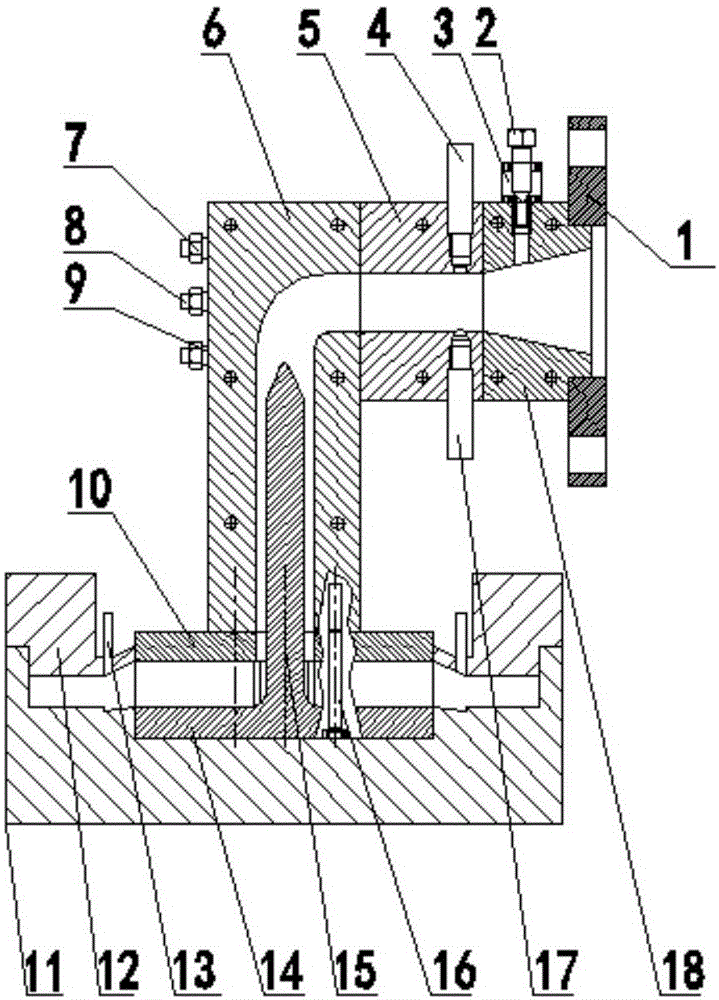

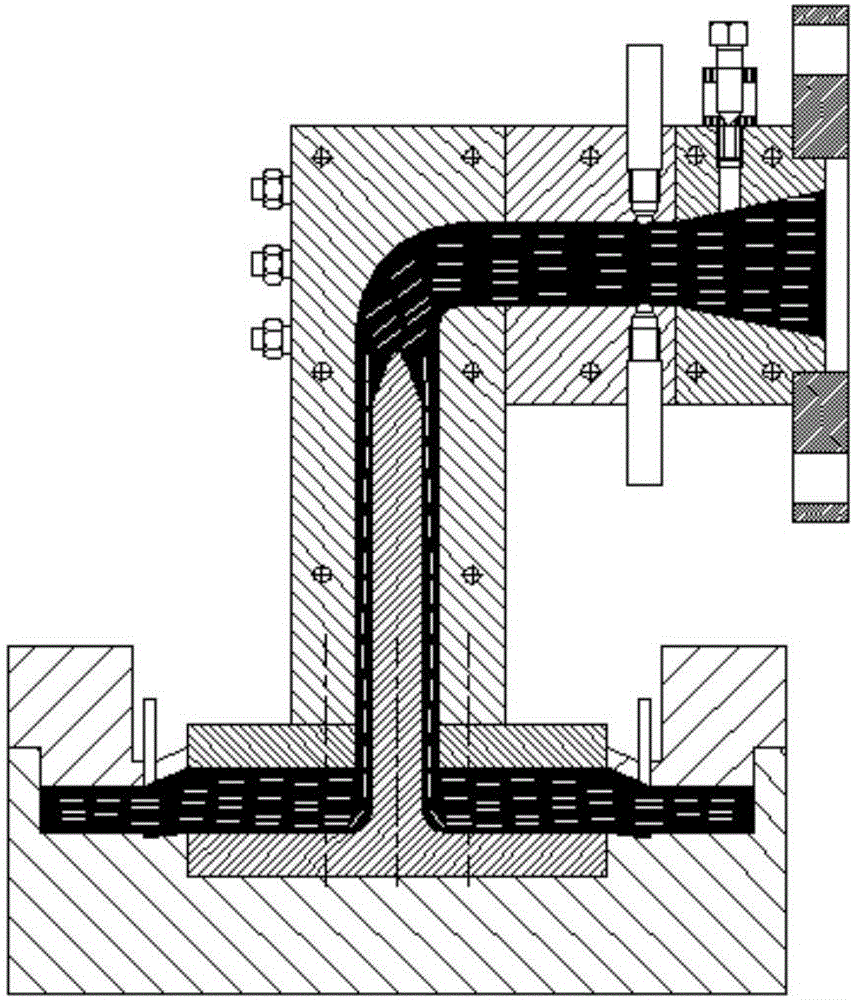

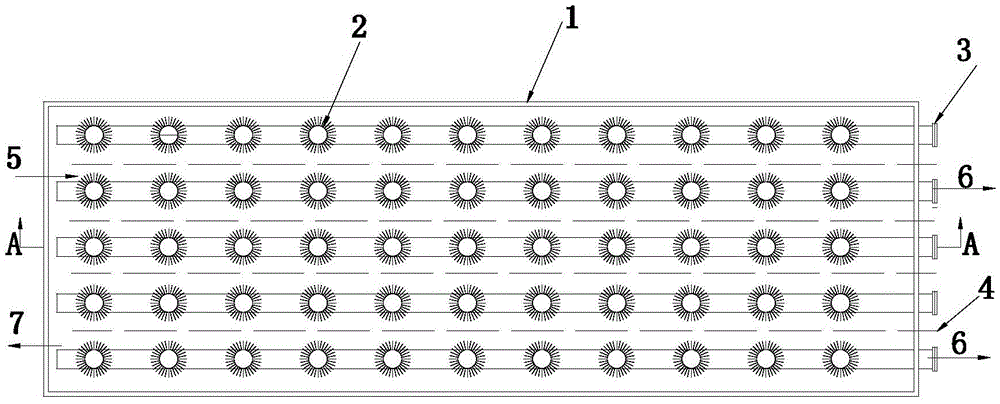

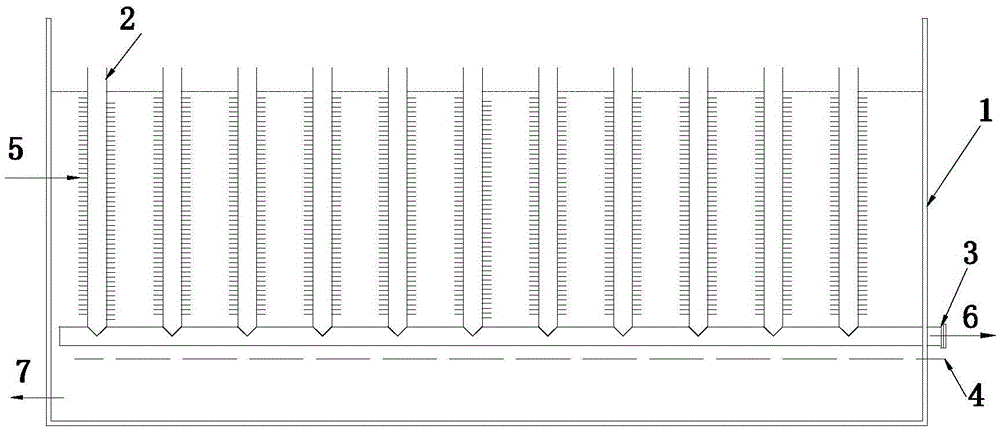

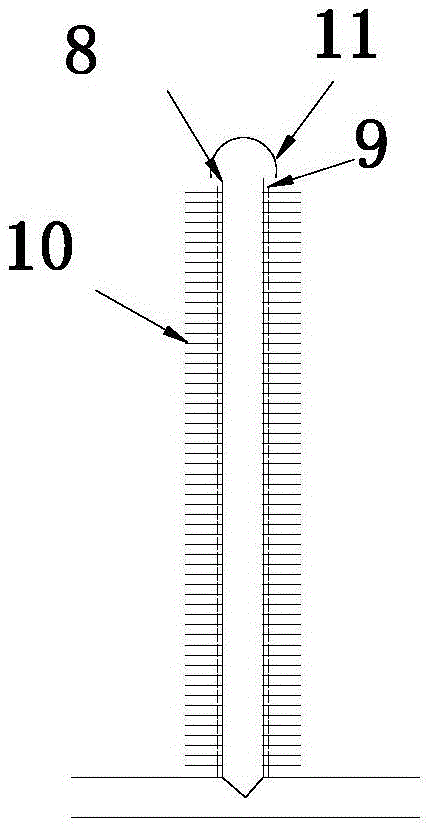

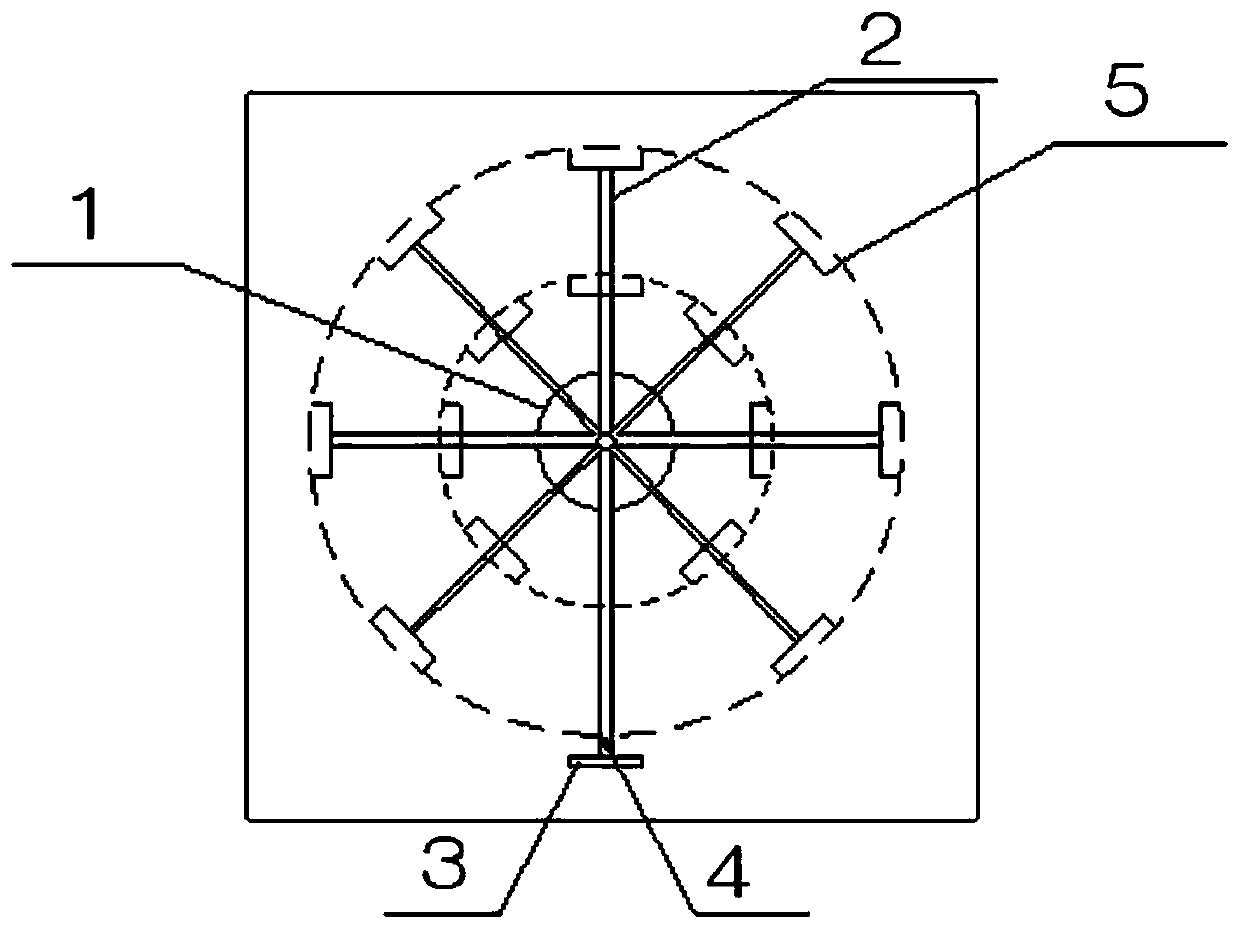

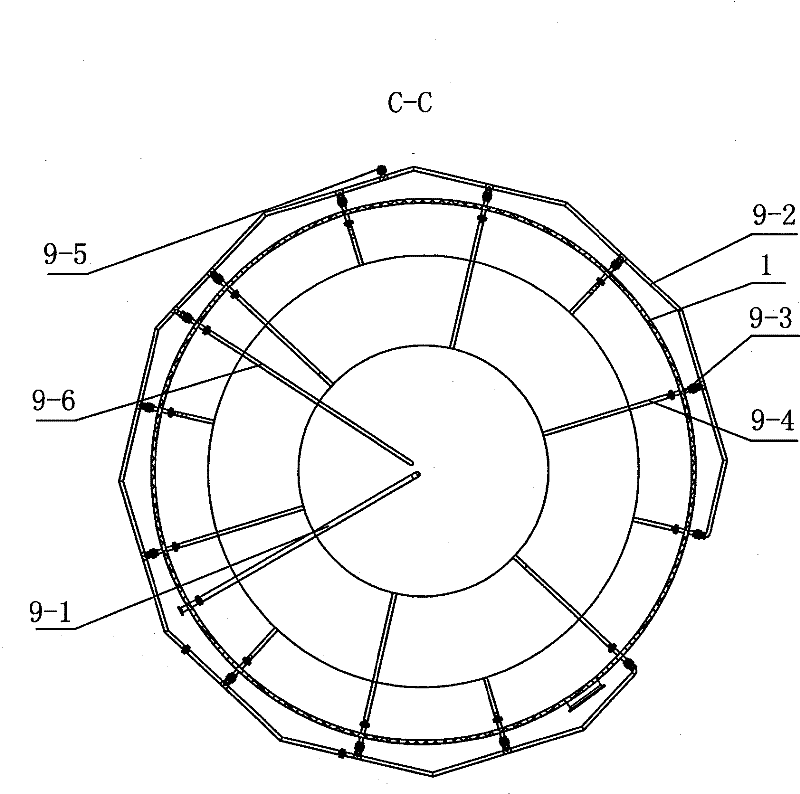

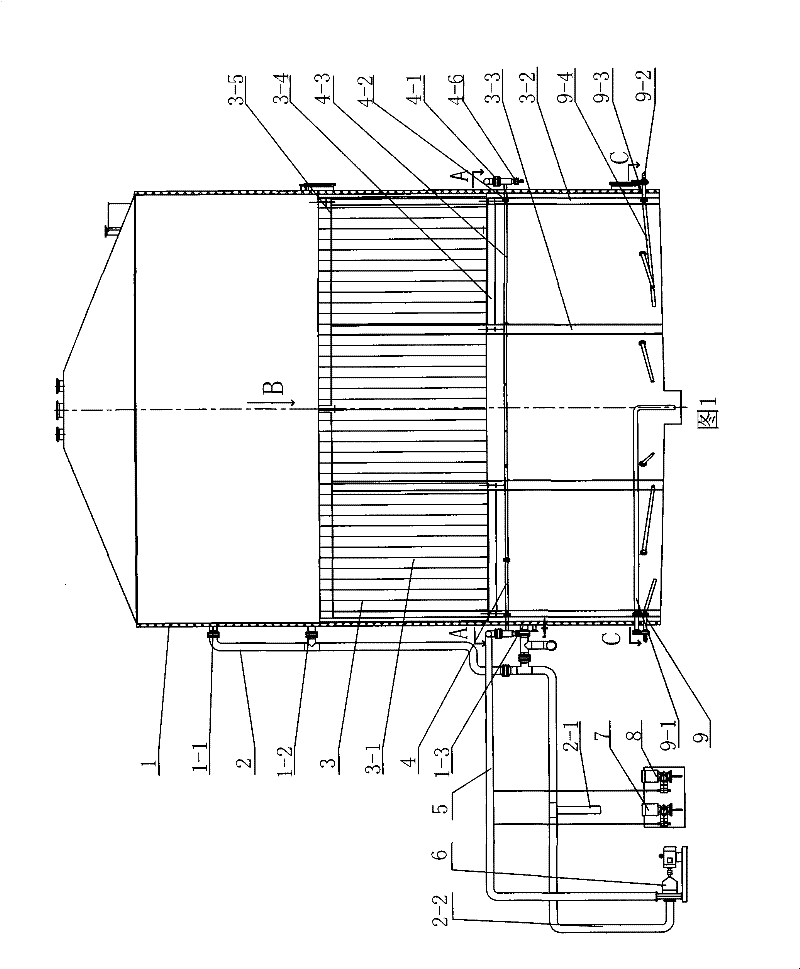

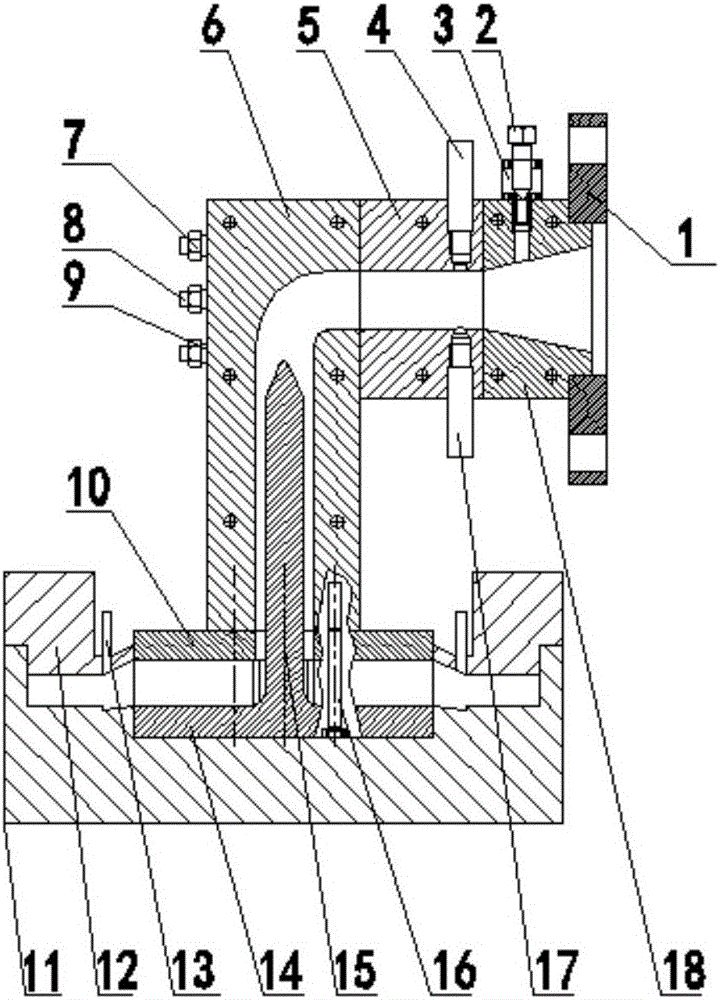

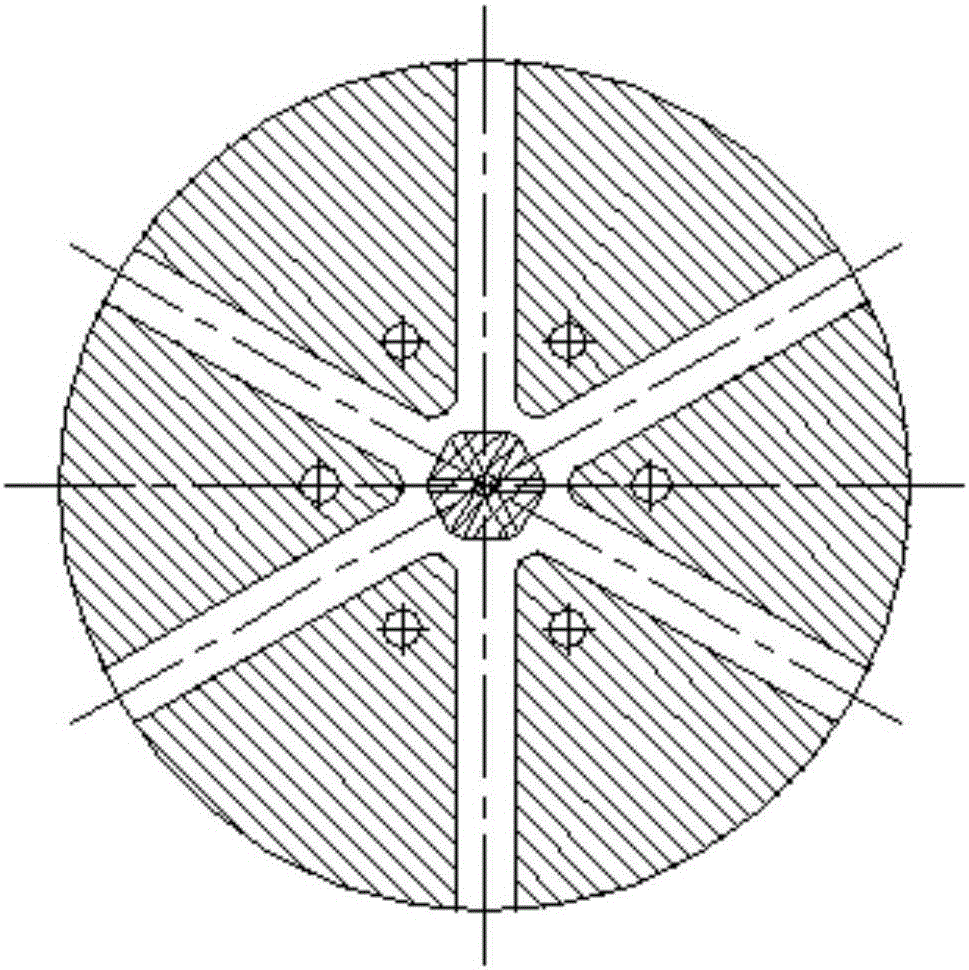

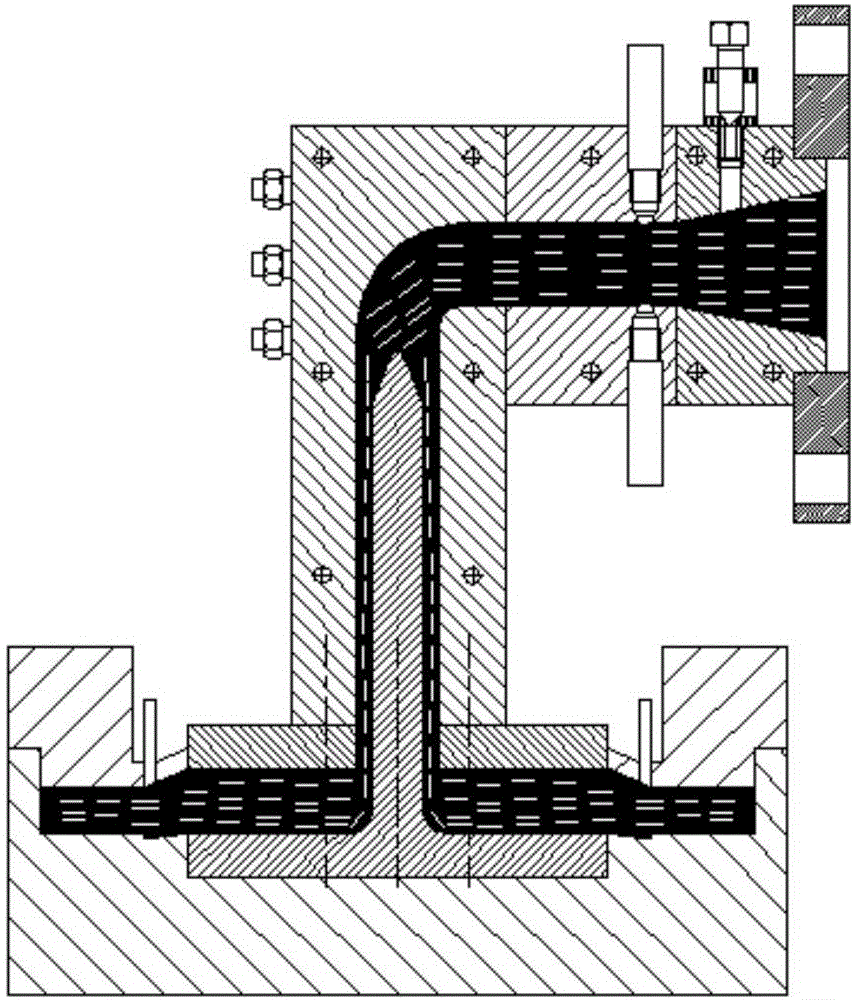

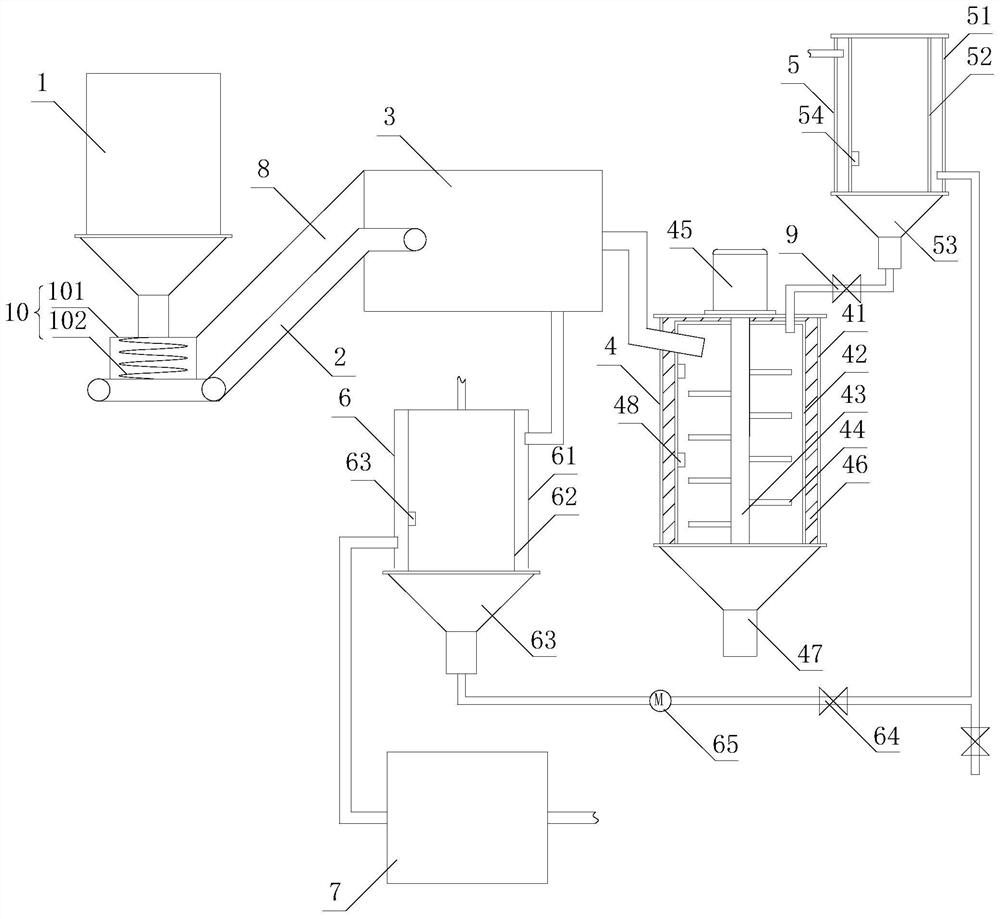

Anaerobic reactor

ActiveCN101497476ASolve easy blockageReduce foulingTreatment with anaerobic digestion processesAnaerobic reactorCirculating pump

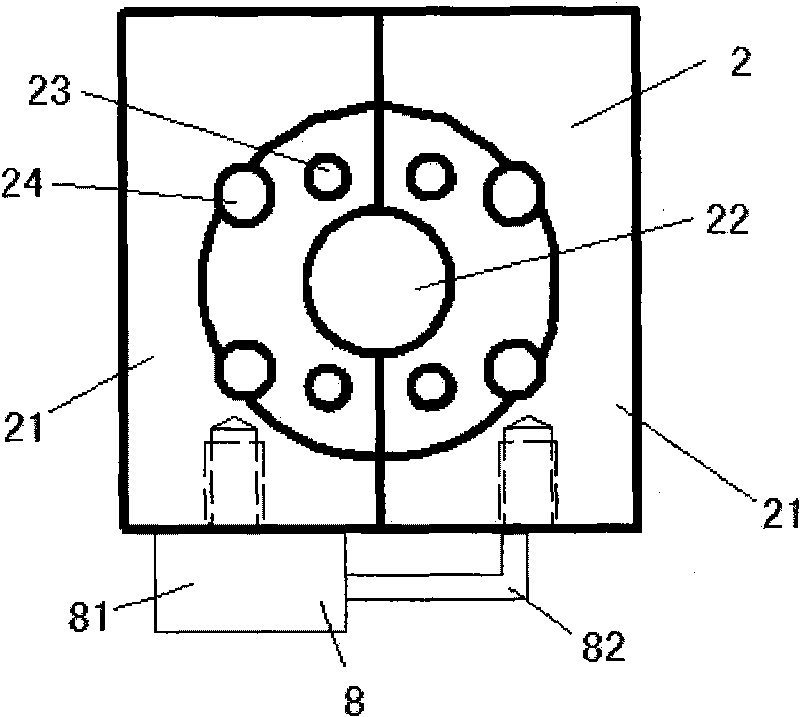

The invention relates to an anaerobic reactor. The anaerobic reactor comprises a cylinder body, a water inlet pipe, a water outlet pipe, a filling device on the middle part of the water outlet pipe, a water distribution device at the bottom of the filling device and a sludge discharge device at the bottom of the water distribution device; the water distribution device comprises a water distribution main pipe and more than four closed annular water distribution branch pipes; water outlet holes of the water distribution branch pipes are alternately arranged along more than three concentric circumferences; the cylinder body is positioned on the upper part of the filling device; the lower part of each water distribution branch pipe is provided with more than two water outlets; the water outlets are connected with the water outlet pipe; a reflowing pipe of the water outlet pipe is mixed with the water inlet pipe by a circulating pump and is communicated with the water distribution main pipe; a first medicating device and a second medicating device are communicated with the water inlet pipe respectively through connecting pipes; the filling device comprises a filling rack, a membrane hanging rack and a zonal biomembrane strip; the biomembrane strip is hung on the membrane hanging rack; and the sludge discharge device comprises a sludge discharge main pipe and six sludge discharge branch pipes arranged in length alternation along radial direction. The anaerobic reactor has the characteristics of reasonable water distribution, compact structure and stable operation of the reactor.

Owner:WELLE ENVIRONMENTAL GRP CO LTD

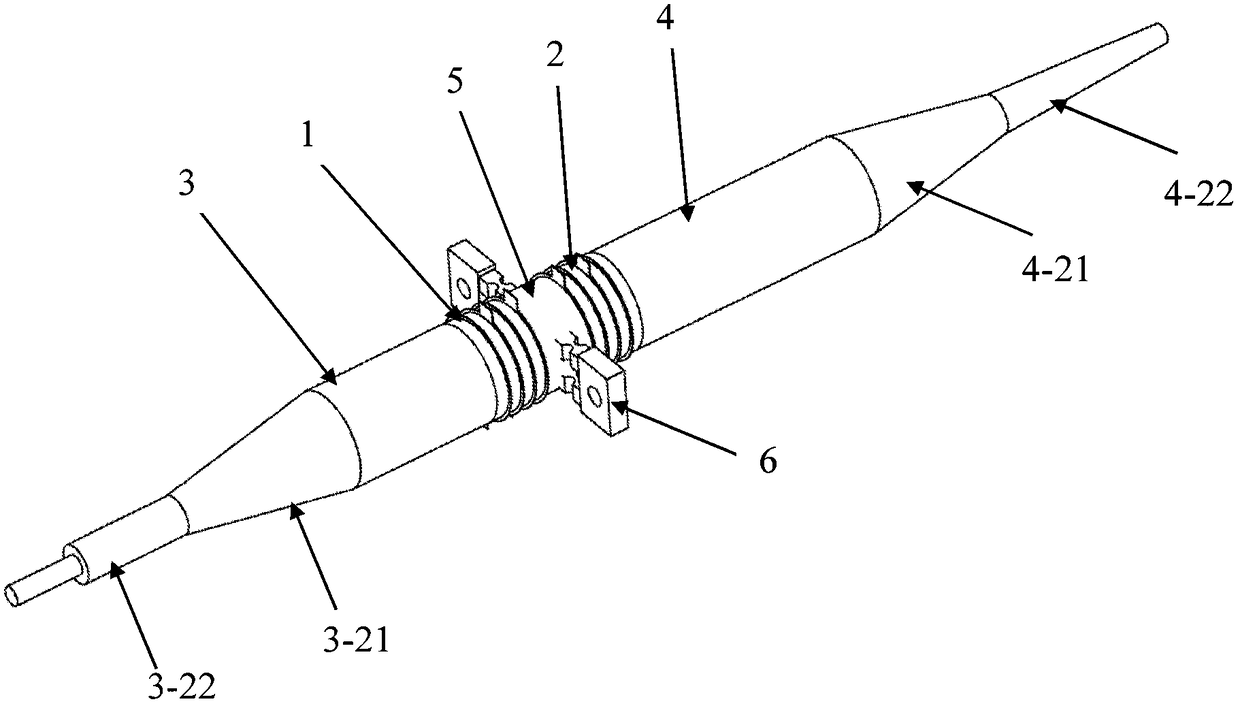

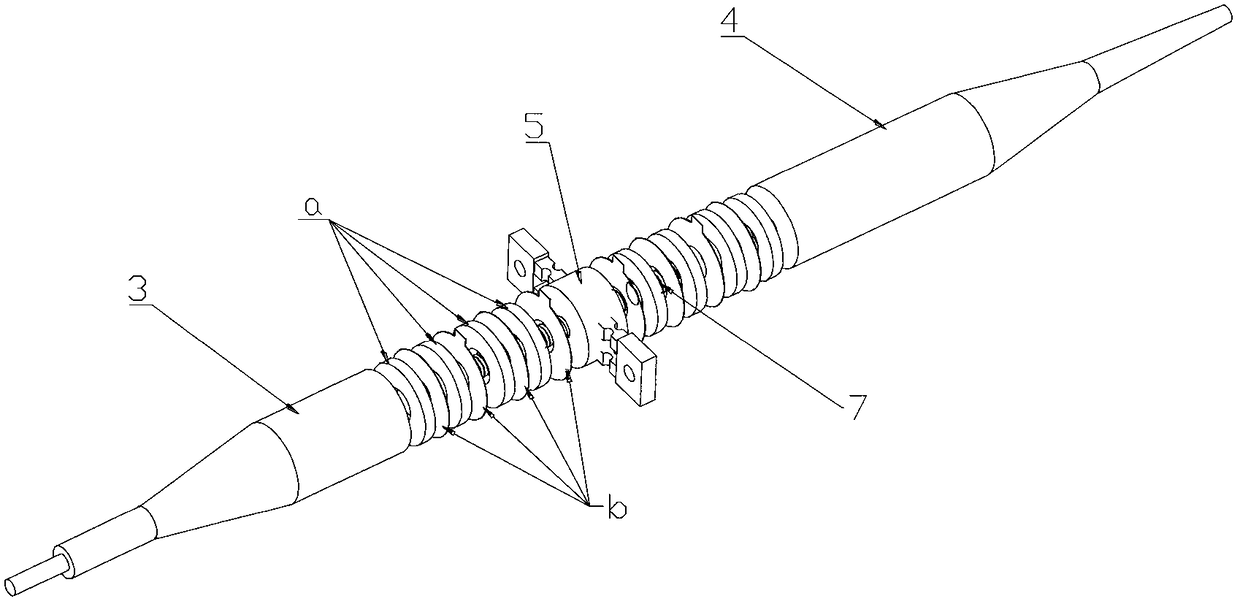

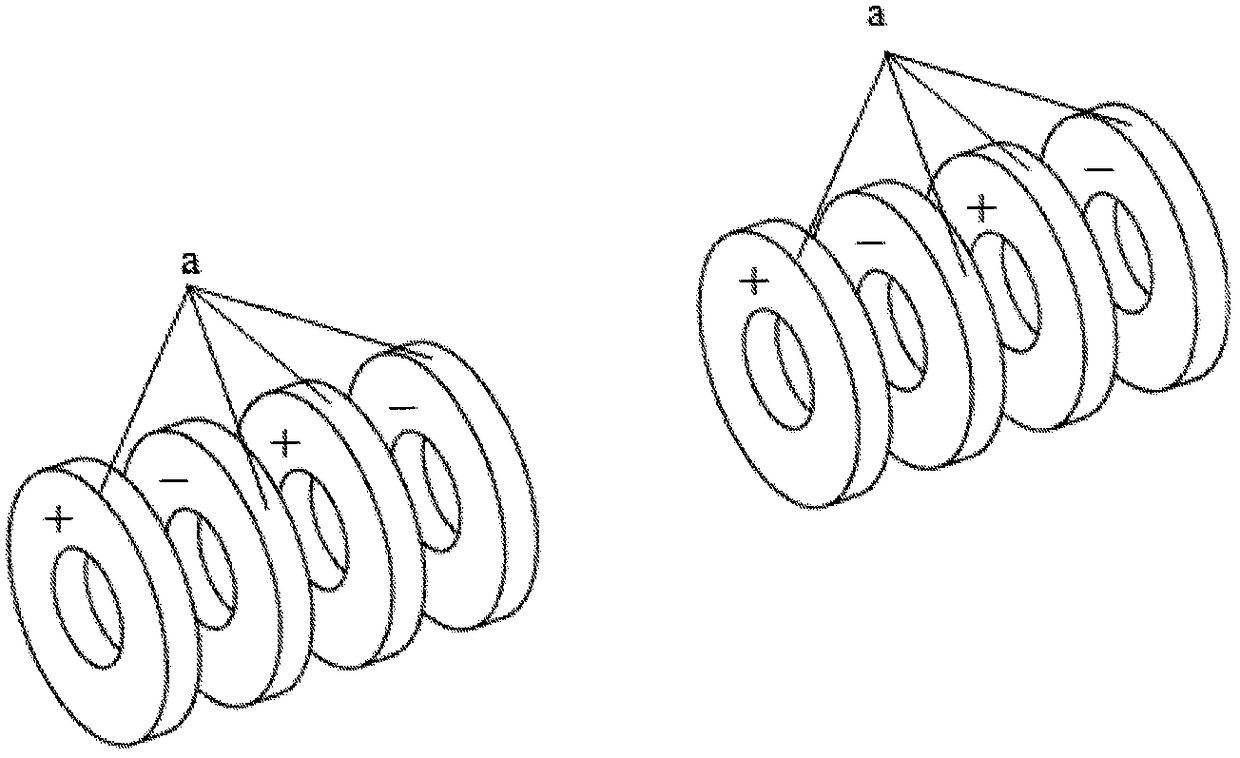

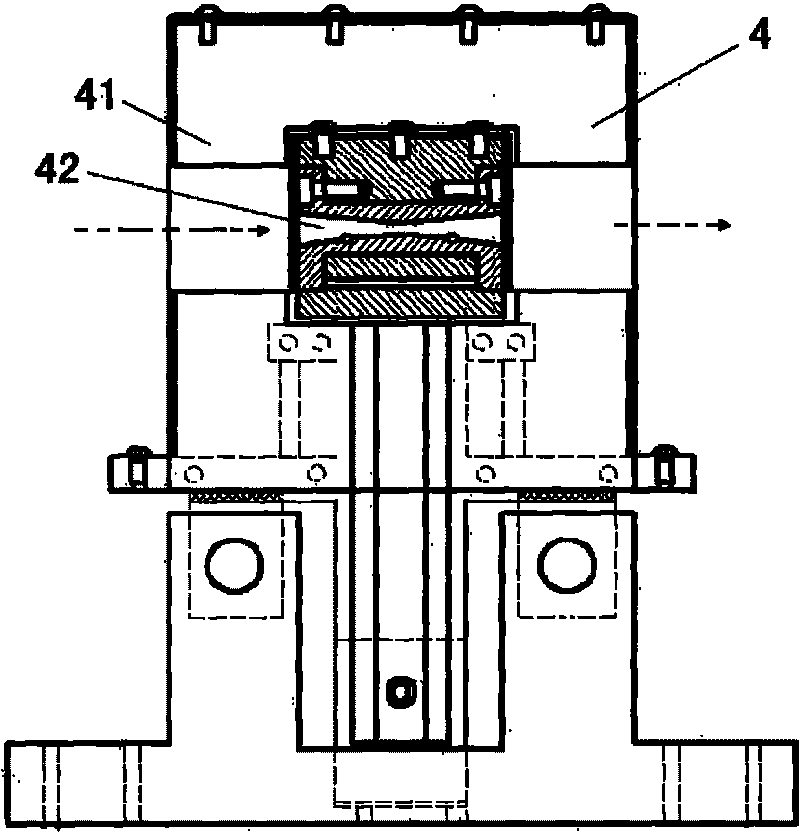

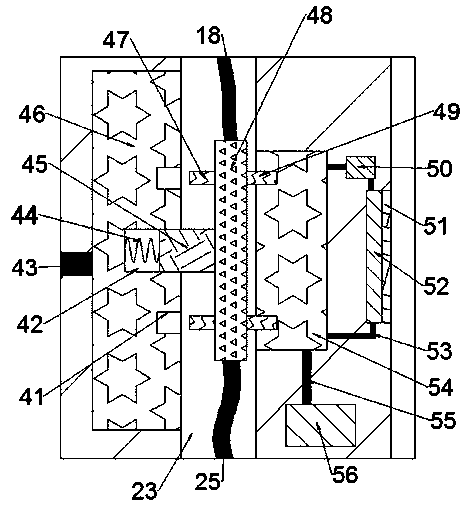

Series composite structure double-frequency multi-amplitude piezoelectric ultrasonic transducer

InactiveCN108176574AReduced service lifeReduce energy consumptionMechanical vibrations separationUltrasonic wire bondingUltrasonic transmission

The invention discloses a series composite structure double-frequency and multi-amplitude piezoelectric ultrasonic transducer applied to a thermal ultrasonic wire bonding and sealing process of an integrated circuit chip. The transducer is composed of two sets of double-ended radiating piezoelectric oscillators and two two-stage mechanical variable-amplitude poles with different amplification factors. The transducer can work at the frequency near the frequency of 60 kHz or 120 kHz and has three driving modes. Under simple harmonic excitation signals with the same frequency, the transducer canobtain multiple amplitude outputs to meet the different requirements of the wire bonding process of the integrated circuit chip and improve the bonding connection efficiency and reliability. Meanwhile, clamping mechanisms of the composite structure ultrasonic transducer adopt flexible flange clamping mechanisms formed by circular arc hinges, the influence of the clamping rack disturbance torque onthe ultrasonic transmission efficiency in the axial ultrasonic transmission process of the variable-amplitude pole can be effectively lowered, and the utilization rate of ultrasonic energy is increased.

Owner:TIANJIN POLYTECHNIC UNIV

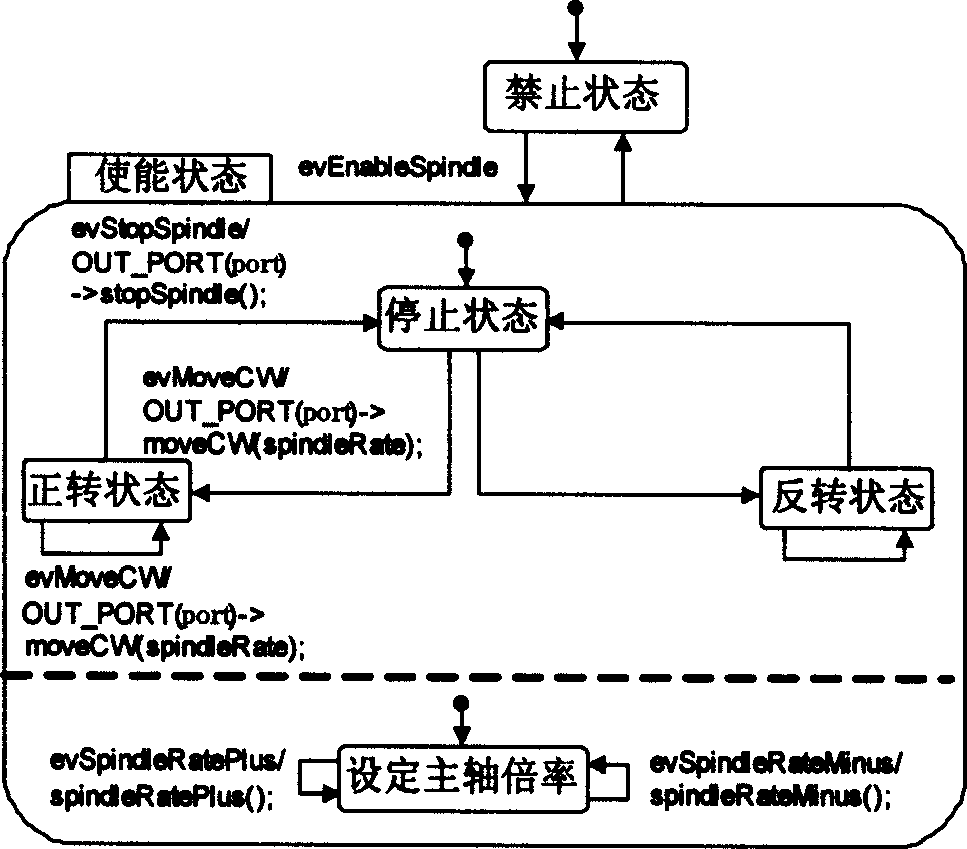

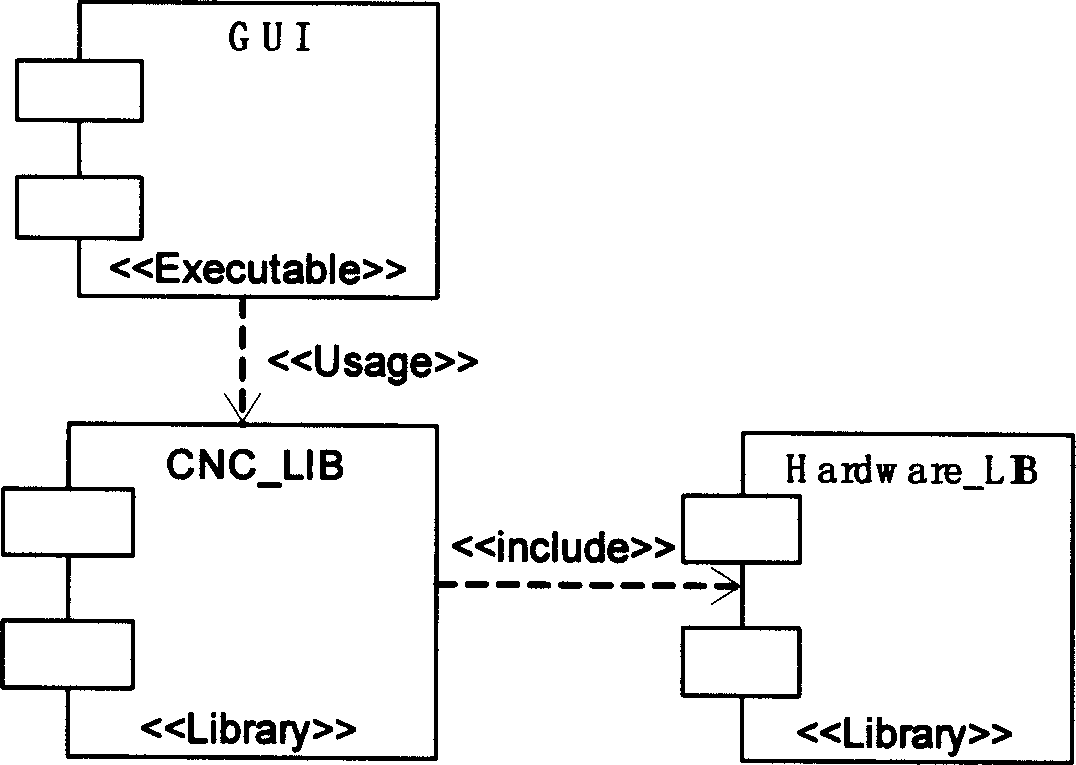

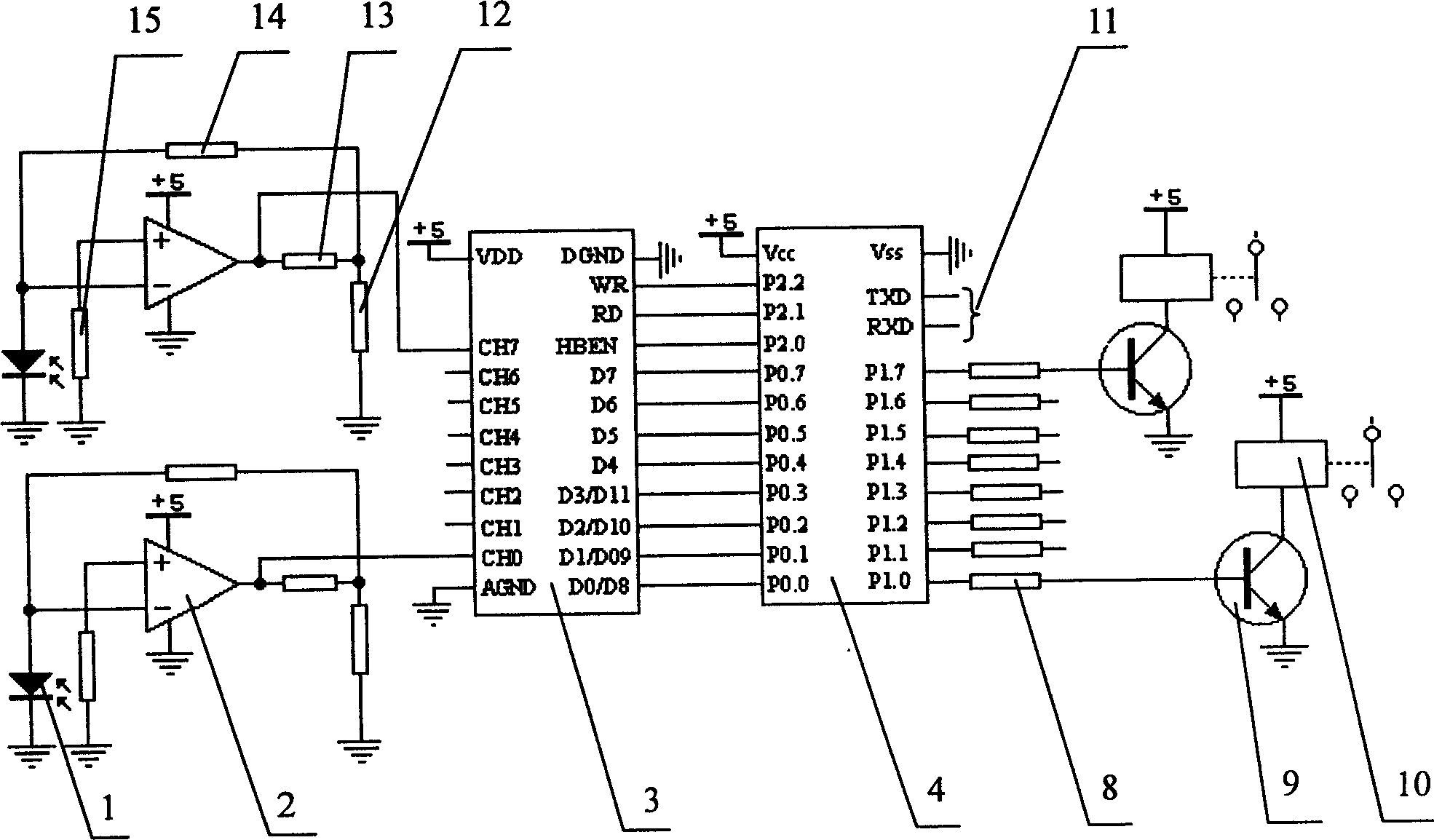

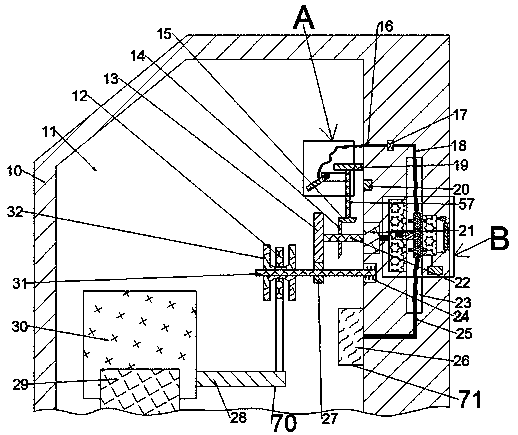

Opening structural computer digital control system able to re-configurate

InactiveCN1601416ARealize the control applicationGuaranteed robustnessComputer controlSimulator controlModel driven developmentHuman–machine interface

The invention is characterized by that making numerical system undergo the process of function module division, maknig model creation based on model drive development method, separating function of module from its behavious, utilizing change of state graph of correspondent module to despatch the the condition of its function execution so as to implement reuse of module function; using port to make communication between modules, said port can utilize its contract abstract interface to make interaction with man-machine interface and bottom layer hardware equipment so as to make related hardware application program meet the interface function requirement provided by system, and in the model layer increasing / reducing or replacing correspondent module so as to implement change of system functino. Said invention also provides the application of said numerical control system.

Owner:东莞市升力智能科技有限公司

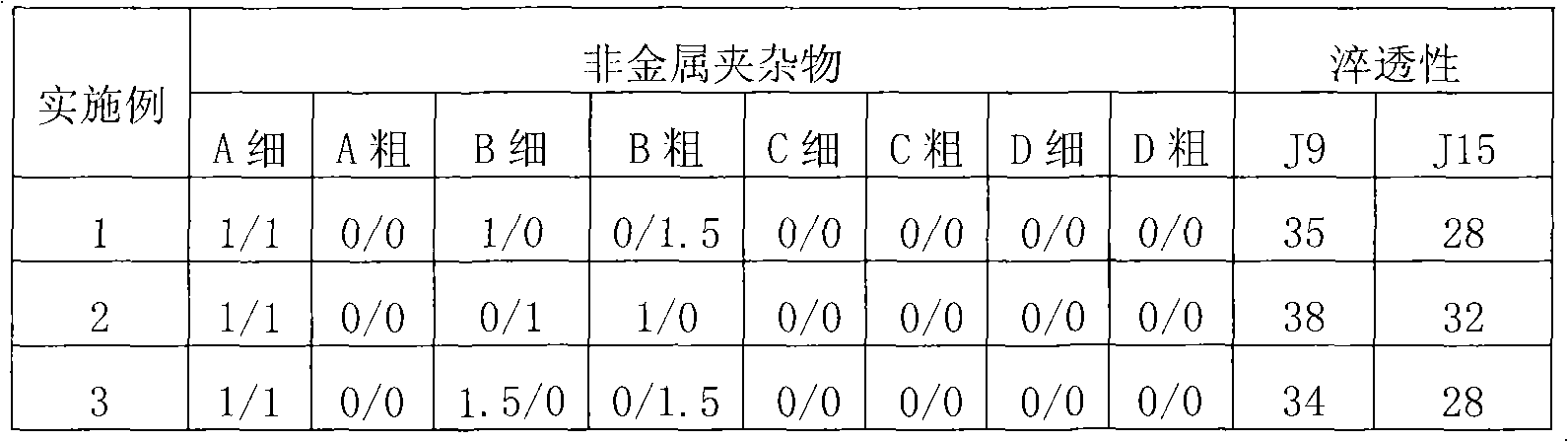

Low-carbon Mn-Cr steel for engine camshaft and manufacturing method thereof

InactiveCN101805874AGood effectImprove hardenabilityTemperature control deviceProcess efficiency improvementQuenchingImpurity

The invention relates to a low-carbon Mn-Cr steel for a camshaft and a manufacturing method thereof. The steel comprises the following components in percentage by weight: 0.17-0.22% of C, 0.17-0.37% of Si, 1.00-1.50% of Mn, 1.00-1.50% of Cr, 0.005-0.025% of P, 0.001-0.020% of S, 0.01-0.20% of Cu, 0.01-0.20% of Ni, 0.010-0.060% of Al, 0-0.15*10-4% of <0> and the balance of Fe and inevitable impurity. The manufacturing method comprises: smelting, alloying, continuously casting, pouring, casting blank, carrying out hot rolling technology and electrosmelting; the terminal point <C> =>0.10%, P <=0.015%, and steel tapping is carried out at the temperature of 1620-1650 DEG C; and LF external refining is carried out, and VD vacuum deaeration is carried out. The invention adopts complete-protection continuously casting, pouring, casting blank and hot rolling to prepare the material. The low-carbon Mn-Cr steel of the invention has high quenching degree and high purity and is used for manufacturing large-power engine camshafts.

Owner:LAIWU IRON & STEEL GRP

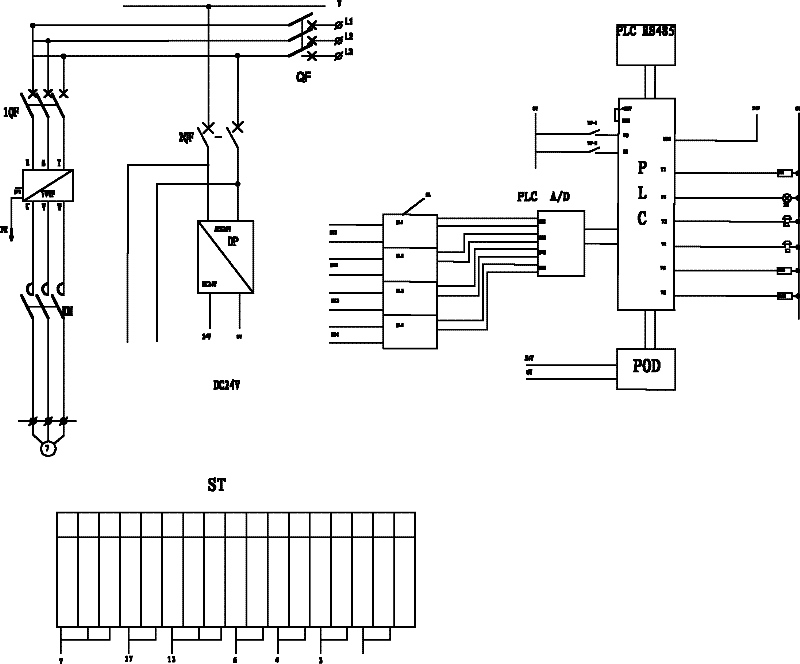

Micro nano bubble generator

InactiveCN102218275AIncrease profitImprove air flotation efficiencyFlow mixersMixing methodsMicro nanoSource type

The invention discloses a micro nano bubble generator which comprises a water intake pipe and a drainage pipe; one end of the water intake pipe is connected with a booster pump; the other end of the booster pump is connected with the top part of an air saturator in a sealing manner through a pipeline; an electromagnetic flowmeter is arranged on the pipeline; the top part of the air saturator is communicated with an air intake pipe in a sealing manner; an electromagnetic valve arranged on the air intake pipe is arranged in a control cabinet; an ejector nozzle, an ejector throat chamber, a liquid level floating ball, an air dissolved water absorption pipe are arranged in the air saturator; the ejector nozzle is connected with a pipeline; the ejector throat chamber is arranged on a position matched with the lower side of the ejector nozzle; an air liquid cavity is arranged between the ejector nozzle and the ejector throat chamber; a switch of the electromagnetic valve is controlled by a programmable controller; and the air dissolved water absorption pipe extends to the outside of the air saturator and is connected with the drainage pipe. The micro nano bubble generator can effectively remove dispersible oil uniformly dispersed in the water with an oil drop grain diameter equal to or less than 10 Mu m; meanwhile, oxidation desulfurising treatment on oily sewage or dissolved oxygen treatment by adding nitrogen is realized based on improving the air floatation oil by using different air source types.

Owner:大庆鑫禹科技有限公司

Punching machine driven by linear motor

InactiveCN103144337AOvercome the shortcomings of small output force and contamination of hydraulic componentsOvercoming Pollution DisadvantagesPress ramLength effectPunching

The invention discloses a punching machine driven by a linear motor. The punching machine comprises a machine frame, wherein the machine frame comprises a linear motor, at least one force enhancing hinging rod mechanism, at least one synchronous mechanism and at least one punching device, the punching machine utilizes the linear motor as a driving element, a middle conversion mechanism is omitted, the work efficiency is high, the length effect of the constant force enhancing lever and the angle effect among hinging rods are utilized for output force amplification, and the punching machine is applicable to occasions requiring the punching head output force amplification.

Owner:SUZHOU POLYTECHNIC INST OF AGRI

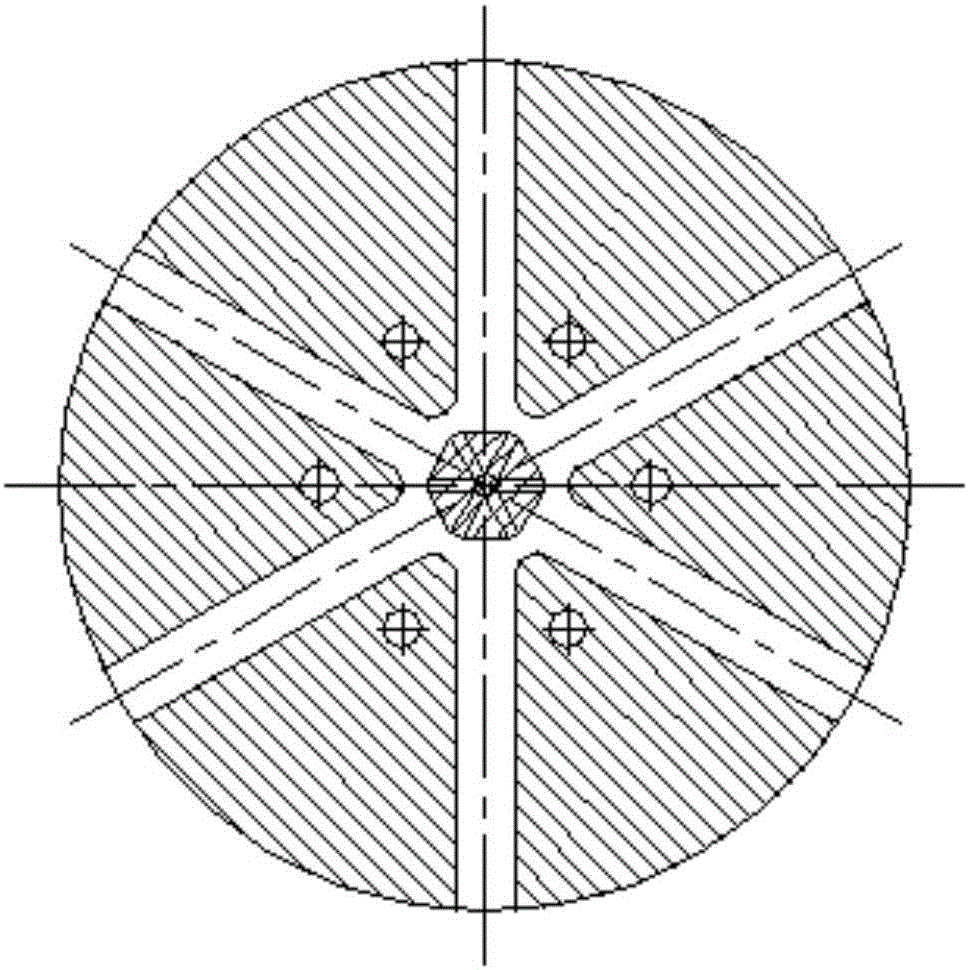

Radial orientation forming method of short fiber in tire tread rubber

The invention discloses a radial orientation forming method of short fiber in tire tread rubber. A device for achieving the radial orientation forming method of the short fiber in the tire tread rubber comprises an inlet section, a transition section, a flow distributing section and a shaping section. A cylindrical flow channel in the flow distributing section is deformed at 90 degrees, a flow distributing column is arranged at center of the deformed flow channel in the flow distributing section, and the cross section of the flow distributing column is a hexagon. The tail end of the flow distributing column is connected with the shaping section. The shaping section is composed of an upper shaping plate, a lower shaping plate and an inter-plate mold cavity. A flow channel in the shaping section starts from the center, rubber materials are extruded along six equal-cross-section flow channels, and flow channel openings are opposite to the edges of the hexagon. The cross section area of the flow distributing column is one second that of a cylindrical structure. A pre-vulcanizing device which partitions the tire pattern tread is arranged outside the shaping section in a matched manner. The device for achieving the radial orientation forming method of the short fiber in the tire tread rubber solves the technological problem that in the prior art, when the short fiber rubber materials are vulcanized in a tire segmented mold, the movement direction of the short fiber changes, and then the orientation degree is lowered; and the radial orientation degree of the fiber-reinforced tread rubber is improved, and the novel radial orientation forming method of the short fiber is put forward.

Owner:青岛国程中嘉高新科技开发有限公司

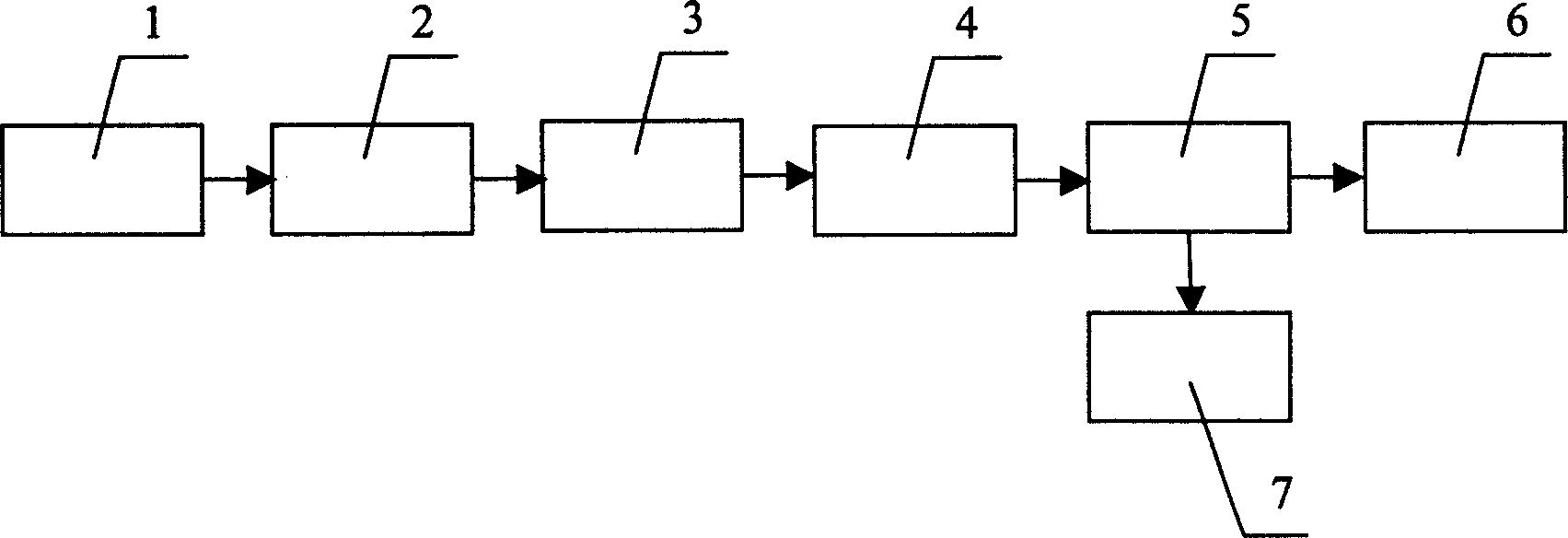

Natural fiber granulating process for preparing composite materials

The invention discloses a natural fiber granulating process for preparing composite materials. The natural fiber granulating process comprises steps as follows: (1) opening natural fibers and low-melting fibers and mixing the natural fibers with the low-melting fibers in mass ratio of 95 / 5-5 / 95 so as to obtain blend fibers, wherein the melting point of the low-melting fiber is lower than 200 DEG C; (2), carding and drawing the blend fibers obtained from the step (1) to form natural fiber tops; (3) simultaneously heating and twisting the natural fiber tops obtained from the step (2), obtaining natural fiber formed tops by cooling and forming, and finally obtaining natural fiber granules via cutting. After the natural fibers are granulated by aid of the process, granulated natural fibers are fed into an extrusion machine, and then problems of difficulty of feeding of the natural fibers and difficulty of dispersing fibers in resin when preparing natural fiber reinforced composite materials by adopting the extrusion molding are resolved.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

Flame alarm based on broad band gap semiconductor transducer

InactiveCN1544896AOvercome the disadvantages of needing DC high voltage power supplySolve potential safety hazardsSpectrum investigationFire alarmsSignal processing circuitsShock resistance

The invention is a broad band gap semiconductor sensor based flame alarm, composed of flame sensor, signal amplifying circuit, signal converting circuit, signal processing circuit, executing circuit, flame damper and acousto-optic alarm. Its character: the flame sensor is a broad band gap semiconductor sensor and has high-sensitivity output response only to the UV light in the flame whose wavelength is shorter than UVB and no response to sunlight and tungsten lamp, thus able to prevent other misalarms. It has simple structure, small bulk, low price, shock resistance, long service life, etc, and can be independently used and provide external communication port to compose system. It can meet different requirements of various fireproof occasions, especially applied to gas station, warehouse, and other places.

Owner:TONGJI UNIV

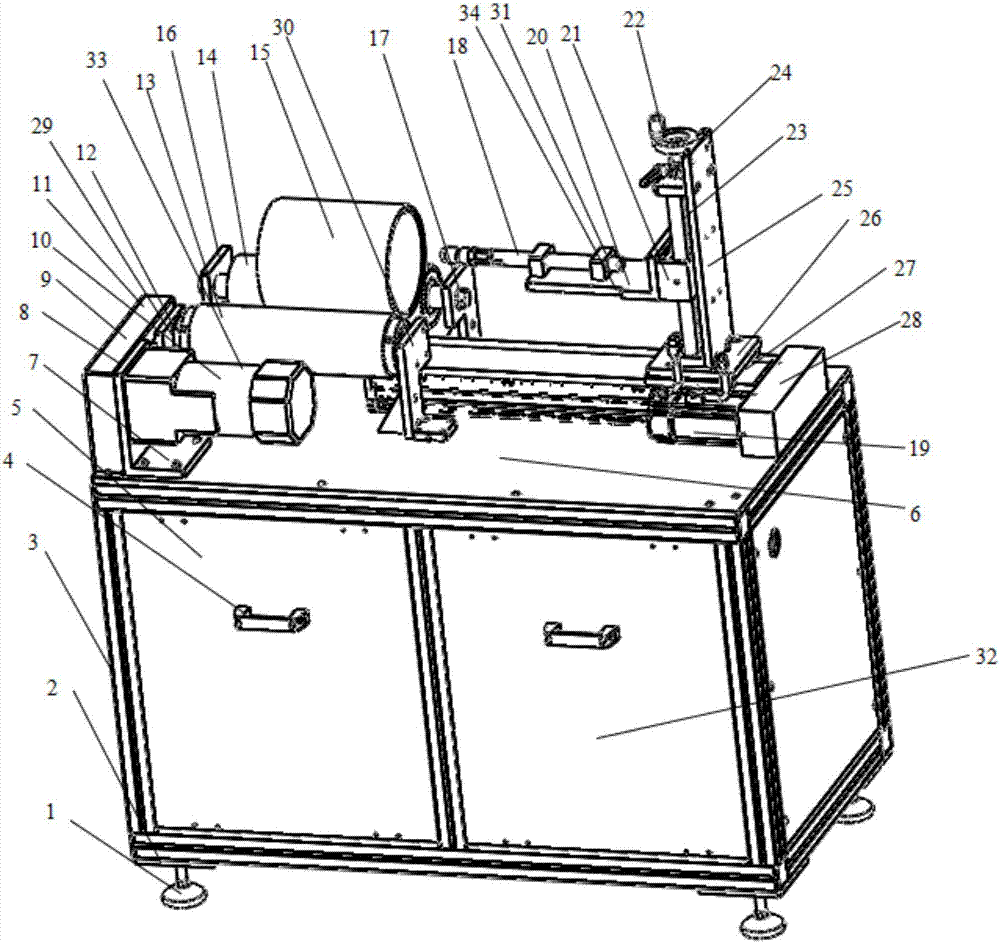

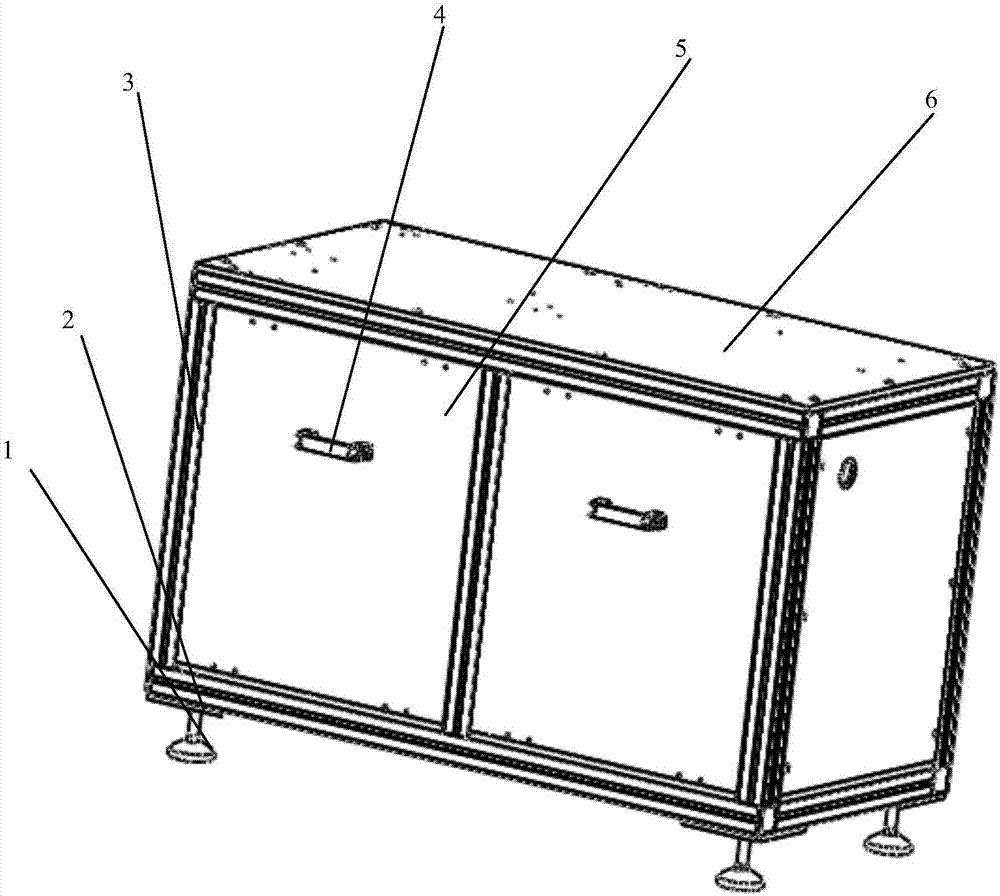

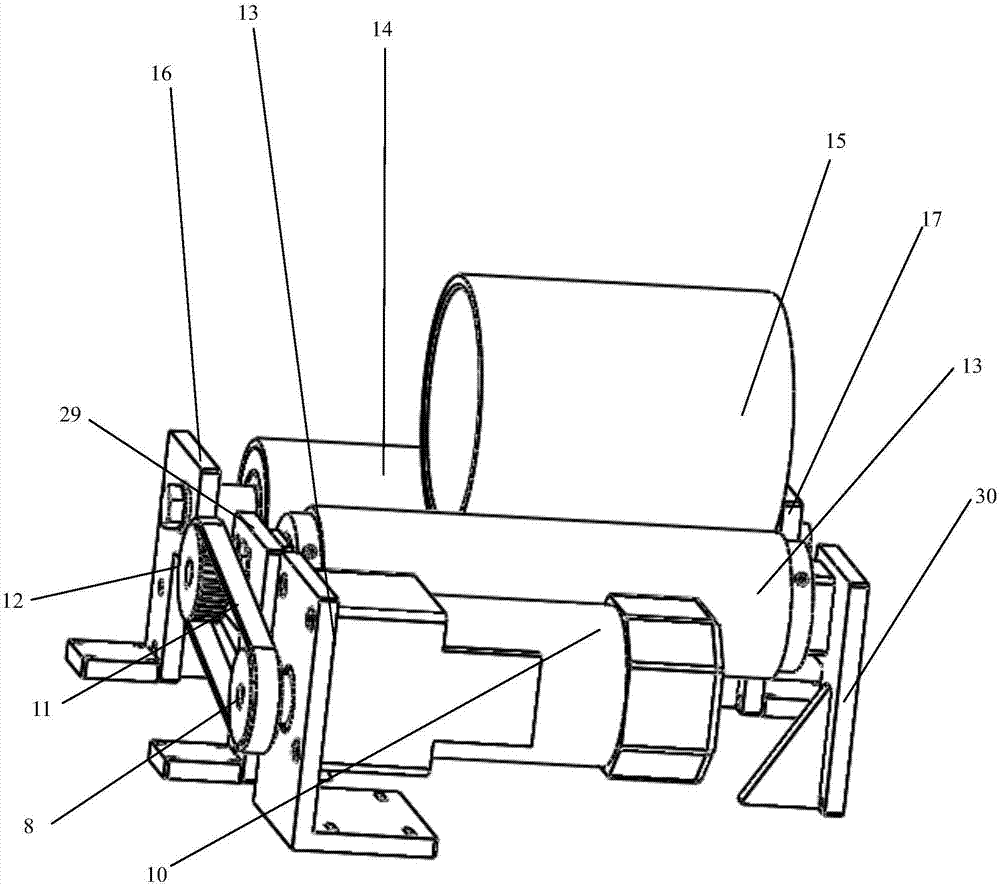

Spraying device for inner surfaces of pipe fittings

The invention discloses a spraying device for inner surfaces of pipe fittings, which belongs to the technical field of spraying devices. The device comprises a lower cabinet body, a pipe fitting speed adjusting mechanism and a spraying mechanism; the pipe fitting speed adjusting mechanism and the spraying mechanism are located above the lower cabinet body; the pipe fitting speed adjusting mechanism comprises an electric motor mounting plate, a first drive device, a driving belt wheel, a synchronous belt, a driven belt wheel, a driving roller, a workpiece and a driven roller; and the spraying mechanism comprises an electric cylinder, a sliding block, a bottom plate, a lifting rack, a lead screw, a hand wheel, a slide bearing and a spray gun. Rotation of the workpiece is realized by using the pipe fitting speed adjusting mechanism, continuous and uniform spraying of an inner pipe surface of the workpiece is finished by the spraying mechanism, and the pipe fittings of various models can be machined by collaboration and coordination of the pipe fitting speed adjusting mechanism and the spraying mechanism. The spraying device can effectively reduce dependency on manual operation and is high in spraying quality, and meanwhile, the device is simple and light in structure, higher in efficiency and precision and lower in cost, and meets multiple machining requirements.

Owner:芜湖威发电子科技有限公司

Bio-contact oxidation filter sedimentation tank

ActiveCN105668792ASave landReduce energy consumptionBiological treatment apparatusTreatment with aerobic and anaerobic processesAeration systemSludge

The invention relates to a bio-contact oxidation filter sedimentation tank which mainly comprises a tank body, a filter system, a water collection system, an aeration system and other facilities, wherein the common bio-contact oxidation tank, aeration tank, sedimentation tank and filter tank in sewage treatment are organically combined. The sewage is subjected to biochemical degradation and filter sedimentation in the facilities and then enters next process or is discharged after reaching the standard; and the settled sludge flows back or is removed. Through the invention, the treatment efficiency of the sewage treatment facilities can be improved, the energy consumption is lowered, and the investment and operation cost are reduced.

Owner:SUZHOU ANFENG ENVIRONMENT PROTECTION TECH CO LTD

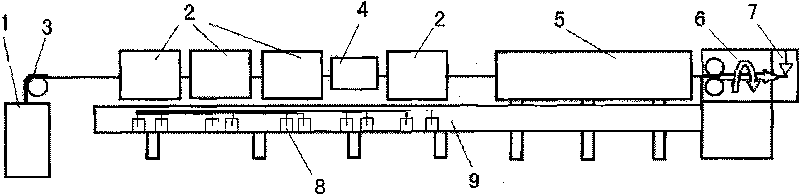

Natural-fiber composite material pelletizer

The invention relates to a natural-fiber composite material pelletizer which comprises a material barrel and more than one heating unit, wherein the material barrel is connected with the first heating unit by a material feeding rack; after the first heating unit is connected with other heating units in series via a transmission belt, the last heating unit is connected with a molding unit via the transmission belt; the output end of the molding unit is connected with another heating unit, a cooling unit, a twisting unit and a material cutting unit in series in an orderly manner via the transmission belt; the bottoms of each heating unit and the molding unit are respectively provided with a pneumatic plant; and each heating unit, the molding unit, the cooling unit, the twisting unit and the material cutting unit are arranged on a frame and controlled by a control unit. As more than one heating unit and one molding unit are used for heating and molding natural-fiber composite strips, the invention solves the problems of difficult material feeding during extrusion molding and difficult dispersion in resin. The invention can be widely used for pelletization in various natural-fiber composite material fields.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

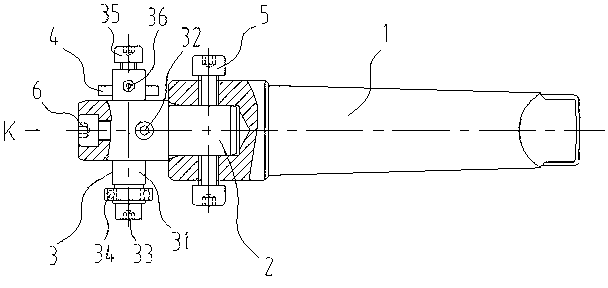

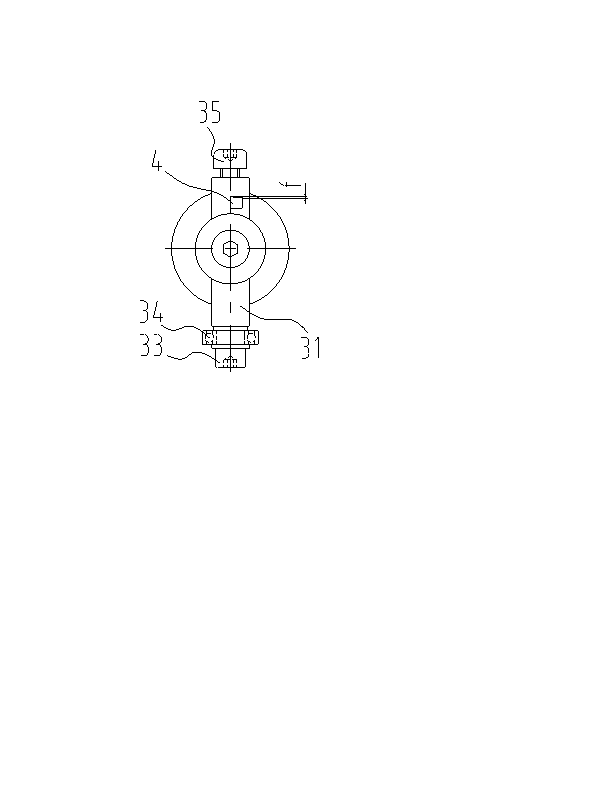

Cutter for processing valve seat seal groove

InactiveCN103231103AReduce processSimple structureMilling cuttersMilling equipment detailsEngineeringValve seat

The invention discloses a cutter for processing a valve seat seal groove. The valve seat seal groove comprises a cutter handle (1), a cutter head (2), a cutter rod (3) and a cutter blade (4). One end of the cutter head (2) is connected to the cutter handle (1). The cutter rod (3) is connected to the cutter head (2). The cutter blade (4) is connected to the cutter rod (3). The cutter has a simple structure, avoids a center correction process, and has a high processing precision. Parts processed by the cutter have good size uniformity. The cutter improves processing efficiency by 2-6 times.

Owner:LIUYANG FY HYDRAULIC CYLINDER

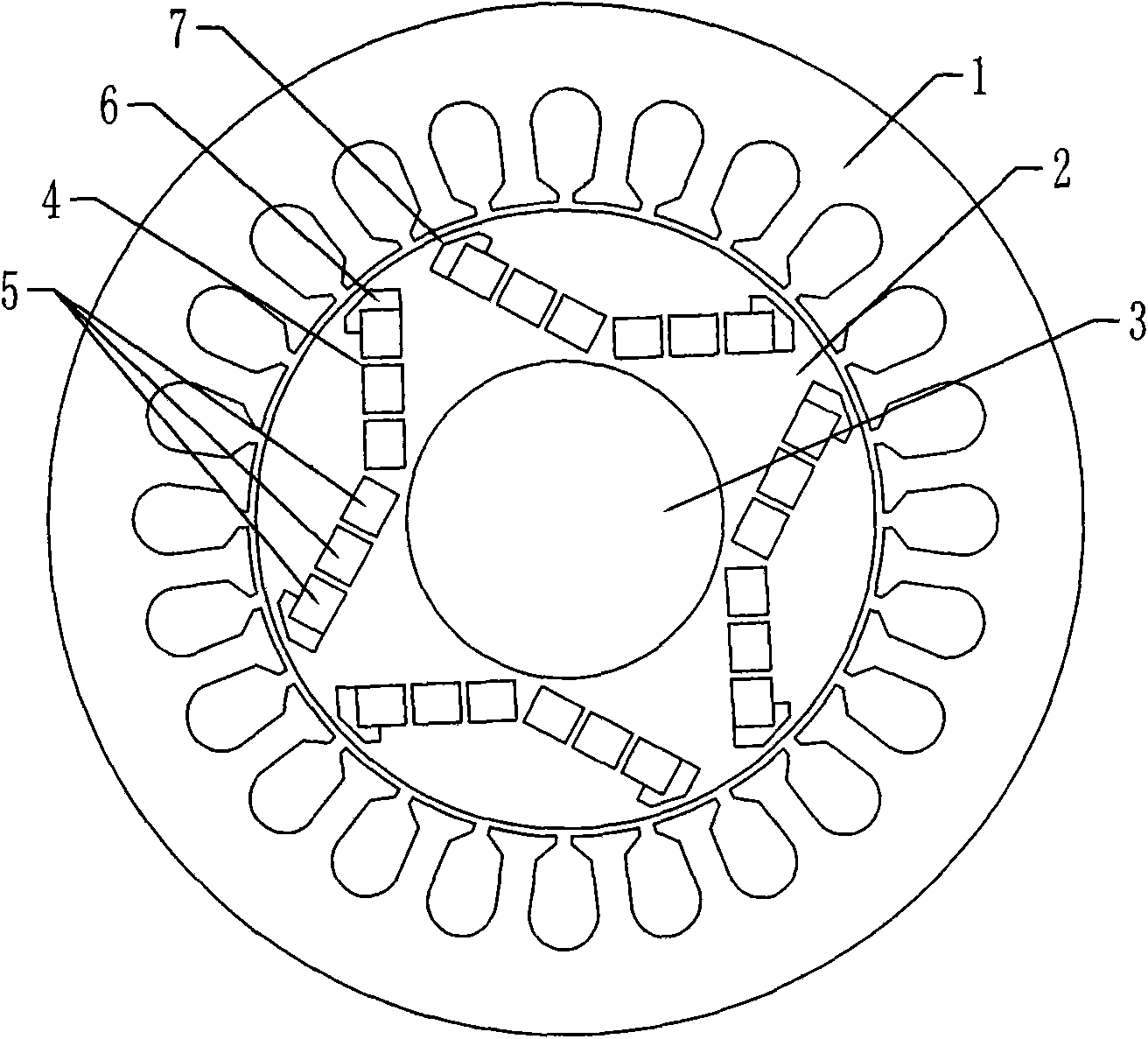

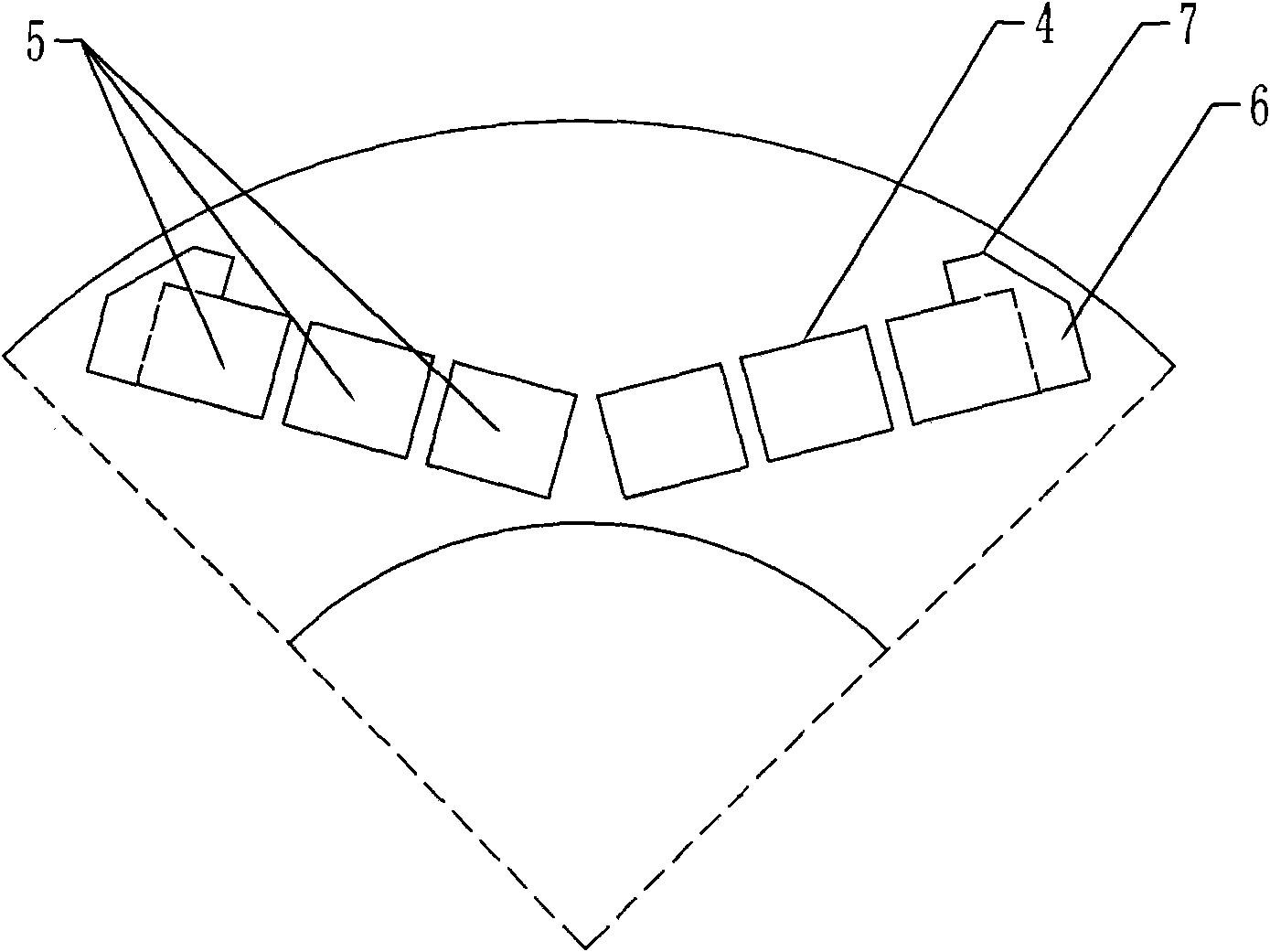

Large-powder low-torque pulsation permanent magnet synchronous motor for electro-spindle

InactiveCN101527485ASmall field-weakening speed rangeMeet different processing requirementsSynchronous machine detailsPermanent magnet synchronous motorMoment of inertia

A large-powder low-torque pulsation permanent magnet synchronous motor for an electro-spindle is disclosed, relating to the field of motor and solving the problems of complex structure of the motor, low efficiency of the motor, inferior heat dissipation condition, large rotational inertia, poor dynamic property, low processing precision, low efficiency, low powder density, large volume of the motor and low control precision. A permanent magnet of the invention is a segmented permanent magnet set composed of 2n permanent magnets having rectangular cross sections; an end face of a rotor core is divided averagely into 2P areas, each of which is provided, in an axial direction, with 2n pores having the rectangular cross sections; along a circle center line of the end face of the rotor core, the pores are symmetrically arrayed in a V or W shape, an opening of which faces the outer edge of the rotor core; the permanent magnets are embedded in the pores; the width of a magnetic bridge is 0.5-L / 2mm; two sides of the outer edge of the pores arrayed at the head and the tail of the V or W shape extend in the direction of the outer edge of the rotor core so as to form a magnetic isolation pore in which a non-magnetic conduction material is filled to form a magnetic isolation bridge. The invention weakens the vibration of the electro-spindle motor by virtue of the shape and the size of the magnetic isolation bridge.

Owner:HARBIN INST OF TECH

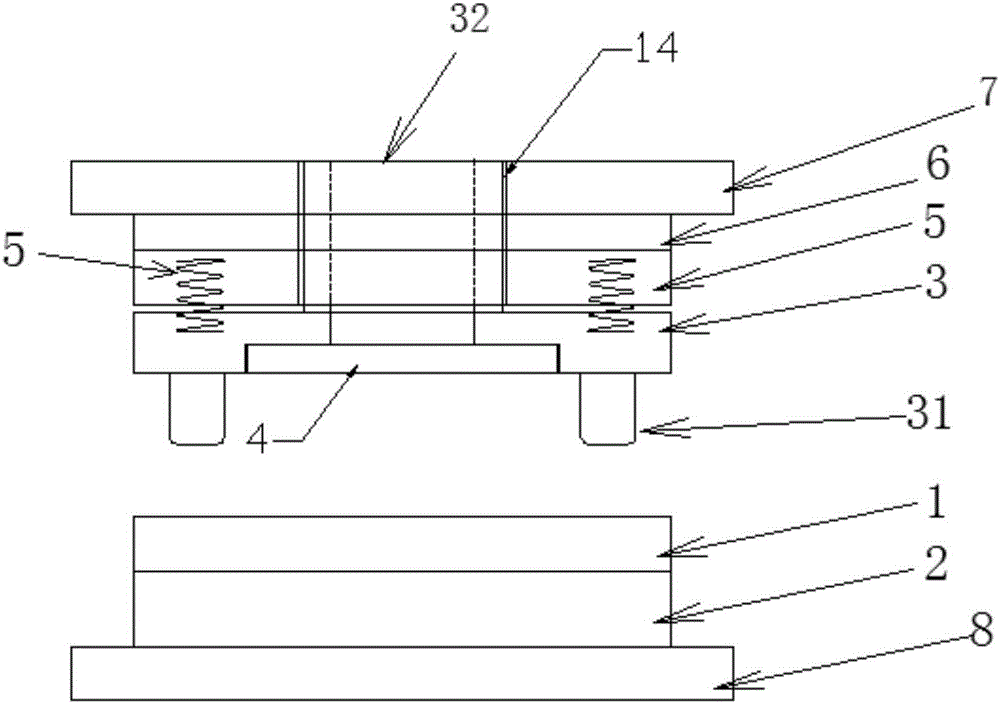

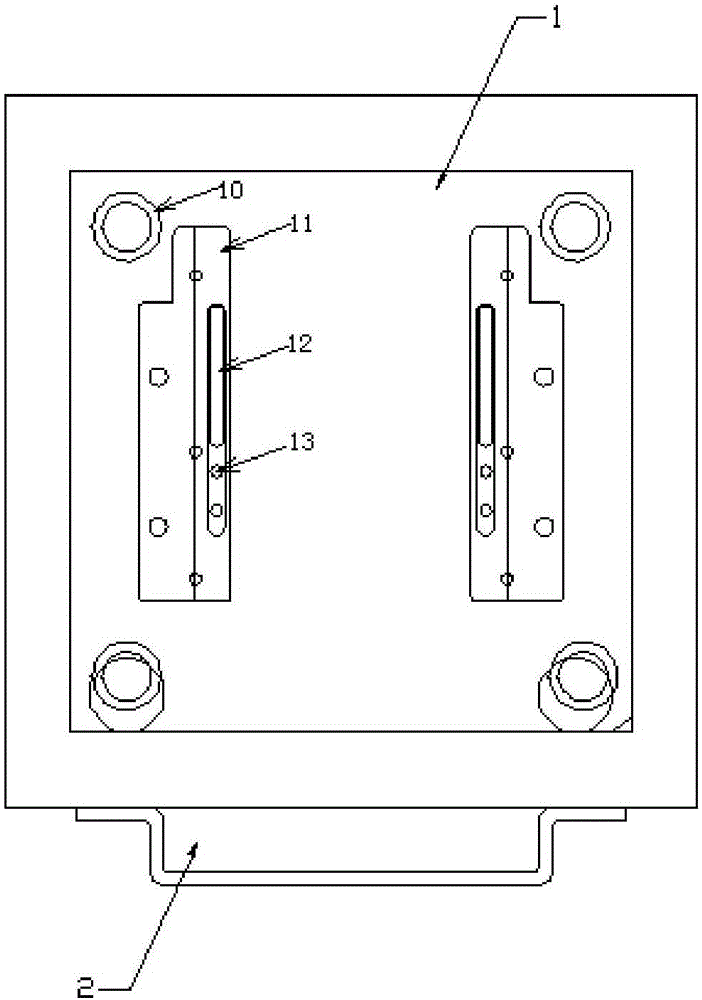

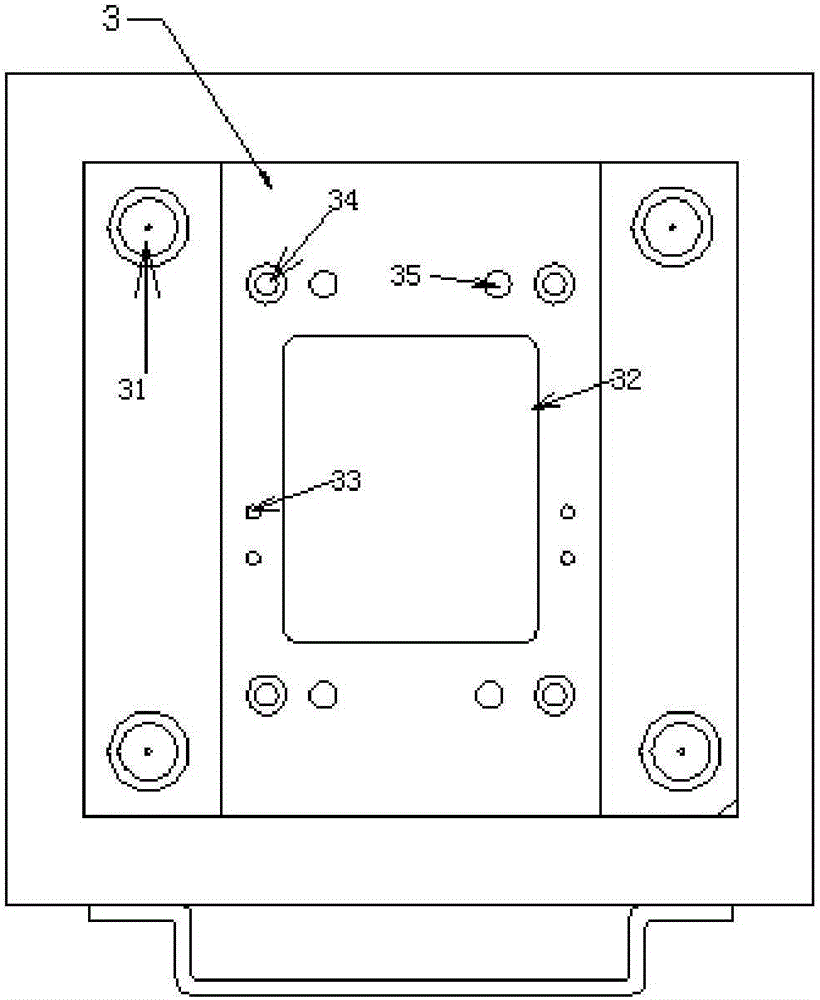

Waste-sucking hardware die holder universal for die cutting

InactiveCN106270115AReduce the number of replacementsLow input costStripping-off devicesEjection devicesEngravingElectrical and Electronics engineering

The invention provides a waste-sucking hardware die holder universal for die cutting. The waste-sucking hardware die holder comprises a female die, a stripper plate and a waste-sucking engraving die; a die containing cavity concaved inwards is formed in the bottom of the stripper plate, the waste-sucking engraving die is arranged in the die containing cavity, punches and FPD locating columns are arranged in the die containing cavity of the stripper plate, and guide columns are arranged at the bottom of the stripper plate; and the top of the stripper plate is connected to an upper die frame plate through springs, the upper die frame plate is provided with a discharging groove penetrating through the die containing cavity of the stripper plate, and the punches are located on the side edges of the discharging groove. According to the waste-sucking hardware die holder, automatic waste suction can be realized, and the frequency of replacing dies can be reduced; and because the waste-sucking engraving die and the stripper plate are detachably connected and a long hole type contact pin avoiding hole is formed in the female die, when different products are processed and different positions of a contact pin are needed, the different processing requirements can be met by just replacing the waste-sucking engraving die, and then the time of replacing a whole set of dies can be greatly reduced for operators.

Owner:TIANJIN RIJIN TECH

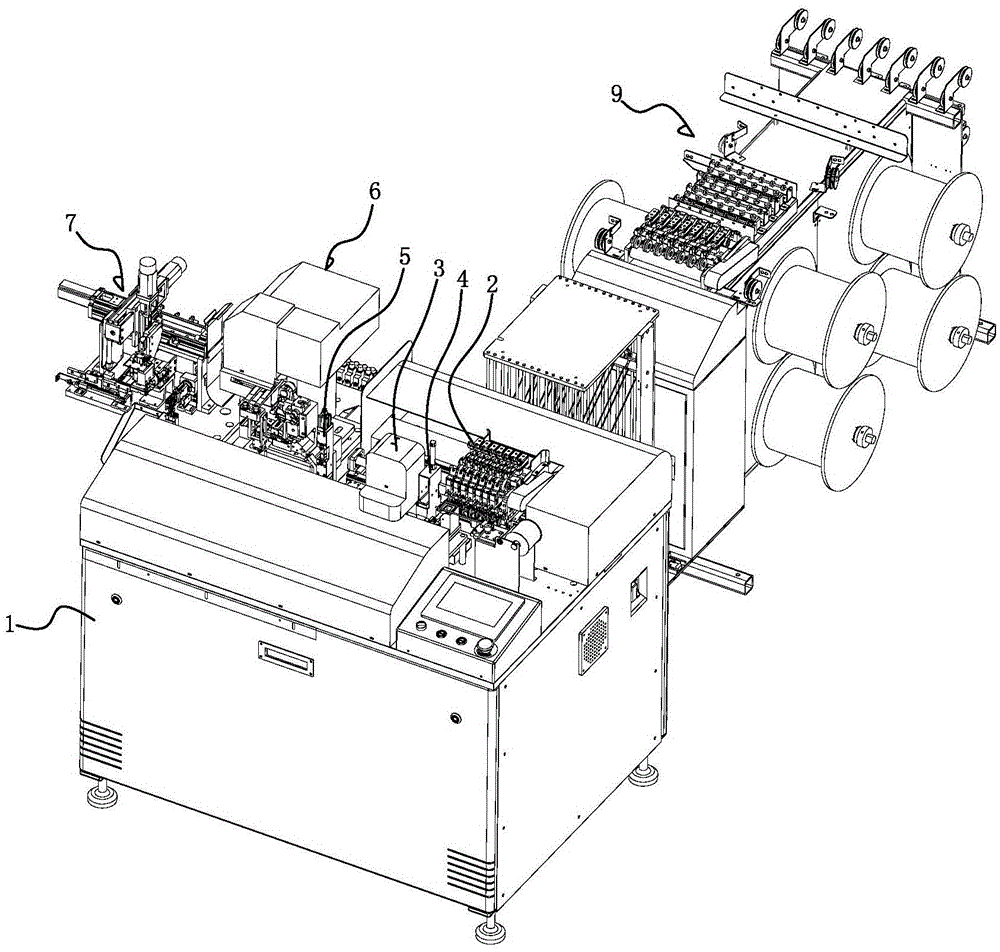

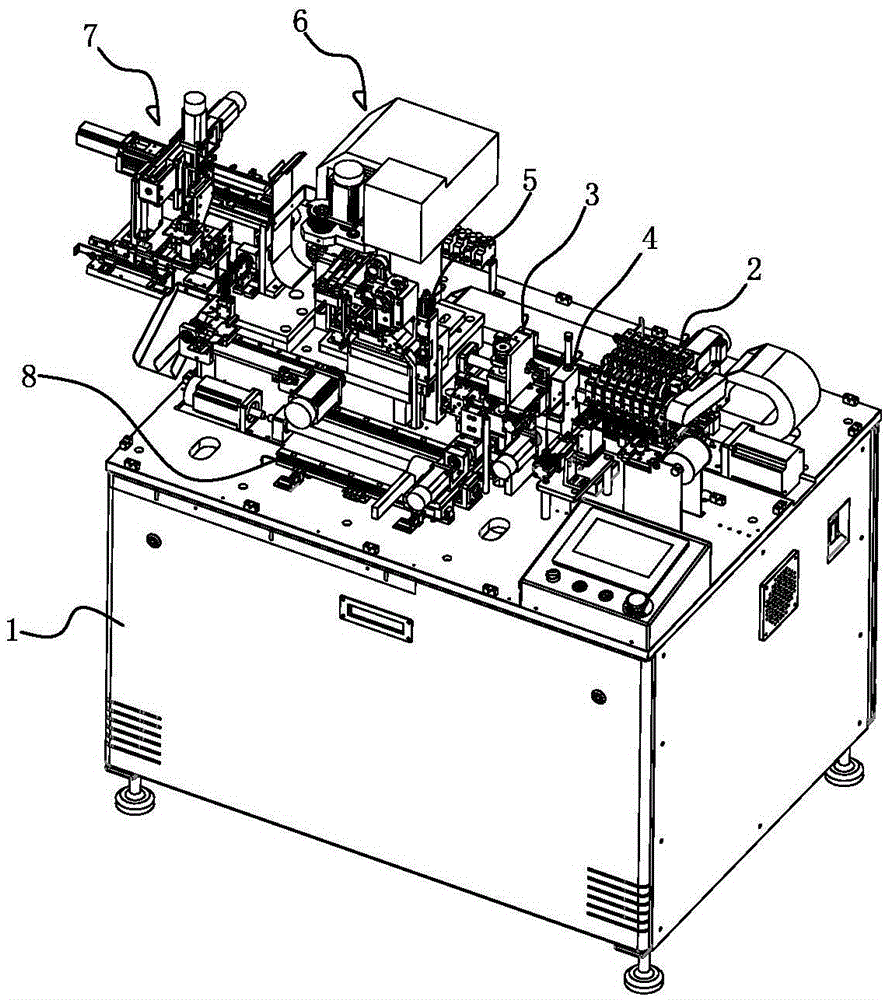

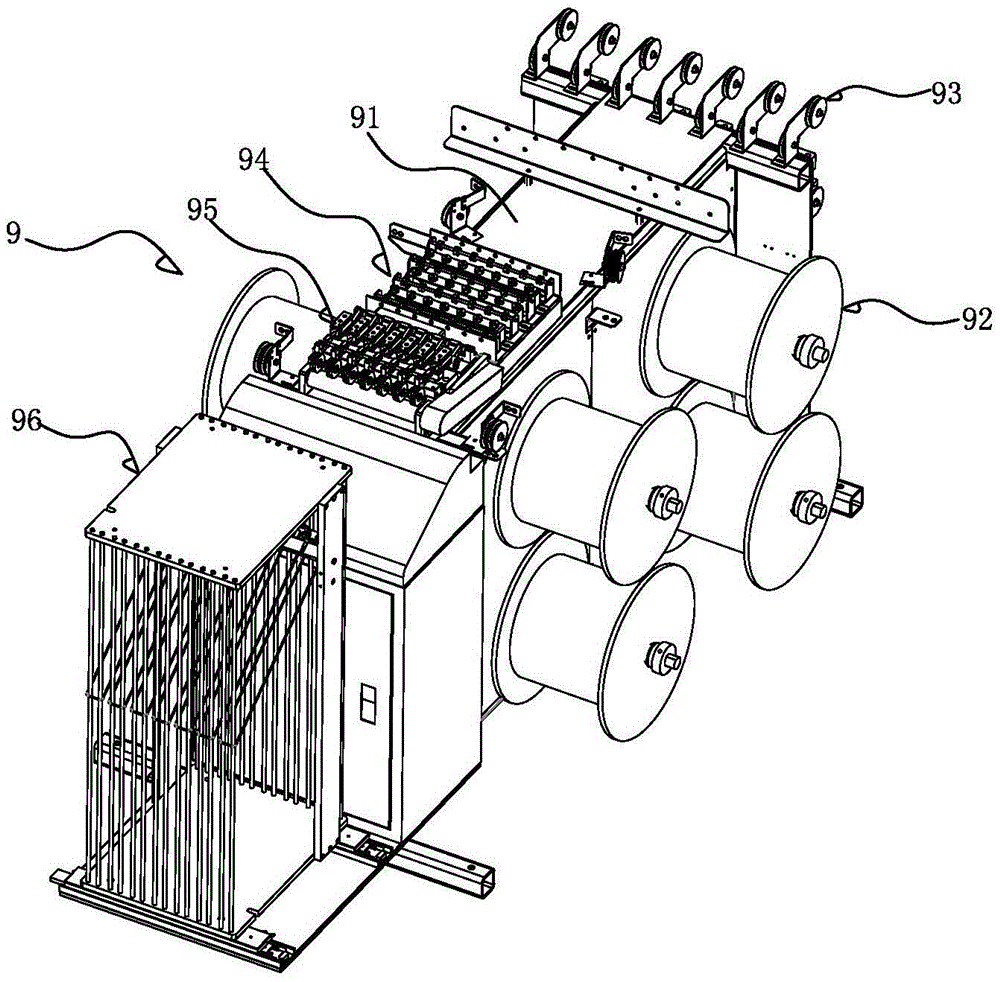

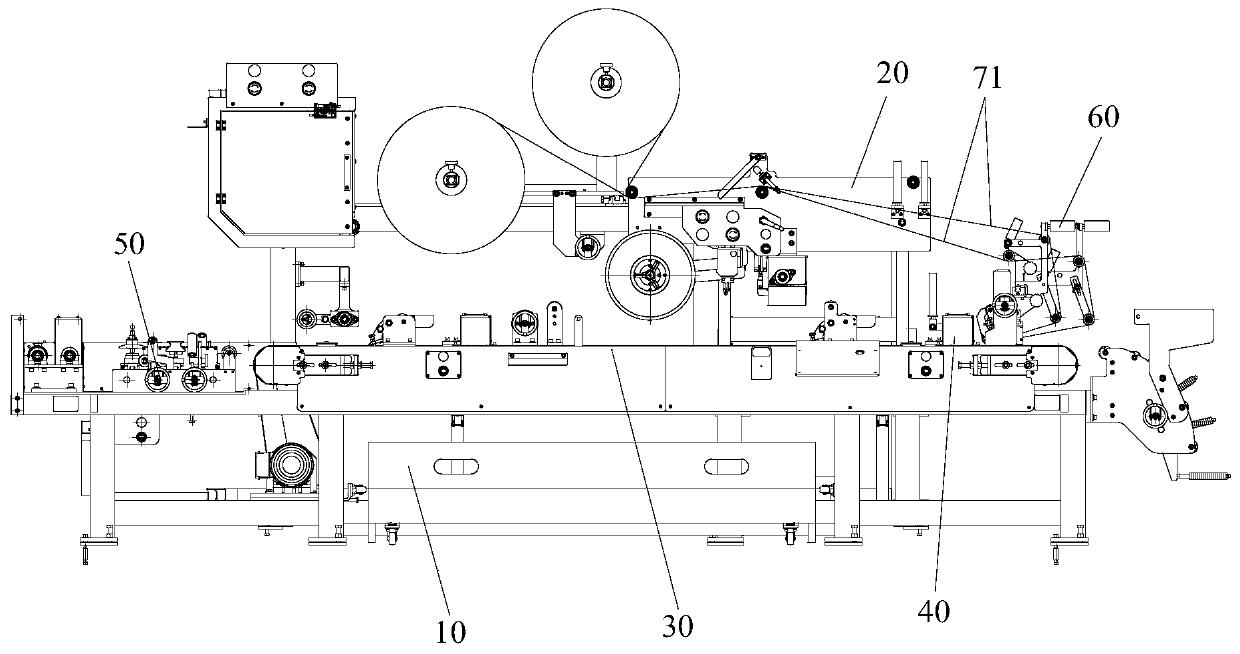

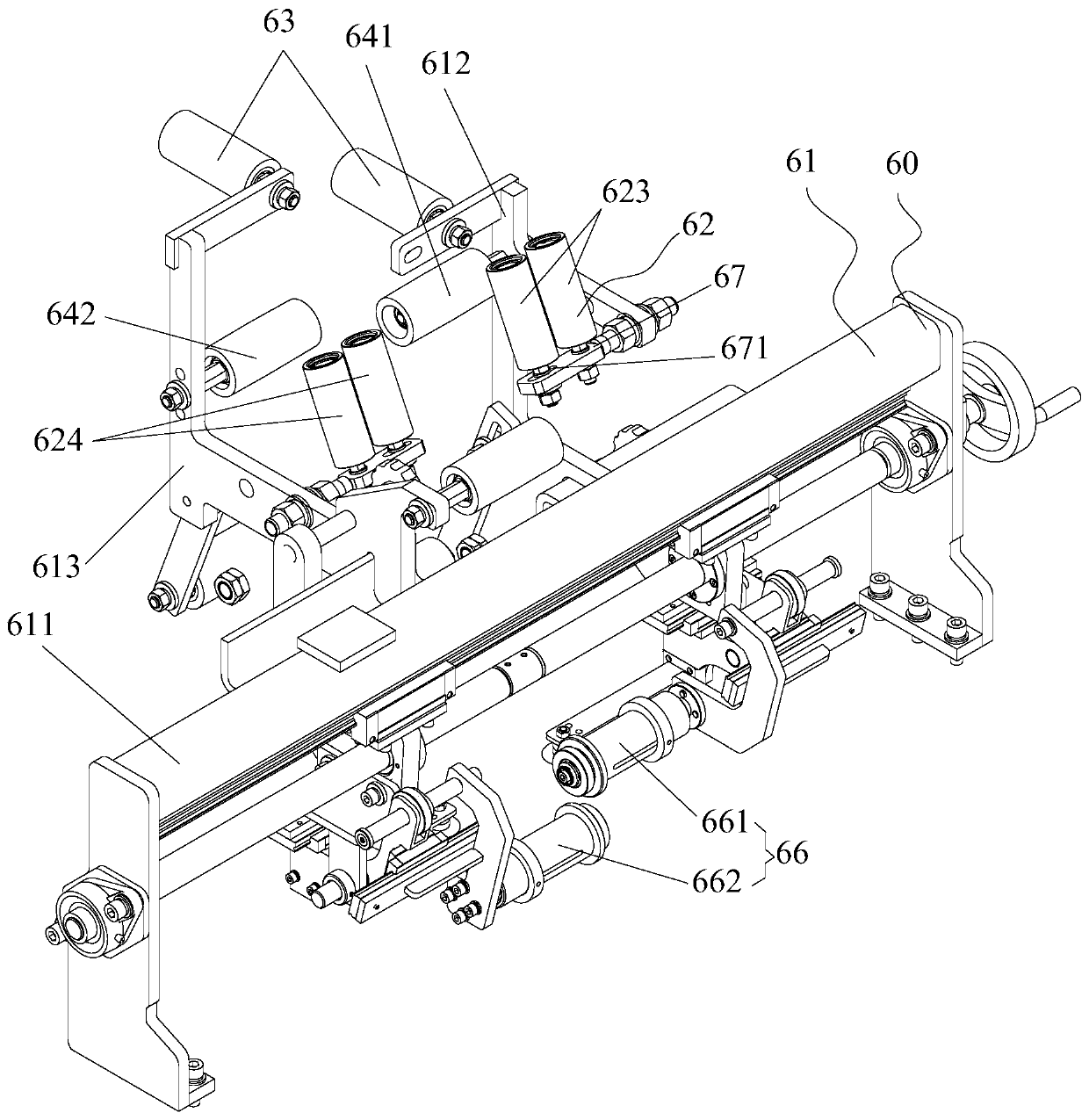

Terminal crimping and shell plugging device for full-automatic wire stripping terminal crimping and shell plugging machine

InactiveCN105655840AHigh degree of automationImprove working precisionContact member assembly/disassemblyConnection formation by deformationEngineeringAutomation

The invention discloses a terminal crimping and shell plugging device for a full-automatic wire stripping terminal crimping and shell plugging machine. The terminal crimping and shell plugging device comprises a terminal crimping device and a three-axis rubber shell plugging device, wherein the terminal crimping device comprises an terminal crimping mechanism and a dual-track translation feeding mechanism, wherein the terminal crimping mechanism is installed on a machine base of the full-automatic wire stripping terminal crimping and shell plugging machine, and the dual-track translation feeding mechanism is installed on the terminal crimping mechanism. The three-axis rubber shell plugging device is installed on the machine base and located on the side of the terminal crimping device. The dual-track translation feeding mechanism is located above the rear-end feeding device and comprises a first installation frame, a first track, a second track, sliding blocks, feeding arms and a motor assembly, wherein the first installation frame is installed on the terminal crimping mechanism, the first and second tracks are installed on the first installation frame, the sliding blocks are installed on the first and second tracks, the feeding arms are installed on the sliding blocks and vertically distributed, the motor assembly is installed on the first installation frame and used for driving the feeding arms to translate in the direction of the first track and the second track, and material clamps are arranged at the lower ends of the feeding arms. The terminal crimping and shell plugging device is high in automation degree, smooth in operation, high in working precision, high in efficiency and good in quality.

Owner:宗智辉

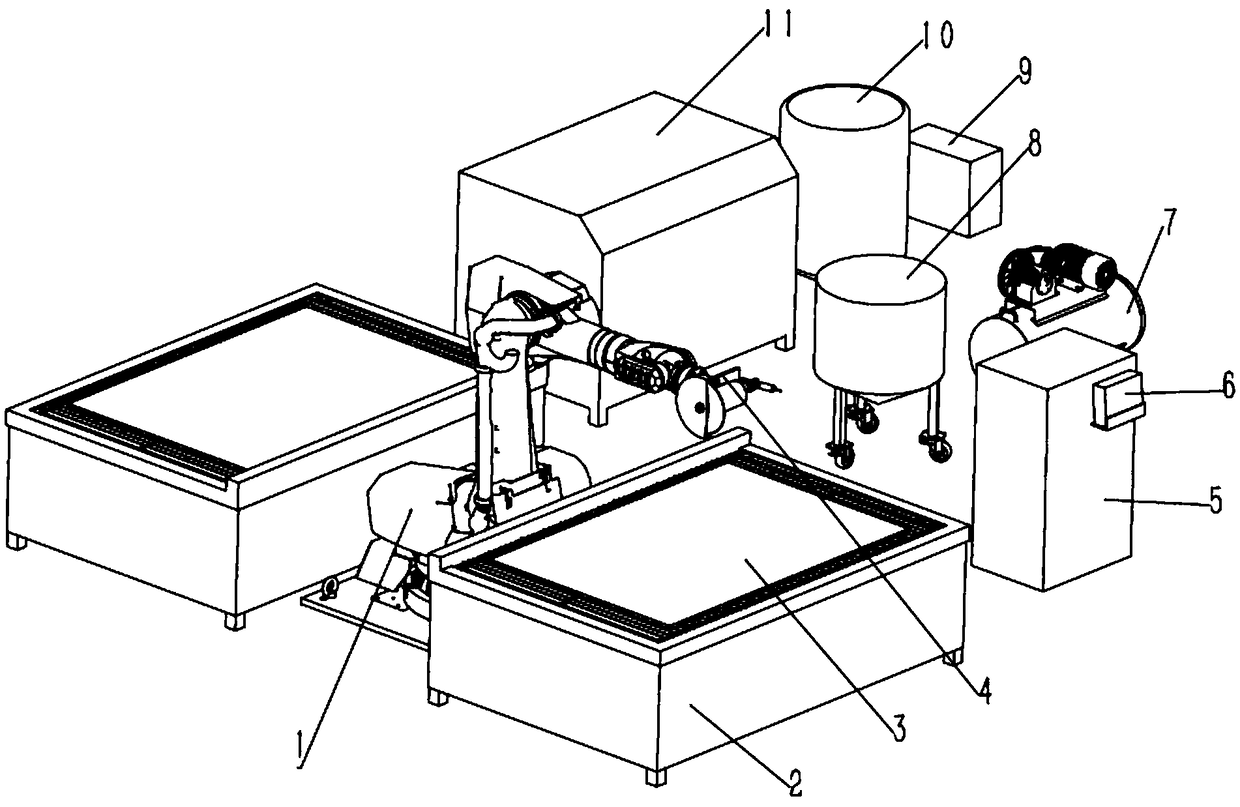

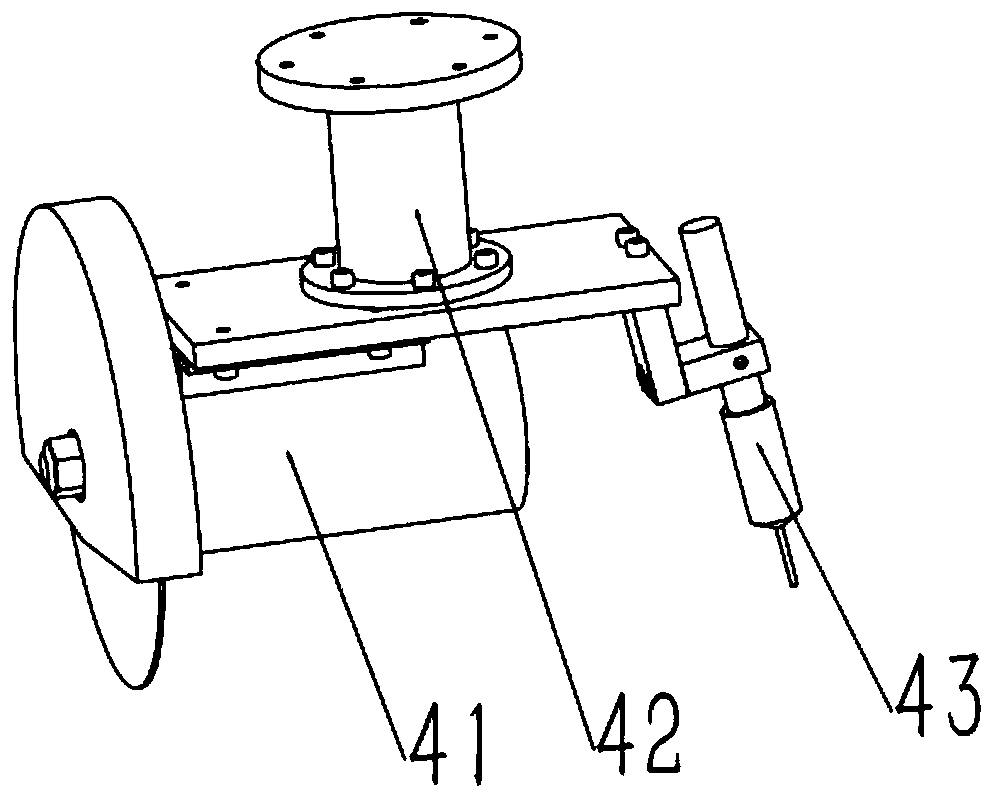

Stone combined machining robot system

PendingCN108943423AImprove cutting processing flexibilityCorrection of mechanical errorsAbrasive feedersWorking accessoriesRobotic systemsAgricultural engineering

The invention discloses a stone combined machining robot system. The stone combined machining robot system comprises a mechanical arm, a cutting platform, a double-station cutting device, an air pressing device, a water supply device, a supercharging device and a control device; the mechanical arm, the double-station cutting device, the air pressing device, the water supply device and the supercharging device are connected with the control device; the double-station cutting device comprises a cutter frame, a saw blade cutting mechanism and a water tool bit; the saw blade cutting mechanism andthe water tool bit are arranged at two ends of the cutter frame; the mechanical arm is detachably connected with the cutter frame; two ends of the water supply device are connected with the water toolbit and the water supply device; and the supercharging device is connected with the water tool bit. The stone combined machining robot system can realize combined machining of simple straight lines and complex curved lines of stones, is precise and stable in machining process, realizes automatic and efficient machining, and reduces the labor cost.

Owner:云浮中科石材创新科技有限公司 +1

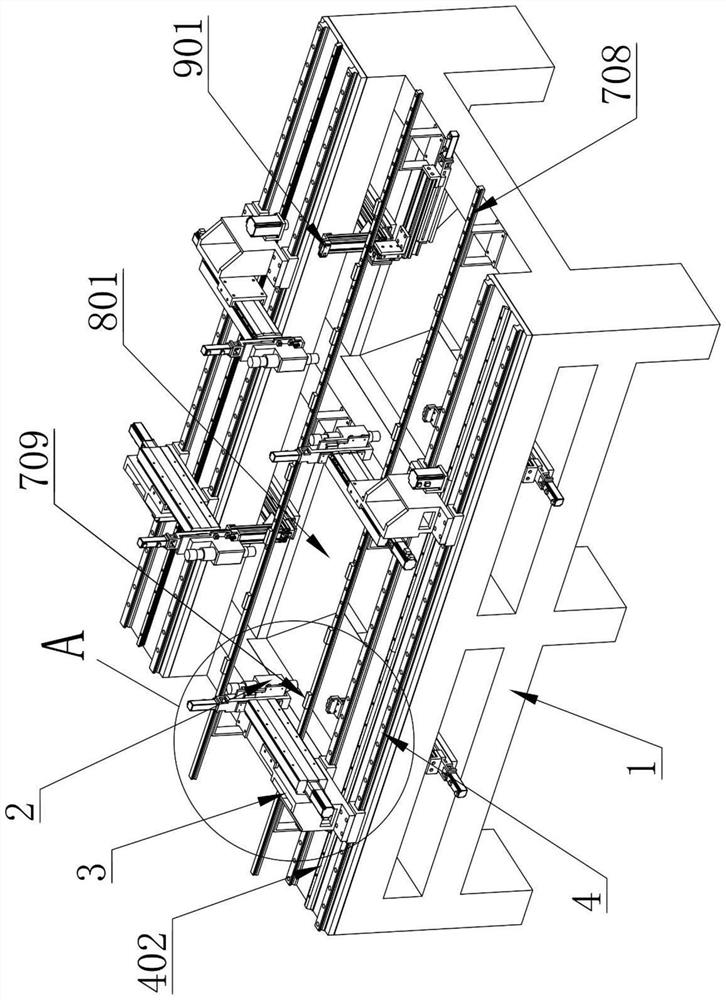

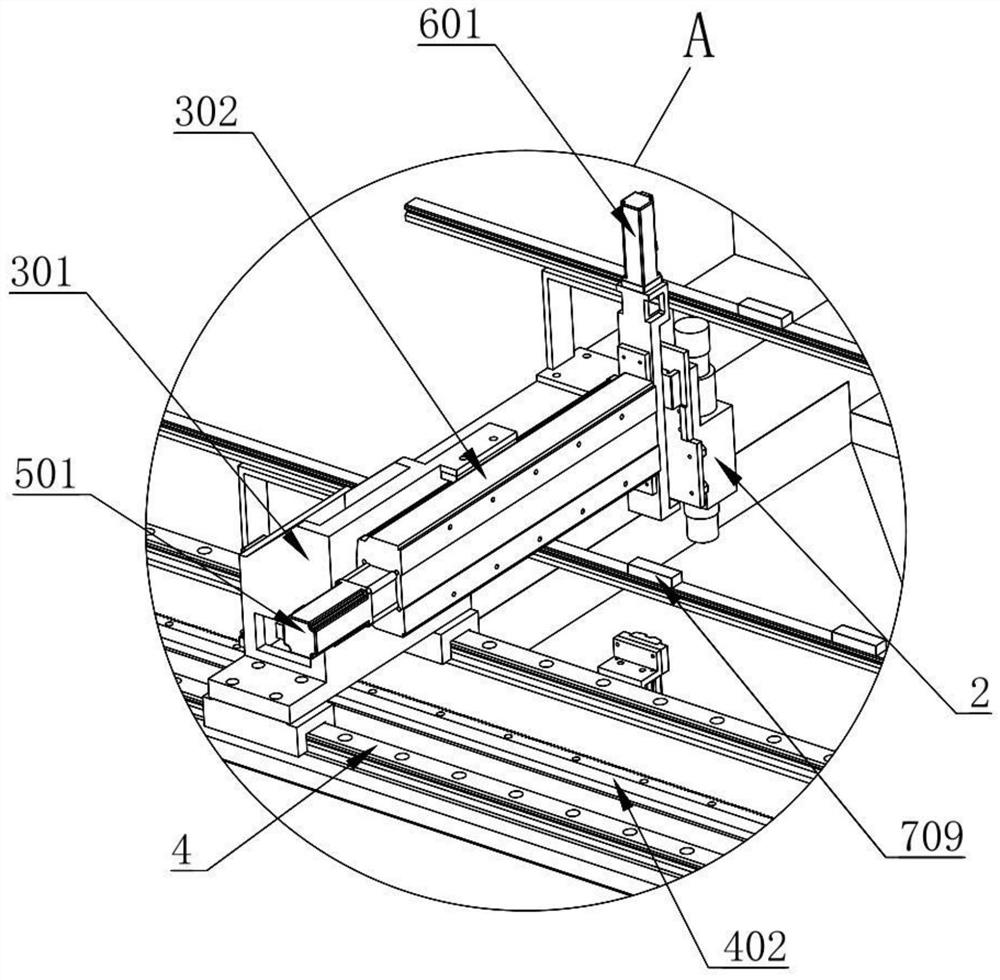

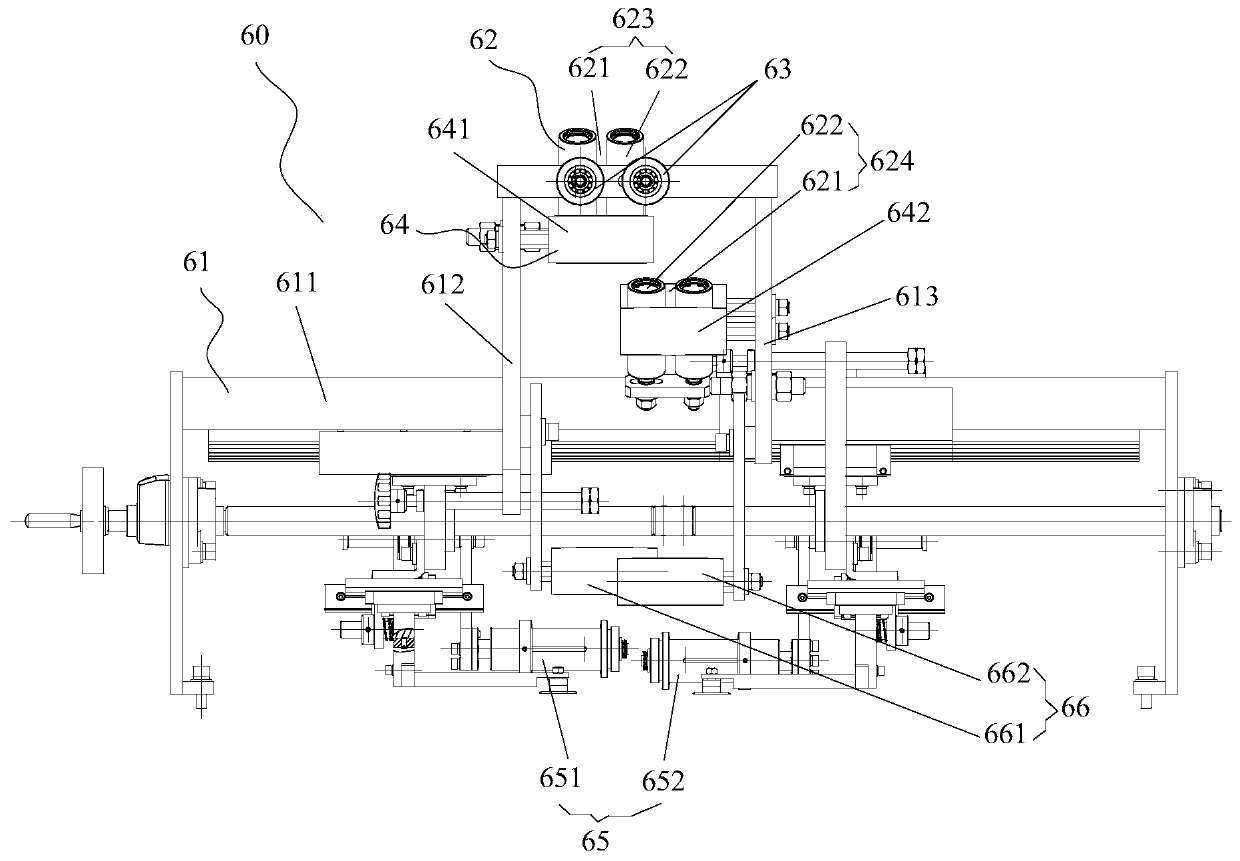

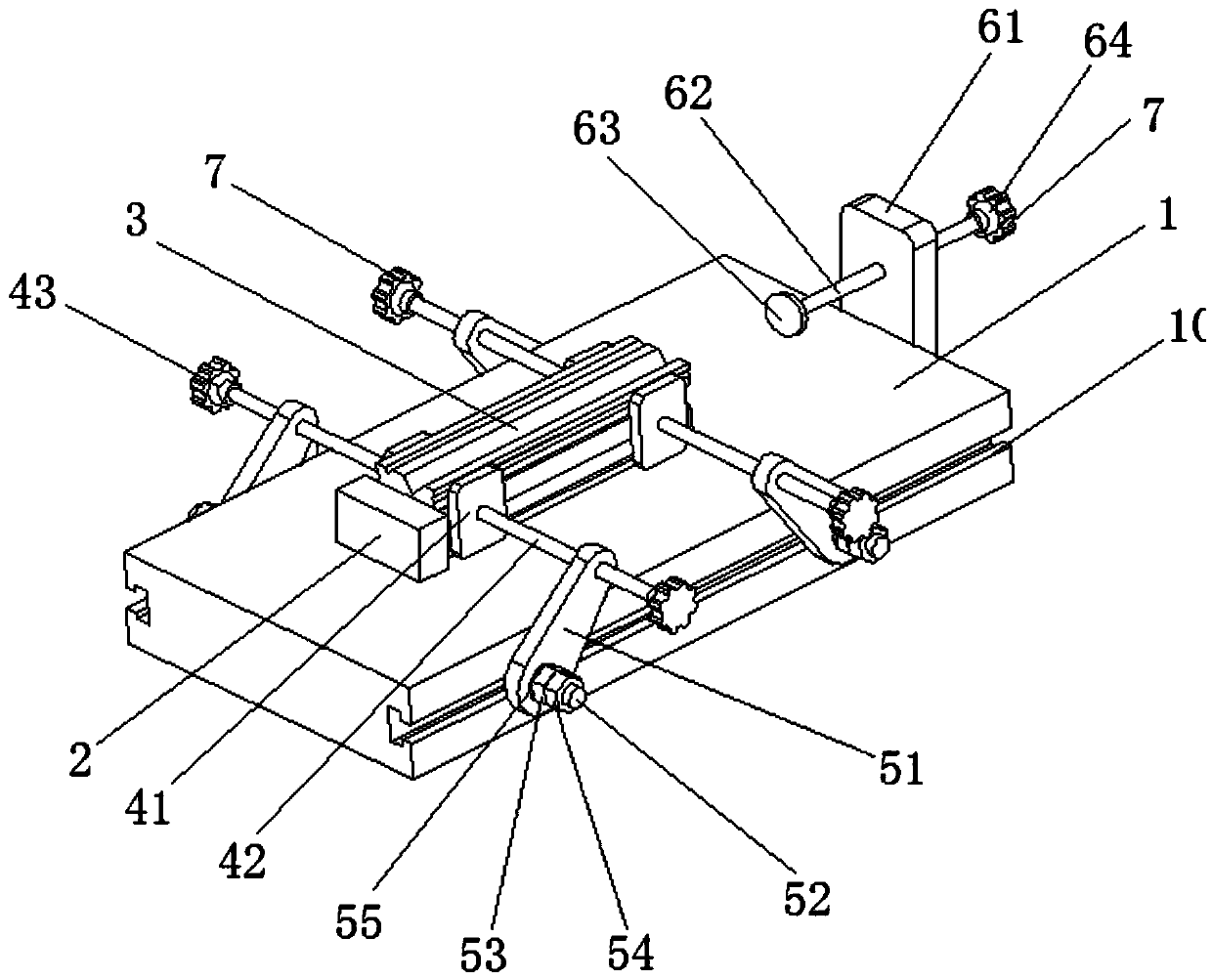

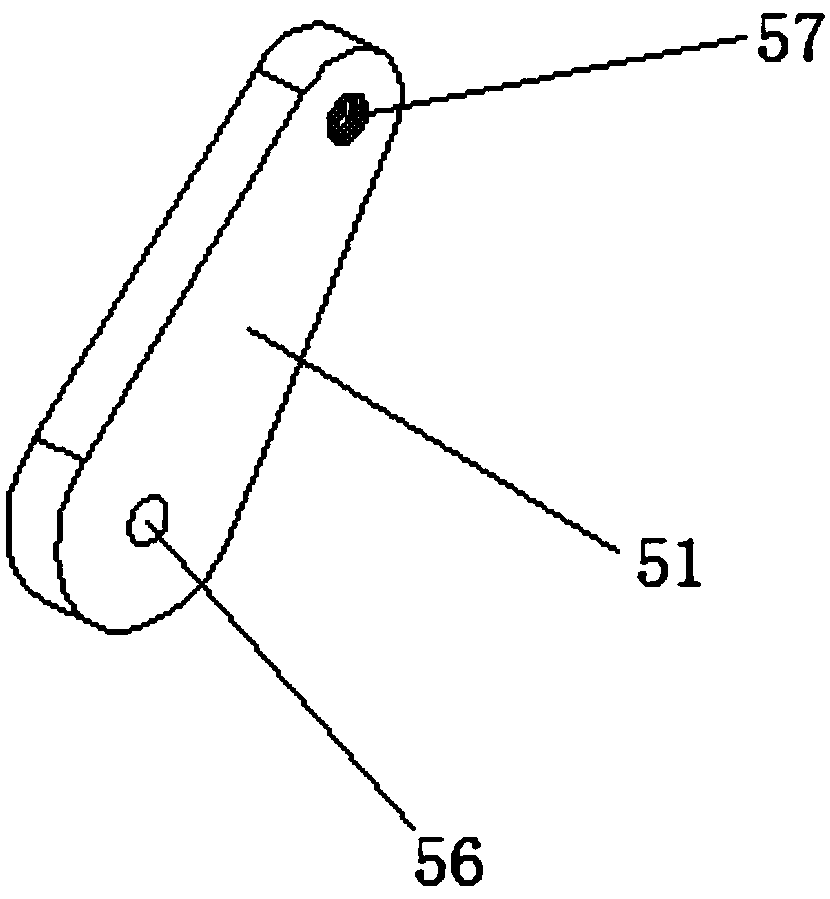

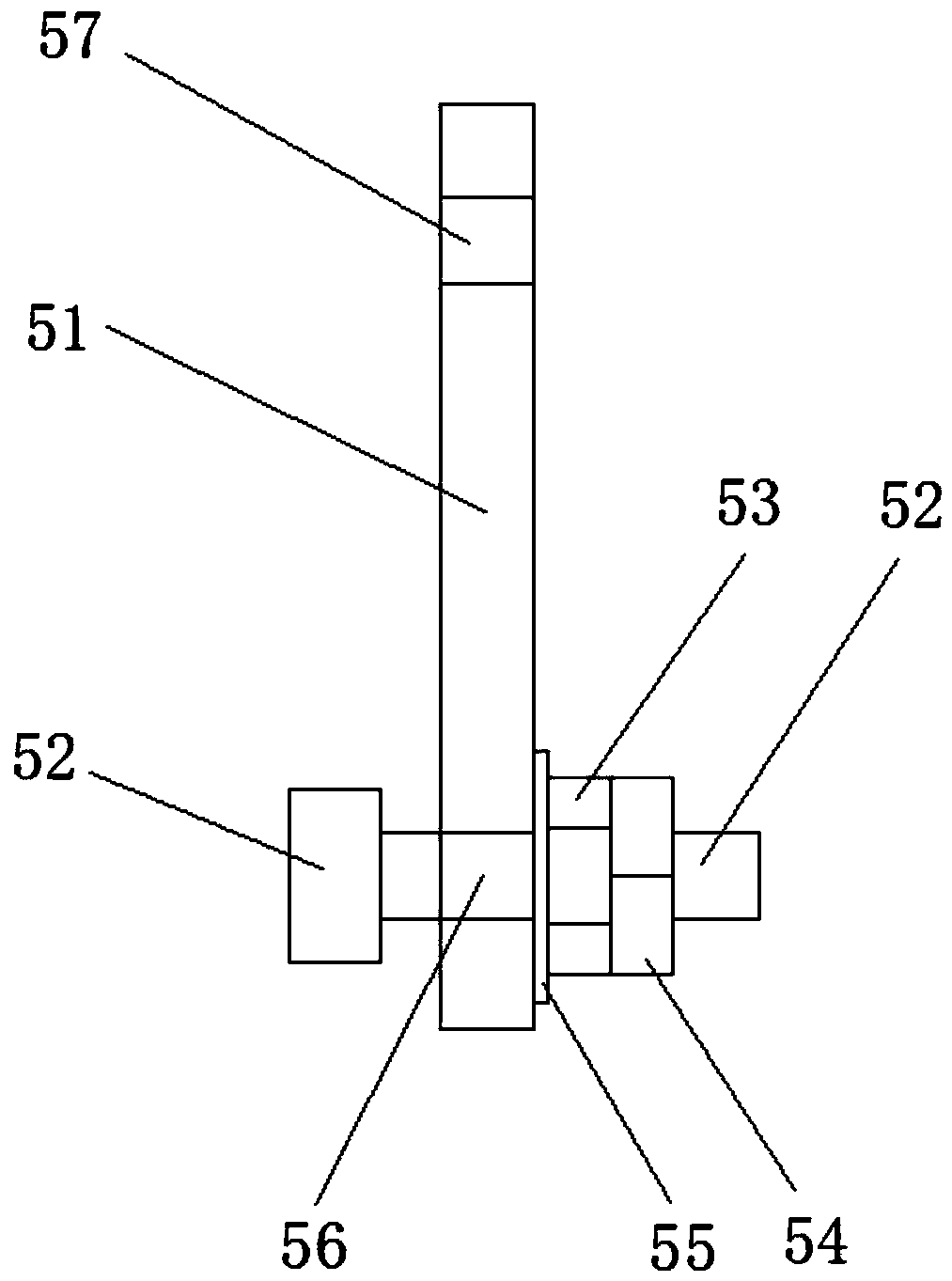

Multi-station full-automatic laser cutting machine

PendingCN112809200APrecise positioningAchieve recyclingWelding/cutting auxillary devicesAuxillary welding devicesControl engineeringProcess engineering

The invention provides a multi-station full-automatic laser cutting machine which comprises a support. The support is provided with a feeding mechanism, laser cutting devices and a driving mechanism for driving the laser cutting devices to move; the driving mechanism comprises a sliding frame assembly installed on the support in a sliding mode; the support is provided with a sliding rail corresponding to the sliding frame assembly; the sliding frame assembly comprises a first sliding frame and a second sliding frame which can slide relatively; and the laser cutting device is arranged on the second sliding frame in a lifting mode through the driving mechanism. When the multi-station full-automatic laser cutting machine is used, the laser cutting devices move to machining positions through the driving mechanism to conduct laser cutting. According to the multi-station full-automatic laser cutting machine provided by the invention, the first sliding frame and the second sliding frame are arranged, so that the laser cutting devices can move in different directions and can quickly and flexibly move to the machining positions; and the multiple laser cutting devices are arranged, so that machining can be conducted at the same time, different machining requirements are met, and the production efficiency is improved.

Owner:SIMTO GROUP

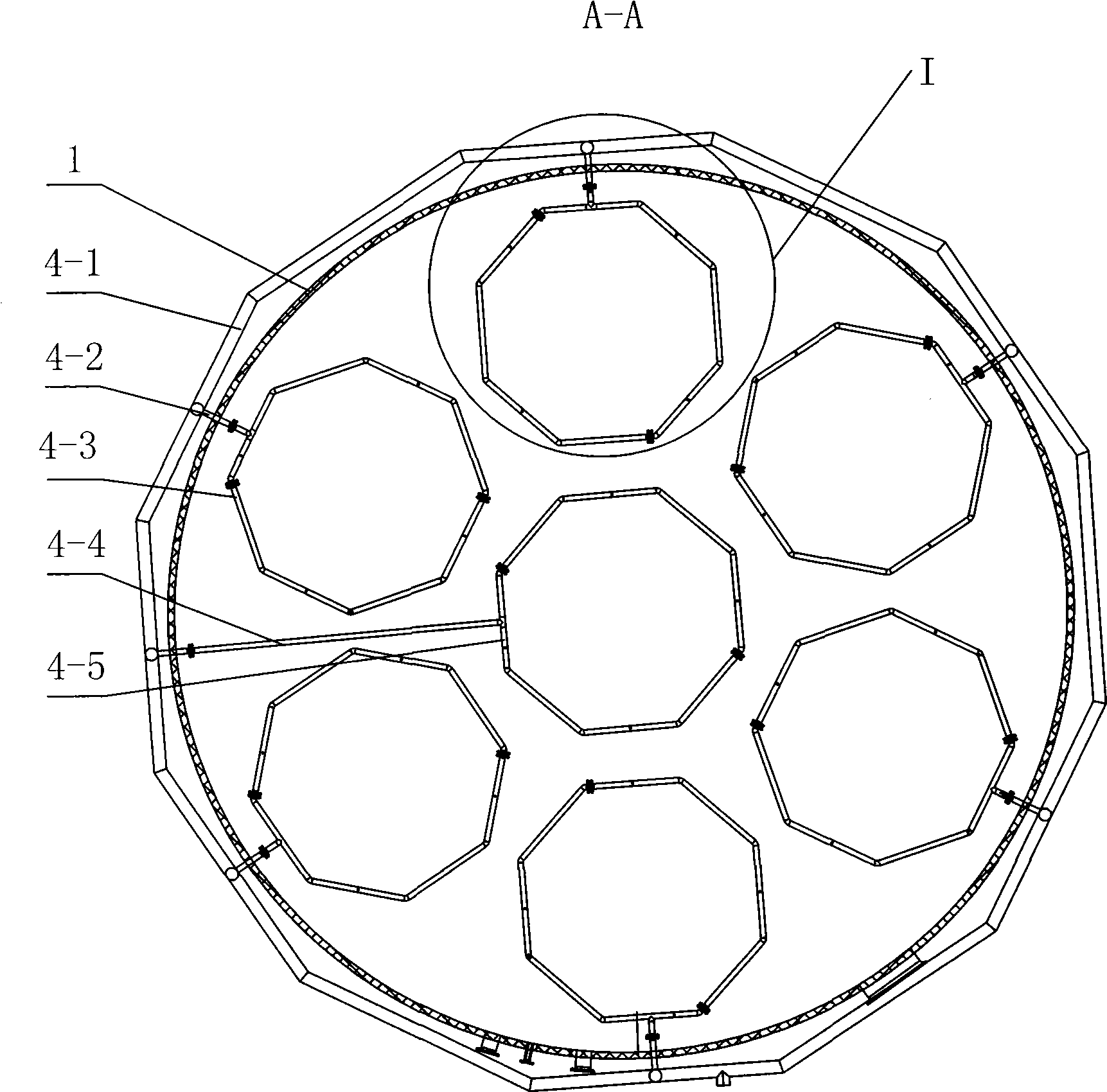

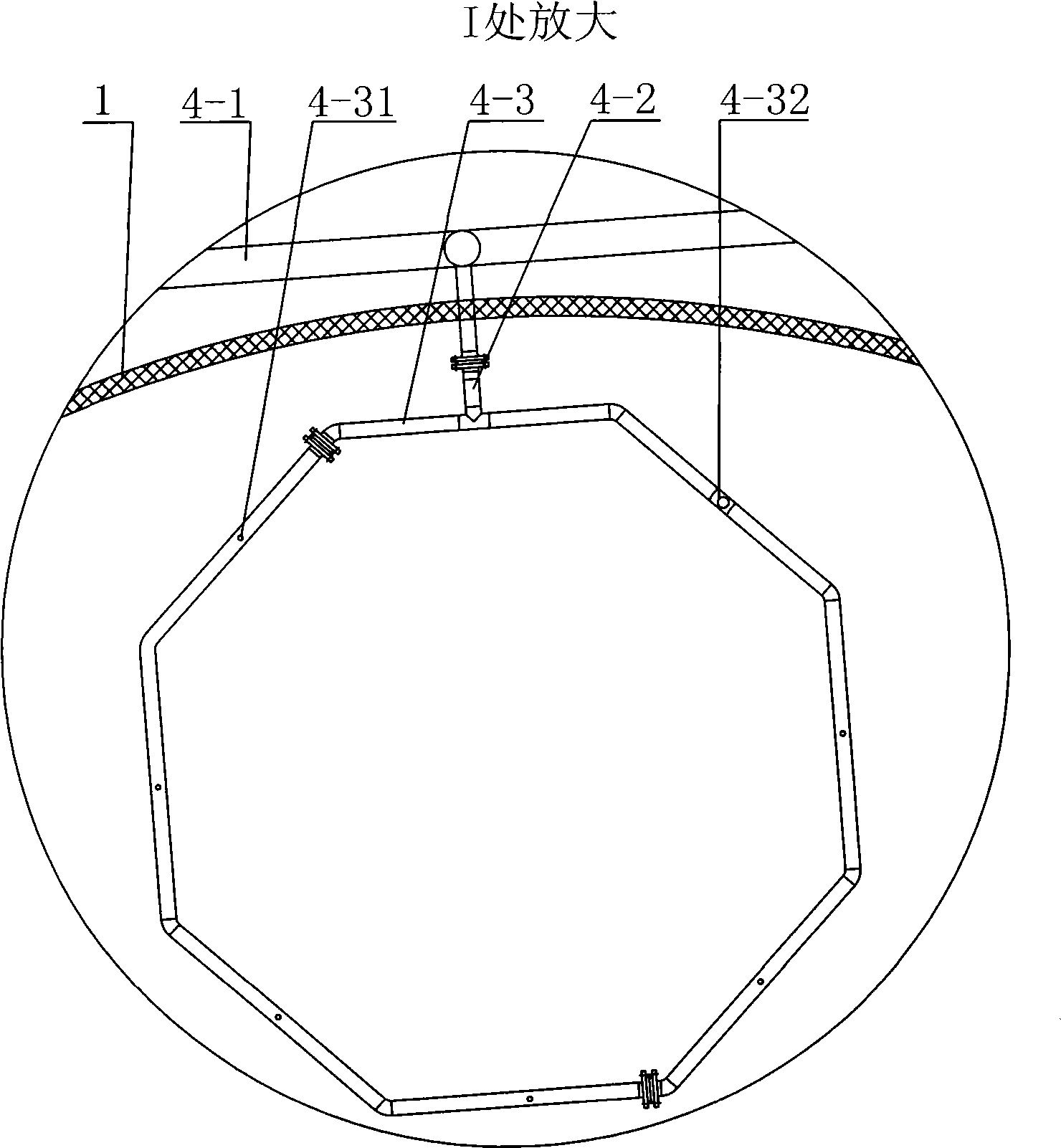

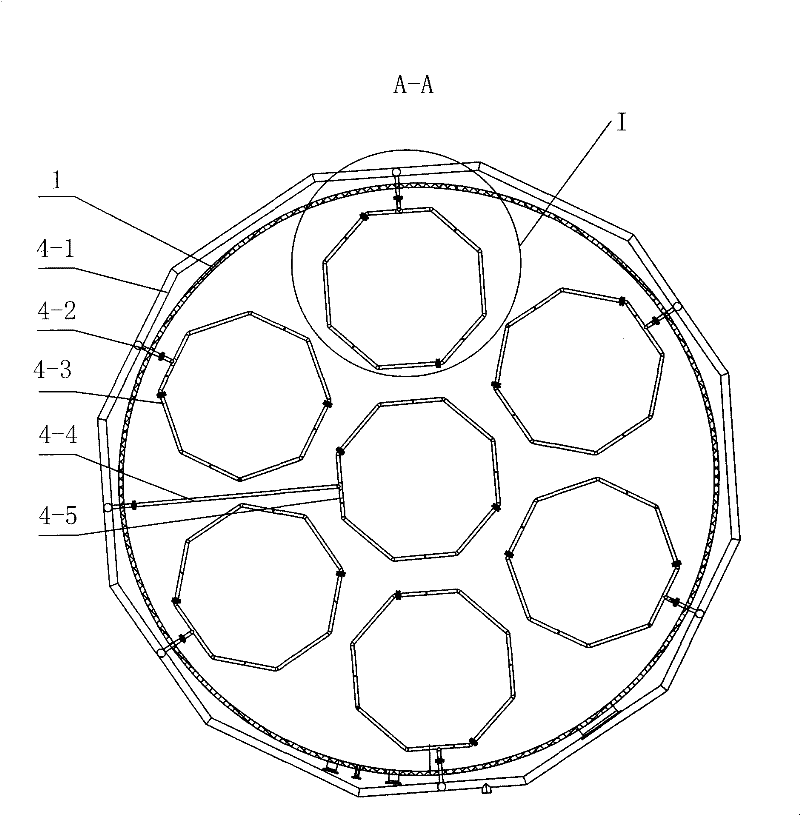

Circular stirrup machining device

PendingCN110883267AImprove adaptabilityMeet different processing requirementsCircular discClassical mechanics

The invention provides a circular stirrup machining device. The circular stirrup machining device comprises a center disk, telescopic support rods, a steel bar fixing part and a plurality of arc-shaped components. According to the circular stirrup machining device, the plurality of movable arc-shaped components are mounted on the center disk, and telescopic side rods are arranged on the two sidesof the interiors of the arc-shaped components. The circular stirrup machining device can machine different diameters and curvatures of circular stirrups and has the good adaptability to meet differentmachining requirements.

Owner:中国人民解放军63926部队

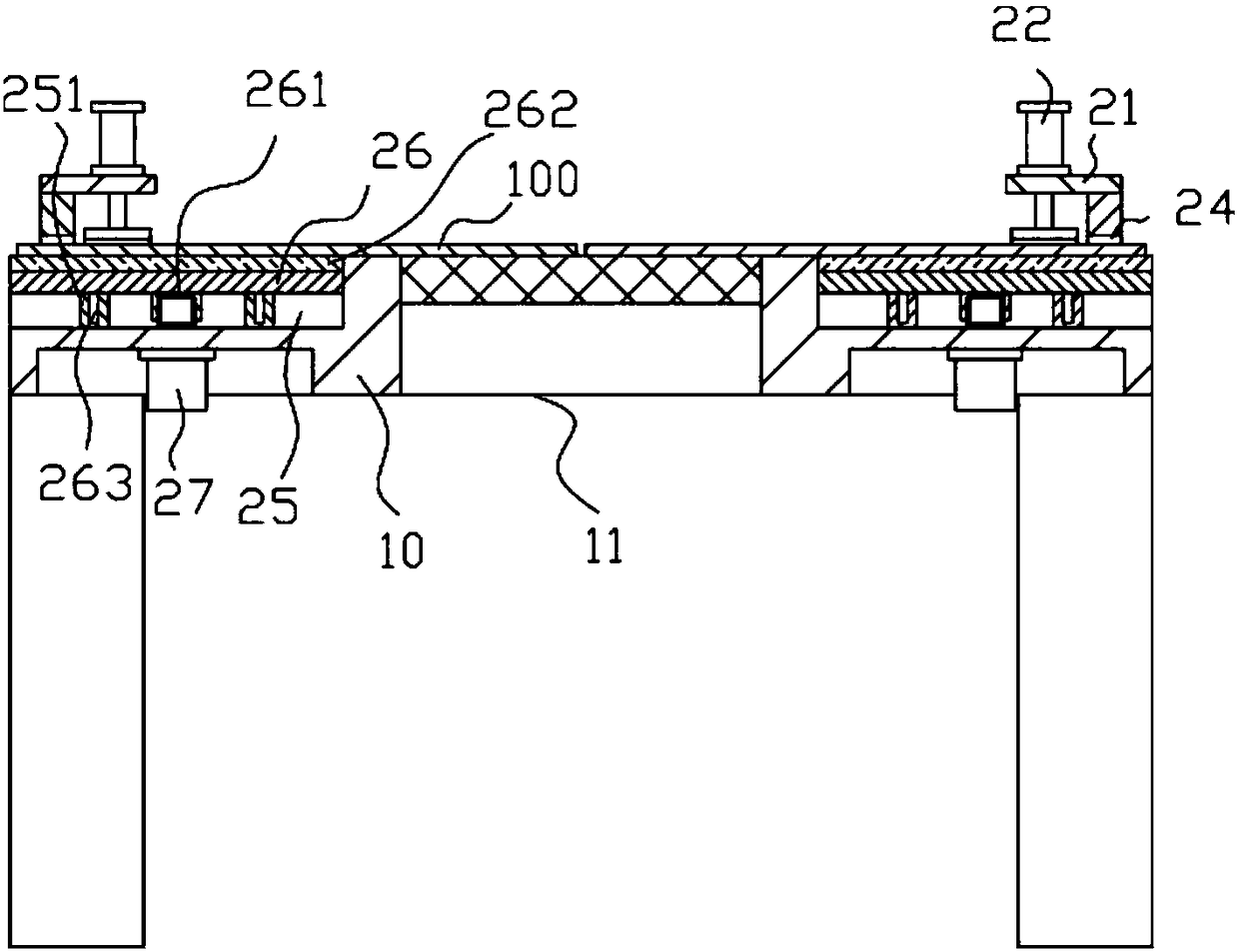

Sheet clamping mechanism for automobile processing plate laser welding machine

InactiveCN108188572AHigh degree of automationMeet different processing requirementsLaser beam welding apparatusEngineeringLaser

The invention discloses a sheet clamping mechanism for an automobile processing plate laser welding machine. The sheet clamping mechanism for the automobile processing plate laser welding machine comprises a rack; the middle portion of a top plate of the rack is provided with a processing through groove; the top face of the top plate of the rack located at front and rear sides of processing through groove is fixedly provided with a clamping supporting plate; the top face of the clamping supporting plate is fixedly provided with horizontal clamping supporting plates; the top faces of the horizontal clamping supporting plates are fixedly provided with multiple upper pressing air cylinders; push rods of the upper pressing air cylinders pass through the bottom faces of the horizontal clampingsupporting plates and are fixedly provided with upper pressing plates; the middle portions of the bottom faces of the upper pressing plates are provided with feeding through grooves; a plate to be processes is inserted in the feeding through grooves in a sleeving mode; the bottom surface of the plate to be processed is inserted in lifting and adjusting grooves in a sleeving mode; and bottom facesof the top plates of the racks are fixedly provided with lifting motors. The sheet clamping mechanism for the automobile processing plate laser welding machine is high in degree of automation and canautomatically clamp and fix the plate to be processed to carry out high-low fine adjustment to meet different processing requirements, and the sheet clamping mechanism for the automobile processing plate laser welding machine is very convenient.

Owner:FOSHAN BENJIEPU ELECTROMECHANICAL TECH CO LTD

Anaerobic reactor

ActiveCN101497476BSolve easy blockageReduce foulingTreatment with anaerobic digestion processesAnaerobic reactorCirculating pump

The invention relates to an anaerobic reactor. The anaerobic reactor comprises a cylinder body, a water inlet pipe, a water outlet pipe, a filling device on the middle part of the water outlet pipe, a water distribution device at the bottom of the filling device and a sludge discharge device at the bottom of the water distribution device; the water distribution device comprises a water distribution main pipe and more than four closed annular water distribution branch pipes; water outlet holes of the water distribution branch pipes are alternately arranged along more than three concentric circumferences; the cylinder body is positioned on the upper part of the filling device; the lower part of each water distribution branch pipe is provided with more than two water outlets; the water outlets are connected with the water outlet pipe; a reflowing pipe of the water outlet pipe is mixed with the water inlet pipe by a circulating pump and is communicated with the water distribution main pipe; a first medicating device and a second medicating device are communicated with the water inlet pipe respectively through connecting pipes; the filling device comprises a filling rack, a membrane hanging rack and a zonal biomembrane strip; the biomembrane strip is hung on the membrane hanging rack; and the sludge discharge device comprises a sludge discharge main pipe and six sludge discharge branch pipes arranged in length alternation along radial direction. The anaerobic reactor has the characteristics of reasonable water distribution, compact structure and stable operation of the reactor.

Owner:WELLE ENVIRONMENTAL GRP CO LTD

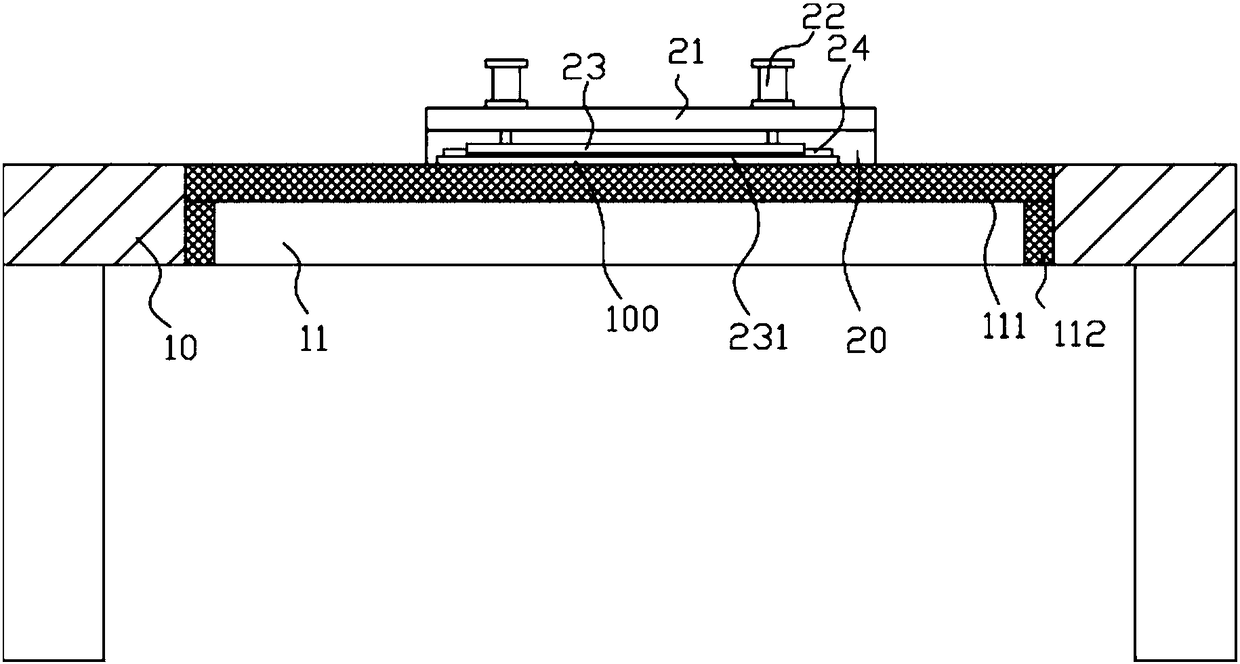

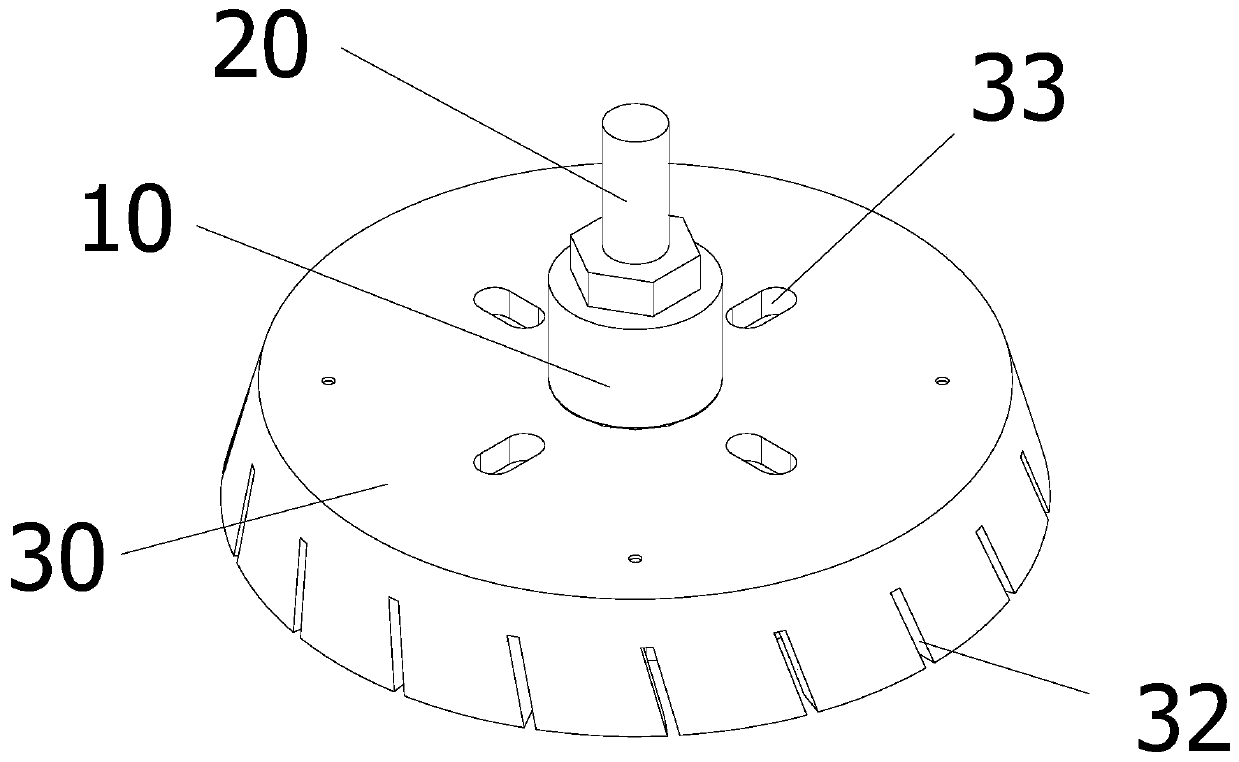

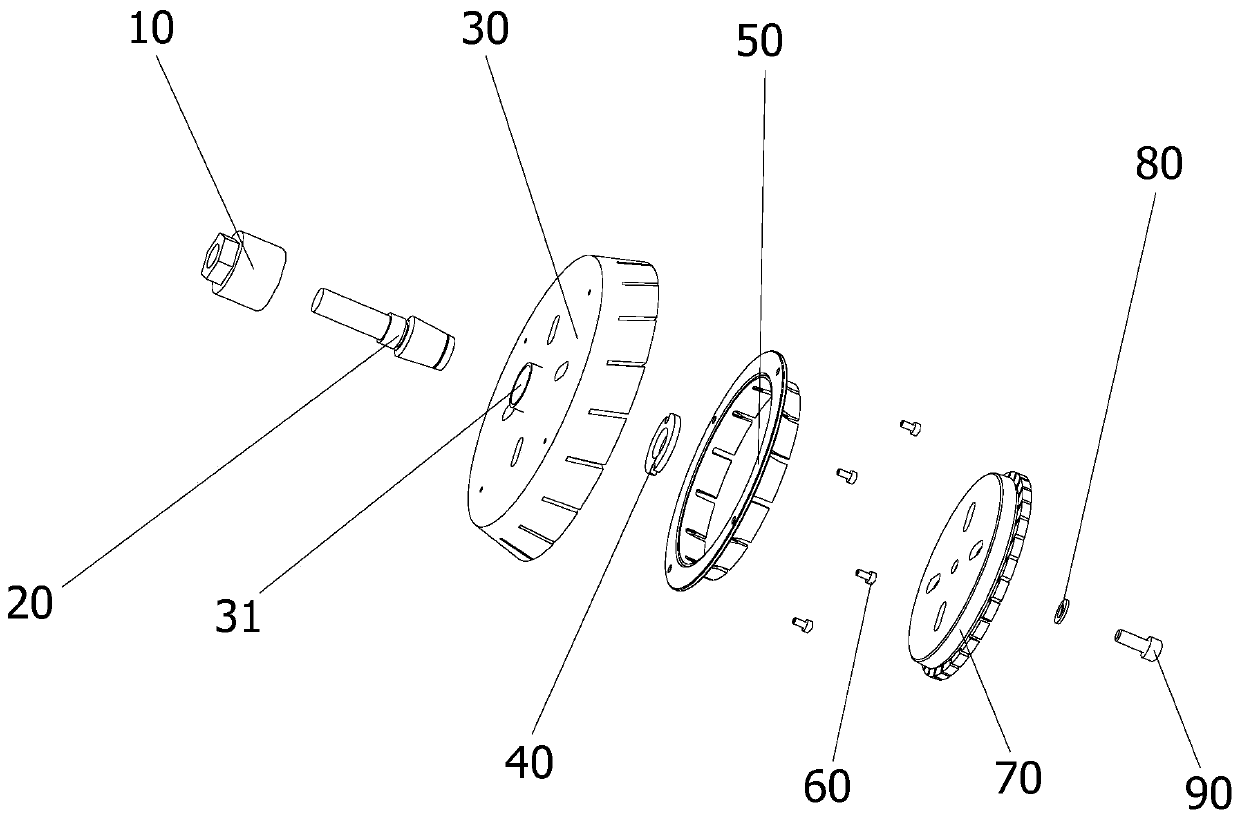

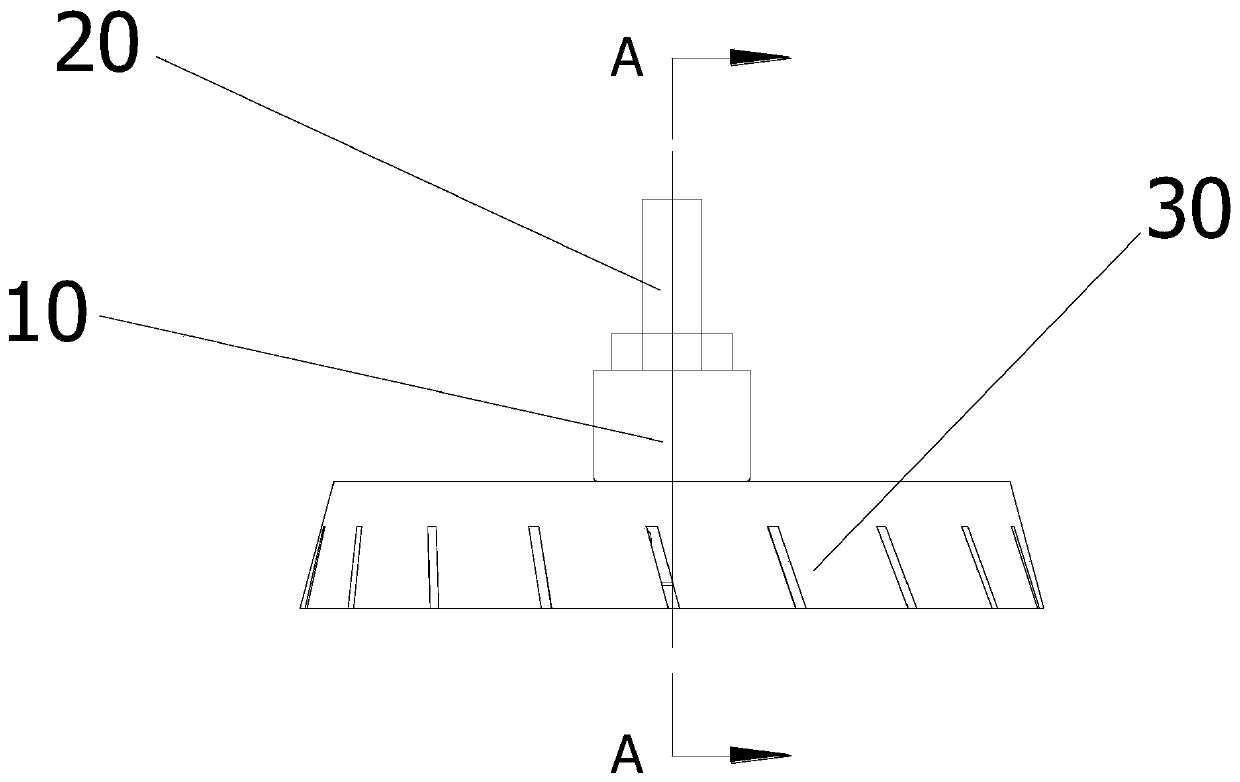

Compound vibrating grinding wheel for ultrasonic processing

ActiveCN110355622AConvenience and accuracyGood coaxialityGrinding machine componentsBonded abrasive wheelsEngineeringUltrasonic assisted

The invention discloses a compound vibrating grinding wheel for ultrasonic processing. The compound vibrating grinding wheel is provided with inner and outer grinding rings which are connected througha connecting flange. Under the action of ultrasonic vibration, the inner and outer rings can vibrate ultrasonically simultaneously to exert the ultrasonic assisted grinding processing ability fully,so that the production efficiency can be improved. The shape and the mounting position of the connecting flange can be determined according to the modal of the outer grinding ring, so that friction ofthe connecting flange on a pitch circle and a pitch diameter is reduced; the inner side of the connecting flange is connected to a cone surface of the inner grinding ring, so that the transfer loss of ultrasonic sound among interfaces is reduced, the ultrasonic transfer efficiency is guaranteed, and the positioning precision is improved at the same time; the axial height of the inner grinding ring can be adjusted, and the end surface height difference of the inner and outer grinding rings can be changed by adjusting the axial height of the inner grinding ring, so that the grinding depth of the inner grinding ring is further controlled, and therefore, the production efficiency is improved by carrying out coarse processing and finish processing in a same step. The grooving forms of the inner and outer rings are changed to obtain ultrasonic vibration of different forms, so that different processing demands are met.

Owner:DALIAN UNIV OF TECH

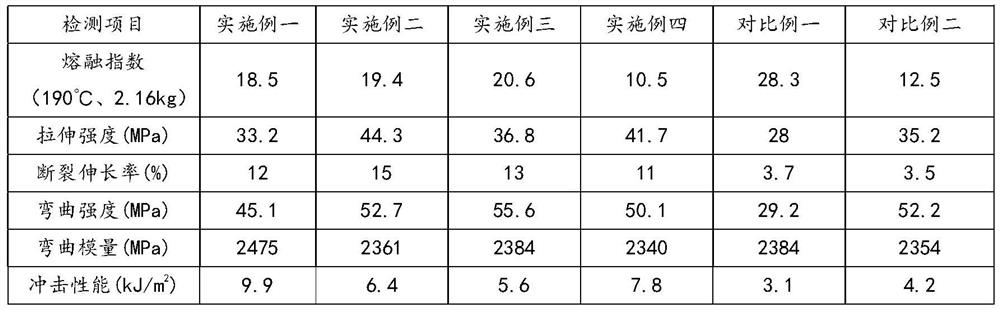

Coffee-flavored completely biodegradable plant-based material as well as preparation method and application thereof

InactiveCN112961479AComply with relevant regulations for contact materialsGood compatibilityBiologyMaterials science

The invention discloses a coffee-flavored completely biodegradable plant-based material as well as a preparation method and application thereof, and belongs to the technical field of polymer modification. The material comprises the following components in percentage by mass: 40-90% of polylactic acid; 3-30% of toughening resin; 1-50% of coffee grounds; and the balance of auxiliaries. The coffee-flavored completely biodegradable plant-based material is obtained by extrusion granulation or molding through extensional rheological plasticizing extrusion equipment. The material can be applied to food contact materials such as disposable catering materials and food packaging materials, the environmental protection pressure is reduced, and the application level of the coffee grounds is improved. The material has the advantages of simple preparation process and controllable and adjustable reaction process.

Owner:SIIICO TECH CO LTD

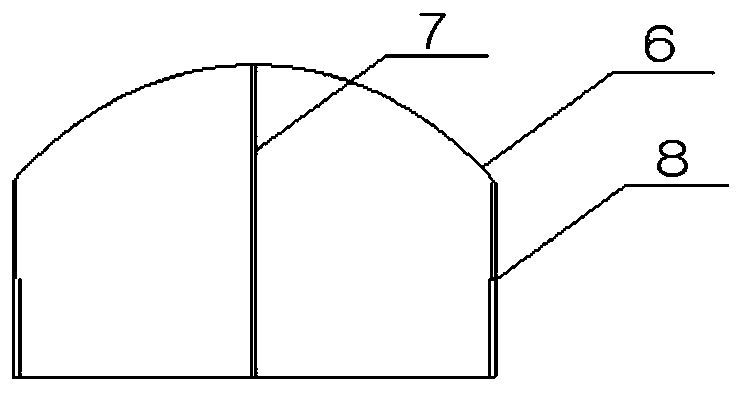

Extrusion molding and presulfurization integrated device for short fiber radial orientation strengthened annular tread

ActiveCN106738763AOrientation principle is simpleGood orientationTyresEngineeringMechanical engineering

The invention discloses an extrusion molding and presulfurization integrated device for a short fiber radial orientation strengthened annular tread. The extrusion molding and presulfurization integrated device comprises an inlet section, a transition section, a flow dividing section, a setting section and a presulfurization device. A cylindrical runner in the flow dividing section is subjected to 90 degrees of deformation firstly, and a flow dividing column with the cross section being hexagonal is arranged in the deformed center of the runner of the flow dividing section. The tail end of the flow dividing column is connected with the setting section. The setting section is composed of an upper setting plate, a lower setting plate and an interplate die cavity. Runners in the setting section take the center of the setting section as a starting point. Rubber is extruded along the six runners with the equal cross sections, runner openings are opposite to the edges of the hexagon, and the cross sectional area of the flow dividing column is one half of that of a cylindrical structure. The presulfurization device with the partitioning tyre pattern face is arranged outside the setting section in a matched mode. According to the extrusion molding and presulfurization integrated device for the short fiber radial orientation strengthened annular tread, the technical problem that in the prior art, when the short fiber rubber is vulcanized in a tyre segment mould, the short fiber movement direction is changed, so that the orientation degree is reduced is solved, the radial orientation degree of fiber strengthened thread rubber is increased, and a novel method for the short fiber radial orientation is put forward.

Owner:青岛国程中嘉高新科技开发有限公司

Adjustable machine tool working lamp

InactiveCN111023007AGood lighting effectMeet different processing requirementsLighting support devicesElectric circuit arrangementsLighting systemElectric energy

The invention discloses an adjustable machine tool working lamp comprising a machine tool housing. A working cavity is formed in the machine tool housing. A power generation mechanism is arranged in the working cavity and comprises an electric guide rail arranged in the working cavity; a workbench is controlled on the upper side of the electric guide rail; a generator is embedded in the right endwall of the working cavity; and a transmission shaft is arranged in the left end surface of the generator. Mechanical energy generated by movement of the machine tool can be used for generating powerto provide electric energy for the lighting system, so that environmental protection is realized; the brightness of the working environment can be automatically detected, the illuminating lamp is capable of being automatically turned on and turned off, so that the work is facilitated; the machine tool working lamp is further provided with illumination equipment for centralized illumination to independently illuminate the machine tool workbench so as to meet different requirements of machine tool machining; the illumination equipment for centralized illumination can move along with the machinetool workbench and illuminate the machine tool workbench all the time, so that the illumination effect is good and the illumination angle is adjusted so as to adapt to workpieces with different sizes.

Owner:东阳故宏机械科技有限公司

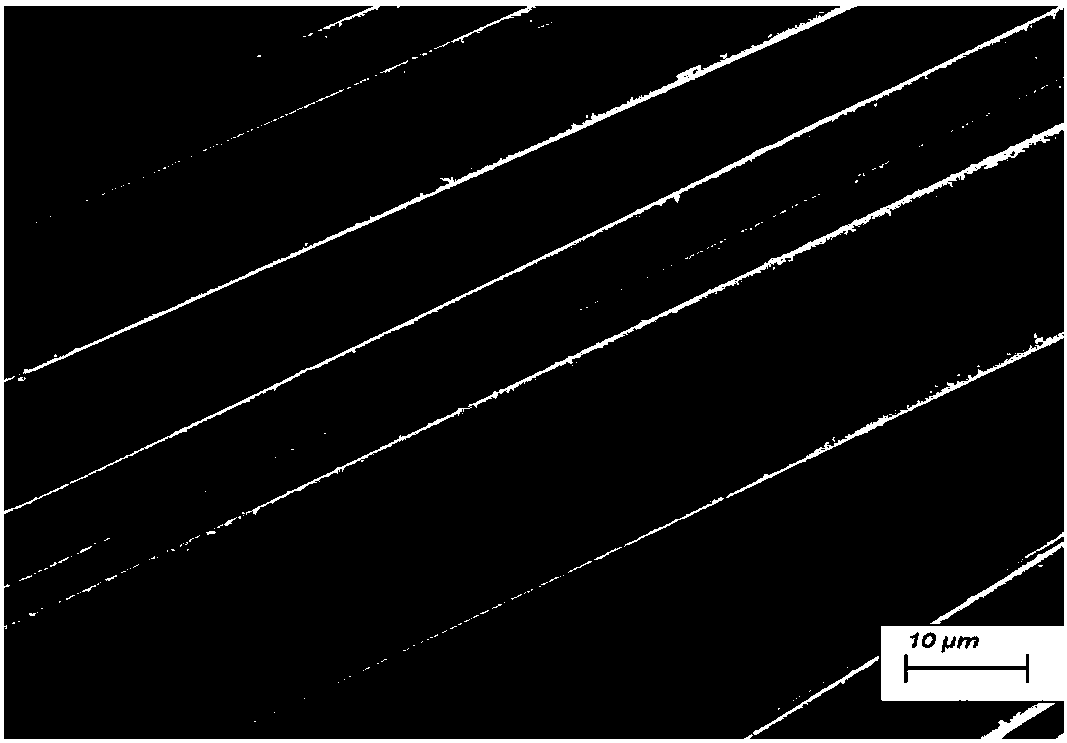

Surface bionic modification method and application of high-performance polyimide fiber

ActiveCN108486888AAchieve the desired effectAchieve their goalsFibre typesFiber-reinforced compositeDopamine

The invention provides a surface bionic modification method and application of high-performance polyimide fiber, and belongs to the technical field of high-performance fiber surface modification. Thesurface bionic modification method comprises the steps of preparation of a polydopamine solution, conditioning of pH of a suffering solution, determination of a treatment condition and way and washingand drying treatment ways of treated fiber. The surface bionic modification method adopts dopamine to modify the fiber surface, the polymerization condition is simple, the environment is mild, the reaction process is easy and convenient to operate, and the repeatability is high. The obtained polyimide fiber wrapped with polydopamine retains the excellent mechanical property, has the high surfacepolarity and surface energy, and can be effectively combined with resin and functional groups to prepare high-performance dopamine modifying polyimide fiber reinforced composite materials and functional materials.

Owner:BEIJING UNIV OF CHEM TECH

Modified asphalt mixing equipment and mixing method thereof

InactiveCN112709110AReduce generationReduce shockRoads maintainenceProcess engineeringHeat conservation

The invention relates to modified asphalt mixing equipment which comprises an aggregate bin, a lifting mechanism, a drying bin, a mixing bin, an asphalt bin, a heat exchange bin and a dust removal mechanism, aggregate in the aggregate bin is conveyed to the drying bin through the lifting mechanism, and a discharging port of the drying bin is communicated with a feeding port of the mixing bin; a discharging port of the asphalt bin is communicated with the other feeding port of the mixing bin, a liquid inlet of a heat preservation cavity of the asphalt bin is communicated with a liquid outlet of the heat exchange bin, the heat preservation cavity of the asphalt bin is communicated with the heat exchange bin, a transduction cavity of the heat exchange bin is communicated with the drying bin, and the transduction cavity of the heat exchange bin is communicated with the dust removal mechanism. Targeted heating and stirring are conducted through the mixing bin, meanwhile, high-temperature flue gas in the drying bin enters the heat exchange bin to heat heat exchange liquid, the heat exchange liquid is conveyed into the asphalt bin to heat and preserve heat of asphalt, repeated utilization of heat energy is achieved, energy is saved, the cost is reduced, and the flue gas is exhausted after being treated by the dust removal mechanism. and environmental pollution is avoided.

Owner:襄阳路桥建设集团有限公司

Edge wrapping and attaching equipment and rubber sheet attaching method

The invention provides edge wrapping and attaching equipment and a rubber sheet attaching method. The edge wrapping and attaching equipment comprises a rack, a rubber sheet guide device, a conveying belt, an attaching device, an edge wrapping device and a rubber sheet positioning device, wherein the rubber sheet positioning device is arranged on the rack and positioned at the upstream of the attaching device; the rubber sheet positioning device comprises a support and a positioning roller group, a second positioning roller, a guide roller, an attaching roller and a laminating roller which arearranged on the support; the positioning roller group is provided with a passing area for a first rubber sheet to pass through so that the positioning roller group can position the first rubber sheet;the first rubber sheet passes through the passing area after being guided by the rubber sheet guide device, sequentially passes through the guide roller and the attaching roller, and is compacted with the cord fabric under the pressing of the laminating roller; the second positioning roller is used for positioning a second rubber sheet, and the second rubber sheet is compacted with the cord fabric by the attaching roller under the pressing cooperation of the laminating roller. The edge wrapping and attaching equipment solves the problem that in the prior art, edge wrapping and attaching equipment cannot simultaneously achieve the attachment of off-line rubber sheets, on-line rubber sheets and the cord fabric and consequently the radial tire processing is influenced.

Owner:MESNAC

Improved adjusting and locking mechanism for pressing corners of part of paving machine

The invention discloses an improved adjusting and locking mechanism for pressing corners of a part of a paving machine, comprising an operation table, a fixing block, a mold block, adjusting mechanisms and locking mechanisms, wherein the fixing block is arranged on the left side of the top surface of the operation table, the mold block is arranged on the operation table and positioned at one sideof the fixing block, the two sides of the front part and the two sides of the rear part of the mold block are provided with the adjusting mechanisms, each adjusting mechanism comprises a cushion block, a threaded adjusting column and an adjusting handwheel, the two sides of the front part and the two sides of the rear part of the operation table are provided with sliding grooves, a plurality of locking mechanisms are installed in the sliding grooves, and each locking mechanism comprises a high-strength connecting plate, a fixing bolt, an inner locking nut, an outer locking nut and a gasket. The improved adjusting and locking mechanism has a reasonable structure, can fix the left and right sides of the mold block, improves the fixing effect, has high positioning accuracy, good stability andwide application range, can meet different processing requirements, can reduce production cost, improve the anti-skid performance of the adjusting handwheels and a limiting handwheel, is convenient for rotating, and saves time and labor.

Owner:浙江奥桑机械设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com