Coffee-flavored completely biodegradable plant-based material as well as preparation method and application thereof

A biodegradable, plant-based technology, applied in the field of polymer modification, can solve the problems of large organic load, high moisture content, high acidity value, etc., and achieve the effects of decreased crystallization performance, increased molecular weight, and reduced molecular regularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

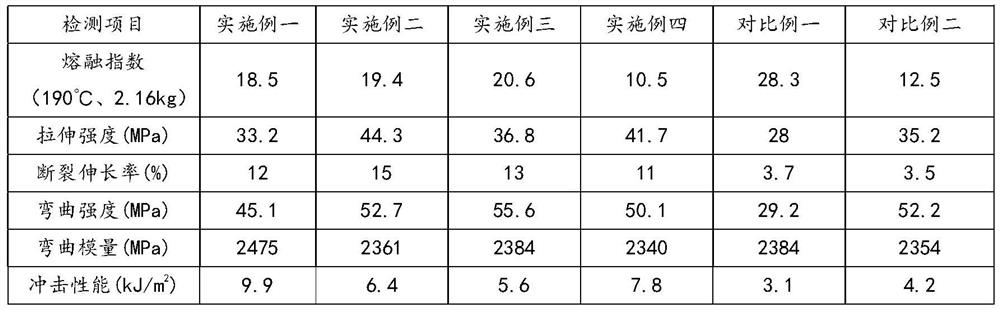

Examples

Embodiment 1

[0040] Dry the polylactic acid resin, toughened resin, and coffee grounds, and grind the coffee grounds to a particle size of 40 mesh, then weigh 67.2% polylactic acid resin, 10% PBAT, 20% coffee grounds, 0.5% Nucleating agent, 2% plasticizer, 0.3% antioxidant, polylactic acid resin, PBAT, and additives were added to the high-speed mixer and mixed for 1 minute, then coffee grounds were added and mixed for 5 minutes, and then pulled The elongational rheological plasticizing extrusion equipment performs melt extrusion granulation. The elongational rheological eccentric rotor structure is designed with an eccentricity e of 1.5mm, the number of straight segments in the functional section is 4, and the compression ratio between the maximum pitch and the minimum pitch is 2.0.

Embodiment 2

[0042] Dry the polylactic acid resin, toughened resin, and coffee grounds, and grind the coffee grounds to a particle size of 60 mesh, then weigh 67.2% polylactic acid resin, 10% PBS, 20% coffee grounds, 0.5% Nucleating agent, 2% plasticizer, 0.3% antioxidant, polylactic acid resin, PBS, and additives were added to the high-speed mixer and mixed for 1 minute, then coffee grounds were added and mixed for 5 minutes, and then pulled The elongational rheological plasticizing extrusion equipment is used for melt extrusion and granulation. The elongational rheological eccentric rotor structure is designed with an eccentricity e of 1.5mm, the number of straight segments in the functional section is 4, and the compression ratio between the maximum pitch and the minimum pitch is 3.6.

Embodiment 3

[0044] Dry the polylactic acid resin, toughened resin, and coffee grounds, and grind the coffee grounds to a particle size of 150 mesh, then weigh 70.2% polylactic acid resin, 10% PBAT, 15% coffee grounds, 0.5% Nucleating agent, 2% plasticizer, 0.3% antioxidant, polylactic acid resin, PBAT, and additives were added to the high-speed mixer and mixed for 1 minute, then coffee grounds were added and mixed for 5 minutes, and then pulled The elongational rheological plasticizing extrusion equipment performs melt extrusion and granulation. The elongational rheological eccentric rotor structure is designed with an eccentricity e of 3mm, the number of straight segments in the functional section is 6, and the compression ratio between the maximum pitch and the minimum pitch is 2.0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com