Natural-fiber composite material pelletizer

A composite material and natural fiber technology, applied in the field of natural fiber composite material granulator, can solve the problems of insufficient reinforcement, difficult dispersion of fibers, unevenness, etc., and achieve improved bonding, controllable fiber length, and good fusion The effect of bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

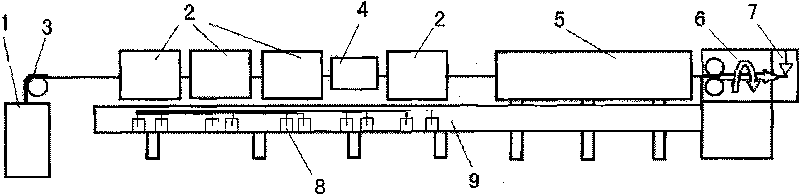

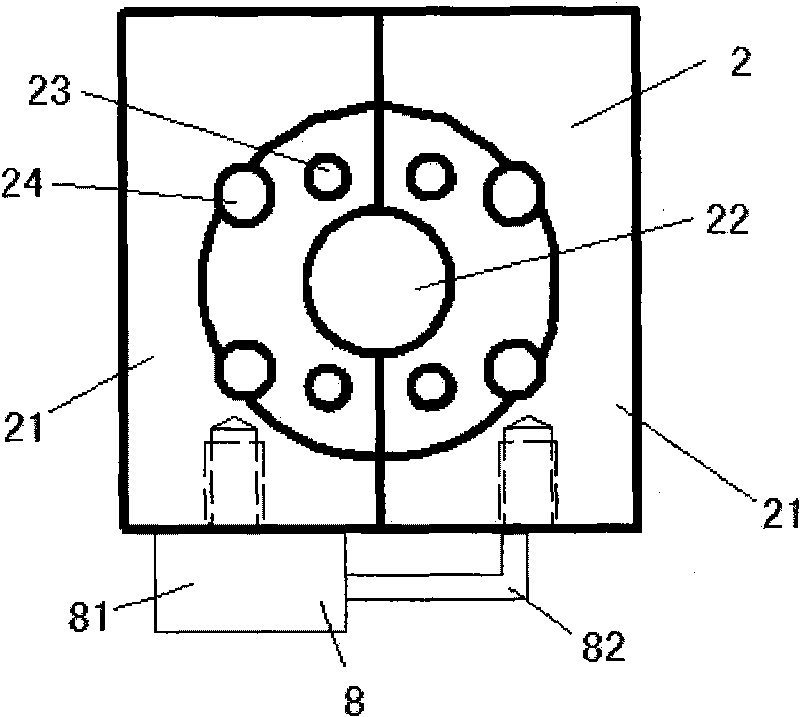

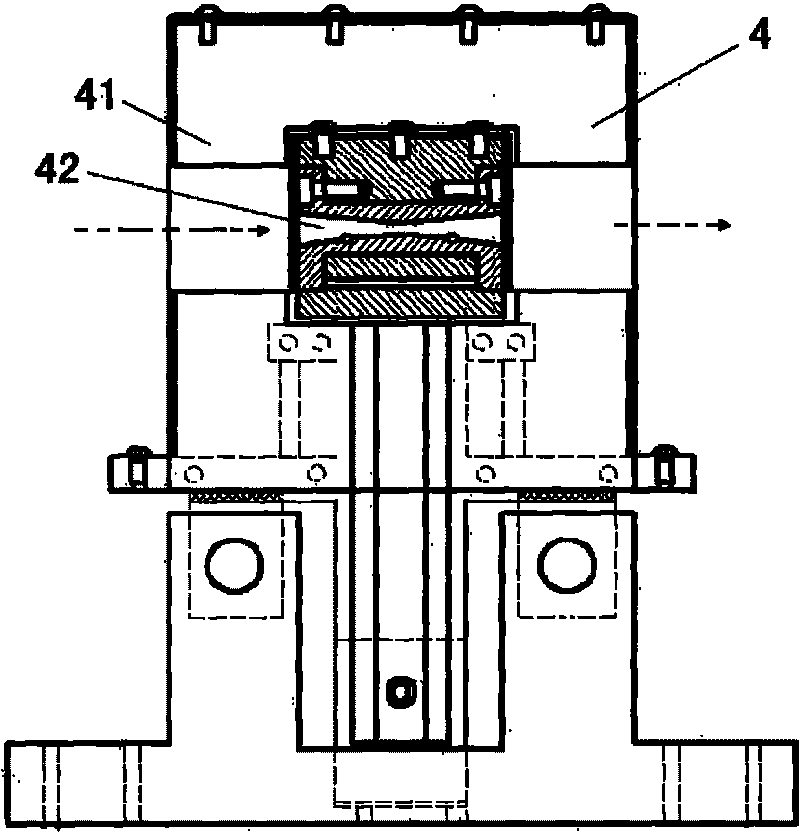

[0016] Such as figure 1 , figure 2 As shown, the present invention comprises a material tank 1 and more than one heating unit 2, the material tank 1 is connected with the first heating unit 2 through a feeding frame 3, and the first heating unit 2 is connected with other more than one heating unit 2 After being connected in series by the transmission belt, the last heating unit 2 is connected in series with the sizing unit 4 through the transmission belt, and the output end of the sizing unit 4 is connected in series to another heating unit 2, a cooling unit 5, and a twisting unit 6 in sequence through the transmission belt And cutting unit 7. A pneumatic device 8 is provided at the bottom of each heating unit 2 and sizing unit 4 , and the pneumatic device 8 includes a cylinder block 81 and a cylinder piston 82 . And each heating unit 2, sizing un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com