Large-powder low-torque pulsation permanent magnet synchronous motor for electro-spindle

A permanent magnet synchronous motor, torque pulsation technology, applied in synchronous machines, synchronous machine parts, electrical components, etc., can solve the problems of low machining accuracy, low motor efficiency, and low power density of induction motors, and improve constant power. Operating range, significant energy-saving effect, and effect of reducing torque ripple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

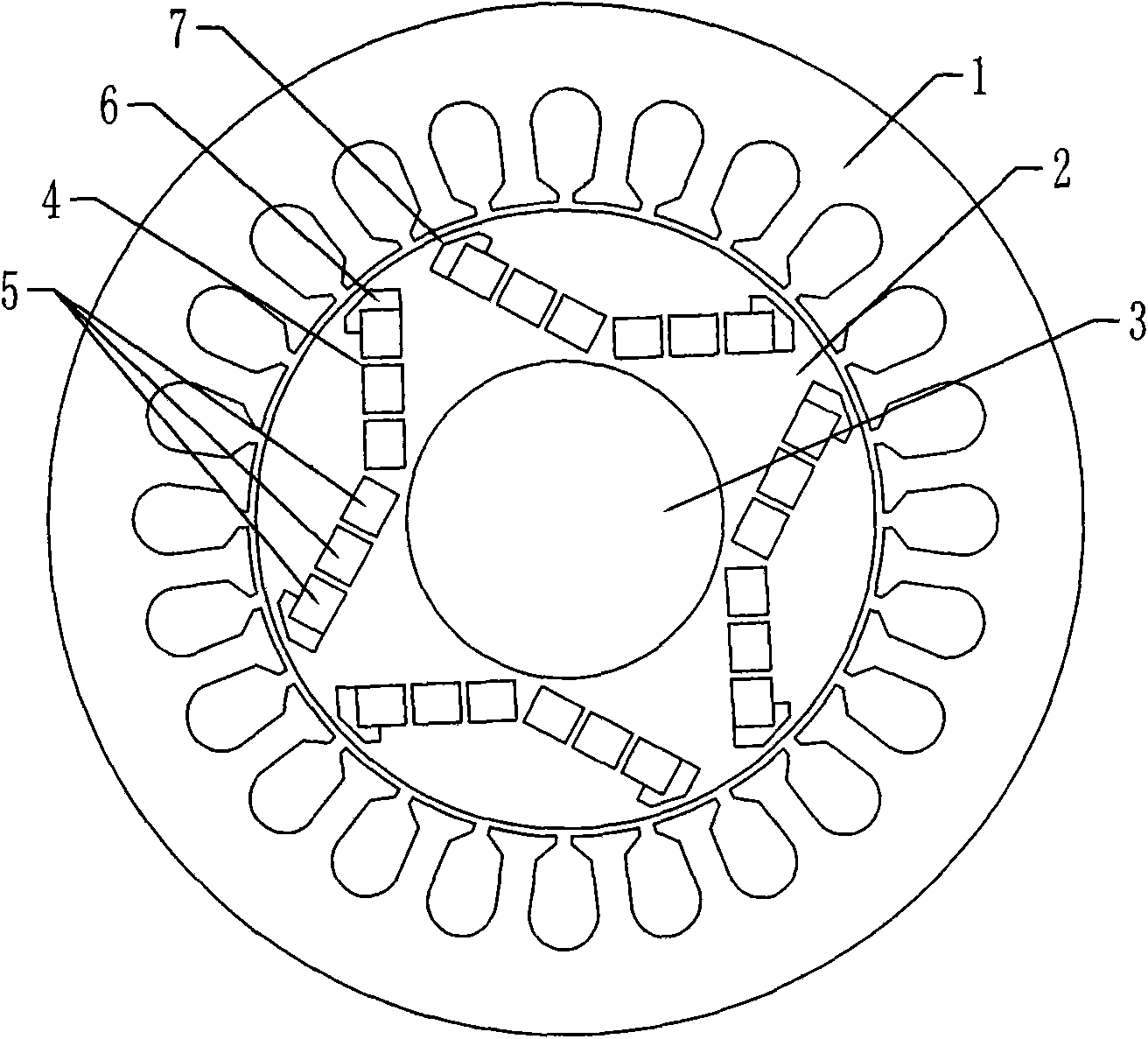

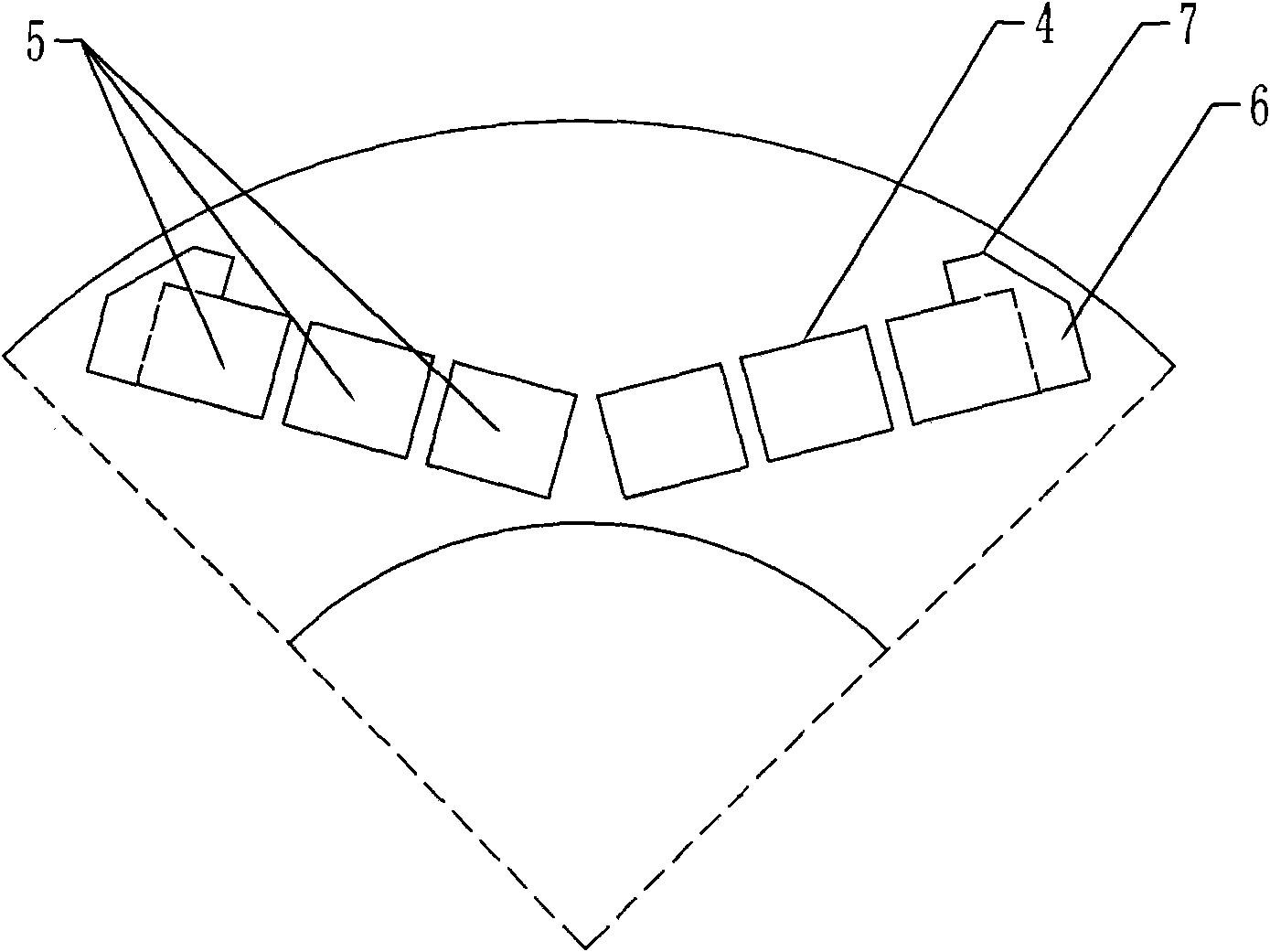

[0009] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment, this embodiment is made up of stator 1, rotor, rotating shaft 3, permanent magnet and magnetic isolation bridge 6; Composed of permanent magnets with a rectangular cross-section; the end face of the rotor core 2 of the rotor is divided into 2P areas on average, and P is the number of pole pairs of the motor; 2n holes 4 with a rectangular cross-section are opened in each area along the axial direction of the rotor core 2 , n is a natural number; the 2n holes 4 of rectangular cross-section are arranged symmetrically along the center line of the end face of the rotor core 2 into a V-shaped or W-shaped opening facing the outer edge of the rotor core 2; such an arrangement can be made in a limited space More permanent magnets are placed inside to ensure that the permanent magnets provide sufficient effective magnetic flux. The cross-section of each group of segmented permanent magnet...

specific Embodiment approach 2

[0010] Specific implementation mode two: combination figure 2 This embodiment is described. The difference between this embodiment and the first embodiment is that the thickness between the magnetic isolation hole 7 and the outer edge of the rotor core 2 is 0.5mm-10mm. Other compositions and connection methods are the same as those in Embodiment 1.

specific Embodiment approach 3

[0011] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the segmented permanent magnet group 5 adopts NdFeB permanent magnets as permanent magnets with a rectangular cross section. Other compositions and connection methods are the same as those in Embodiment 1. NdFeB permanent magnets have high coercivity and remanence.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com