Anaerobic reactor

An anaerobic reactor and cylinder technology, which is applied in the field of anaerobic reactors, can solve the problems of reducing the rising velocity of sewage surface, easy clogging and agglomeration of fillers, and affecting the treatment effect, so as to improve the utilization rate of equipment volume and strengthen Effect of mixing and contacting, improving purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

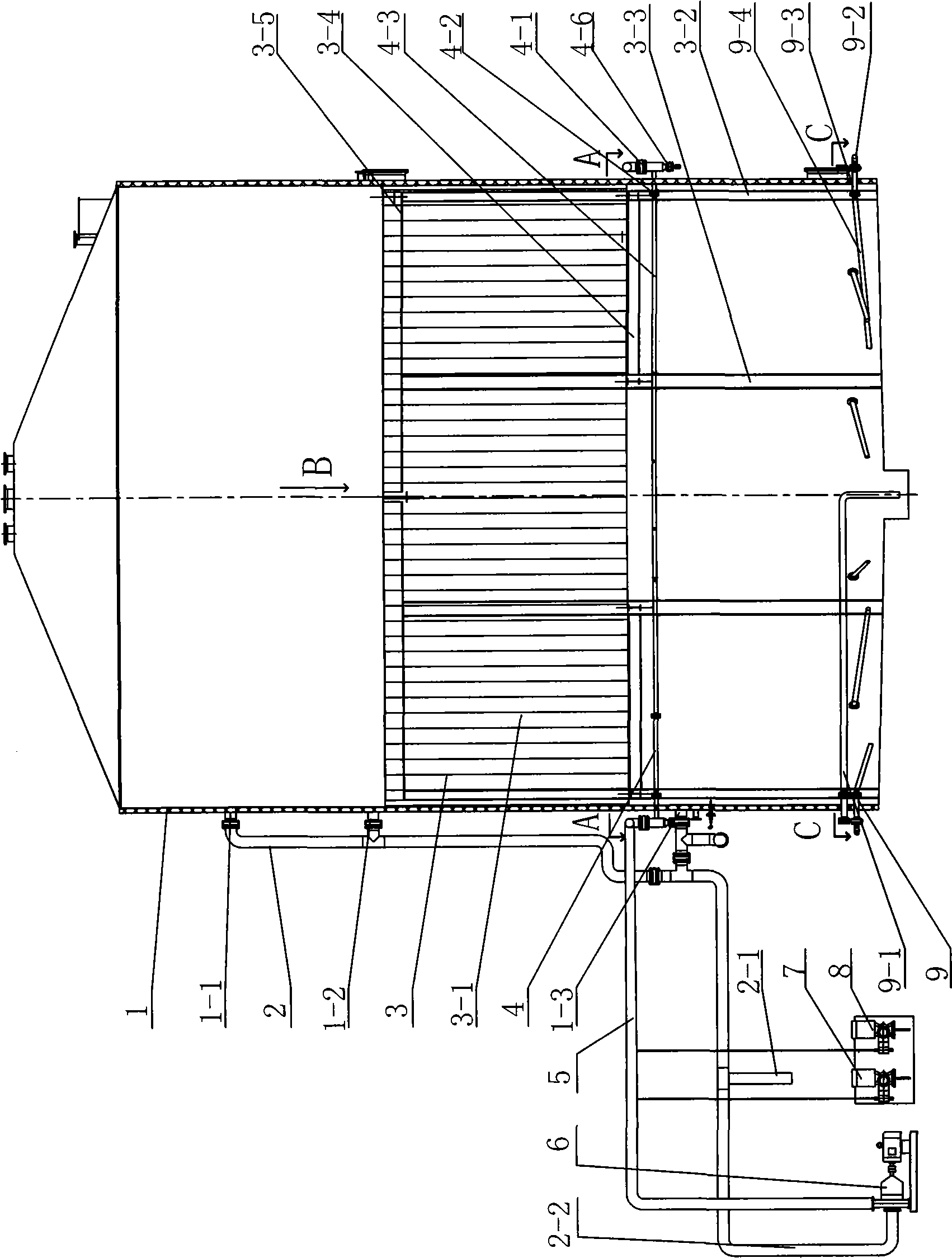

[0023] See figure 1 As shown, the anaerobic reactor of the present invention includes a cylinder body 1 , a water inlet pipe 5 , an outlet pipe 2 , a water distribution device 4 , a packing device 3 and a sludge discharge device 9 .

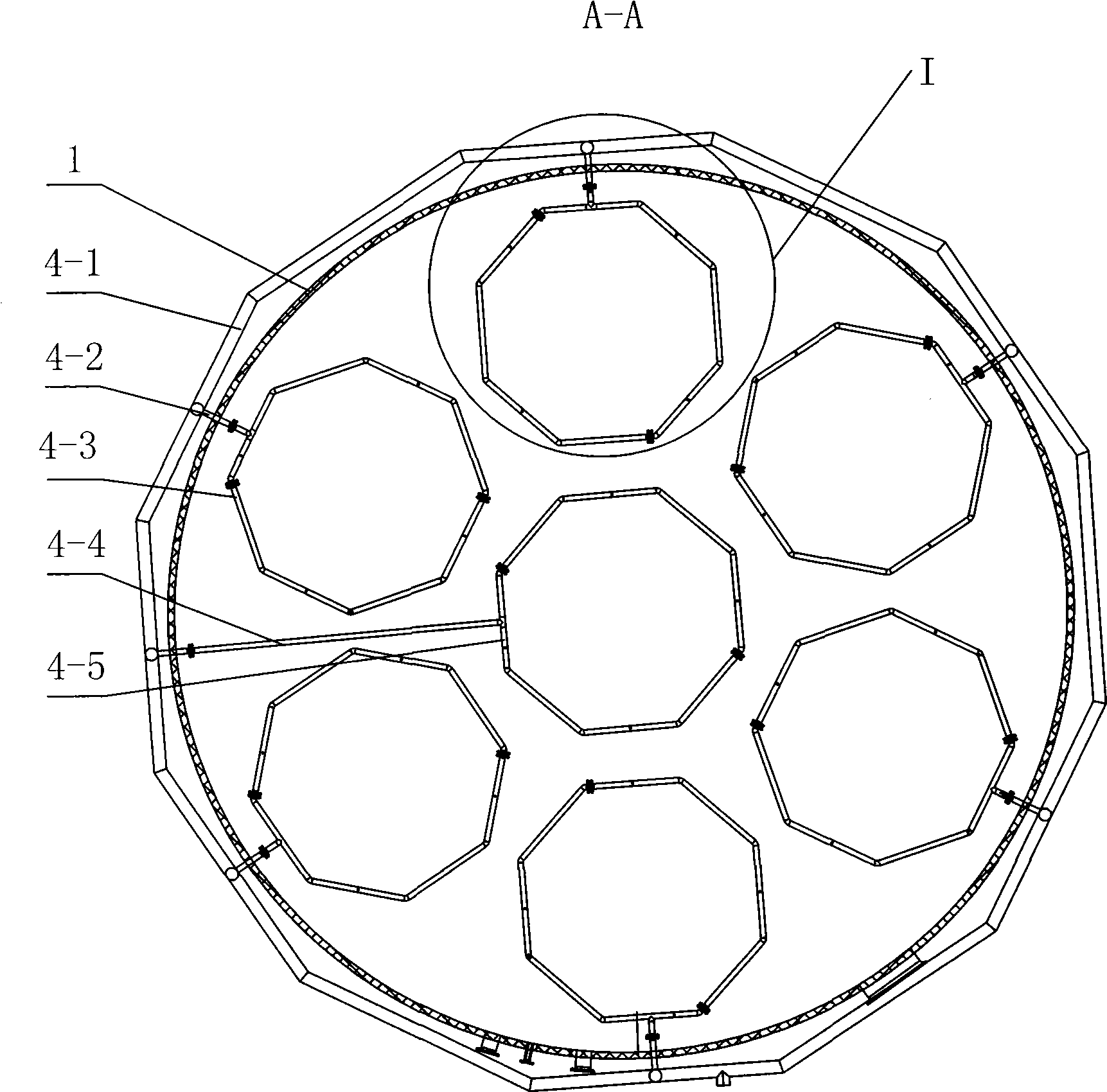

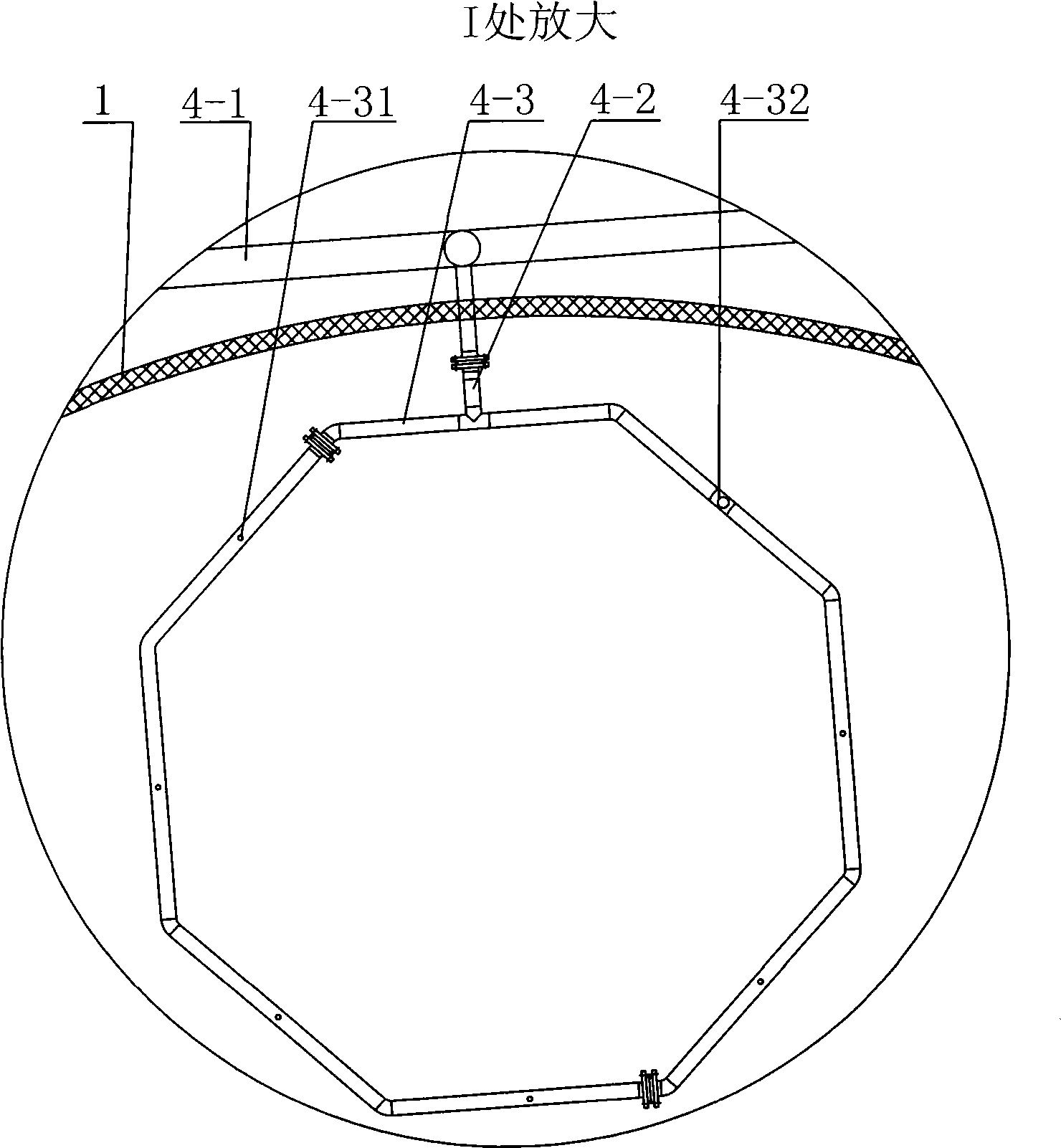

[0024] See Figure 1~3 As shown, the water distribution device 4 of the present invention is located at the bottom of the packing device 3 and above the sludge suspension layer. The water distribution device 4 includes a water distribution main pipe 4-1 and a water distribution branch pipe 4-3, the water distribution main pipe 4-1 is connected with the water inlet pipe 5 through the water inlet, and the water distribution main pipe 4-1 is provided with a flushing joint 4-6, which can Add medicine to the water distribution branch pipe 4-3 for flushing to solve the problem that the water distribution device is easy to block. The water distribution main pipe 4-1 of the present invention is arranged on the outer periphery of the cylinder body 1, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com