Method for transforming coal bed gas horizontal well system

A technology for horizontal wells and coalbed methane, applied in the direction of earthwork drilling, wellbore/well components, and production fluids, etc. It can solve the problems of lost circulation, collapse and sticking, low-efficiency development, unfavorable high production, etc., and improve drainage and production efficiency , Speed up the construction progress and promote the effect of development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

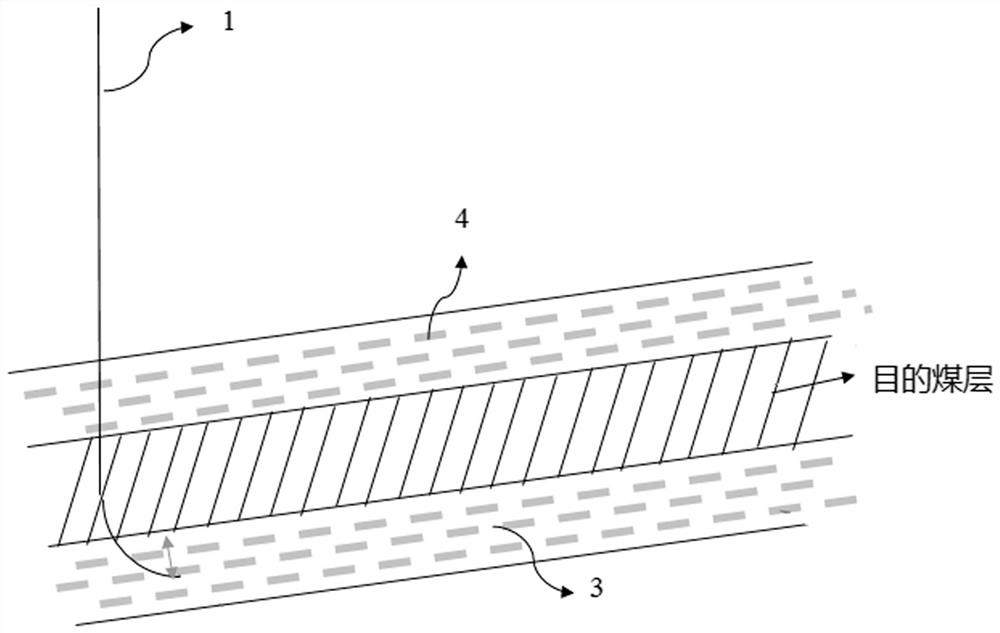

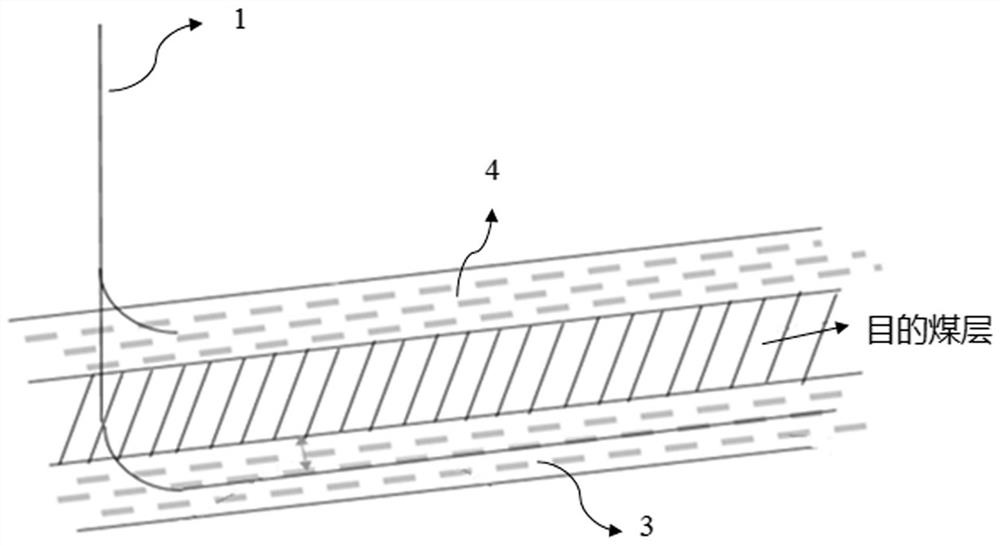

[0116] Such as figure 1As shown, the first horizontal well (that is, the vertical section of the first horizontal well track 1) uses a D311.2mm roller cone bit, and the drilling tool combination: Φ311.15mmPDC+Φ177.8mmX / O+Φ177mmDC+Φ165mmDC+Φ165mmX / O+ Φ127mmDP, Bantu mud drilling fluid drilled through the bedrock weathered zone for 20m, completed drilling at a depth of 60-80m, and lowered the D24.5mm surface casing with cement injection for full sealing. The main function of the first opening is to seal the loose layer and gravel layer on the surface .

[0117] D215.9mm drill bit is used for the second opening of the horizontal well (that is, the bending section of the first horizontal well trajectory 1), and the drill tool assembly: Φ215.9mmPDC+Φ172mm*1.5°Motor+Φ172mmFV+Φ172mmUBHO+Φ172mmNMDC+Φ127mmDP+Φ127mmHWDP; drilling purpose After the coal seam, drill 10-20m with a well inclination angle of 90°-98° and keep it 0.2-2.0m below the target coal seam, then pull out the drill, r...

Embodiment 2

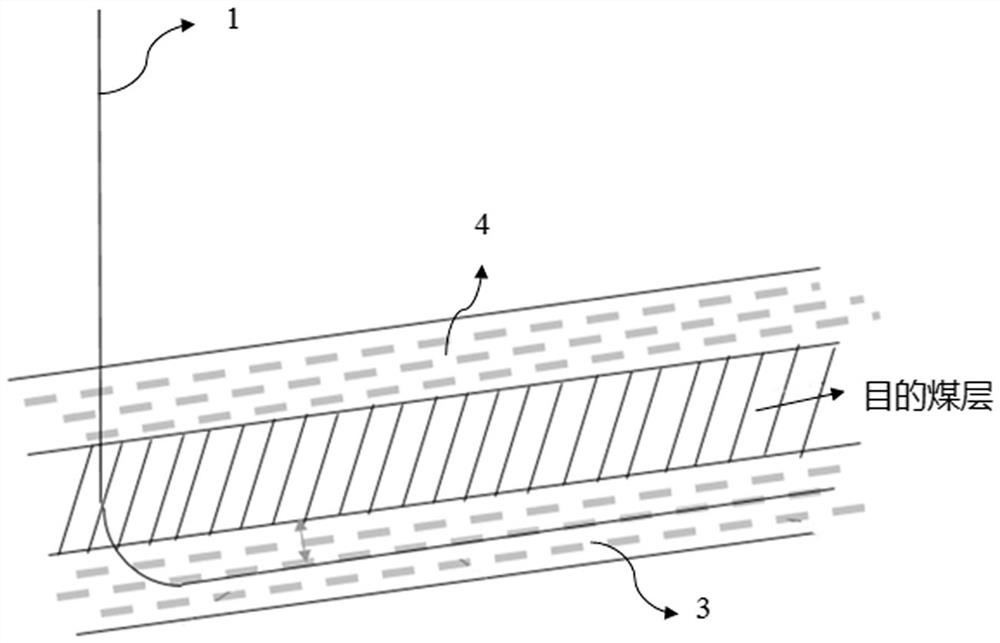

[0124] As soon as the horizontal well was opened (that is, the vertical section of the first horizontal well track 1), the D311.2mm roller cone bit was used to drill through the bedrock weathered zone for 20m, and the drilling was completed at a depth of 60m, and the D244.5mm surface casing was run and sealed. Surface loose layer, gravel layer. The entry depth is 58m, and the cement is fully sealed.

[0125] The second opening (that is, the bending section and the horizontal section of the first horizontal well trajectory 1) uses D215.9mm drill bit, drill tool assembly: Φ215.9mm PDC+Φ172mm*1.5°Motor+X / O+Φ172mmFV+Φ172mmUBHO+Φ172mmNMDC+NMDC +GAP+NMDC+Φ127mmHWDP+Φ127mmDP; the near-bit instrument or rotary steerable instrument can be used to speed up the ROP, and after drilling through the target coal seam, drill with a well inclination angle of 90°~98° and keep it 0.2~2.0m below the target coal seam 300-2000m After the completion of the first horizontal well trajectory 1, the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com