Plate overturning machine and numerical-control cutting production line thereof

A technology of turning machines and plates, applied in the directions of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of low operation efficiency of plate workpieces, high labor intensity of workers, affecting processing quality, etc., and achieve simple and reasonable structure and labor costs. Reduced, practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

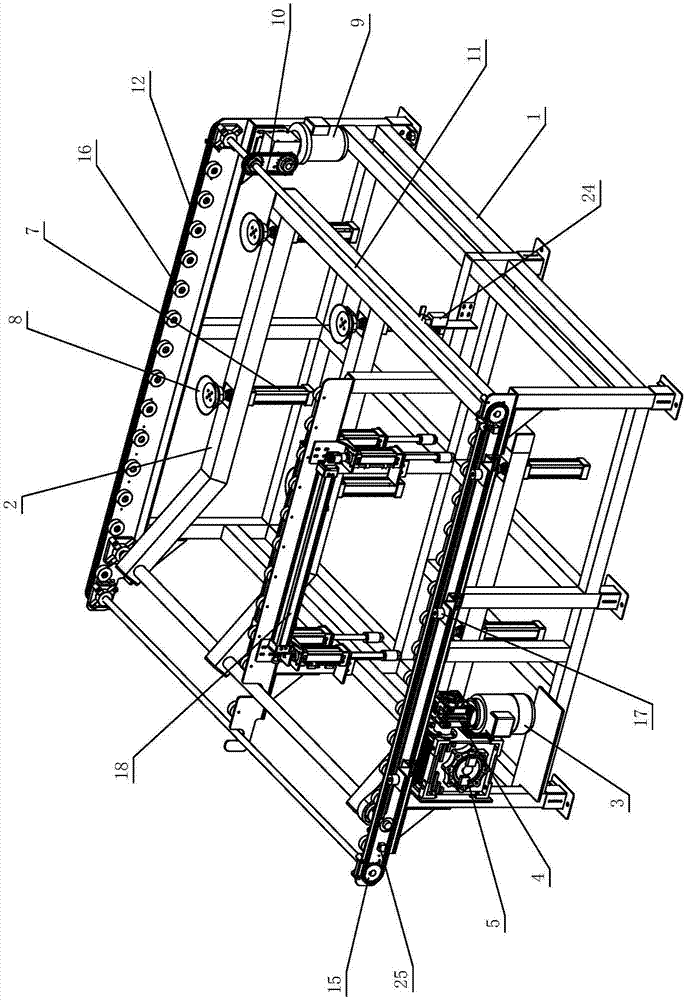

[0027] see Figure 1-Figure 6, the CNC cutting production line involved in this embodiment includes a plate turning machine A, a numerical control cutting machine B and an electric control cabinet D, the plate turning machine A is set on the side of the numerical control cutting machine B, and the electronic control The cabinet D is located on the other side of the CNC cutting machine B, and the plate turning machine A transports the turned plate-shaped workpiece C to the CNC cutting machine B; the CNC cutting machine B and the plate turning machine A are respectively controlled by the electric control cabinet D. Wherein, the plate turning machine includes an equipment frame 1 for carrying various mechanisms, and the equipment frame 1 is provided with a turning mechanism and a conveying mechanism; the turning mechanism includes a turning arm 2, a sucker assembly and a turning drive assembly; the turning arm 2 rotates on one side Connect the equipment frame 1; the suction cup a...

no. 2 example

[0050] see Figure 17-Figure 19 , this plate turning machine and its CNC cutting production line are different from the first embodiment in that the CNC cutting production line involved includes a plate turning machine A, two CNC cutting machines B and an electric control cabinet D. The plate turning machine A is set between two CNC cutting machines B, the electric control cabinet D is located on the side of any CNC cutting machine B, and the plate turning machine A picks up the plate-shaped workpiece from one CNC cutting machine B C turns over and conveys it to another CNC cutting machine B to realize the connection between two CNC cutting machines B to meet different production needs; CNC cutting machine B and plate turning machine A are respectively powered Control cabinet D control.

[0051] Furthermore, in order to cooperate with the connection of two CNC cutting machines B, the moving starting position of the block 13 is set on the other side of the feeding area; the push...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com