Cutter for processing valve seat seal groove

A technology for sealing grooves and tools, applied in the field of processing tools, can solve the problems of low processing efficiency, cumbersome process, complex structure, etc., and achieve the effects of high processing precision, simple tool structure, and simple correction program.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

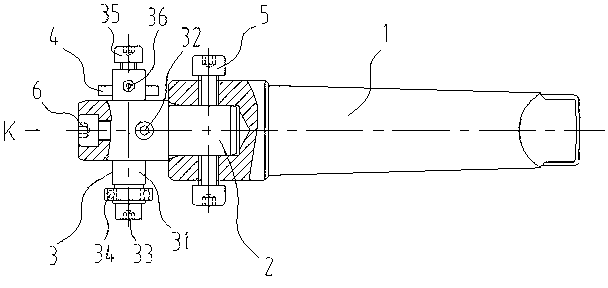

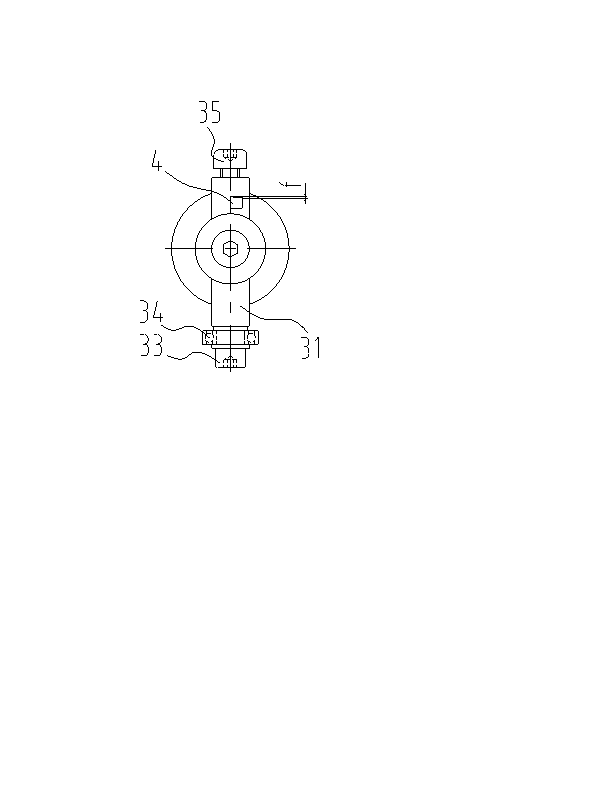

[0031] Such as figure 1 As shown, the cutter includes a knife handle 1, a cutter head 2, a knife bar 3 and a blade 4, one end of the knife head 2 is connected with the knife handle 1, the knife bar 3 is connected with the knife head 2, and the blade 4 is connected with the knife bar 3. The tool has simple structure, low production cost, strong pertinence and good practicability, and can be produced and used by various demand enterprises without professional tool processing equipment. And because the cutter head 2 is provided, the center of the machining hole can be quickly found when the sealing groove of the valve seat is processed, the process of correcting t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com