External hanging type optimization method and device for numerical control system

A technology of numerical control system and optimization method, applied in the direction of numerical control, electrical program control, etc., can solve the problems of low processing efficiency of numerical control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

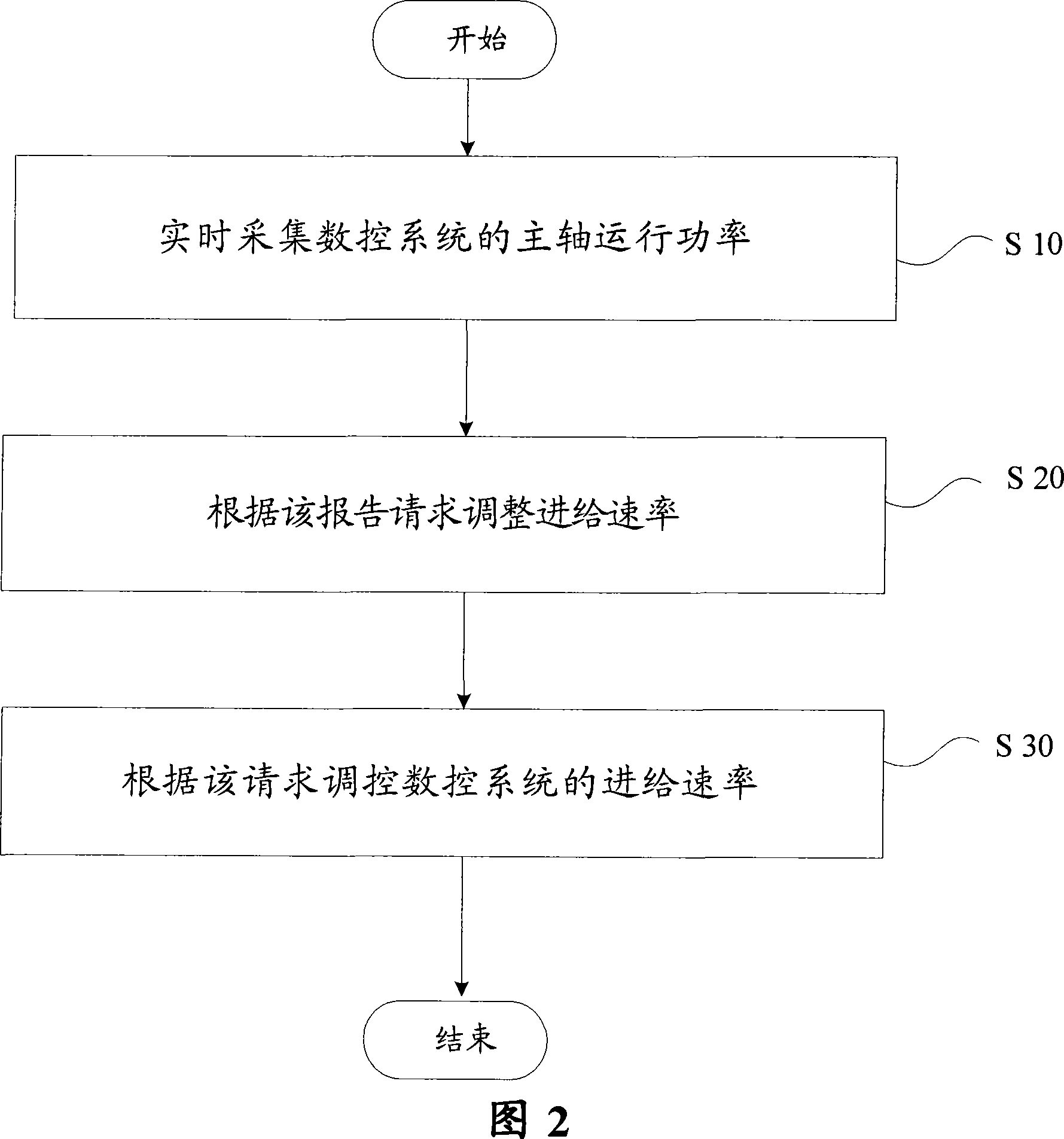

[0023] Fig. 2 shows a flowchart of a plug-in optimization method according to an embodiment of the present invention, including the following steps:

[0024] Step S10: collecting the running power of the spindle of the numerical control system in real time;

[0025] Step S20: requesting to adjust the feed rate according to the report, that is, if the operating power of the spindle is lower than a predetermined load rate, request to increase the feed rate; if the spindle operating power is higher than the predetermined load rate, then request to reduce the feed rate; and

[0026] Step S30: adjust the feed rate of the numerical control system according to the request.

[0027] Compared with the prior art, this embodiment increases the control of the feed rate. In this embodiment, the feed rate of the CNC system is no longer limited t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com