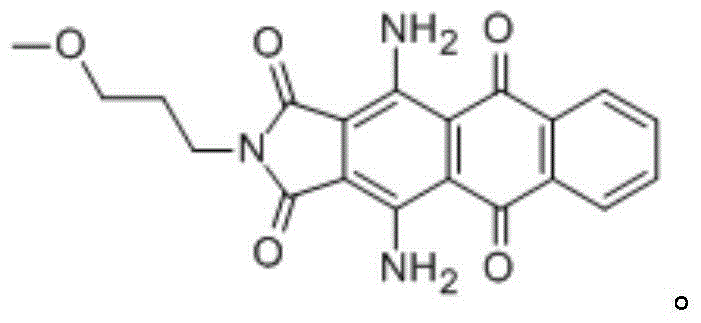

Clean production process of 1,4-diaminoanthraquinone-2-sulfonic acid

A diaminoanthraquinone, clean production technology, applied in the preparation of sulfonic acid, organic chemistry, etc., can solve the problems of wasting energy, dark color, and high COD in wastewater, and achieve the effects of reducing costs, solving high COD, and reducing waste residue discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037]Add 300g of o-dichlorobenzene and 40g of 1,4-diaminoanthraquinone leuco into a 500mL flask, slowly add 91g of chlorosulfonic acid at 40°C, keep the vacuum at -0.005MPa during the dropping process, and slowly raise the temperature after the dropping Incubate at 140°C for 3.5h, keep the vacuum at -0.005MPa during the reaction, use liquid chromatography to detect that the remaining amount of 1,4-diaminoanthraquinone ≤ 2% is the end point of sulfonation, cool down, and dilute with 400mL of water to obtain The material is neutralized with liquid caustic soda, and the solvent o-dichlorobenzene is evaporated by raising the temperature. The evaporated solvent can be directly reused as the reaction solvent. During the distillation process, water can be added appropriately according to the reaction system to maintain the fluidity of the material. After the condensation tube is free of oil When the beads come out, the distillation is stopped, and the impurities are filtered out whil...

Embodiment 2

[0041] Add 300g of o-dichlorobenzene and 40g of 1,4-diaminoanthraquinone leuco into a 500mL flask, slowly add 93g of chlorosulfonic acid at 40°C, keep the vacuum at -0.005MPa during the dropping, and slowly raise the temperature after the dropping Incubate at 140°C for 3.5h, keep the vacuum at -0.005MPa during the reaction, use liquid chromatography to detect that the remaining amount of 1,4-diaminoanthraquinone ≤ 2% is the end point of sulfonation, cool down, and dilute with 400mL of water to obtain The material is neutralized with liquid caustic soda, and the solvent o-dichlorobenzene is evaporated by raising the temperature. The evaporated solvent can be directly reused as the reaction solvent. During the distillation process, water can be added appropriately according to the reaction system to maintain the fluidity of the material. After the condensation tube is free of oil When the beads come out, the distillation is stopped, and the impurities are filtered out while it is...

Embodiment 3

[0045] The other conditions are the same as in Example 2, except that the system vacuum is kept at -0.002MPa during the addition of chlorosulfonic acid and the reaction process.

[0046] The total yield of the finally obtained sulfonated product filter cake is 96%, and the content is greater than 98%. 2.0% of 1,4-diaminoanthraquinone can be recovered, and 1.2% of sulfonic acid filter cake can be recovered. The amount of high-concentration wastewater obtained by stripping is reduced to 75ml, and the solvent is removed and then directly incinerated. The low-COD waste water (COD is 400mg / L, COD removal rate up to 96%) obtained by extraction can be directly used in the next-level biodegradation process without further removal of organic matters.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com