Device for extracting gasoline and diesel oil from used lubricating oil

A technology for waste lubricating oil, gasoline and diesel, applied in the petroleum industry, processing hydrocarbon oil, hydrocarbon oil treatment products and other directions, can solve the problems of pollution, seldom recycling, can not be continuous production, etc., to achieve pollution-free resource utilization, Optimal resource utilization and the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

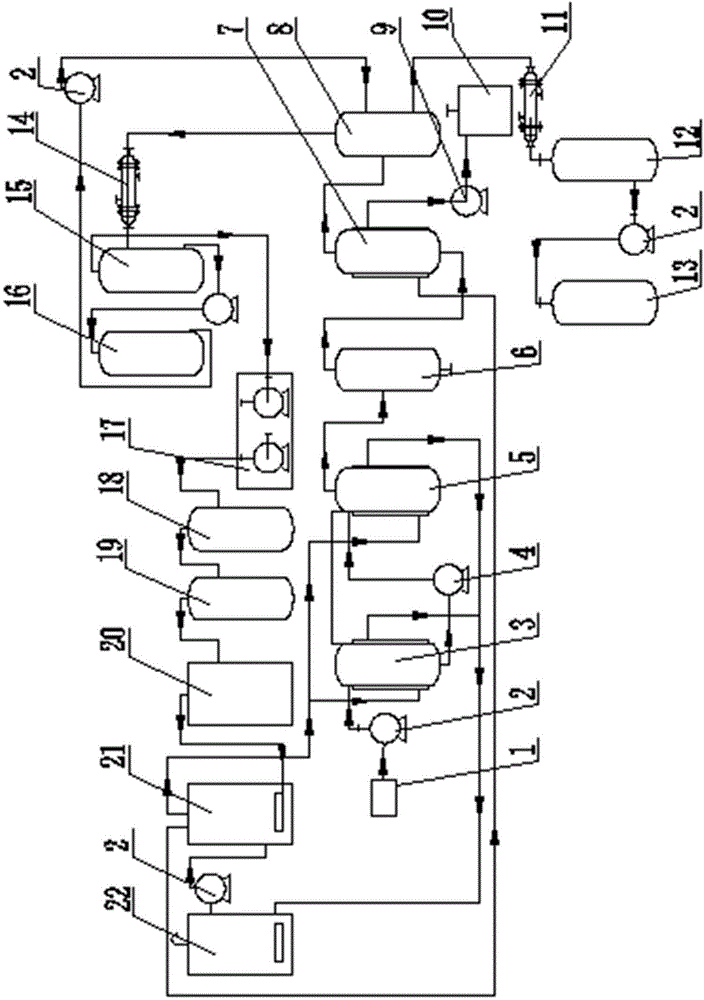

[0025] Referring to the accompanying drawings, a device for refining gasoline and diesel oil using waste lubricating oil includes a settling tank 1, a high-temperature oil pump 2, a flash tank 3, a vaporization kettle 4, a vaporization kettle filter tower 5, a fixed-bed catalytic tower 6, a fractionation tower 7, and Fan 8, flue gas purification device 9, diesel water cooler 10, diesel intermediate tank 11, gear oil pump 12, diesel storage tank 13, return pump 14, gasoline water cooler 15, oil-gas separation tank 16, gasoline storage tank 17 , vacuum pump group 18, dry gas buffer tank 19, dry gas desulfurization and dechlorination tower 20, dry gas cabinet 21, molten salt heating furnace 22, molten salt pump 23, molten salt tank 24.

[0026] One end of the settling tank 1 is filled with waste lubricating oil, and the other end is connected to the high-temperature oil pump 2. The purpose of the settling tank 1 is to conduct random inspection and separation of the waste lubricati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com