Capillary system type writing tool

A writing tool, direct liquid technology, applied in writing utensils, printing, other ink pens, etc., can solve the problems of ink leakage and poor ink return effect, and achieve the effect of preventing ink leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

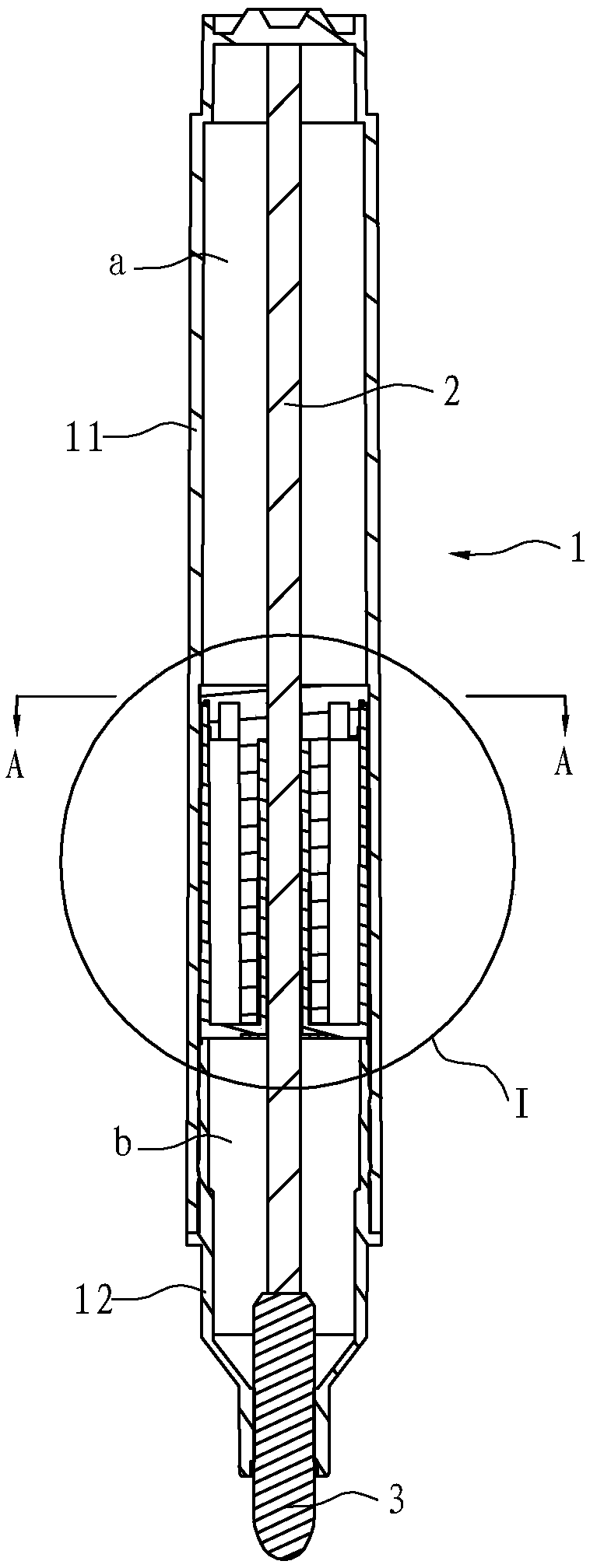

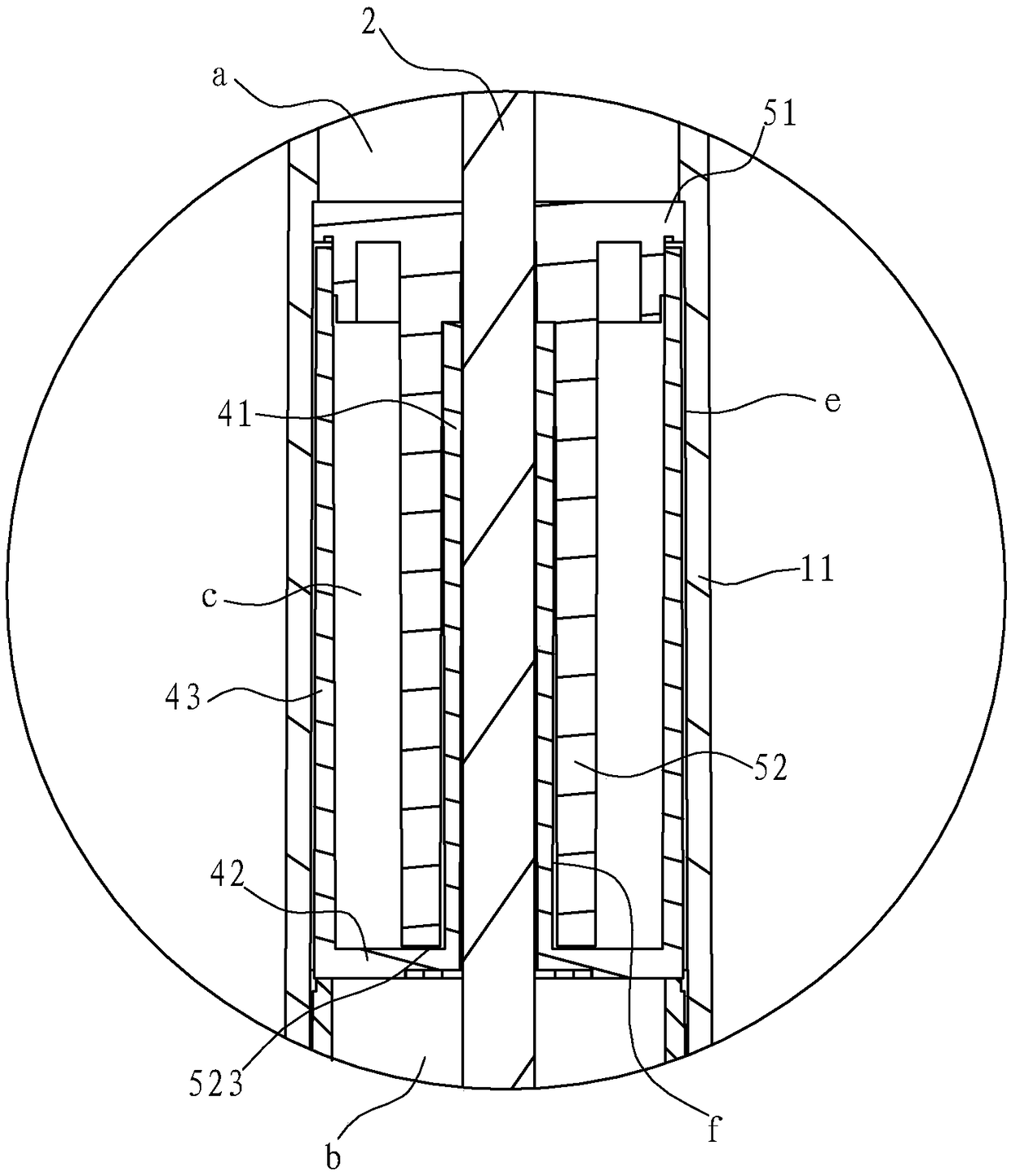

[0036] Such as Figure 1 to Figure 8 As shown, a direct-liquid writing tool includes a pen case 1, a water guide core 2, a nib 3 and an ink storage part. The pen case 1 includes an upper shell 11 and a lower shell 12 that are connected up and down, and the water guide core 2 is inserted into the In the inner chamber of the pen case 1 , the nib 3 is connected to the bottom of the water guide core 2 and partly exposed at the bottom of the lower shell 12 of the pen case 1 .

[0037]The above-mentioned ink storage part is located in the inner cavity of the pen case 1, and divides the inner cavity of the pen case 1 into an upper ink supply chamber a and a lower atmospheric communication chamber b. The upper part of the water guide core 2 extends into the ink supply chamber a through the ink storage part, and the ink in the ink supply chamber a can be transferred to the nib 3 to realize stable ink supply. Inside the ink storage part, there is an ink buffer channel that detours alon...

Embodiment 2

[0044] Such as Figure 9 As shown, different from Embodiment 1, in this embodiment, there is one air guide channel e, that is, the number of corresponding second grooves 431 and third grooves 432 is one.

Embodiment 3

[0046] Such as Figure 10 As shown, the difference from Embodiment 2 is that in this embodiment, in order to further reduce ink remaining in the ink buffer cavity c, an ink-absorbing core 6 is accommodated in the ink return channel f, and a cotton core is used in this embodiment, and The cotton core is in contact with the water diversion core, and the cotton core can absorb the residual ink in the ink buffer chamber c and attract the ink to the water diversion core for writing by the nib.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com