Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Fast curing at low temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Epoxy resin binder used for repairing blade and preparation method thereof

ActiveCN101698787AFast curingLower the activation energy of the reactionNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyWind driven

The invention relates to a preparation method of repairing adhesive, in particular to a binder for repairing blade of a wind driven generator, belonging to the high polymer material field. The preparation method of double-component epoxy resin binder used for repairing blade is simple in operation and low in cost. The double-component epoxy resin binder for repairing blade which is made by the method of the invention has high tenacity, high shear strength, low heat and low shrink, thus being suitable for repairing and binding of large structural part; solidification is rapid, the binder can be rapidly solidified in 10-30 minutes at 5-25 DEG C and reach certain strength; and the binder is used for repairing defect of blade of wind driven generator.

Owner:镇江市电子化工材料工程研究中心有限公司

Single-component surface pasting adhesive capable of being rapidly cured

InactiveCN101463239AShelf life stabilityFast curing at low temperatureEpoxy resin adhesivesAdhesiveSurface mounting

The invention discloses a fast-curable one-component surface mount adhesive, which is composed of a liquid epoxy resin, a modified epoxy resin, a reactive diluent, a latent curing agent, an accelerating agent, a thixotropic agent, an inorganic filler and a paint. The components thereof have the following weight percents: 20-80% of the liquid epoxy resin, 0-10% of the modified epoxy resin; 1-10% of the reactive diluent; 1-9% of the latent curing agent; 2-18% of the accelerating agent; 3-10% of the thixotropic agent; 0-30% of the inorganic filler and 0-3% of the paint. The invention, compared with the current product, is low in viscosity, excellent in thixotropy and remarkable in electrical performance and can be rapidly cured in 90 seconds under the temperature of 120 DEG C, furthermore, the invention has high adhesion force and good heat and impact resistance, thus can be applied to the technical field of the surface mount.

Owner:SHENZHEN DOVER TECH

One-component epoxy adhesive used for bonding LED backlight modules LENS

InactiveCN104774584AFast curing at low temperatureExcellent damp heat aging performanceNon-macromolecular adhesive additivesEpoxy resin adhesivesAging resistanceLow temperature curing

The present invention relates to the technical field of adhesives, and relates to a one-component epoxy adhesive used for bonding LED backlight modules LENS, and a preparation method thereof. The one-component epoxy adhesive comprises the following components by weight: 30-40 parts of epoxy resin; 10-15 parts of an epoxy flexibilizer; 34-40 parts of polymercaptan; 20-30 parts of a filler; 5-7 parts of a promoter; 1-2 parts of a stabilizer; 0.5-1 part of a coupling agent and 1-2 parts of a water absorbent. Compared with the previous invention, the one-component epoxy adhesive has excellent heat and humidity aging resistance while maintaining low temperature curing performance.

Owner:TONSAN ADHESIVES INC

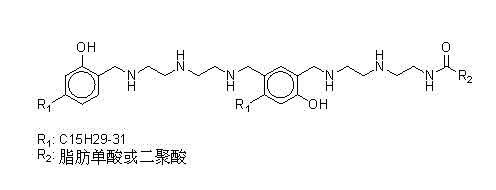

Cashew phenolic aldehyde amide epoxy hardener for four-season-general type anticorrosive paint and preparation method of cashew phenolic aldehyde amide epoxy hardener

ActiveCN102977670AComponent ratio scienceImprove reaction efficiencyOrganic compound preparationCarboxylic acid amides preparationFeeding orderDiethylenetriamine

The invention discloses a cashew phenolic aldehyde amide epoxy hardener for four-season-general type anticorrosive paint and a preparation method of the cashew phenolic aldehyde amide epoxy hardener. The cashew phenolic aldehyde amide epoxy hardener is composed of, by weight, one part of diethylenetriamine, 2.5-3 parts of dimer acids or fat single acids, 2.8-3.2 parts of anacardol, one part of the diethylenetriamine, and 0.9-1.2 parts of 96%-purity paraformaldehyde. Raw material composition, and the best matching and the feeding order of each material are optimized through a large number of experiments, and each component matching is scientific and reasonable. The method of mannich addition after amidation is utilized, the whole process is strong in operability, cost is low, production periods are short, productivity is high, the prepared cashew phenolic aldehyde amide epoxy hardener can be general in four seasons, drying is rapid, operation periods are short, anti-corrosion performance is good, and water-proof performance is excellent. The cashew phenolic aldehyde amide epoxy hardener can be widely used in the fields of pipe and storage tank storage corrosion prevention, adhesion agents, metallic top coats, chip heavy corrosion prevention and the like.

Owner:江苏三木化工股份有限公司

Anisotropic conductive film and semiconductor device bonded by the same

ActiveCN103160221AAvoid warpingFast curing at low temperatureNon-insulated conductorsFilm/foil adhesivesAnisotropic conductive filmEpoxy

A semiconductor device bonded by an anisotropic conductive film and an anisotropic conductive film composition, the anisotropic conductive film including a reactive monomer having an epoxy equivalent weight of about 120 to about 180 g / eq; a hydrogenated epoxy resin; and a sulfonium cation curing catalyst. The anisotropic conductive film according to an embodiment may be rapidly cured at low temperature, and serious warpage thereof during heat curing may be reduced and / or prevented. The embodiments provide an anisotropic conductive film that employs a reactive monomer having a particular epoxy equivalent weight to achieve rapid low-temperature curing. The embodiments provide an anisotropic conductive film that uses, e.g., sulfonium borate, as a sulfonium cation curing catalyst to help reduce and / or prevent emission of large amounts of fluorine ions in polymerization of cations. The embodiments provide an anisotropic conductive film that further includes a hydrogenated epoxy resin to help enhance reaction efficiency with a sulfonium cation curing catalyst, thereby exhibiting excellent rapid low-temperature curing properties.

Owner:KUKDO ADVANCED MATERIALS CO LTD

Method for preparing epoxy resin curing agent by degrading polyethylene terephthalate with glycerine

InactiveCN102120721AFast curingFast curing at low temperatureOrganic chemistryPlastic recyclingEpoxyPolyethylene terephthalate glycol

A method for preparing epoxy resin curing agent by degrading polyethylene terephthalate (PET) with glycerine relates to the technical field of the preparation of the epoxy resin curing agent. The method comprises the following steps: adding glycerine and ZnAc2 used as catalyst in a four-necked flask in turn according to a certain ratio, fixing the four-necked flask on an electric mixer, slowly heating to ensure that catalyst is completely dissolved, introducing nitrogen, then adding polyethylene terephthalate continuously heating to ensure that PET is completely dissolved, starting the mixer to react; cooling the reaction product, transferring the reaction product to a reduced pressure distillation device to obtain an intermediate product after the reduced pressure distillation; and adding the intermediate product and sodium methylate used as catalyst in the four-necked flask, continuously dropping diethanol amine in the reaction system with a constant pressure funnel, and controllingthe reaction temperature to react and obtain the epoxy resin curing agent. By adopting the invention, the epoxy resin curing agent which has the functions such as curing, toughening, antiflaming and promoting and is characterized by fast curing, low-temperature curing, low water absorption and the like, can be prepared.

Owner:JIANGNAN UNIV

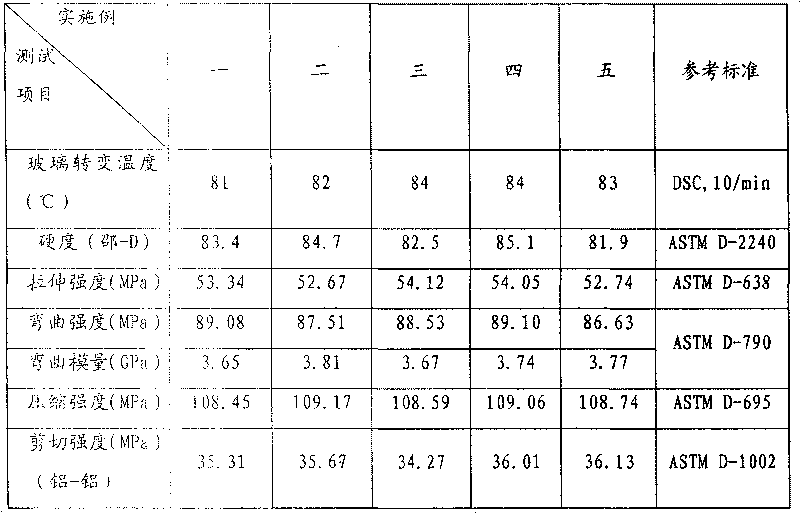

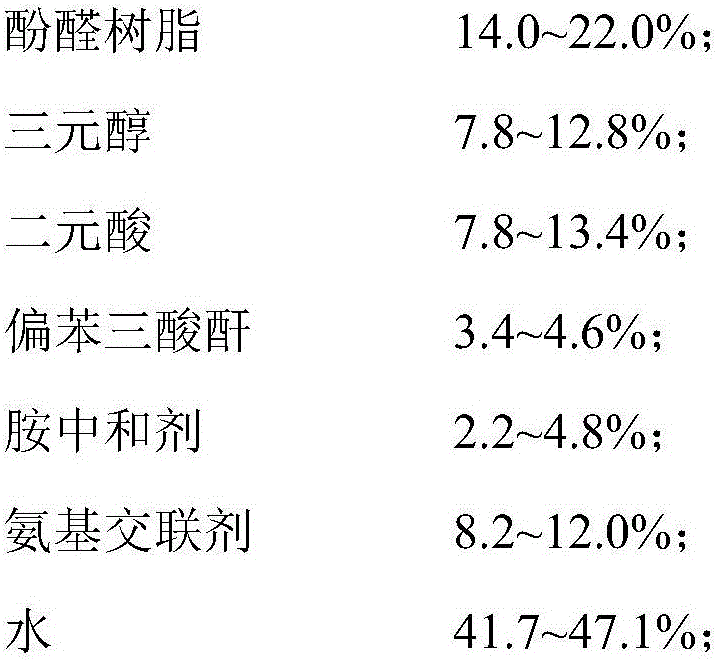

Waterborne impregnating insulation varnish capable of being quickly cured at low temperature and preparation method thereof

ActiveCN104194581AFast curing at low temperatureHigh mechanical strengthPolyester coatingsPolymer sciencePtru catalyst

The invention relates to a waterborne impregnating insulation varnish capable of being quickly cured at a low temperature and a preparation method thereof. The preparation method comprises the following steps of preparing phenol and polyformaldehyde in the presence of a basic catalyst to obtain phenolic resin, and then reacting phenolic resin with a trihydric alcohol, dibasic acid and trimellitic anhydride, neutralizing with amine and adding an amino crosslinking agent and water to obtain waterborne alkyd polyester containing high content of phenolic resin. The insulation varnish disclosed by the invention has the performances of both phenolic resin and alkyd polyester, the curing speed of the insulation varnish is greatly improved compared with the conventional alkyd resin and alkyd resin modified by phenolic aldehyde, the curing temperature is reduced to 120 DEG C and the cured varnish film has the advantages of excellent mechanical performance and electrical insulation property.

Owner:ELANTAS ZHUHAI CO LTD

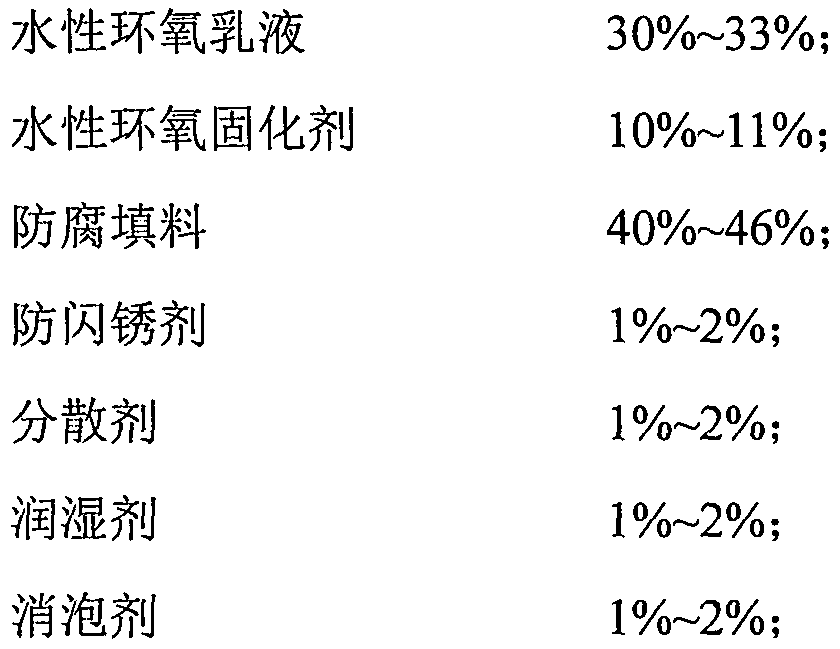

Waterborne epoxy flash-rust preventing paint

InactiveCN106634448AImprove toughnessImprove heat resistanceAnti-corrosive paintsEpoxy resin coatingsEmulsionLow temperature curing

The invention relates to waterborne epoxy flash-rust preventing paint which is prepared from 30% to 33% of waterborne epoxy emulsion, 10% to 11% of waterborne epoxy curing agent, 40% to 46% of anti-corrosive filler, 1% to 2% of flash-rust preventing agent, 1% to 2% of dispersing agent, 1% to 2% of wetting agent, 1% to 2% of defoaming agent and the balance of water in percentage by mass. According to the waterborne epoxy flash-rust preventing paint disclosed by the invention, the waterborne epoxy emulsion and the waterborne epoxy curing agent which are modified by pure plant cardanol are utilized, so that a prepared paint film is high in film hardness, good in adhesive force, excellent in anti-corrosive performance and mechanical performance, safe and environment-friendly and has no pollution. According to the waterborne epoxy flash-rust preventing paint disclosed by the invention, the paint film is better in flash-rust prevention ability and wider in construction environment, and can resist to low-temperature curing.

Owner:上海美东生物材料股份有限公司

A kind of low-temperature fast-curing water-based impregnated insulating varnish and preparation method thereof

ActiveCN104194581BFast curing at low temperatureHigh mechanical strengthPolyester coatingsPolyesterTriol

The invention relates to a water-based low-temperature fast-curing impregnated insulating varnish and a preparation method thereof, which is obtained from the following components through the following preparation method: phenolic resin is prepared by phenol and paraformaldehyde under conditions catalyzed by an alkaline catalyst, and then the Reaction of phenolic resin with trihydric alcohol, dibasic acid and trimellitic anhydride, neutralization with amine, addition of amino crosslinking agent and water to prepare water-based alkyd polyester with high content of phenolic resin. The insulating varnish of the present invention has the properties of both phenolic resin and alkyd polyester, the curing speed is greatly improved compared with general alkyd resin and phenolic modified alkyd resin, and the curing temperature is also reduced to 120 ° C. The mechanical properties of the cured paint film and excellent electrical insulation properties.

Owner:ELANTAS ZHUHAI CO LTD

Modified tertiary aliphatic amine type epoxy resin latency curing agent and preparation method thereof

The invention discloses a modified tertiary aliphatic amine type epoxy resin latency curing agent which is prepared by enabling urea or isocyanate to react with polyamine and tertiary aliphatic aminewith amino or hydroxyl in a solvent, removing the solvent and crushing the obtained solid. The prepared latency curing agent is simple and easy in material obtaining, simple and convenient in processand can be cured at a low temperature, and a cured product is light in color and has good adhesion strength.

Owner:广东固研电子材料有限公司

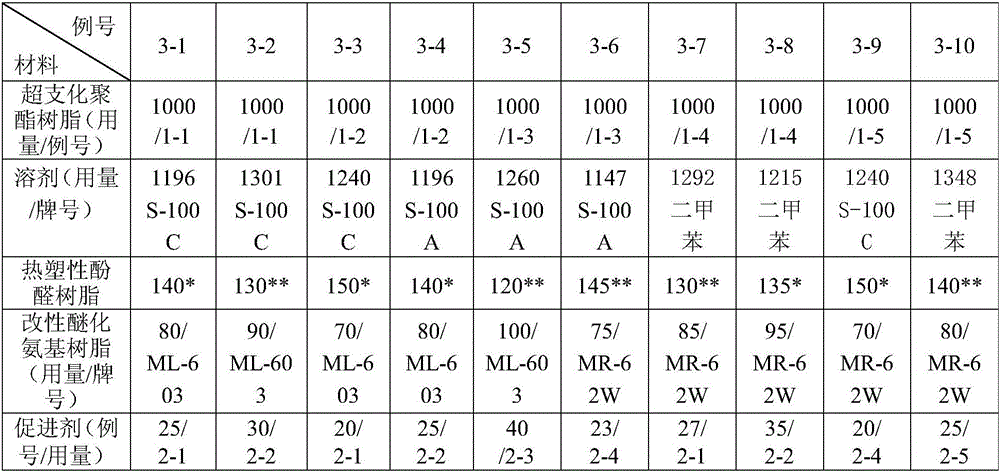

Low-temperature-resistant two-component solvent-free epoxy coating for pipeline joint coating

ActiveCN110724440AFast curing at low temperatureNo crackRubber derivative coatingsAnti-corrosive paintsPolymer scienceThiourea

The invention discloses a low-temperature-resistant two-component solvent-free epoxy coating for pipeline joint coating. The low-temperature-resistant two-component solvent-free epoxy coating for pipeline joint coating is composed of a component A and a component B; wherein the component A comprises, by weight, 30 to 45% of bisphenol F epoxy resin; 5-10% of bisphenol A epoxy resin; 5 to 10% of epoxy butyronitrile prepolymer; 3-7% of a glycidyl ether reactive diluent, 15-25% of modified silica powder, 8-15% of titanium dioxide, 3-10% of aluminum dihydrogen tripolyphosphate, 4-10% of mica powder, 0.6-1.4% of a thixotropic agent, 0.2-0.5% of a dispersing agent, 0.2-0.5% of a leveling agent, 0.3-0.7% of an antifoaming agent and 0.1-0.7% of carbon black; the component B is prepared from 50 to 75% of Mannich base and 25 to 50% of a thiourea-polyamine condensate. Compared with a common epoxy coating, the low-temperature-resistant two-component solvent-free epoxy coating for pipeline joint coating has the characteristics of being high in low-temperature curing speed, free of crystallization and precipitation, excellent in low-temperature bending resistance, excellent in low-temperature impact resistance, excellent in hot water soaking resistance, excellent in cold and hot impact resistance and the like.

Owner:CYG CHANGTONG NEW MATERIAL

Carbon fiber cloth adhesive for underwater or humid environment reinforcement engineering and preparation method thereof

PendingCN113897160AImprove hydrophobicityImprove moisture resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesAdhesive cementFiber

The invention discloses a carbon fiber cloth adhesive for underwater or humid environment reinforcement engineering and a preparation method thereof. The adhesive is obtained by well mixing a component A and a component B. The component A is prepared from fluorinated epoxy resin, hydroxymethyl bisphenol A type epoxy resin, bisphenol S type epoxy resin, diglycidyl aniline, trimethylolpropane triglycidyl ether, a toughening agent, water-absorbent resin, a defoaming agent, a dispersing agent, active silica powder, carbon nanotubes, cement and fumed silica. The component B is prepared from aliphatic amide polyamine, isophorone diamine, a curing agent, DMP-30, a coupling agent, a defoaming agent, a dispersing agent, active silica powder, carbon nanotubes, cement and fumed silica. The adhesive prepared by the invention has the advantages of high water interface bonding strength, high colloid mechanical strength, good toughness, strong impact resistance and fatigue resistance, good construction performance and the like, and the bonding effect and durability of the carbon fiber cloth adhesive in water environment reinforcement engineering can be remarkably improved.

Owner:山西省交通科技研发有限公司 +2

Method for preparing water-soluble resin

InactiveCN101885792AImprove moisture resistanceHigh strengthPolyureas/polyurethane adhesivesNitrile polymer adhesivesAdhesiveWater soluble

The invention relates to a method for preparing resin, in particular to a method for preparing water-soluble resin. The method for preparing the water-soluble resin is characterized by comprising the following steps of: adding 30 to 50 kilograms of raw materials into a reaction kettle at the temperature of between 190 and 210 DEG C under the pressure of between 1.3 and 1.7MPa, then adding 1 to 3 kilograms of sodium hydroxide and 50 to 70 kilograms of water into the reaction kettle to perform alkaline hydrolysis reaction for 2 to 4 hours, adding 0.2 to 2 liters of low molecular aldehyde substance and 0.3 to 1 liter of silane into the reaction kettle and further reacting for 4 to 5 hours, and obtaining the water-soluble resin after the reaction is finished. The method has the advantages that: the water-soluble resin prepared by the method thoroughly solves the pollution problem of adhesive for casting by using the water as a medium, and has the advantages of low-temperature quick curing, energy conservation, no pollution, no odor, high strength, good collapsibility, wet creep resistance, dry moisture absorption resistance and the like.

Owner:山东良艺化工新材料有限公司

Impregnating resin for high-frequency and low-frequency electronic transformers

ActiveCN103773198ASimple preparation processGood composition stabilityPolyester coatingsTransformerLow temperature curing

The invention discloses impregnating resin for high-frequency and low-frequency electronic transformers. The impregnating resin comprises the following materials in percent by weight: 45-60% of polyester resin, 10-20% of a curing agent, 5-10% of oily phenolic resin, 0.02-2% of a functional additive and 25-40% of a diluting agent. Compared with the prior art, the impregnating resin has the advantages that (1) the manufacturing process is simple and the stability of composition is good; (2) not only are the mechanical strength and the bonding force improved, but also the softness is improved, the aspects of heat resistance and strong permeability are also excellent, the heat-resistant level can reach F level, and the comprehensive performance is better; (3) the impregnating resin also has the advantages of fast low-temperature curing, strong permeability, good internal drying performance, excellent secondary solderability and stable storage and the like. The impregnating resin disclosed by the invention does not contain dangerous and forbidden matters specified by the European ROSH regulations, completely meets the requirement on the impregnation process of the electronic transformer, and is excellent electronic-insulating impregnating varnish which can be comparable with foreign similar products.

Owner:浙江博菲电气股份有限公司

Method for preparing bi-component polyurethane pouring sealant and product thereof

ActiveCN102102006BSimple processProcess conditions are easy to controlOther chemical processesPolyureas/polyurethane adhesivesEnd-groupLow temperature curing

The invention relates to a bi-component polyurethane pouring sealant and a preparation method thereof. The polyurethane pouring sealant consists of a component A and a component B, wherein the component A is a hydroxyl end group component, and the component B is NCO-terminated polyurethane prepolymer prepared by reacting a hydroxyl compound with isocyanate. In the using process, the component A and the component B are mixed in a certain ratio. The prepared bi-component polyurethane pouring sealant is suitable for encapsulating medium and small electronic elements, such as encapsulation of circuit controllers of home appliances such as igniters and sensors, moistureproof and shockproof sealing of electronic and electric switches and sealed optical instruments of electronic elements, and the like; and the bi-component polyurethane pouring sealant does not contain any solvent, is adjustable in drying speed, can be cured at normal temperature or low temperature and stored stably, and has the advantages of good adhesion, flexibility, water resistance, flame retardancy, electric property and the like.

Owner:DONGGUAN HONGDA POLYUREFHANE RESIN

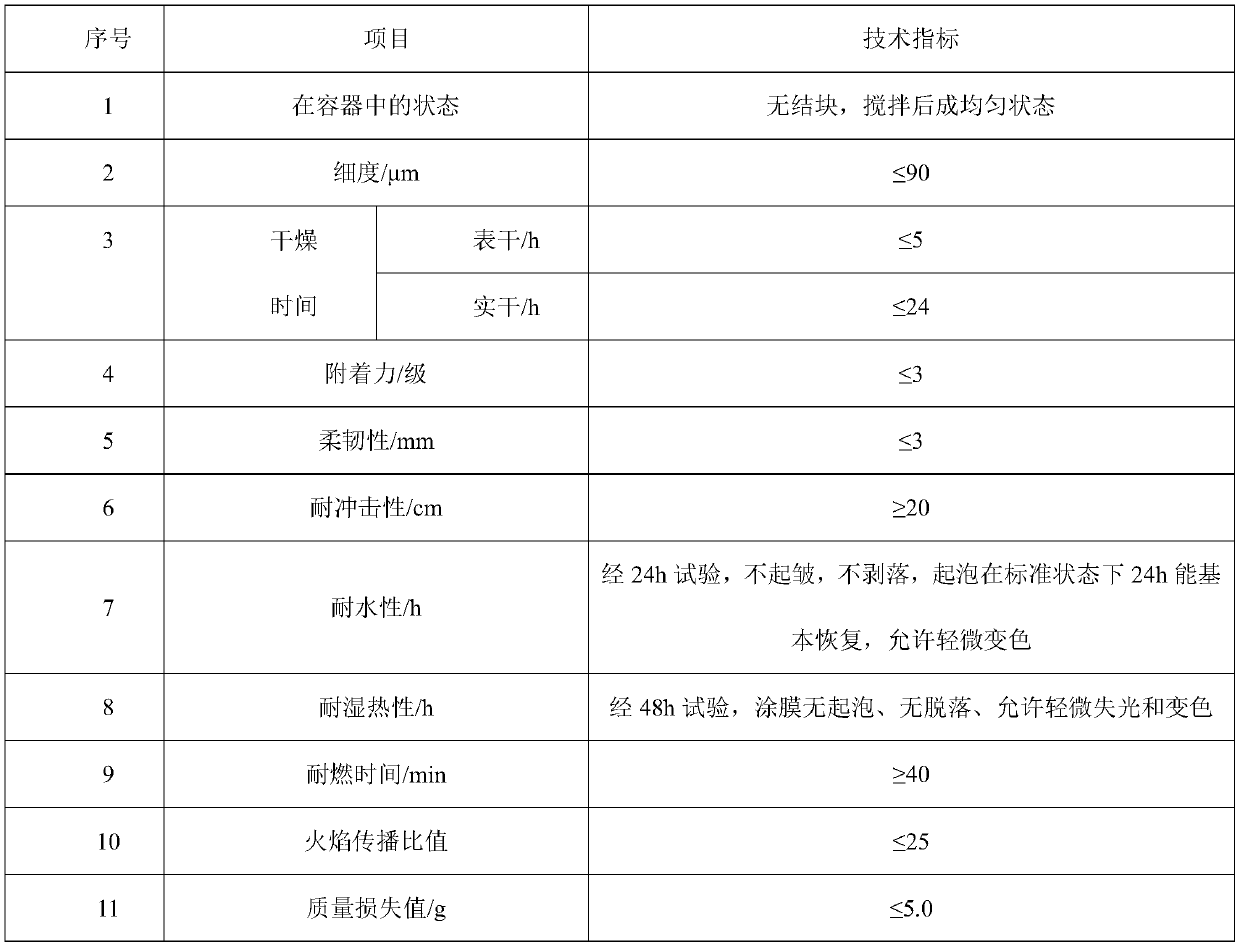

Fireproof coating for rail transit locomotive/vehicle and preparation method of fireproof coating

ActiveCN109913093ANot easy to break throughStrong adhesionFireproof paintsEpoxy resin coatingsCarbon layerEpoxy

The invention relates to a fireproof coating for a rail transit locomotive / vehicle and a preparation method of the fireproof coating. The fireproof coating for the rail transit locomotive / vehicle is prepared by taking poly-alpha-methyl styrene modified epoxy resin, a fire retardant and the like as the components of the coating, taking modified amine and a curing agent accelerator as components ofa curing agent, and using a proper amount of a diluent in the construction. The main purpose is to obtain a fireproof coating product for the rail transit locomotive / vehicle, the thickness of a film of the fireproof coating product for the rail transit locomotive / vehicle is thin (less than or equal to 2.0 mm), the expansion coefficient is large, the structural strength of a carbon layer is high, the heat conductivity coefficient is low, the fire resistance is strong, the adhesive property is good, the spraying is convenient in the construction, and the comprehensive performances are excellent.

Owner:株洲市九华新材料涂装实业有限公司

Polyurethane pouring sealant and preparation method thereof

PendingCN113861381ALow viscosityFast curing at low temperatureNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer scienceSealant

The invention relates to the field of polyurethane materials, in particular to a preparation method of a polyurethane pouring sealant, which comprises the following steps: preparing a component A; preparing the component B; and preparing the polyurethane pouring sealant: mixing the component A in the step S1 and the component B in the step S2 to obtain the polyurethane pouring sealant. The polyurethane pouring sealant provided by the invention has the characteristics of small viscosity, normal-temperature curing, and controllable curing speed and time, has excellent film performance, and also has good flexibility, water resistance, flame retardance and electrical performance, and can be applied to potting of electric appliance elements. The invention also provides a preparation method of the polyurethane pouring sealant. The preparation method is simple and rapid.

Owner:DONGGUAN HONGDA POLYUREFHANE RESIN

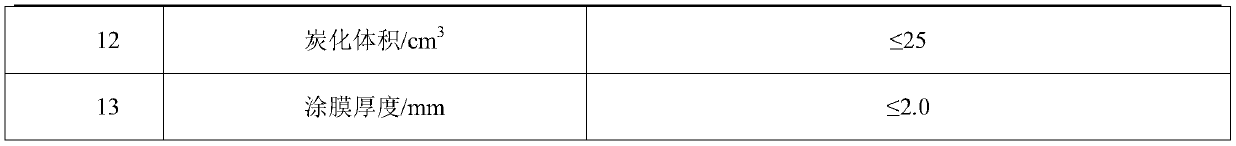

A low-temperature fast-curing glass fiber-wrapped wire impregnation resin and preparation method thereof

ActiveCN104449264BIncrease elasticityAvoid technical issues with crackingPolyester coatingsGlass fiberFiber

The invention discloses a low-temperature rapid-curing impregnating resin for a glass-fiber-clad conductor and a preparation method of the low-temperature rapid-curing impregnating resin. The impregnating resin is characterized by being prepared from the following components in parts by mass: 1,000 parts of hyperbranched polyester resin, 1,140 to 1,350 parts of solvent A, 120 to 150 parts of thermoplastic phenolic resin, 70 to 100 parts of modified etherified amino resin, and 20 to 40 parts of accelerant. The preparation method comprises the steps of preparing the hyperbranched polyester resin through a catalyst; preparing the accelerant; feeding the hyperbranched polyester resin and the solvent A into a reactor; heating to 120 DEG C; uniformly agitating; cooling to less than 80 DEG C; feeding the thermoplastic phenolic resin and the modified etherified amino resin; uniformly agitating; cooling to less than 50 DEG C; feeding the accelerant; uniformly agitating; and filtering to obtain the filtrate which is the impregnating resin. The impregnating resin is applicable to the manufacturing of glass fiber winding coil parts of an electric welder, a plasma cutting machine, a voltage stabilizer, a dry type transformer, an electric reactor of a large generator unit and the like.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

Cashew phenolic aldehyde amide epoxy hardener for four-season-general type anticorrosive paint and preparation method of cashew phenolic aldehyde amide epoxy hardener

ActiveCN102977670BComponent ratio scienceImprove reaction efficiencyOrganic compound preparationCarboxylic acid amides preparationDiethylenetriaminePliability

The invention discloses a cashew phenolic aldehyde amide epoxy hardener for four-season-general type anticorrosive paint and a preparation method of the cashew phenolic aldehyde amide epoxy hardener. The cashew phenolic aldehyde amide epoxy hardener is composed of, by weight, one part of diethylenetriamine, 2.5-3 parts of dimer acids or fat single acids, 2.8-3.2 parts of anacardol, one part of the diethylenetriamine, and 0.9-1.2 parts of 96%-purity paraformaldehyde. Raw material composition, and the best matching and the feeding order of each material are optimized through a large number of experiments, and each component matching is scientific and reasonable. The method of mannich addition after amidation is utilized, the whole process is strong in operability, cost is low, production periods are short, productivity is high, the prepared cashew phenolic aldehyde amide epoxy hardener can be general in four seasons, drying is rapid, operation periods are short, anti-corrosion performance is good, and water-proof performance is excellent. The cashew phenolic aldehyde amide epoxy hardener can be widely used in the fields of pipe and storage tank storage corrosion prevention, adhesion agents, metallic top coats, chip heavy corrosion prevention and the like.

Owner:江苏三木化工股份有限公司

A low-temperature-resistant two-component solvent-free epoxy coating for pipe joints

ActiveCN110724440BFast curing at low temperatureNo crackRubber derivative coatingsAnti-corrosive paintsThioureaLow temperature curing

A low-temperature resistant two-component solvent-free epoxy coating, which is composed of A component and B component, wherein in weight percentage, A component includes: bisphenol F type epoxy resin 30-45%, bisphenol A type Epoxy resin 5‑10%, epoxy nitrile prepolymer 5‑10%, glycidyl ether reactive diluent 3‑7%, modified silica powder 15‑25%, titanium dioxide 8‑15%, tripolyphosphoric acid Aluminum dihydrogen 3‑10%, mica powder 4‑10%, thixotropic agent 0.6‑1.4%, dispersant 0.2‑0.5%, leveling agent 0.2‑0.5%, defoamer 0.3‑0.7%, carbon black 0.1‑ 0.7%; B component includes: Mannich base 50-75%, thiourea-polyamine condensate 25-50%. Compared with ordinary epoxy coatings, the low-temperature resistant two-component solvent-free epoxy coating for pipe jointing of the present invention has fast curing speed at low temperature, no crystallization and no precipitation, excellent low-temperature bending resistance, excellent low-temperature impact resistance, and heat resistance Excellent water immersion performance, excellent thermal shock resistance and other characteristics.

Owner:CYG CHANGTONG NEW MATERIAL

Anisotropic conductive film and semiconductor device bonded by the same

ActiveCN103160221BAvoid warpingFast curing at low temperatureNon-insulated conductorsFilm/foil adhesivesEpoxyAnisotropic conductive film

A semiconductor device bonded by an anisotropic conductive film and an anisotropic conductive film composition, the anisotropic conductive film including a reactive monomer having an epoxy equivalent weight of about 120 to about 180 g / eq; a hydrogenated epoxy resin; and a sulfonium cation curing catalyst.

Owner:KUKDO ADVANCED MATERIALS CO LTD

Preparation method of corrosion-resistant structural adhesive for wind turbine blade

InactiveCN111849411AImprove corrosion resistanceHigh heat distortion temperatureNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesTurbine bladeAdhesive

The invention discloses a preparation method of a corrosion-resistant structural adhesive for a wind turbine blade, and belongs to the technical field of wind turbine structural adhesives. The corrosion-resistant structural adhesive has the characteristics of good heat resistance and corrosion resistance, excellent toughness and thermal stability, low curing heat release and ultralow shrinkage. The corrosion-resistant structural adhesive can be used for bonding wind turbine blade base materials, can be widely applied to fan blades, and is small in thermal shrinkage, approximate to zero shrinkage, low in water absorption and porosity, high in heat-resistant grade and suitable for being used as the corrosion-resistant structural adhesive for the wind turbine blades after being cured.

Owner:安徽国成顺风风力发电有限公司

Thermo-sensitive epoxy resin powder paint

InactiveCN100999642BImprove liquidityReduce surface tensionPowdery paintsEpoxy resin coatingsEpoxyLow temperature curing

The thermosensitive epoxy resin powder paint consists of low softening point epoxy resin 60-70 wt%, curing agent 3-6 wt%, photoinitiator 0.5-1.0 wt%, leveling agent 1-2 wt%, defoaming agent 0.5-1.0 wt%, and pigment and stuffing 20-35 wt%. The present invention has imidazole type low temperature curing agent resulting in low temperature fast curing and photoinitiator to further raise low temperature curing speed, so that the paint has high low temperature curing speed. The present invention has short production period, low power consumption, low production cost and high production efficiency.

Owner:宁波市鄞州东海粉末涂料有限公司

Low-temperature fast-curing anti-hydrogen sulfide solvent-free coating for pipelines and preparation method thereof

ActiveCN103509438BFast curing at low temperatureFast curingAnti-corrosive paintsEpoxy resin coatingsSolvent freeFirming agent

Owner:SHANGHAI HILONG SHINE NEW MATERIAL

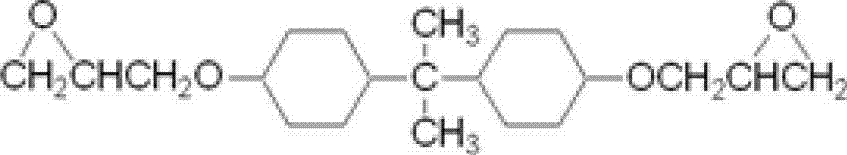

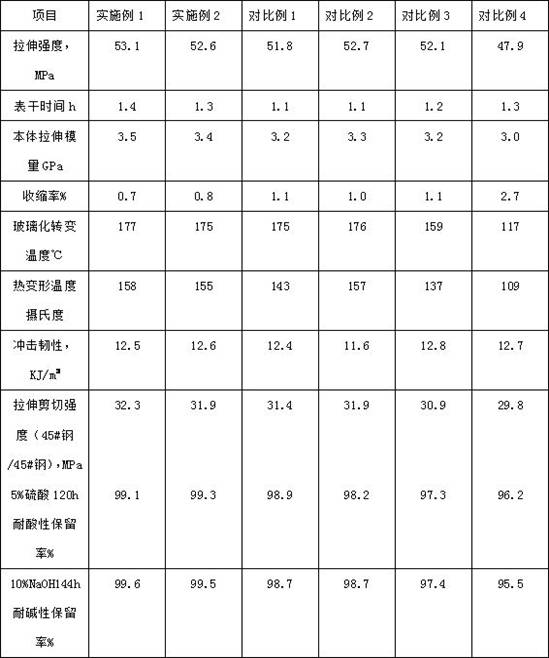

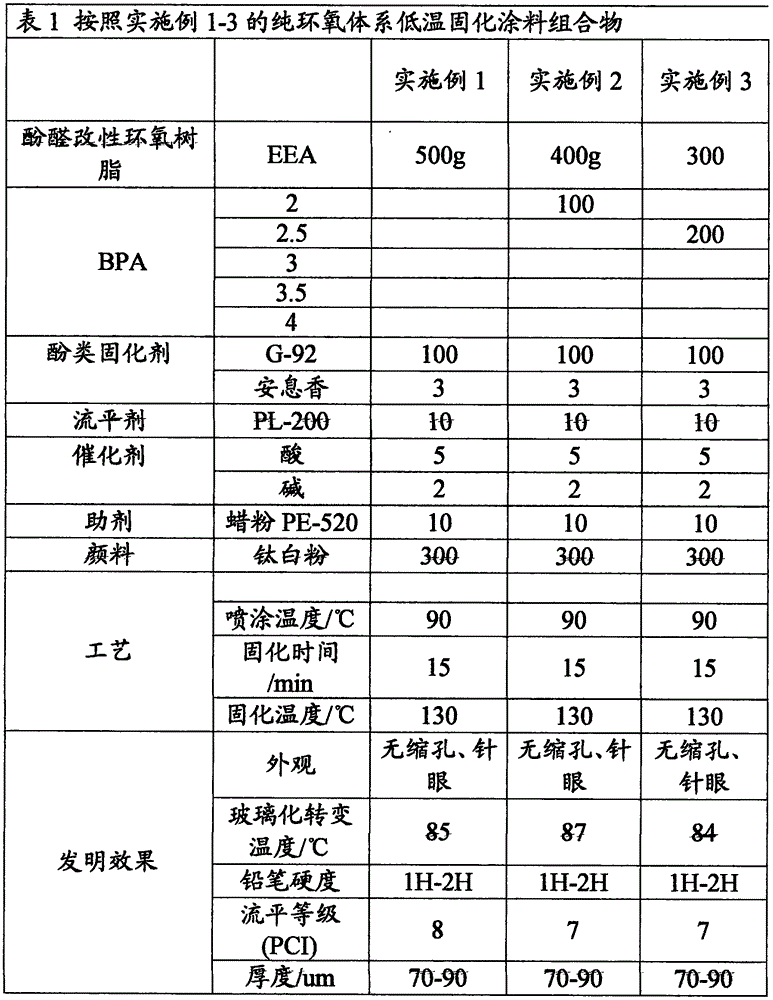

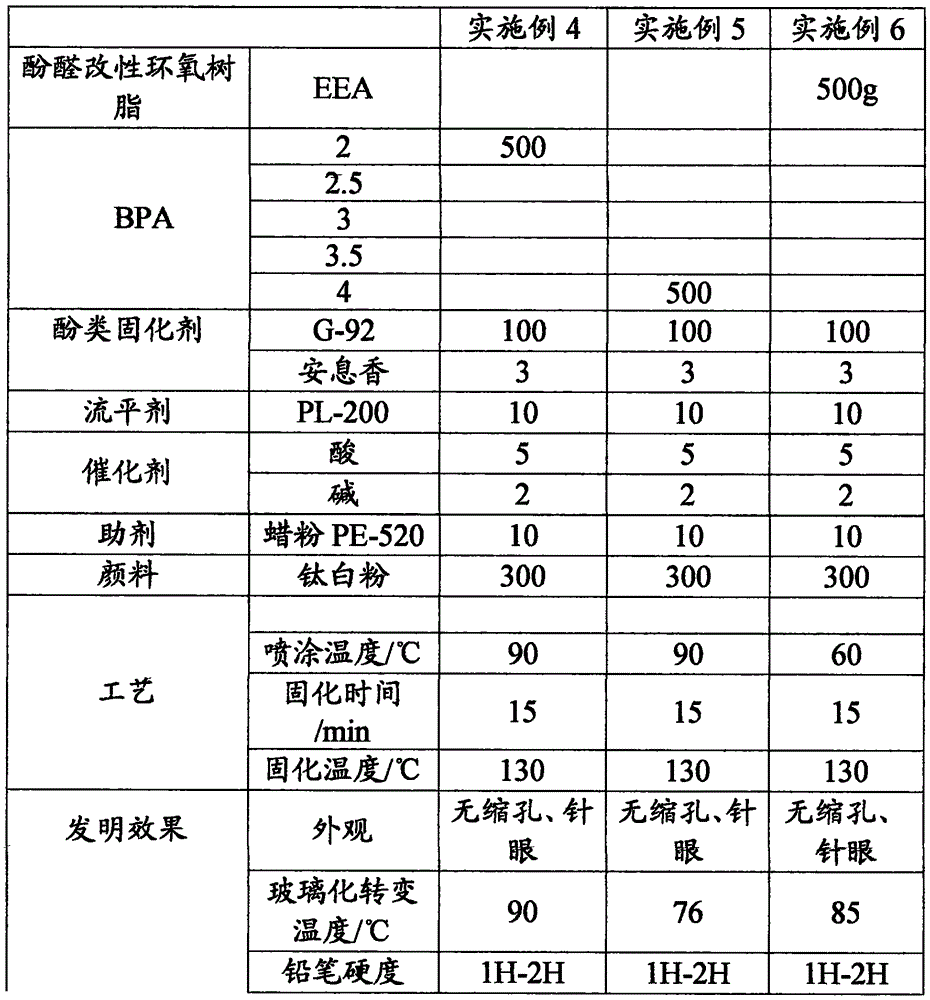

Pure epoxy system low-temperature curing coating material composition for carbon fiber substrate, and coating material thereof

The invention relates to a low-temperature curing coating material composition for a carbon fiber substrate, wherein the low-temperature curing coating material composition comprises type 2-4 BPA or phenol formaldehyde modified epoxy resin, a phenolic curing agent, and a catalyst. According to the present invention, the application problem of the carbon fiber primary coat is solved; and the low-temperature fast curing is achieved (120 DEG C@15 min), the thickness of the one-time formed film is more than 100 [mu]m, the leveling is good, the PCI grade is more than 8, the hardness is high, and the pencil hardness is more than 1 H while the good corrosion resistance is provided.

Owner:福建万顺粉末涂料有限公司

A kind of asphalt pavement cold repair material that can quickly open traffic and preparation method thereof

The invention belongs to the technical field of road maintenance repairing and relates to an asphalt pavement cold patching material available for quick opening of traffic and a preparation method thereof; the cold patching material comprises component A, component B and component C; the component A comprises, by weight, 100 parts of limestone mineral material, and 3-5 parts of cement; the component B comprises, by weight, 100 parts of emulsified asphalt, and 40-60 parts of self-emulsified waterborne epoxy resin; the component C comprises, by weight, 100 parts of waterborne epoxy curing agent, and 30-50 parts of an accelerant. Compared with the prior art, the asphalt pavement cold patching material and the preparation method thereof have the advantages that early strength of waterborne epoxy-modified emulsified asphalt mixture can be improved to shorten the time to open the traffic; the material has good water solubility, the preparation process is simple, the preparation conditions are mild, construction is convenient and quick, skilled personnel and special equipment are not required, the material has good low-temperature operability and workability, and is free of volatile solvents, friendly to the construction environment, capable of patching a pavement quickly and good for environmental protection.

Owner:山西省交通科技研发有限公司

A preparation method of low-temperature fast-curing resistance flame-retardant structural adhesive

ActiveCN112521892BFast curing at low temperatureLower resistanceNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyPolymer science

The invention relates to a low-temperature fast-curing resistance flame-retardant structural adhesive, which is composed of the following raw materials: 10-20 parts of self-synthesized flame-retardant epoxy resin gel, 25-25 parts of tricyclopentyl dimethoxy epoxy resin 35 parts, 3-8 parts of new low-viscosity toughening agent, 20-30 parts of inositol hexa(mercaptopropionate), 4-6 parts of imidazole adduct, 6-33 parts of superfine aluminum hydroxide. The structural adhesive prepared by the invention has the advantages of fast curing speed at low temperature, easy operation of one component, good impedance performance, good flame retardancy, low shrinkage, good bonding strength, etc., and is suitable for various micro-motor inductance coils and related difficult Structural bonding of sticky materials.

Owner:YANTAI DARBOND TECH

A kind of conductive silver glue applied to electronic resonator and its preparation method

ActiveCN111004598BLow viscosityFast curing at low temperatureNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesPolyamideFirming agent

The invention belongs to the technical field of conductive silver glue, in particular to a conductive silver glue applied to an electronic resonator, comprising the following components by weight: 60-80 parts of silver powder, 0.1-2 parts of graphene gel, epoxy resin 5-10 parts of resin, 1-5 parts of phenolic resin, 1-4 parts of polyamide resin, 5-10 parts of thinner, 1-3 parts of curing agent, 0.1-2 parts of accelerator, 1-3 parts of coupling agent, Additive 1-5 parts, with strong tensile shear force, very low volume resistivity, very low viscosity, can withstand high temperature above 250 ℃, suitable for reflow soldering process.

Owner:常州烯奇新材料有限公司

Epoxy resin binder used for repairing blade and preparation method thereof

ActiveCN101698787BFast curingLower the activation energy of the reactionNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyWind driven

The invention relates to a preparation method of repairing adhesive, in particular to a binder for repairing blade of a wind driven generator, belonging to the high polymer material field. The preparation method of double-component epoxy resin binder used for repairing blade is simple in operation and low in cost. The double-component epoxy resin binder for repairing blade which is made by the method of the invention has high tenacity, high shear strength, low heat and low shrink, thus being suitable for repairing and binding of large structural part; solidification is rapid, the binder can be rapidly solidified in 10-30 minutes at 5-25 DEG C and reach certain strength; and the binder is used for repairing defect of blade of wind driven generator.

Owner:镇江市电子化工材料工程研究中心有限公司

Fireproof coating for rail transit locomotive/vehicle and preparation method thereof

ActiveCN109913093BNot easy to break throughStrong adhesionFireproof paintsEpoxy resin coatingsCarbon layerMethyl benzene

The invention relates to a fireproof coating for a rail transit locomotive / vehicle and a preparation method of the fireproof coating. The fireproof coating for the rail transit locomotive / vehicle is prepared by taking poly-alpha-methyl styrene modified epoxy resin, a fire retardant and the like as the components of the coating, taking modified amine and a curing agent accelerator as components ofa curing agent, and using a proper amount of a diluent in the construction. The main purpose is to obtain a fireproof coating product for the rail transit locomotive / vehicle, the thickness of a film of the fireproof coating product for the rail transit locomotive / vehicle is thin (less than or equal to 2.0 mm), the expansion coefficient is large, the structural strength of a carbon layer is high, the heat conductivity coefficient is low, the fire resistance is strong, the adhesive property is good, the spraying is convenient in the construction, and the comprehensive performances are excellent.

Owner:株洲市九华新材料涂装实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com