A low-temperature fast-curing glass fiber-wrapped wire impregnation resin and preparation method thereof

A technology of glass fiber-wrapped wire and impregnated resin, which is applied in the direction of coating, polyester coating, etc., can solve the problems of long curing time, hard and brittle toughness of the paint film, high curing temperature, etc., to avoid cracking of the insulating structure, mechanical and chemical resistance Guaranteed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

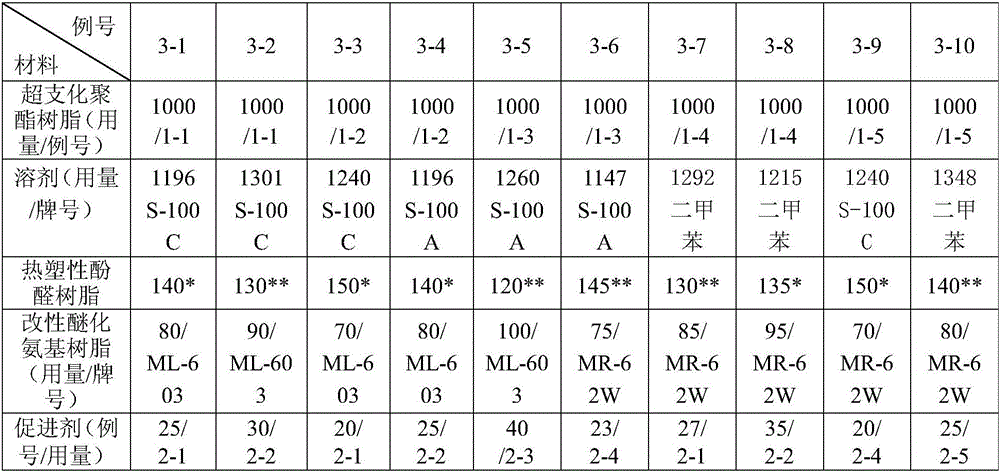

Examples

Embodiment 1-1

[0051] Add 384kg of linseed oil and 135kg of glycerol into the reactor Ⅰ, add 0.2kg of lithium hydroxide under stirring, keep warm at 265℃~270℃ for 30 minutes, cool down to 200℃, and add 320kg of polyester powder material, 0.1kg of zinc acetate, heated up to 230°C to 240°C, and after 3 hours of heat preservation and reaction, turn on the vacuum pump to make the vacuum in the reactor reach above 0.086MPa in 29 minutes. After reacting for 1 hour, add 200kg of isobenzene Formic acid, 98kg of tris (2-hydroxyethyl) isocyanurate (hereinafter referred to as Saike), 0.4kg of stannous chloride, the temperature is controlled to react at 230°C, the reaction is refluxed for 2 hours, and the vacuum pump is turned on to make the reaction The vacuum degree in the kettle reaches above 0.086MPa in 30 minutes, and when the gelation time reaches (280°C±1°C, 85s), the reaction ends, and the hyperbranched polyester resin is prepared for use.

Embodiment 1-2

[0053] Add 400kg of tung oil and 160kg of trimethylolpropane into the reactor Ⅰ, add 0.2kg of lithium hydroxide under stirring, keep warm at 250℃~255℃ for 30 minutes, cool down to 200℃, and add 360kg of polyester Powder, 0.1㎏ zinc acetate, heat up to 255℃~260℃, after 4 hours of heat preservation reaction, turn on the vacuum pump, make the vacuum degree in the reactor reach above 0.086MPa in 20 minutes, after 2 hours of reaction, add 220㎏ m-benzene in sequence Diformic acid, 75㎏ Saike, 0.4㎏ stannous chloride, control the temperature to react at 200°C, reflux for 3 hours, turn on the vacuum pump, make the vacuum in the reactor reach 0.086MPa or more in 24 minutes, when the gelling time When the temperature reaches (280°C±1°C, 70s), the reaction ends, and a hyperbranched polyester resin is prepared for future use.

Embodiment 1-3

[0055] Add 148kg of linseed oil, 257kg of tung oil, 94kg of glycerol, and 36kg of trimethylolpropane into the reactor Ⅰ, add 0.2kg of lithium hydroxide under stirring, and keep warm at 275℃~280℃ for 30 minutes , lower the temperature to 200°C, add 300kg of polyester powder and 0.1kg of zinc acetate, heat up to 240°C-250°C, and after 3.5 hours of heat preservation, turn on the vacuum pump to make the vacuum in the reactor reach above 0.086MPa in 27 minutes. After reacting for 2.5 hours, add 180 kg of isophthalic acid, 60 kg of SEC, and 0.4 kg of stannous chloride in sequence, control the temperature to react at 225 ° C, and react at reflux for 3.5 hours. Turn on the vacuum pump to make the vacuum in the reactor at It reached above 0.086MPa in 21 minutes, and when the gelation time reached (280°C±1°C, 105s), the reaction was over, and the hyperbranched polyester resin was prepared for use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com