A kind of asphalt pavement cold repair material that can quickly open traffic and preparation method thereof

A cold patching material and open traffic technology, applied in the field of road maintenance and repair, can solve the problems that the early strength of the modified emulsified asphalt mixture cannot be improved, the modification effect is not obvious, and the activity of the curing agent is not high, so as to shorten the open traffic time, Conducive to the effect of environmental protection, good low temperature operation and workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

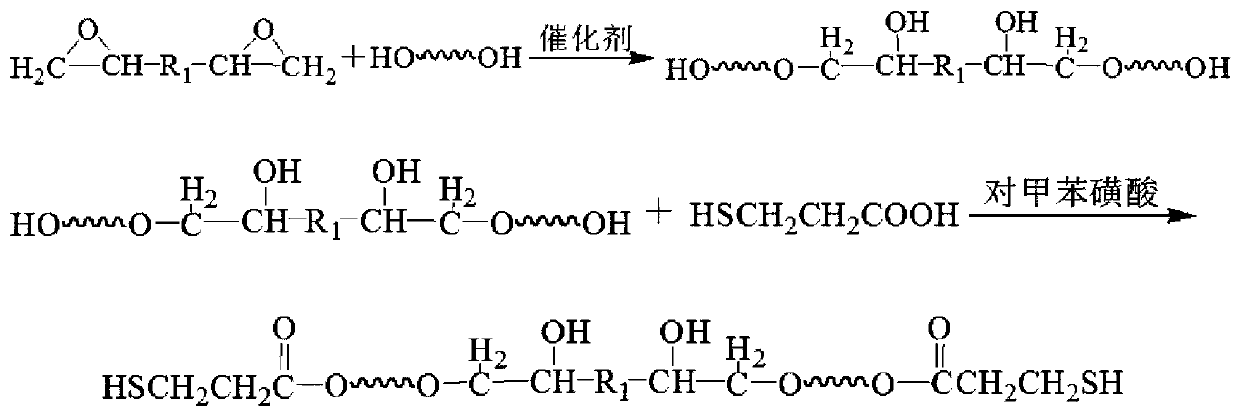

[0028] 1. Synthesis of water-based epoxy curing agent

[0029] 1) Bisphenol A epoxy resin E-51 and polyethylene glycol 400 were reacted at 120° C. for 6 hours in the presence of a catalyst benzyltriethylammonium chloride (1% of the total mass) to obtain an intermediate product.

[0030] 2) In the presence of p-toluenesulfonic acid, mercaptopropionic acid was reacted with the above-mentioned intermediate product at 80° C. for 4 hours, and then heated to 140° C. for 1 hour to prepare a water-based epoxy curing agent. The amount of p-toluenesulfonic acid is 3% of the total mass.

[0031] The molar ratio of the bisphenol A epoxy resin E-51, polyethylene glycol 400, and mercaptopropionic acid is 1:2:2.2.

[0032] 2. Preparation of component A:

[0033] Weigh 100 parts of limestone mineral material by mass (30 parts of particle size 9.5-16mm, 40 parts of particle size 4.75-9.5mm, 20 parts of particle size 2.36-4.75mm, 10 parts of particle size 0-2.36mm), 32.5R cement 3 parts and ...

Embodiment 2

[0042] 1. Synthesis of water-based epoxy curing agent

[0043] 1) Bisphenol A epoxy resin E-51 and polyethylene glycol 600 were reacted at 130° C. for 4 hours in the presence of a catalyst cetyltrimethylammonium chloride (amount of 2% of the total mass) to obtain an intermediate product .

[0044] 2) In the presence of p-toluenesulfonic acid, mercaptopropionic acid was reacted with the above-mentioned intermediate product at 90° C. for 3 hours, and then heated to 130° C. for 2 hours to prepare a water-based epoxy curing agent. The amount of p-toluenesulfonic acid is 2% of the total mass.

[0045] The molar ratio of the bisphenol A epoxy resin E-51, polyethylene glycol 600, and mercaptopropionic acid is 1:2.2:2.4.

[0046] 2. Preparation of component A:

[0047]Weigh 100 parts of limestone mineral material by mass (20 parts of particle size 9.5-16mm, 40 parts of particle size 4.75-9.5mm, 30 parts of particle size 2.36-4.75mm, 10 parts of particle size 0-2.36mm), 42.5R cement...

Embodiment 3

[0056] 1. Synthesis of water-based epoxy curing agent

[0057] 1) Bisphenol A epoxy resin E-44 and polyethylene glycol 400 were reacted at 125° C. for 5 h in the presence of a catalyst, benzyltriethylammonium chloride (3% of the total mass), to obtain an intermediate product.

[0058] 2) In the presence of p-toluenesulfonic acid, mercaptopropionic acid was reacted with the above-mentioned intermediate product at 85° C. for 3 hours, and then heated to 135° C. for 1 hour to prepare a water-based epoxy curing agent. The amount of p-toluenesulfonic acid is 2% of the total mass.

[0059] The molar ratio of the bisphenol A epoxy resin E-44, polyethylene glycol 400, and mercaptopropionic acid is 1:2.1:2.2.

[0060] 2. Preparation of component A:

[0061] Weigh 100 parts of limestone mineral material by mass (40 parts of particle size 9.5-16mm, 30 parts of particle size 4.75-9.5mm, 15 parts of particle size 2.36-4.75mm, 15 parts of particle size 0-2.36mm), 32.5R cement 5 parts and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com