Pneumatic multi-nozzle complex tissue and organ manufacturing system with multiple degrees of freedom

A technology of complex structure and manufacturing system, applied in the direction of processing and manufacturing, manufacturing tools, additive manufacturing, etc., can solve the problems of low forming efficiency, non-replacement, and inability to spray the side surface of the formed body, and achieve the effect of high precision and convenient manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to further understand the technical solutions of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

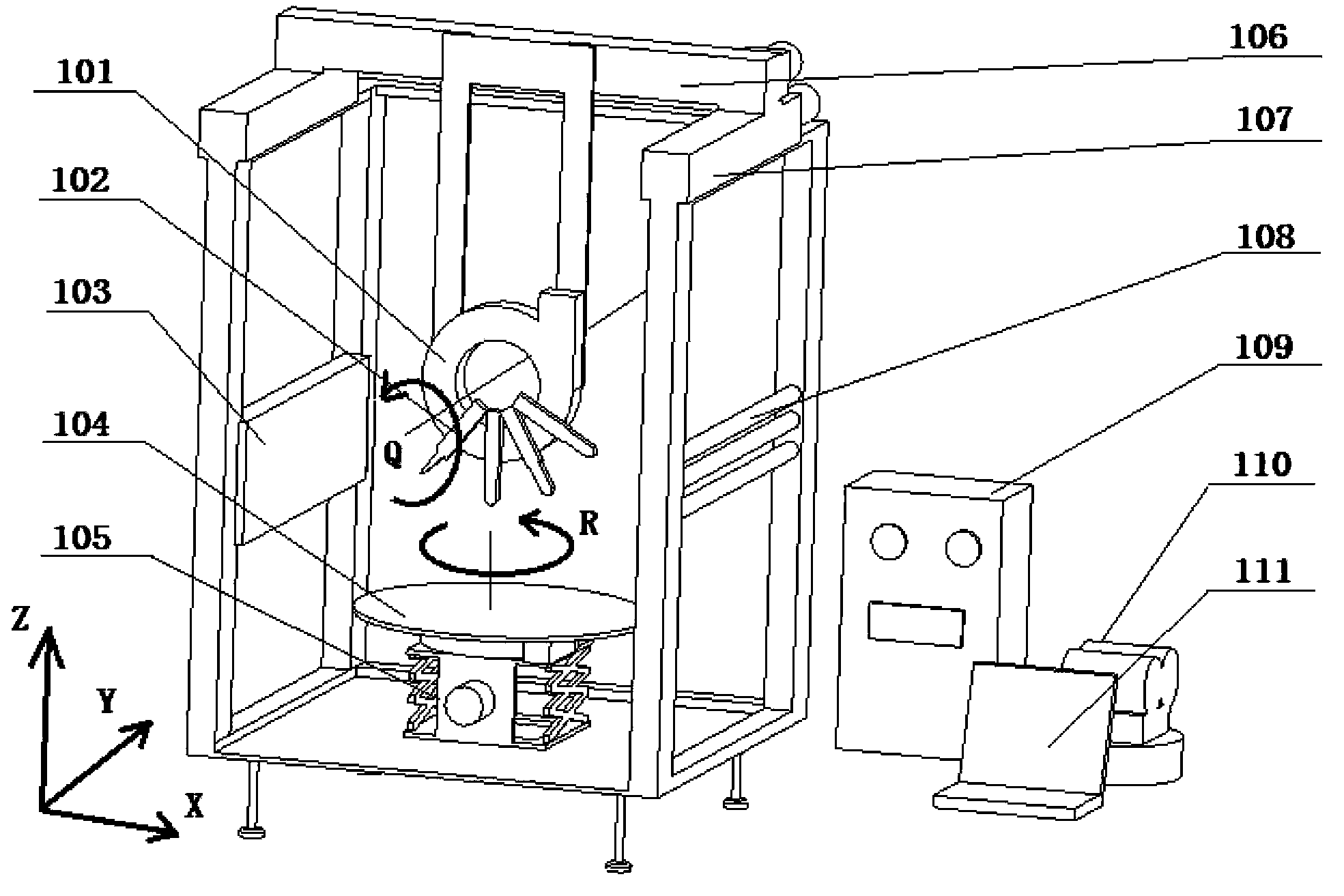

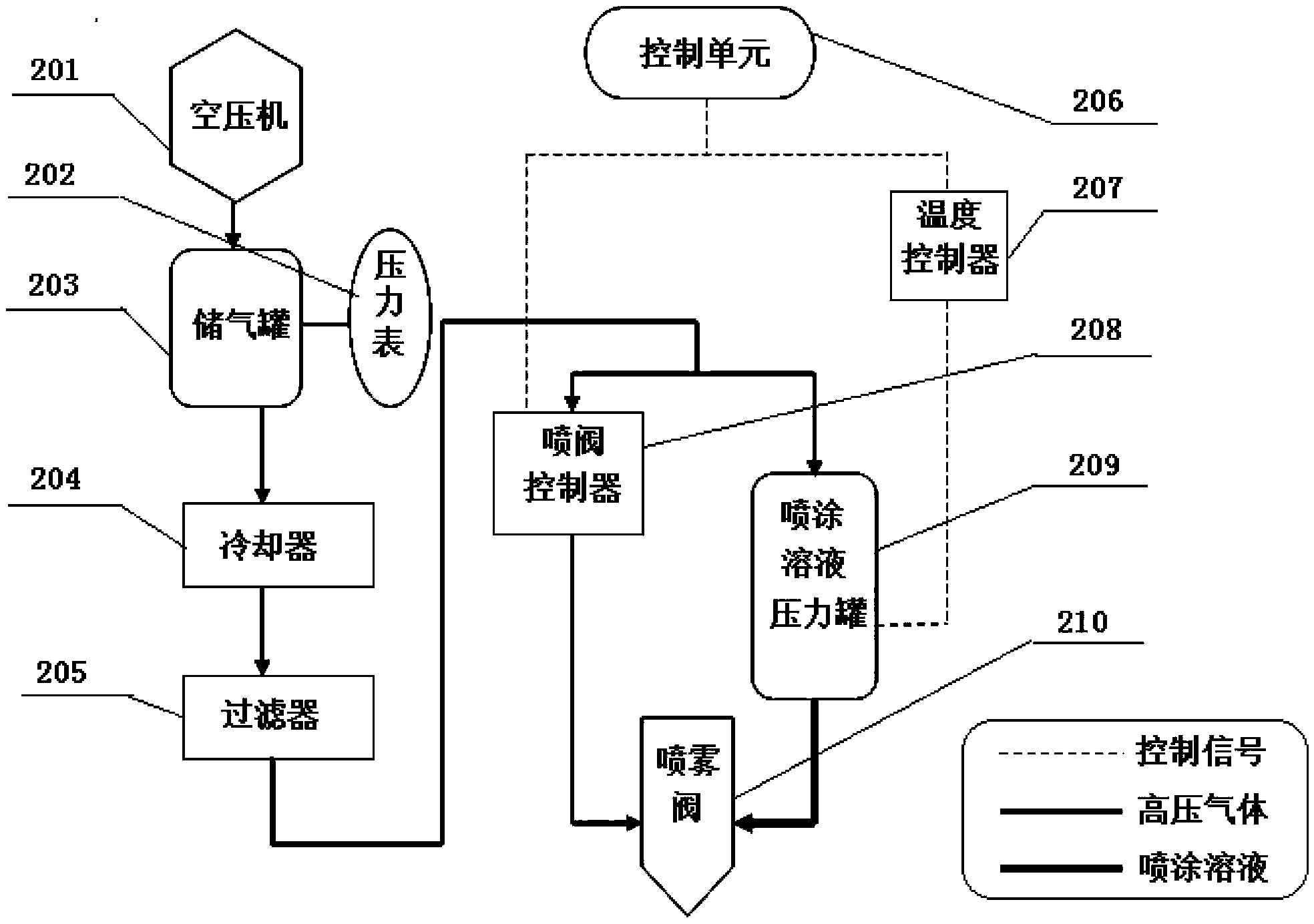

[0037] figure 1It is a schematic diagram of the structural principle of a multi-degree-of-freedom pneumatic multi-nozzle complex tissue and organ manufacturing system of the present invention. The system includes an X-direction movement mechanism 106, a Y-direction movement mechanism 107, a Q-direction rotation mechanism 101 that rotates around the Y-axis, a housing, Lifting platform 105, rotating forming platform 104, high-pressure gas source 110, multi-nozzle forming unit 102, spray solution pressure tank 209, temperature control device 103, sterilizing device 108, electrical control cabinet 109 and control unit 111.

[0038] The Q-direction rotating mechanism 101 rotating around the Y-axis, the lifting table 105, the rotary forming table 104, the multi-nozzle formin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com