Epoxy resin binder used for repairing blade and preparation method thereof

An epoxy resin and adhesive technology, applied in the direction of in-line phenolic epoxy resin adhesive, epoxy resin glue, adhesive, etc. The effect of knot strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

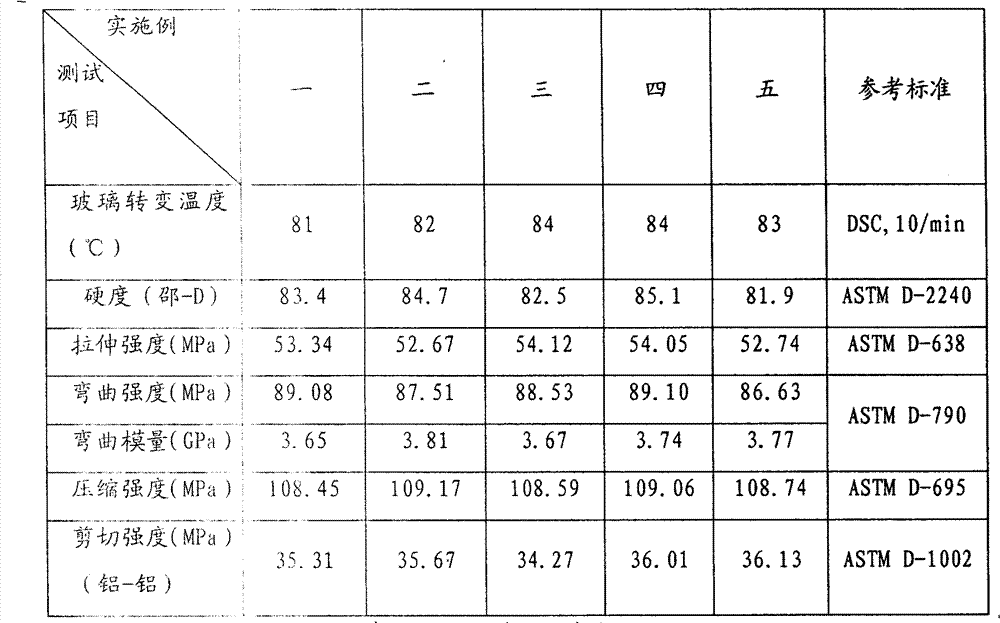

Examples

Embodiment 1

[0029] The steps of this embodiment are as follows,

[0030] a. The following raw materials:

[0031] Bisphenol A epoxy resin 40g

[0032] Bisphenol F type epoxy resin 20g

[0035] Organic bentonite 3g

[0036] ST-560 defoamer 0.01g

[0037] Add in the reactor that thermometer and agitator are housed, heat up to 25 DEG C while stirring, react for 1.5 hours, obtain high viscosity and high thixotropy, the modified epoxy resin that viscosity is 8500mPa·s at room temperature (25 DEG C), That is component A;

[0038] b. Combine the following raw materials:

[0039] Polythiol 40g

[0040] Triethylamine 20g

[0041] Add it into a reactor equipped with a thermometer and a stirrer and stir, raise the temperature to 30°C, react for 2.5 hours, then add 10g of 2-methylimidazole, and keep it at 30°C for 1.5 hours to obtain a light yellow transparent liquid with a viscosity of 25°C 600mPa·s low-viscosity liquid modified amin...

Embodiment 2

[0045] The steps of this embodiment are as follows,

[0046] a. The following raw materials:

[0047] Bisphenol S type epoxy resin 70g

[0048] Fiber reinforcement 15g

[0050] Hydrogenated Castor Oil 5g

[0051] ST-560 defoamer 0.05g

[0052]Add it into a reactor equipped with a thermometer and a stirrer, heat up to 30°C while stirring, and react for 2 hours to obtain a modified epoxy resin with high viscosity and high thixotropy, and a viscosity of 12000mPa·s at room temperature (25°C). That is component A;

[0053] b. Combine the following raw materials:

[0054] Polythiol 60g

[0055] Benzyldimethylamine 40g

[0056] Add it into a reactor equipped with a thermometer and a stirrer, stir, heat up to 30°C, and react for 1.5 hours, then add 15 g of 2-ethylimidazole, and react for 2 hours to obtain a light yellow transparent liquid with a viscosity of 500 mPa at 25°C. s low-viscosity liquid modified amines, which is component B;

[0057] c. Mi...

Embodiment 3

[0060] The steps of this embodiment are as follows,

[0061] a. The following raw materials:

[0062] Cycloaliphatic epoxy resin 80g

[0063] Silica powder 7g

[0064] Fumed silica 8g

[0065] SPA-102 defoamer 0.10g

[0066] Add it into a reactor equipped with a thermometer and a stirrer, heat up to 40°C while stirring, and react for 1.5 hours to obtain a modified epoxy resin with high viscosity and high thixotropy, and a viscosity of 12500mPa·s at room temperature (25°C). That is component A;

[0067] b. Combine the following raw materials:

[0068] Polythiol 70g

[0069] 2,4,6-tris(dimethylaminomethyl)phenol 13g

[0070] Add it into a reactor equipped with a thermometer and a stirrer, stir, raise the temperature to 40°C, and react for 2.5 hours, then add 20g of 2-methylimidazole-copper chloride salt, and react for 3 hours to obtain a light yellow transparent liquid. Low-viscosity liquid modified amines with a lower viscosity of 500mPa·s, which is component B;

[007...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com