Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Extend polymerization time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rubber composition comprising a highly saturated diene elastomer

ActiveUS20150353716A1Extend polymerization timeReduce reduction reactionSpecial tyresElastomerHysteresis

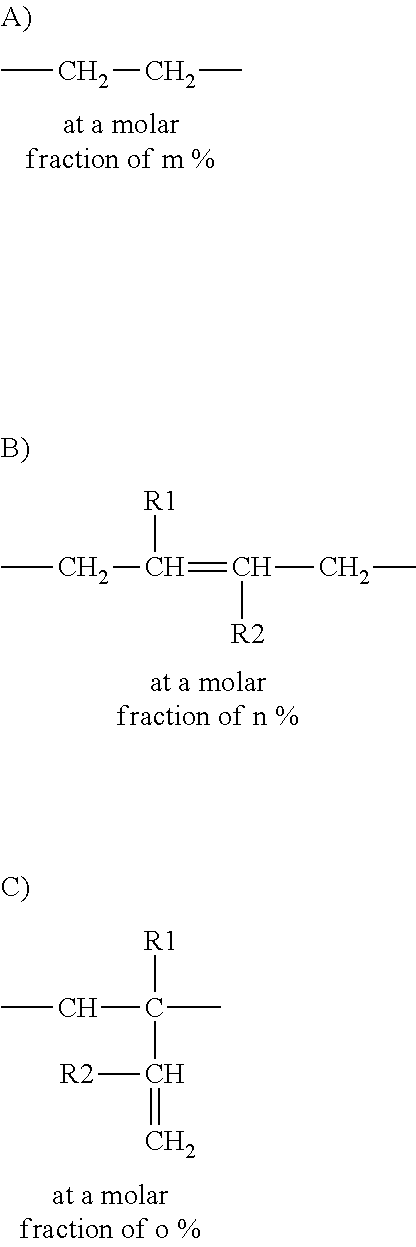

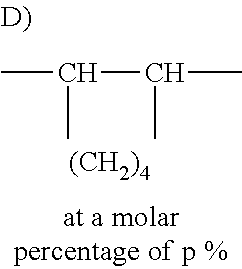

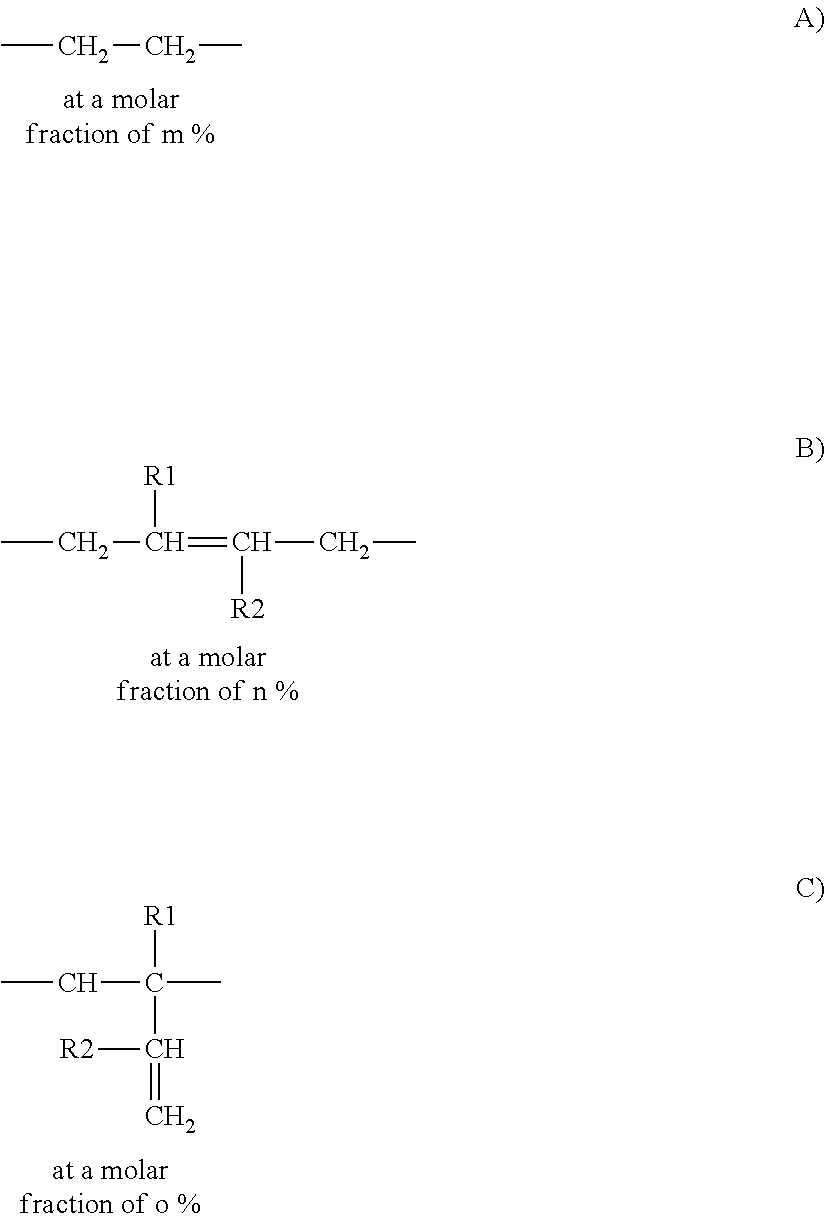

The present invention relates to a rubber composition based on a reinforcing filler and on an elastomer matrix comprising a highly saturated diene elastomer comprising at least five distinct units of A, B, C, D and E distributed randomly within the elastomer at respective molar fractions of m %, n %, o %, p % and q %, where m+n+o+p+q=100; m≧50; n+o+p+q≧10; and 15≧p+q≧2.This rubber composition enables a satisfactory degree of stiffness to be reached while maintaining hysteresis properties acceptable for use in the manufacture of tires for running vehicles.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

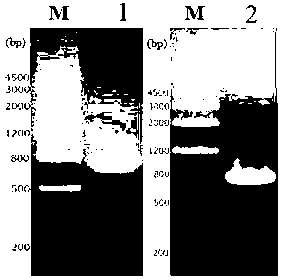

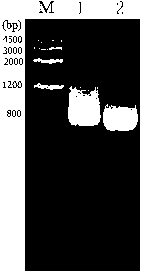

Functional mutant of human plasminogen, its preparation method and application

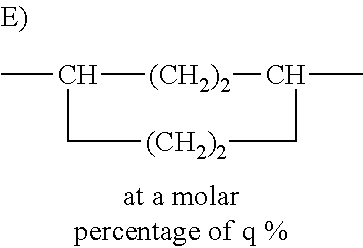

InactiveCN102199587AGood for renaturationExtended half-lifeSenses disorderNervous disorderPichia pastorisEukaryotic plasmids

A functional mutant of human plasminogen disclosed in the invention, respectively, is hPLG-delta K: human plasminogen protein Pro<544>-Asn<791> polypeptide; Pro<559> in RGD-hPLG-delta K: hPLG-delta K is mutated to Asp<559>; and Gly<560> in RHP-hPLG-delta K: hPLG-delta K polypeptide is mutated to His<560>. The invention also discloses a preparation method for the functional mutant. The product is obtained by using a plasmid containing a full-length cDNA sequence of human plasminogen as a template to carry out a PCR to construct a plasmid and using Pichia Pastoris expression. The functional mutant has a dual-function of fibrinolysis and inhibiting platelet aggregation or inhibiting fibrin monomer polymerization.

Owner:GUANGDONG PHARMA UNIV

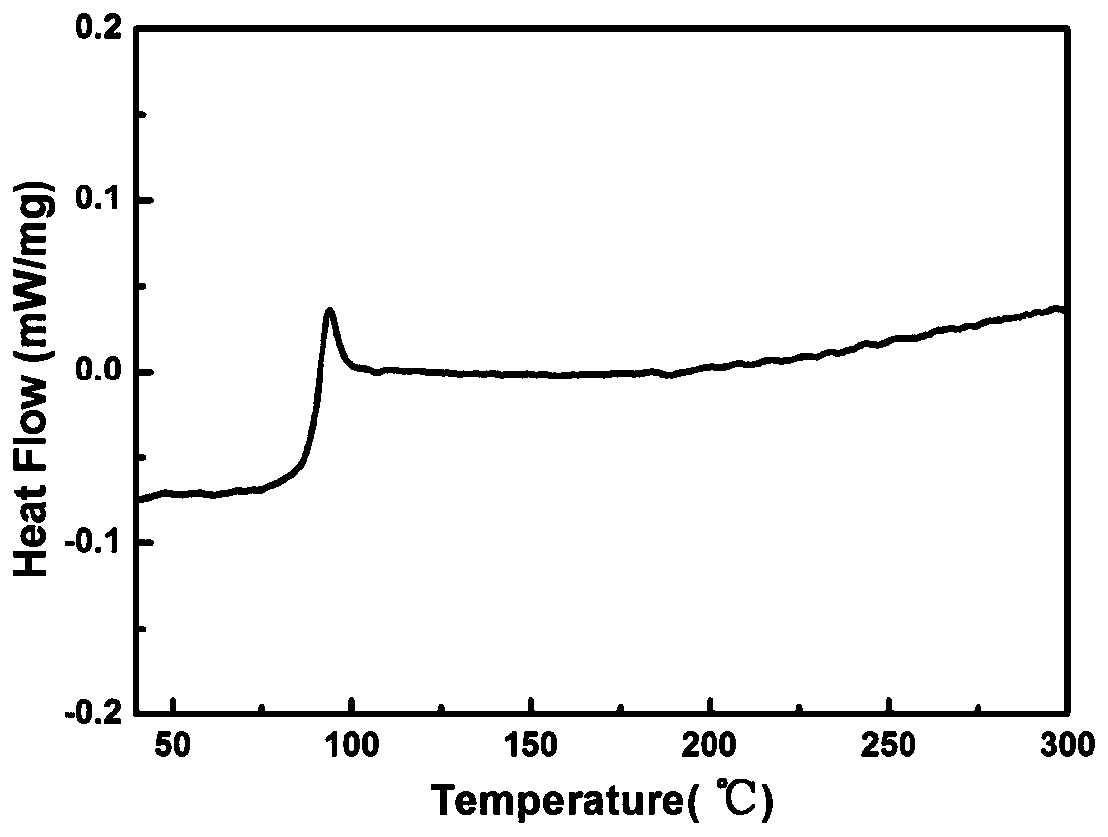

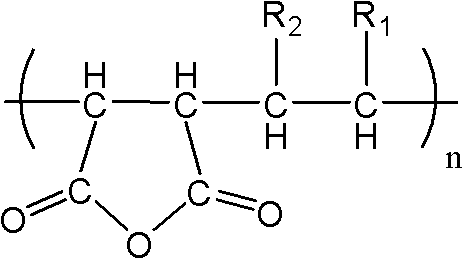

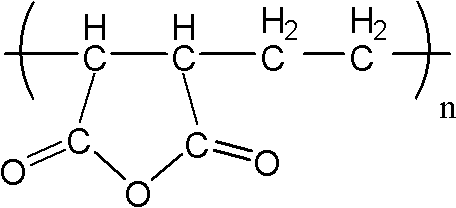

Furan dicarboxylic acid copolyester and preparation method thereof

ActiveCN109810248AHigh tensile modulusHigh tensile strengthMonocomponent copolyesters artificial filamentFuranMechanical property

The invention relates to furan dicarboxylic acid copolyester and a preparation method thereof. The preparation method comprises the following steps: mixing a first component, a second component and athird component with the mole ratio of 1 to (1.1 to 2.0) to (0.0001 to 0.02) with an esterification catalyst to obtain a first intermediate product, wherein the first component comprises at least oneof furan dicarboxylic acid and a furan dicarboxylic acid ester compound, the second component comprises at least one of aromatic diol and aliphatic diol, and the third component comprises polyhydric alcohol with hydroxyl number being greater than or equal to 3; performing prepolymerization reaction and polycondensation on the first intermediate product to obtain the furan dicarboxylic acid copolyester. In the preparation method, the polyhydric alcohol with hydroxyl number being greater than or equal to 3 serves as a connection point of chain segments, so that the chain segment structure of thefuran dicarboxylic acid copolyester is expanded to a network structure, thereby obtaining the colorless or lightcolor furan dicarboxylic acid copolyester with excellent mechanical property and air barrier property and high molecular weight.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

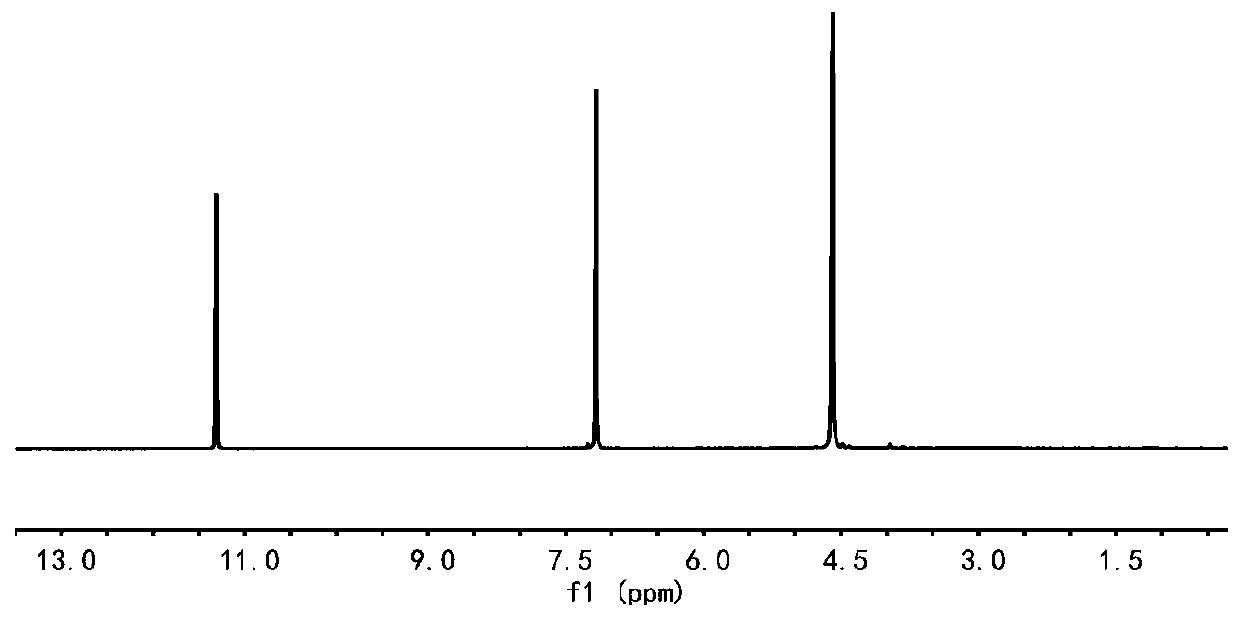

Acrylamide polymer, its preparation method and its application

ActiveCN103864986AHigh viscosity average molecular weightHigh apparent viscosityDrilling compositionCeiling temperatureTemperature difference

The invention discloses an acrylamide polymer, its preparation method and its application, the method is characterized that under the condition of aqueous solution polymerization, under the protection of inert gas, an acrylamide-containing monomer aqueous solution and an initiator are contacted, wherein, the aqueous solution polymerization condition comprises: the polymerization initial temperature is -10-15 DEG C, the polymerization time is 4-15 hours, and the temperature difference of the highest temperature and the lowest temperature in a polymerization process is 10-50 DEG C. The product performance of the polyacrylamide polymer is greatly better than that of the current products.

Owner:CHINA PETROLEUM & CHEM CORP +1

Modified melamine formaldehyde resin with high flexibility

The invention provides modified melamine formaldehyde resin with high flexibility. The modified melamine formaldehyde resin is prepared from the following raw materials in parts by weight: 100 parts of melamine, 160-220 parts of formaldehyde, 10-20 parts of isocyanurate, 5-10 parts of fatty acid amide, 5-8 parts of polyethylene glycol, 3-6 parts of alkylphenol polyoxyethylene ether, 2-5 parts of sodium hydroxide, 40-60 parts of alcohol and 20-30 parts of water. The modified melamine formaldehyde resin with high flexibility disclosed by the invention can be used for effectively prolonging the polymerization time of the modified melamine formaldehyde resin, increasing the storage period of the modified melamine formaldehyde resin and improving the flexibility of the resin. A resin modifying component contained in the modified melamine formaldehyde resin with high flexibility can participate in the copolycondensation reaction of the resin to change the resin structure, so that the cross-linking density is lowered, and thus, the foam strength is increased, the flexibility is increased and the brittleness is lowered. The modified melamine formaldehyde resin is full of elasticity and the stability of the modified melamine formaldehyde resin is increased.

Owner:CHONGZHOU HERUI TECH

Laminated polyester film for protective material for protecting back surface of photovoltaic cells

InactiveUS20130065063A1Improve hydrolysis resistanceImprove adhesionSynthetic resin layered productsElectrical equipmentPolyesterHydrolysis

The present invention provides a polyester film for a protective material for protecting a back surface of photovoltaic cell which exhibits a good hydrolysis resistance and an excellent adhesion property to a sealing resin for photovoltaic cells. The present invention relates to a polyester film for a protective material for protecting a back surface of photovoltaic cells which is in the form of a laminated polyester film comprising the below-mentioned polyester (A) layer as at least one of outermost layers of the film and at least one below-mentioned polyester (B) layer, the laminated polyester film having a terminal carboxyl group content of not more than 26 equivalents / t, and the polyester (A) layer being provided on at least one surface thereof with a coating layer formed of a polyurethane having at least one of a polycarbonate skeleton and a polyether skeleton, and a crosslinking agent:Polyester (A) layer: Layer formed of a polyester comprising an aromatic polyester as a main constitutional component and having a white pigment content of less than 8% by weight; andPolyester (B) layer: Layer formed of a polyester comprising an aromatic polyester as a main constitutional component and having a white pigment content of not less than 8% by weight.

Owner:MITSUBISHI PLASTICS INC

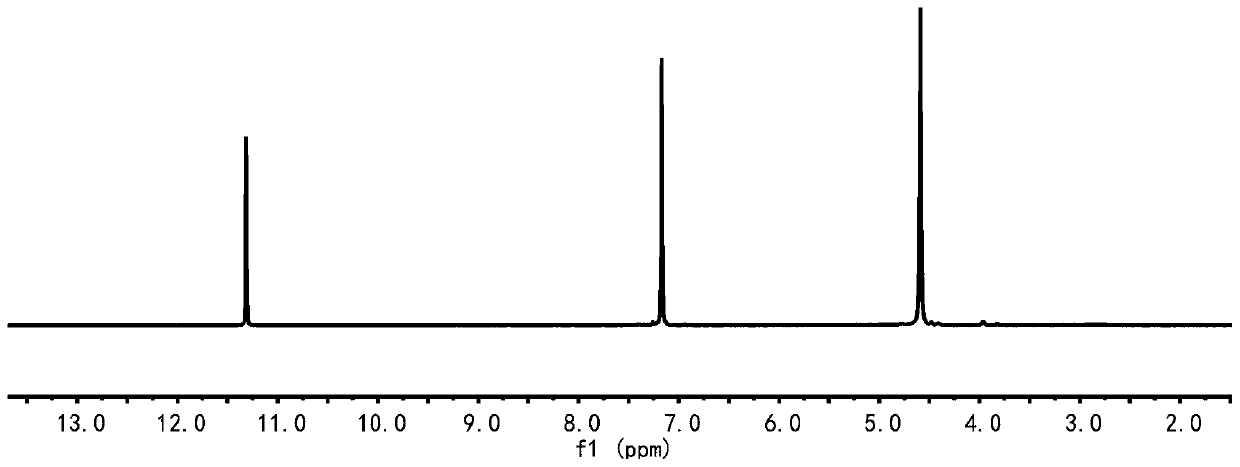

Furyl copolyester and preparation method thereof

ActiveCN109810247AHigh tensile modulusHigh tensile strengthMonocomponent copolyesters artificial filamentFiberEngineering plastic

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

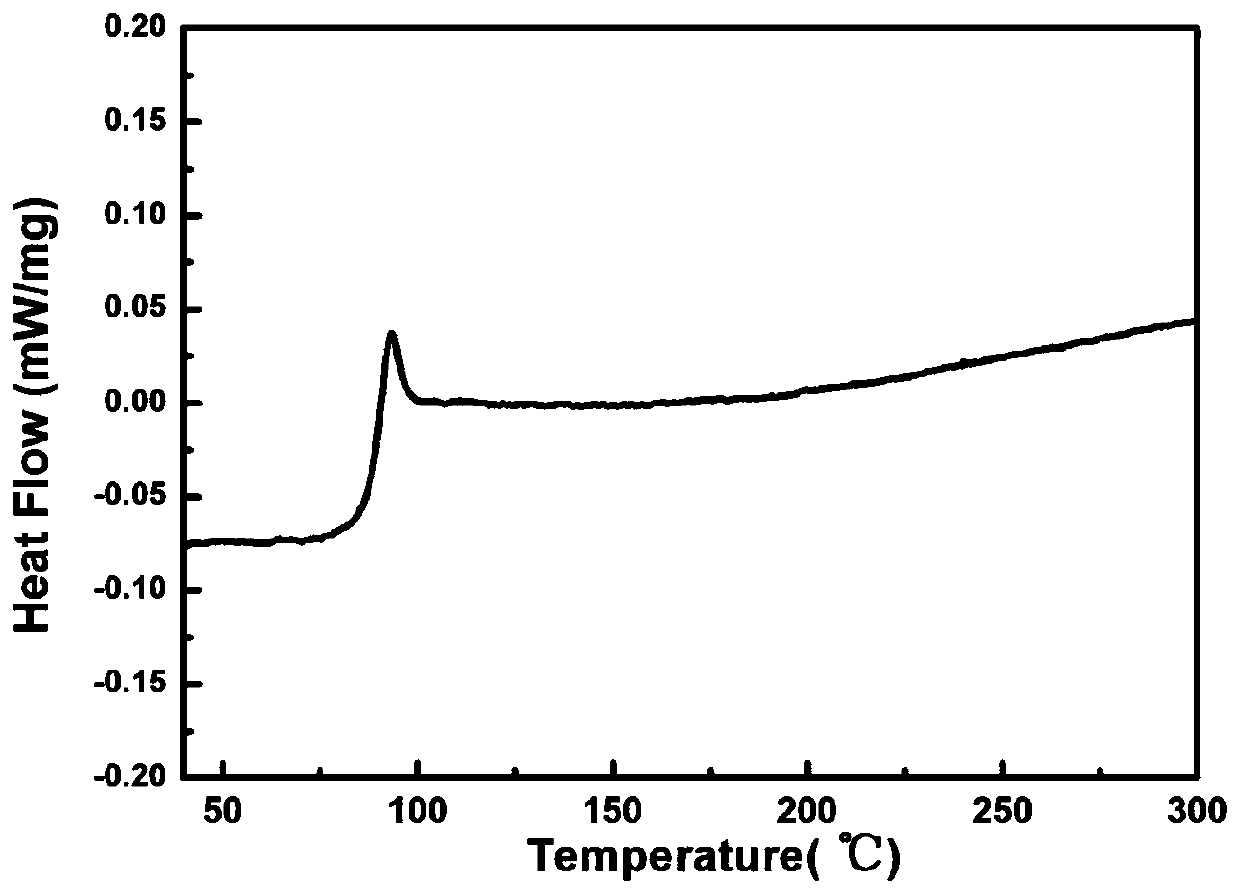

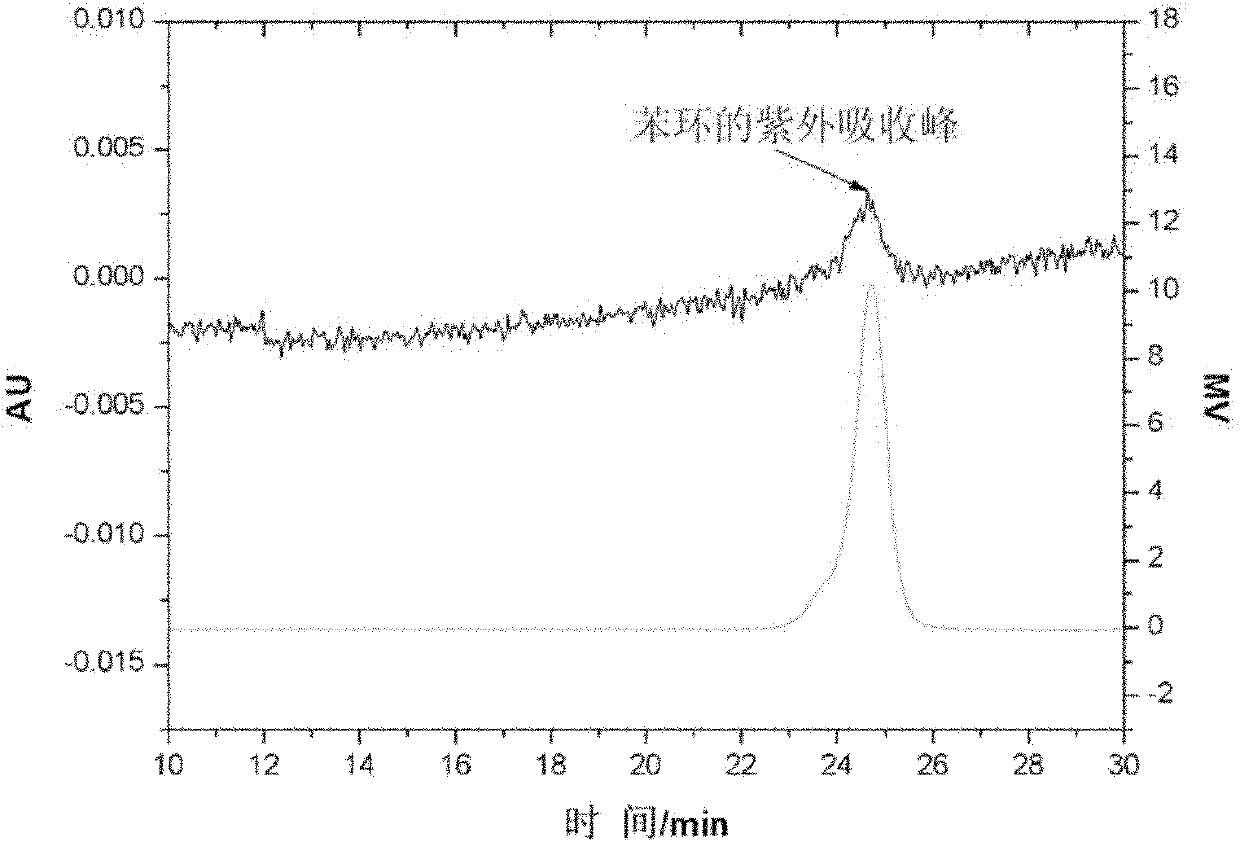

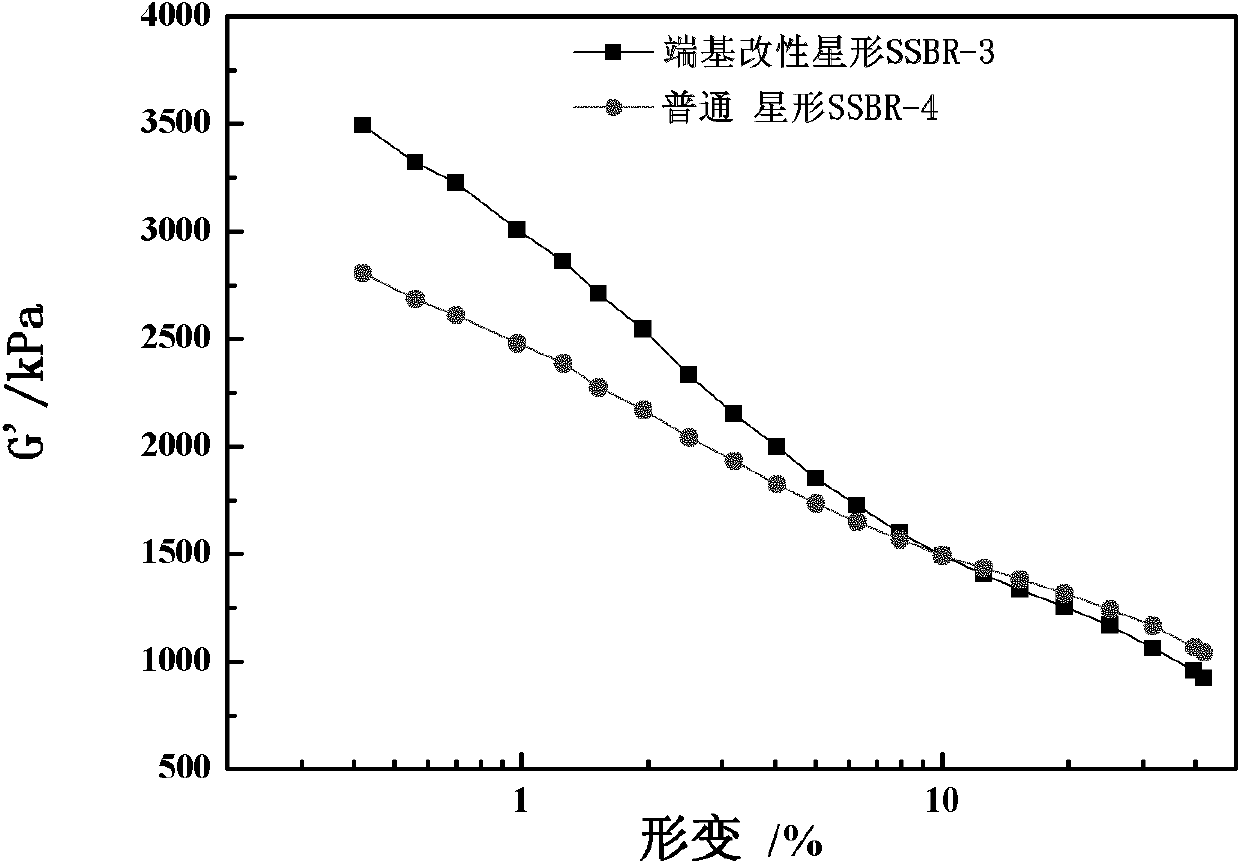

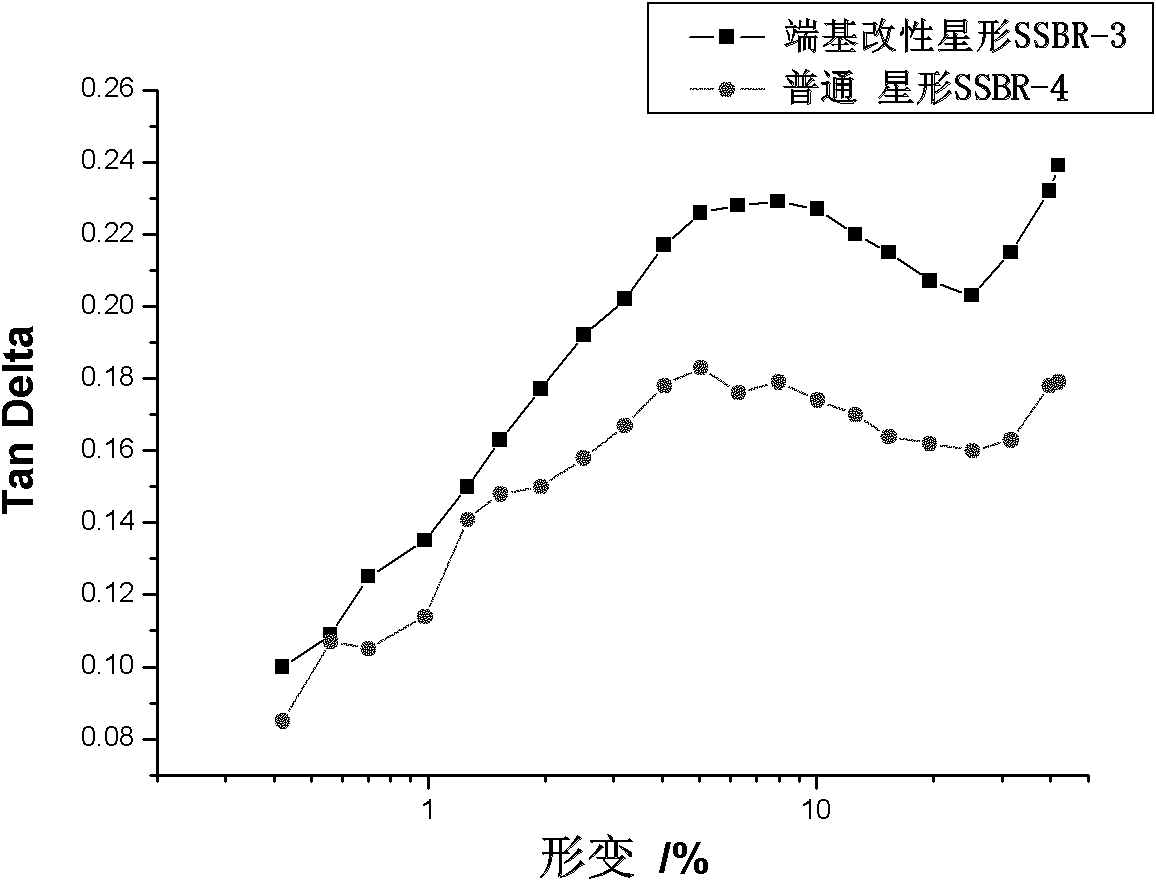

Method for synthesizing star-shaped solution polymerized butadiene-styrene rubber by using modified initiator

InactiveCN102120798AIncrease concentrationReduce concentrationHydrocarbon solventsRolling resistance

The invention discloses a method for synthesizing star-shaped solution polymerized butadiene-styrene rubber by using modified initiator, belonging to the technical field of rubber. The method comprises the following steps: synthesizing a compound I; using the compound I as initiator and Lewis base as structural modifier and randomizer to perform the random copolymerization of butadiene and styrene in hydrocarbon solvent under the protection of nitrogen; and after the copolymerization reaction, adding coupling agent to perform c oupling reaction, stopping the reaction, and performing condensation to obtain the modified star-shaped solution polymerized butadiene-styrene rubber. One end of the rubber has a star-shaped structure through coupling modification, thus the number of free ends can be greatly reduced; the other end has a benzene ring brought by the initiator, thus the affinity to carbon black can be improved; and compared with the unmodified solution polymerized butadiene-styrene rubber, the solution polymerized butadiene-styrene rubber prepared by the method has low rolling resistance, good wet skid resistance and excellent physical and mechanical properties.

Owner:BEIJING UNIV OF CHEM TECH

Method for producing organopolysiloxane emulsion composition

InactiveUS20140378553A1High viscosityExtend polymerization timeCosmetic preparationsHair cosmeticsEmulsionEmulsion polymerization

A method for producing an organopolysiloxane emulsion composition, which enables the organopolysiloxane to be formed with a high viscosity in a short period of time, and suppresses the amount of octamethylcyclotetrasiloxane (D4) to not more than 3,000 ppm. Specifically, a method for producing an organopolysiloxane emulsion which includes emulsifying a mixture containing an organopolysiloxane represented by formula: HO(R12SiO)nH and having a D4 content of not more than 1,000 ppm, a nonionic surfactant, an anionic surfactant, and water, and subjecting the obtained emulsion composition to emulsion polymerization, thus preparing the emulsion composition.

Owner:SHIN ETSU CHEM IND CO LTD

Free radical polymerization initiator composition and its application

InactiveCN102746424ATotal polymerization time shortenedReduce production energy consumptionCompound aDecomposition

The invention belongs to the chemical engineering field, and relates to a free radical polymerization initiator composition and its application. The free radical polymerization initiator composition is obtained through compounding a low temperature initiator having a decomposition temperature which is lower than 60DEG C and a high temperature initiator having a decomposition temperature which is higher than 70DEG C. The application is the application of the free radical polymerization initiator composition in the preparation of an alkenyl ether (ester)-maleic anhydride copolymer, wherein the mass of the free radical polymerization initiator composition accounts for 0.01-1.0% of the total mass of a reaction system. The initiator composition which allows the low temperature polymerization time of a polymerization reaction to be prolonged and the high temperature polymerization time to be reduced is benefit for the stationary reaction generation, and enables the total polymerization time to be shortened and the production energy consumption to be low; and the prepared polymer has the advantages of good quality, high viscosity and environmental protection.

Owner:NANJING HUASHI NEW MATERIAL

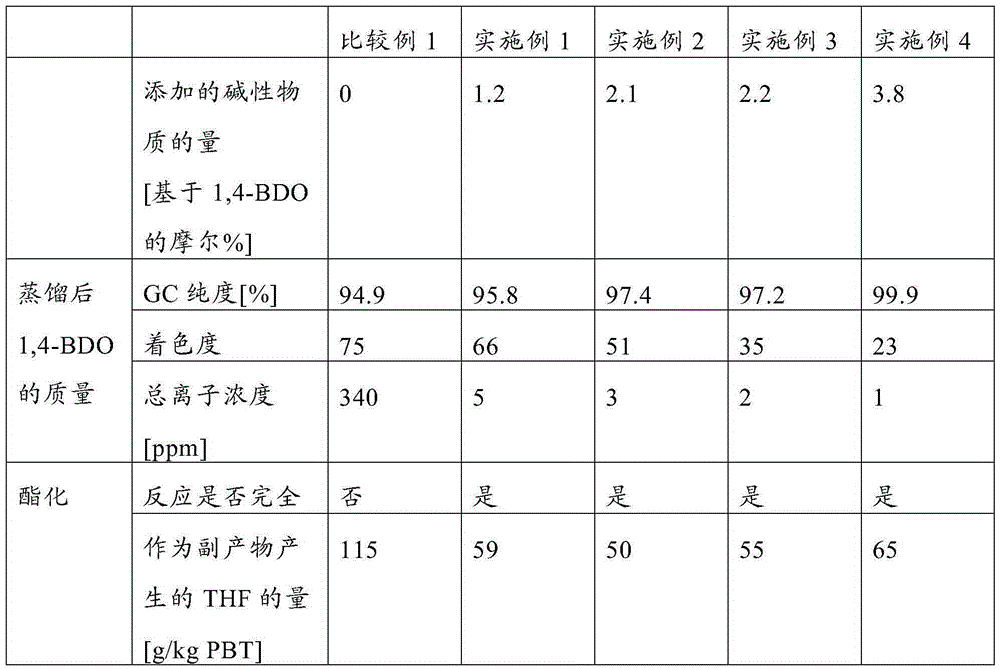

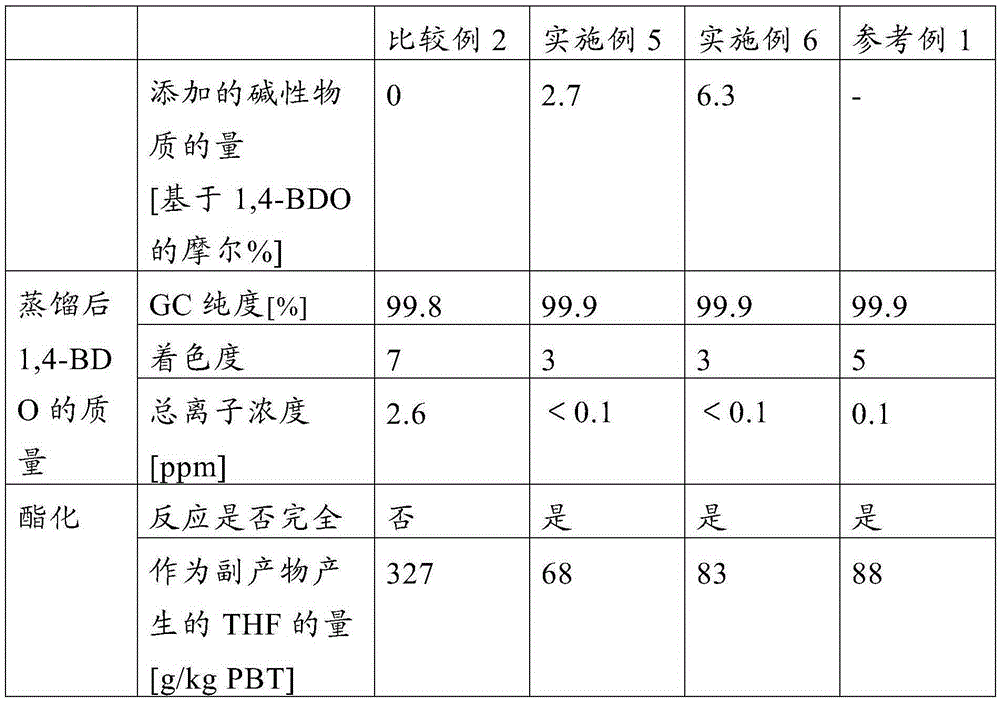

Process of producing 1,4-butanediol

InactiveCN105283431AProlonged occurrenceExtend polymerization timeMembranesSemi-permeable membranes1,4-ButanediolPolyester

A process produces 1,4-butanediol by purifying 1,4-butanediol originated from a fermentation broth, by which process 1,4-butanediol having properties suited as a material of producing a polyester is obtained, which 1,4-butanediol enables to reduce by-production of tetrahydrofuran during the esterification reaction and to reduce the delay in polymerization. The process of producing 1,4-butanediol includes adding an alkaline substance other than an ammonia or an amine to an aqueous 1,4-butanediol-containing solution originated from a fermentation broth; distilling the resulting mixture; and recovering a 1,4-butanediol-containing solution from the vapor flow.

Owner:TORAY IND INC

Rubber composition comprising a highly saturated diene elastomer

ActiveUS10189978B2Extend polymerization timeReduce reduction reactionSpecial tyresElastomerHysteresis

The present invention relates to a rubber composition based on a reinforcing filler and on an elastomer matrix comprising a highly saturated diene elastomer comprising at least five distinct units of A, B, C, D and E distributed randomly within the elastomer at respective molar fractions of m %, n %, o %, p % and q %, where m+n+o+p+q=100; m≥50; n+o+p+q≥10; and 15≥p+q≥2.This rubber composition enables a satisfactory degree of stiffness to be reached while maintaining hysteresis properties acceptable for use in the manufacture of tires for running vehicles.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

Method of preparing peroxide vulcanized fluororubber through nano emulsion polymerization

The invention discloses a method of preparing peroxide vulcanized fluororubber through nano emulsion polymerization. The method comprises following steps: step one, compounding a fluorine ether emulsifier and a co-emulsifier according to a mass ratio of (60:40)-(80:20) to obtain a water solution with a nano emulsion polymeric surfactant concentration of 35-65%; step two, under the action of nano emulsion polymeric surfactant and an initiator, carrying out nano emulsion polymerization of one or more fluorine containing monomers or one or more vulcanized point monomers in a polymerization kettle; and step three, subjecting the latex obtained in polymerization to agglomeration, washing, drying, and dehydration, and preparing peroxide vulcanized fluororubber sheets by an open mill.

Owner:江苏梅兰化工有限公司

High-toughness and water-resistant modified melamine urea-formaldehyde resin

InactiveCN104387542AExtend polymerization timeImprove water resistancePolyethylene glycolAlkylphenol

The invention provides high-toughness and water-resistant modified melamine urea-formaldehyde resin. The high-toughness and water-resistant modified melamine urea-formaldehyde resin is prepared from the following raw materials in parts by weight: 80 parts of urea, 160-220 parts of formaldehyde, 10-20 parts of melamine, 5-10 parts of fatty acid amide, 5-8 parts of polyethylene glycol, 3-6 parts of alkylphenol ethoxylate, 2-5 parts of sodium dihydrogen phosphate, 1-3 parts of hydrochloric acid and 20-30 parts of water. The high-toughness and water-resistant modified melamine urea-formaldehyde resin provided by the invention can effectively improve the toughness and water resistance of the urea-formaldehyde resin. A resin modifying component contained in the high-toughness and water-resistant modified melamine urea-formaldehyde resin provided by the invention can participate in co-condensation polymerization reaction of the resin to change the resin structure and reduce crosslinking density, thereby increasing foam strength, increasing toughness, reducing brittleness, being rich in elasticity and increasing stability.

Owner:CHONGZHOU HERUI TECH

Production method of polyvinyl chloride with small pot suspension method

The invention relates to a polyvinyl chloride, in particular to a production method of the polyvinyl chloride with a small pot suspension method, belonging to the technical field of chemical industry, characterized in that: EHP (peroxydicarbonate-diethylhexyl ester) which has high activity, uniform heat generation, and light sticking is used, based on using the EHP, a composite initiator is used, heat exchange capability of the kettle is fully utilized to allow the reaction speed to be uniform, prevent the acceleration of the post reaction speed to guarantee the timely removal of polymerization heat, and reduce the polymerization time; a composite system of binary PVA (polyvinyl alcohol) with different alcoholysis degrees and a polybasic composite system of HPMC (hydroxypropyl methyl cellulose) and PVA are used; and a secondary water injection technology is used, so that viscosity of the materials is reduced, the heat removing capability of the polymerizing pot is improved, and the quality of the PVC products is increased. According to the invention, the polymerization time is reduced, the viscosity of the materials is reduced, the cleaning time of the polymerizing pot, and a low water-oil ratio can be used for filling, so that the production capacity is improved.

Owner:邱飞

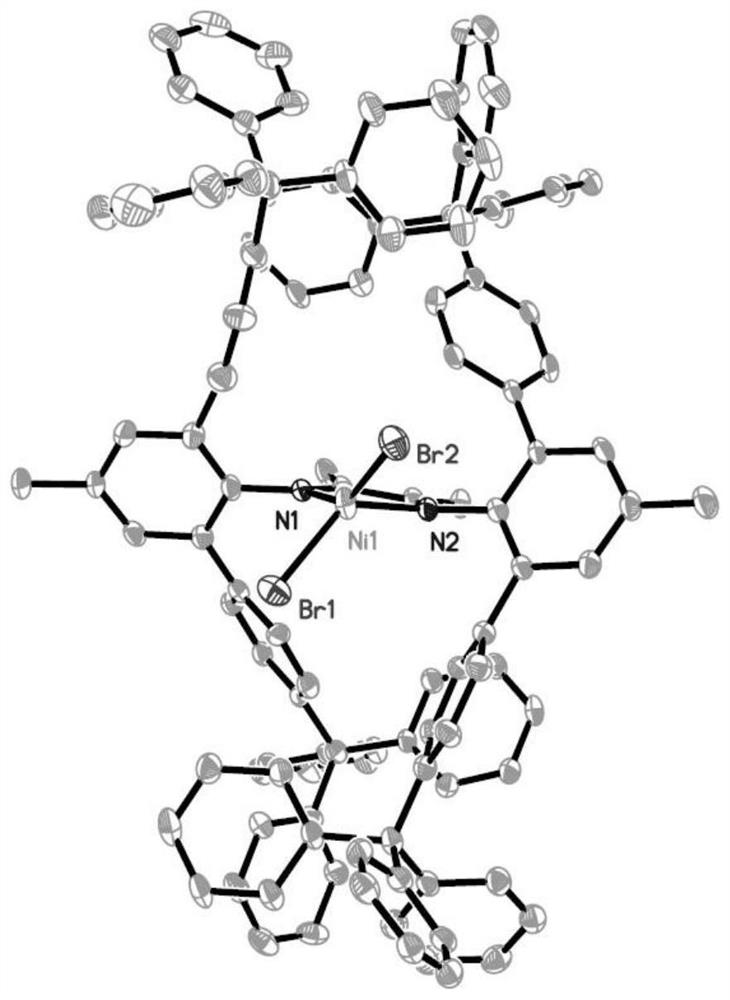

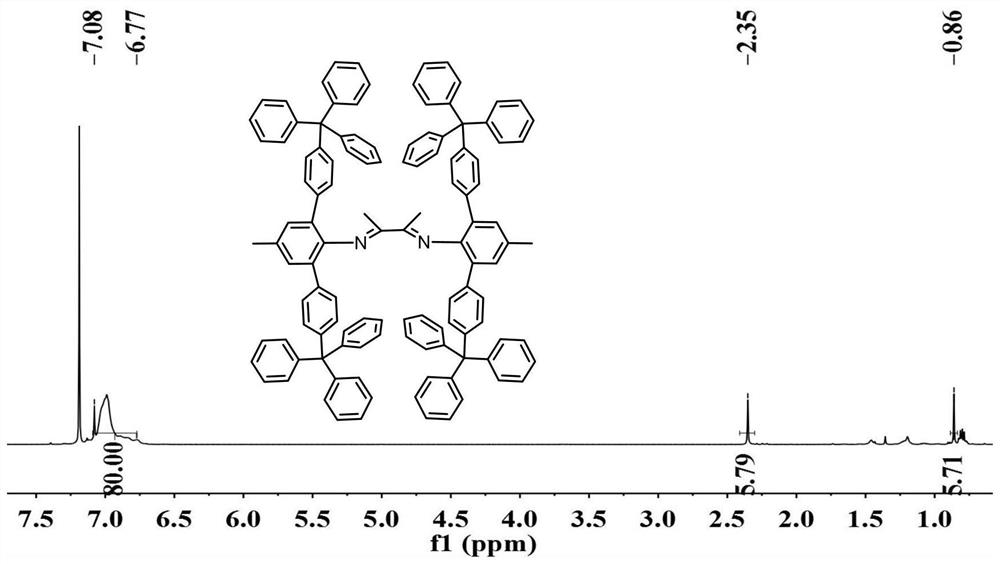

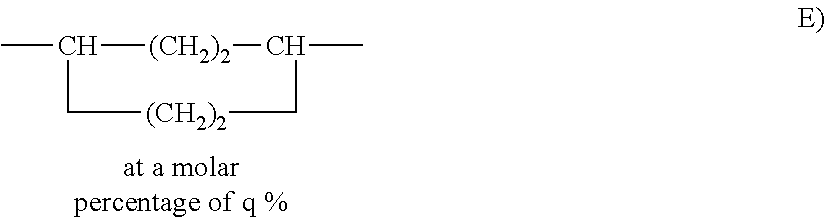

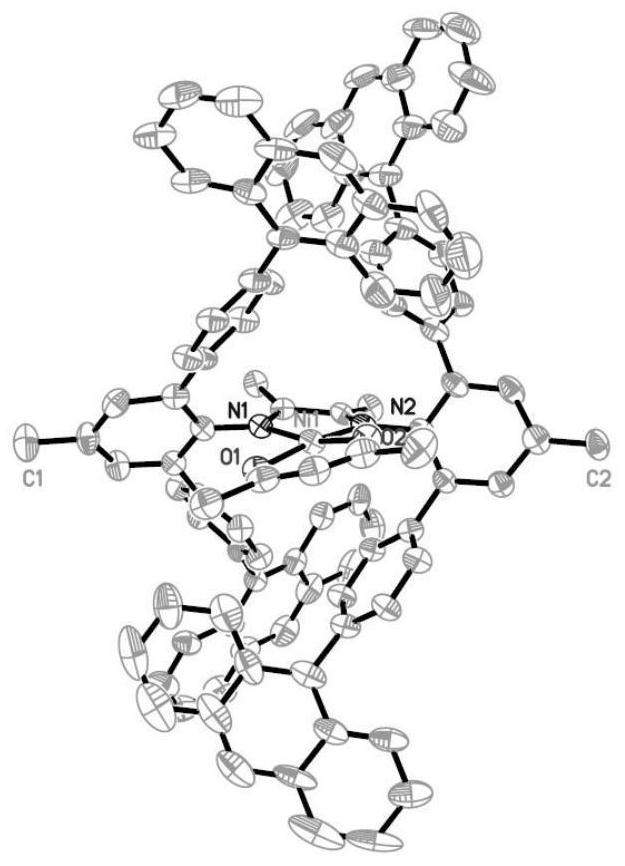

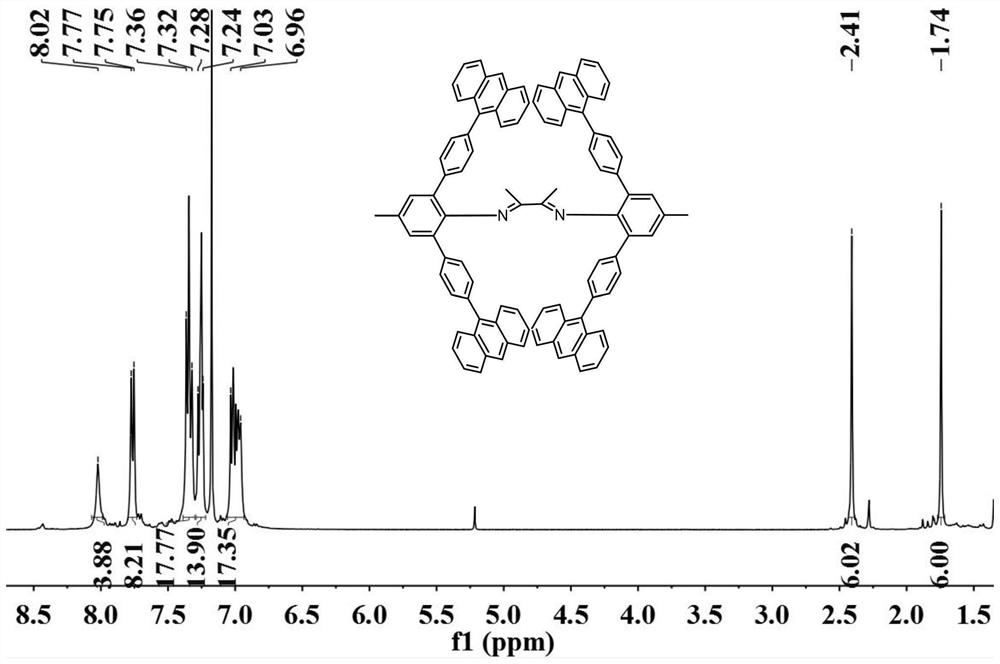

Aromatic amine based on rigid terphenyl structure, alpha-diimine ligand, nickel catalyst and preparation method and application thereof

ActiveCN113135828AImprove performanceImprove catalytic performanceAmino preparation from aminesNickel organic compoundsPolymer sciencePtru catalyst

The invention relates to aromatic amine based on a rigid terphenyl structure, an alpha-diimine ligand, a nickel catalyst and a preparation method and application of the aromatic amine, the alpha-diimine ligand and the nickel catalyst, and belongs to the technical field of catalysts. The structural formula of the nickel catalyst is shown as a formula (III) or a formula (IV), and the nickel catalyst has excellent performance in preparation of polyethylene by catalyzing ethylene polymerization: under the ethylene pressure condition of 8bar, the polymerization time is 10 minutes, and ultrahigh molecular weight polyethylene can be obtained; under the ethylene pressure condition of 1 bar, the ultra-high molecular weight polyethylene can still be obtained after the polymerization time is 30 minutes; and the catalyst has the advantage of high activity, can still maintain the high activity of 2.1 * 10 < 6 > g mol <-1 > h <-1 > even at 150 DEG C, and shows extremely excellent thermal stability.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Pavement repairing device for concrete road maintenance

InactiveCN113931047ARealize sealed storageExtend polymerization timeRoads maintainenceInformation processingArchitectural engineering

The invention relates to the field of road maintenance, in particular to a pavement repairing device for concrete road maintenance. The invention relates to a pavement repairing device for concrete road maintenance, which can move along a road crack to complete pouring at one time through accurate positioning, pressurized pouring and pavement allowance control of a pavement repairing agent. A pavement repairing device for concrete road maintenance comprises an electric trolley, a pouring device, a positioning device, an information processing module and the like. The filling device, the positioning device and the information processing module are fixedly connected in the electric trolley. The effects achieved by the invention are as follows: the electric trolley bears the pouring device and the positioning device to realize crack repair in the moving process, the pouring device is matched with the positioning device, the pouring device is positioned in the crack through the positioning device, and the pouring device moves along with the change of the direction of the crack; and the pouring device achieves one-time pouring of the pavement repairing agent through pressure pouring.

Owner:东营职业学院

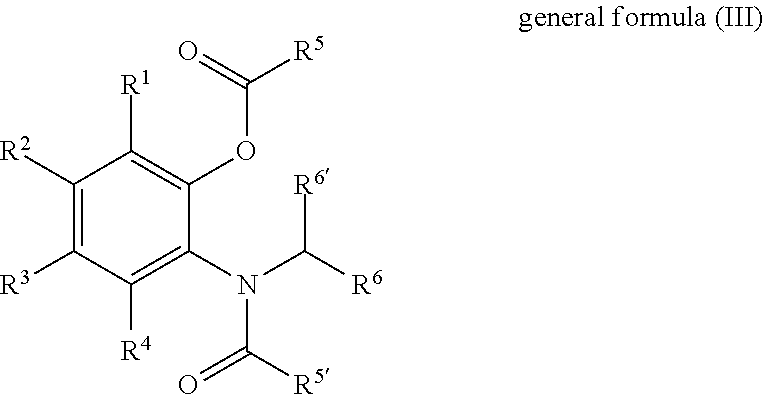

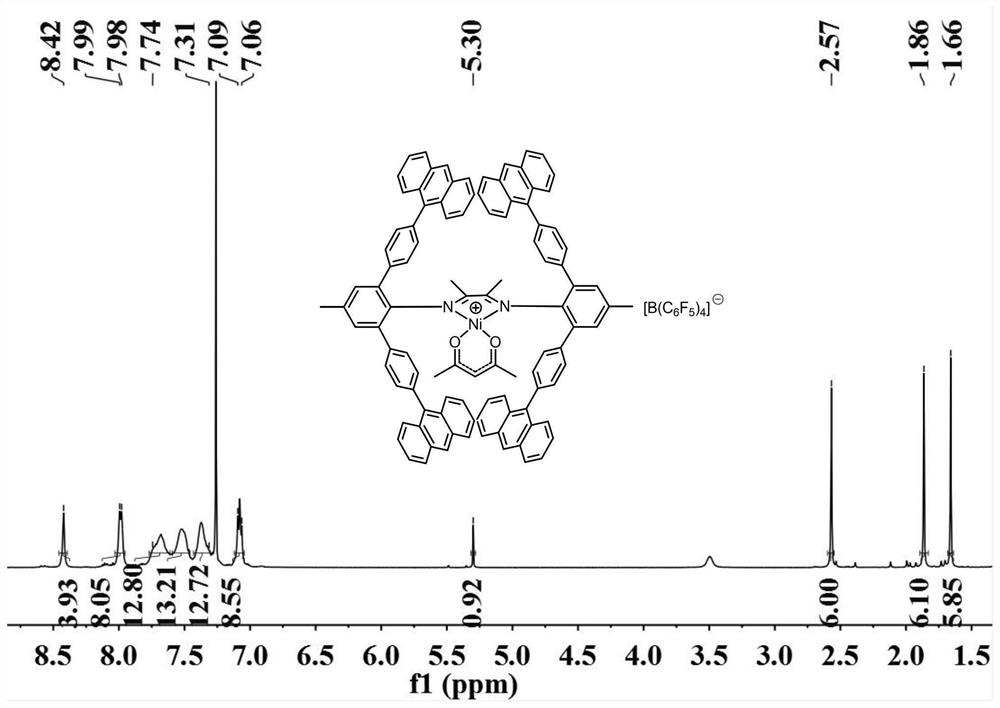

[OONN] tetradentate fourth subgroup metal complexes as well as preparation method and application thereof

PendingCN112778350AEasy to manufactureThe synthesis method is simpleGroup 4/14 organic compounds without C-metal linkagesOlefin polymerizationComposite material

The invention relates to the technical field of olefin polymerization catalysts, and particularly discloses [OONN] tetradentate fourth subgroup metal complexes, a preparation method and application. The [OONN] tetradentate fourth subgroup metal complexes have a structure which is shown in the specification. The [OONN] tetradentate fourth subgroup metal complexes provided by the invention can catalyze ethylene polymerization and ethylene and alpha-olefin copolymerization, and in the polymerization process, the heat resistance is good, and the polymerization time is long. The complexes are simple in synthesis method, easy to prepare and high in yield, the structure is convenient to modify, the complexes can be used for catalyzing ethylene polymerization and ethylene and alpha-olefin copolymerization after being activated by a proper cocatalyst, the problems that an existing olefin polymerization catalyst is relatively tedious in preparation process, high in cost and low in catalytic activity are solved, and the complexes have good industrial application value and wide application field.

Owner:JILIN UNIV

Preparation method of high-solid-content cationic polyacrylamide emulsion

The invention discloses a preparation method of high-solid-content cationic polyacrylamide emulsion. The preparation method disclosed by the invention adopts a segmented initiation process, a 1 to 5 percent low-concentration reducing agent solution is slowly dropwise added in a redox stage to reduce the polymerization rate in the redox stage, the polymerization time is prolonged, and the problemsthat the synthesis of low-molecular-weight polyacrylamide emulsion cannot be initiated at a low temperature and requirements on the heat dissipation capability of equipment are high are solved. According to the preparation, the maximum temperature of the polymerization is controlled within a safe range by slowly dropwise adding the low-concentration reducing agent solution, so that a plenty of time is provided for dissipating the polymerization heat; furthermore, the conversion rate in the redox stage is increased, and the potential safety hazard in an azo initiation stage is eliminated. The low-molecular-weight high-solid-content cationic polyacrylamide emulsion product prepared by the preparation method can be widely applied to various sewage and sludge treatment fields.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

Copolyester of furandicarboxylic acid and preparation method thereof

ActiveCN109810248BHigh tensile modulusHigh tensile strengthMonocomponent copolyesters artificial filamentFuranFormic Acid Esters

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

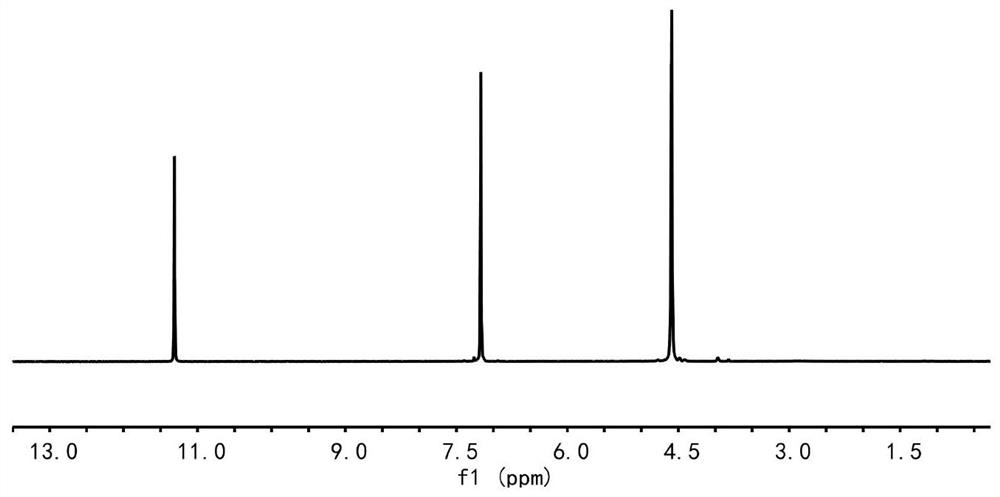

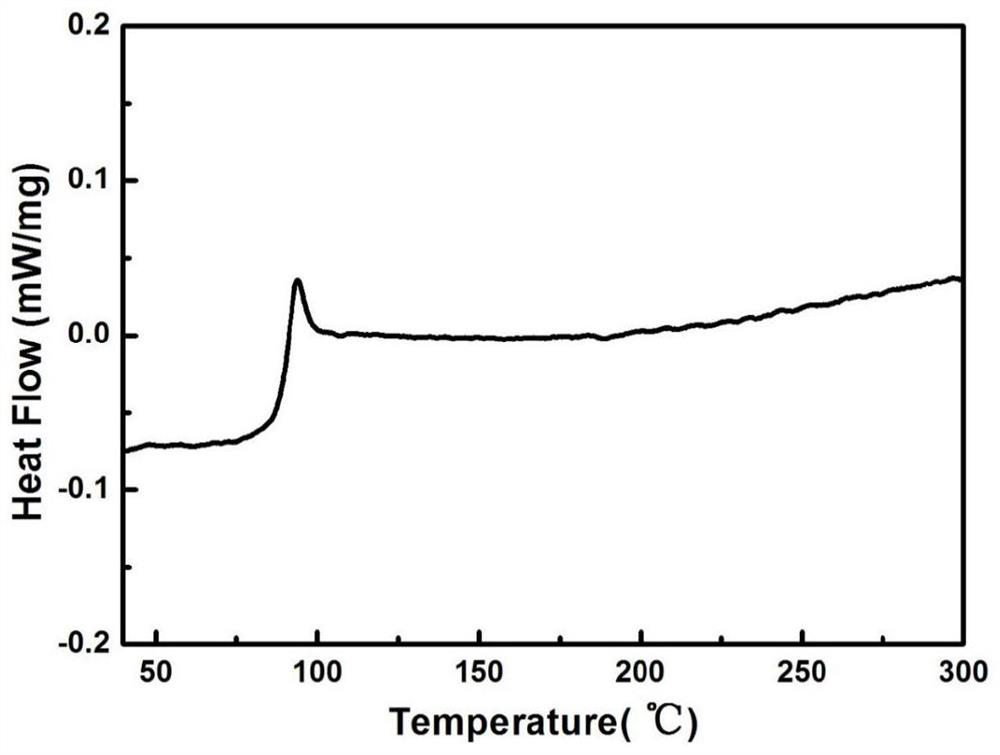

Large-steric-hindrance alpha-diimine ligand, nickel catalyst and preparation method and application thereof

ActiveCN112920300ALarge axial steric hindranceHigh activityImino compound preparationNickel catalystPolymer science

The invention relates to a large-steric-hindrance alpha-diimine ligand, a nickel catalyst and a preparation method and application thereof, belongs to the technical field of catalysts, and solves the two problems of the alpha-diimine catalyst in the prior art: 1) the molecular weight of the obtained copolymer is very low and is generally below 10000; 2) the conditions are harsh, and high temperature and high pressure are usually needed; the structural formula of the nickel catalyst is shown as a formula (II). The nickel catalyst has ultra-large axial steric hindrance, can effectively inhibit chain transfer, has the advantage of high activity (as high as 6.9 x 10 < 7 > gmol <-1 > h <-1 >), can still keep high activity at high temperature, also has excellent thermal stability, and can be used for preparing an ultra-high molecular weight functionalized polyolefin material at normal temperature and normal pressure.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Preparation method of atactic polyether

This invention relates to preparation method of random polyether, primary solve problem of long polymerization time and large catalyzer dosage that exist in ancient technology which takes fatty alcohol or fatty acid as initiator, alkali as catalyzer to prepare random polyether. This invention takes fatty alcohol or fatty acid as initiator, bimetal prussiate as catalyzer to catalyze mixture of oxirane and propylene oxide to gain random polyether, better solve above problem, can be used in industrial production of random polyether.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of melamine resin modifier

ActiveCN103980448BExtend polymerization timeImprove toughnessNon-fibrous pulp additionPaper/cardboardAlkylphenolRoom temperature

Owner:北京霍尔茨家居科技有限公司

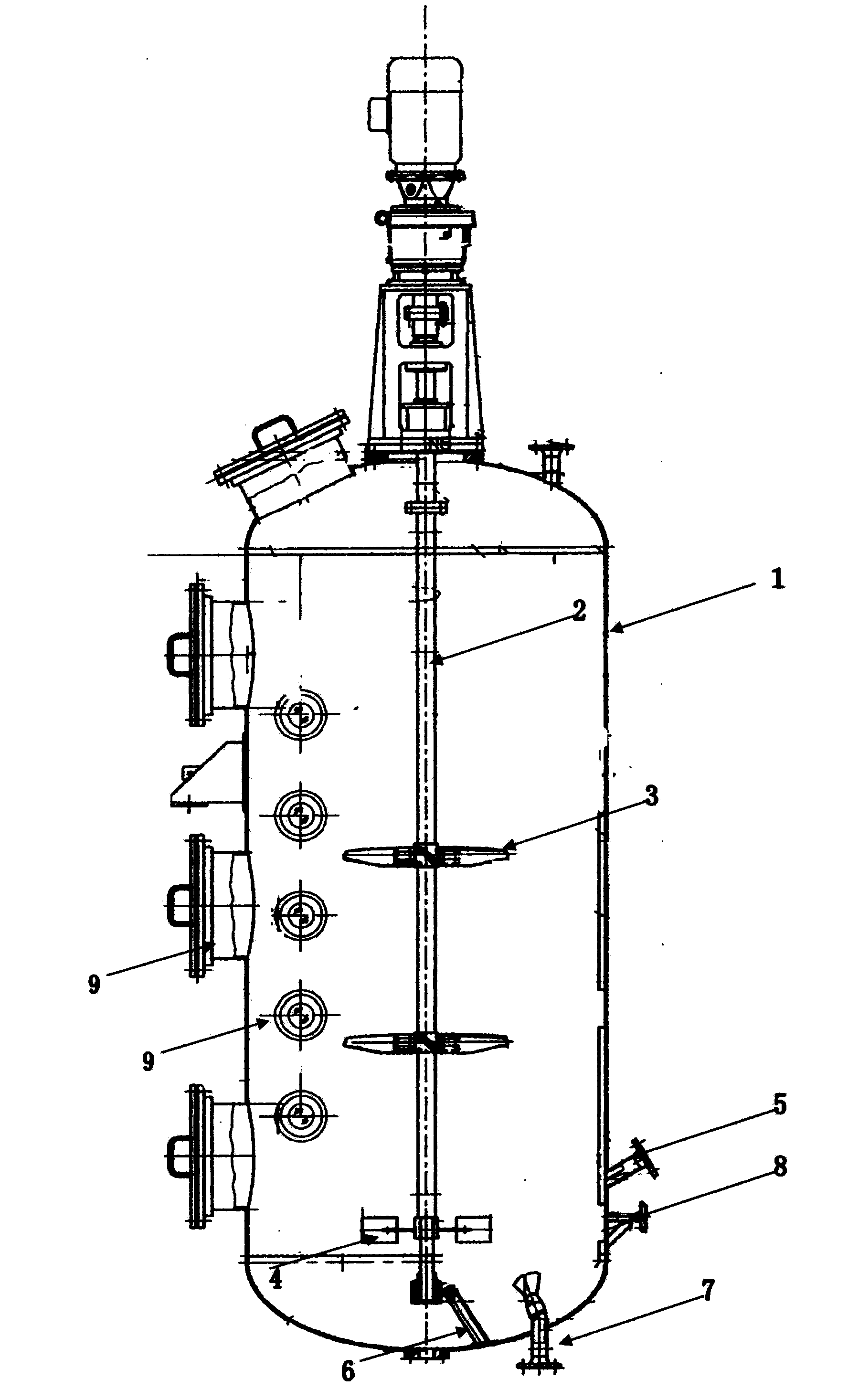

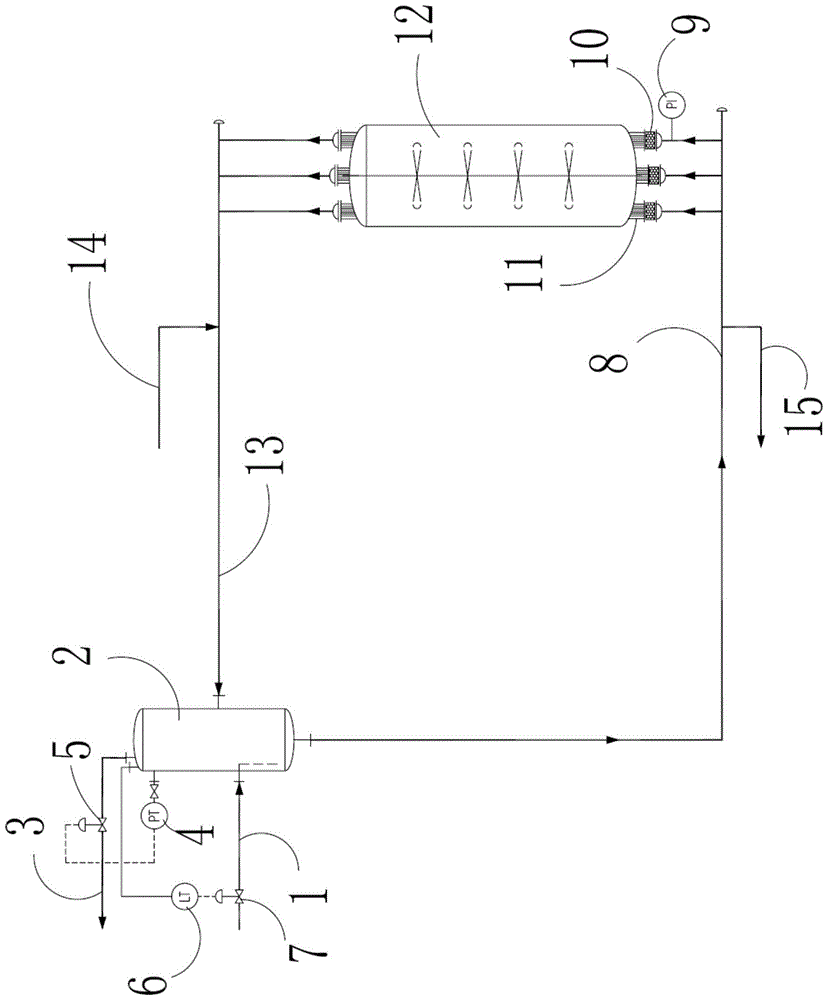

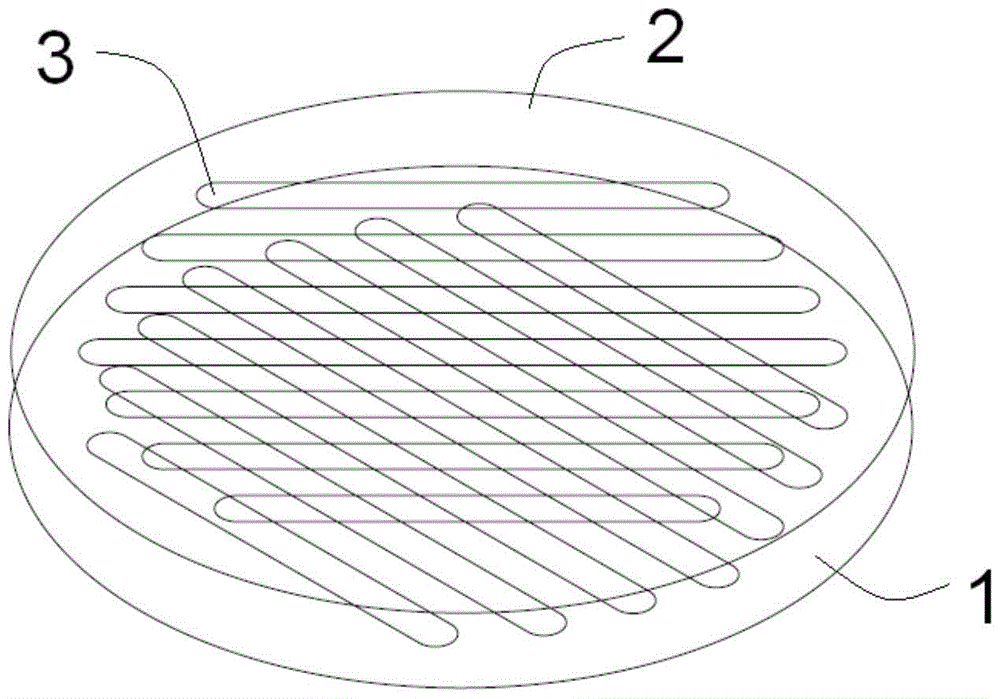

Delay type high-centipoise molecule dynamic synthesis device

InactiveCN103657567AExtend polymerization timeAvoid implosionChemical/physical/physico-chemical stationary reactorsSolventMonomer

The invention relates to a delay type high-centipoise molecule dynamic synthesis device which is suitable for the field of macromolecule polymerization, and especially suitable for high-centipoise macromolecule synthesis. The delay type high-centipoise molecule dynamic synthesis device has the main structure as follows: firstly, a mixer is arranged in a dynamic synthesis device body, an upper-guiding blade is arranged at the upper end of a mixing shaft of the mixer, a dispersing blade is arranged at the lower end of the mixing shaft of the mixer; secondly, a monomer unit, a catalytic medium inlet, a heating medium inlet and a solvent inlet are formed in the bottom end of the dynamic synthesis device body, and are hollow pipelines; the tail ends of the pipelines all point to the position of a center shaft of the mixer, and also point to the edge of the dispersing blade at the lower end of the mixer. When the delay type high-centipoise molecule dynamic synthesis device works, each monomer, medium, solvent and catalyst are injected from respective inlets, and collected to the center shaft of the mixer or the edge of the dispersing blade, fully mixed and dispersed by the dispersing blade and polymerized, and guided to the upper end of a reaction kettle by the upper-guiding blade after the polymerization is completed within a short time, and output through a discharging hole.

Owner:王仲明

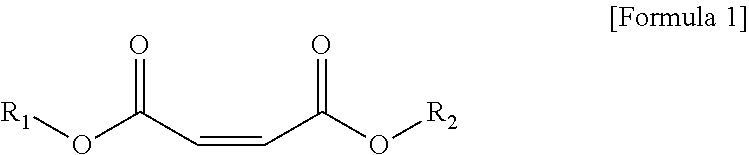

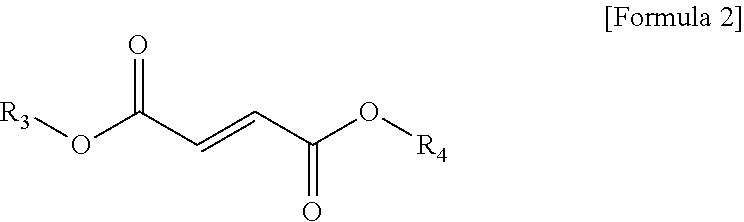

Vinyl chloride-based copolymer, method for preparing the same, and thermoplastic resin composition containing the same

The present invention relates to a vinyl chloride-based copolymer which has good processability and thus is capable of providing molded articles having good appearance characteristics, for example, transparency, a method for preparing the same, a thermoplastic resin composition containing the same, and a thermoplastic resin molded article produced from the thermoplastic resin composition. The vinyl chloride-based copolymer includes N-vinyllactam-based polymer compound derived units and unsaturated fatty acid ester derived units at an appropriate ratio, and may have improved structure stability and good processability due to the N-vinyllactam-based polymer compound derived units and improved plasticity and processability due to the internal plasticizer action of the unsaturated fatty acid ester derived units. Therefore, the vinyl chloride-based copolymer according to the present invention may be easily applied in industries that need thereof.

Owner:LG CHEM LTD

High-flame-retardancy foam material for coal wagon blocking

The invention relates to the technical field of sealing materials and in particular discloses a high-flame-retardancy foam material for coal wagon blocking. The high-flame-retardancy foam material specifically consists of three components of a component A, a component B and a component C, wherein the component A comprises combined polyhydric alcohols; the component B comprises a prepolymer of isocyanate and polyether polyol; the component C is glacial acetic acid; and the combined polyhydric alcohols consist of polyhydric alcohols, micro-pore calcium silicate and magnesium trisilicate in a mass percentage ratio of (10-15):(1-2):(1-2). With the combination of the three components, the flame retardancy and the bonding strength of the foam material are effectively improved, and the foam material can be sufficiently applicable to a blocking environment of a coal wagon; the three-component polyurethane foam material disclosed by the invention is a blocking material which has an expansion time, is good in sealing property, good in bonding force and good in flame retardancy, is good in operability, simple, rapid and convenient to use and low in cost, and is capable of improving the security and the economy efficiency in blocking the coal wagon to a large extent.

Owner:SHANXI YUBANG NEW POWER SCI & TECH

A method for preparing peroxide vulcanized fluororubber by nanoemulsion polymerization

The invention discloses a method of preparing peroxide vulcanized fluororubber through nano emulsion polymerization. The method comprises following steps: step one, compounding a fluorine ether emulsifier and a co-emulsifier according to a mass ratio of (60:40)-(80:20) to obtain a water solution with a nano emulsion polymeric surfactant concentration of 35-65%; step two, under the action of nano emulsion polymeric surfactant and an initiator, carrying out nano emulsion polymerization of one or more fluorine containing monomers or one or more vulcanized point monomers in a polymerization kettle; and step three, subjecting the latex obtained in polymerization to agglomeration, washing, drying, and dehydration, and preparing peroxide vulcanized fluororubber sheets by an open mill.

Owner:江苏梅兰化工有限公司

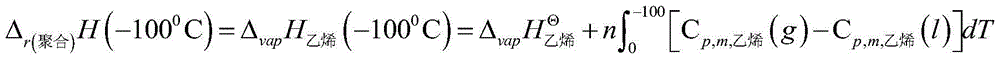

Method for controlling the temperature of butyl rubber reactor

The invention provides a method for controlling temperature of a butyl rubber reactor. The method includes the steps that signals of a pressure transmitter of an ethylene tank are fed back to adjust a pressure regulating valve of the ethylene tank, the pressure of the ethylene tank is controlled below first pressure, the liquid column pressure difference value between normal ethylene liquid level elevation and heat exchange tube bundle top elevation of the reactor is subtracted from ethylene vapourizing pressure below minus 100 DEG C, and the obtained difference value and an adjusting margin value between the pipeline resistance drop from an outlet of the ethylene tank to an inlet of a heat exchange tube bundle of the reactor and a 10KPa adjustable decompression element are added to obtain the first pressure value; pressure drop of the adjustable decompression element is adjusted, so that the pressure of ethylene entering the heat exchange tube bundle of the reactor is equal to the ethylene vaporizing pressure below minus 100 DEG C. The method ensures that reactions are conducted stably below minus 100 DEG C, prolongs polymerization time, reduces the probability of reaction unexpected interrupt, improves productivity and production efficiency and reduces instability of the polymerization process. The method is simple in technological flow path and easy to operate, high in control accuracy, low in operation cost and safe and reliable in production, installation is convenient, and energy does not need to be consumed in the process.

Owner:中石油吉林化工工程有限公司

Functional mutant of human plasminogen, its preparation method and application

InactiveCN102199587BGood for renaturationExtended half-lifeSenses disorderNervous disorderPichia pastorisZymogen

A functional mutant of human plasminogen disclosed in the invention, respectively, is hPLG-delta K: human plasminogen protein Pro<544>-Asn<791> polypeptide; Pro<559> in RGD-hPLG-delta K: hPLG-delta K is mutated to Asp<559>; and Gly<560> in RHP-hPLG-delta K: hPLG-delta K polypeptide is mutated to His<560>. The invention also discloses a preparation method for the functional mutant. The product is obtained by using a plasmid containing a full-length cDNA sequence of human plasminogen as a template to carry out a PCR to construct a plasmid and using Pichia Pastoris expression. The functional mutant has a dual-function of fibrinolysis and inhibiting platelet aggregation or inhibiting fibrin monomer polymerization.

Owner:GUANGDONG PHARMA UNIV

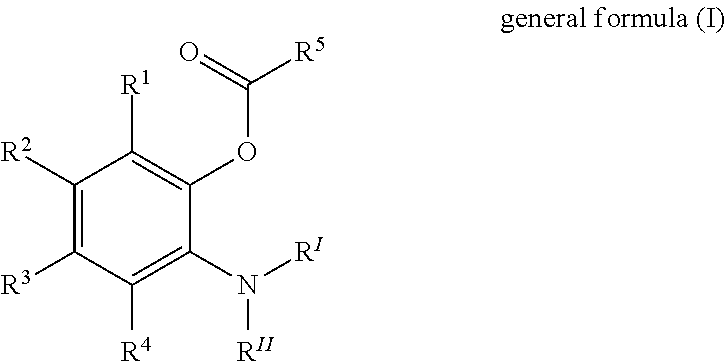

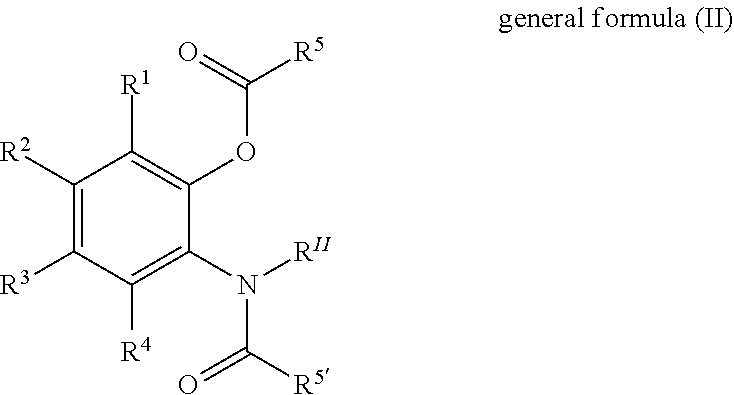

Solid catalyst component for use in olefin polymerisation, catalyst, and application thereof

ActiveUS20200071430A1Increase isotacticity and particle propertyStrong coordinationPolymer sciencePtru catalyst

Provided in the present invention is a solid catalyst component for use in olefin polymerisation, comprising Mg, Ti, a halogen, and at least one electron donor, the electron donor being a 2-substituted amino-phenyl ester compound selected from general formula (I). Also disclosed in the present invention are a catalyst comprising the solid catalyst component, and an application for the catalyst in olefin polymerisation, particularly in propylene polymerization. Also provided in the present invention is a high activity catalyst, said catalyst being able to obtain polypropylene of high isotacticity and wide molecular weight distribution, and not requiring an external electron donor to obtain high isotacticity polypropylene; during polymerization, Al / Ti and Al / Si are reduced, the polymerization time is lengthened, and high activity can still be maintained, suitable for producing low-ash polymers.

Owner:BEIJING LIHE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![[OONN] tetradentate fourth subgroup metal complexes as well as preparation method and application thereof [OONN] tetradentate fourth subgroup metal complexes as well as preparation method and application thereof](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/e73eb467-c854-4843-a3e8-ec5176e9d73c/FDA0002886189060000011.png)

![[OONN] tetradentate fourth subgroup metal complexes as well as preparation method and application thereof [OONN] tetradentate fourth subgroup metal complexes as well as preparation method and application thereof](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/e73eb467-c854-4843-a3e8-ec5176e9d73c/FDA0002886189060000021.png)

![[OONN] tetradentate fourth subgroup metal complexes as well as preparation method and application thereof [OONN] tetradentate fourth subgroup metal complexes as well as preparation method and application thereof](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/e73eb467-c854-4843-a3e8-ec5176e9d73c/FDA0002886189060000031.png)