Method for controlling the temperature of butyl rubber reactor

A technology of butyl rubber and reactor, which is applied in the field of rubber production, can solve the problems that the heat of reaction cannot be removed well, the processing capacity of ethylene compressors increases, and the construction and production costs increase, so as to improve production capacity and production efficiency, Reduced instability, easy-to-handle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following examples can enable those skilled in the art to understand the present invention more fully, but do not limit the present invention in any way.

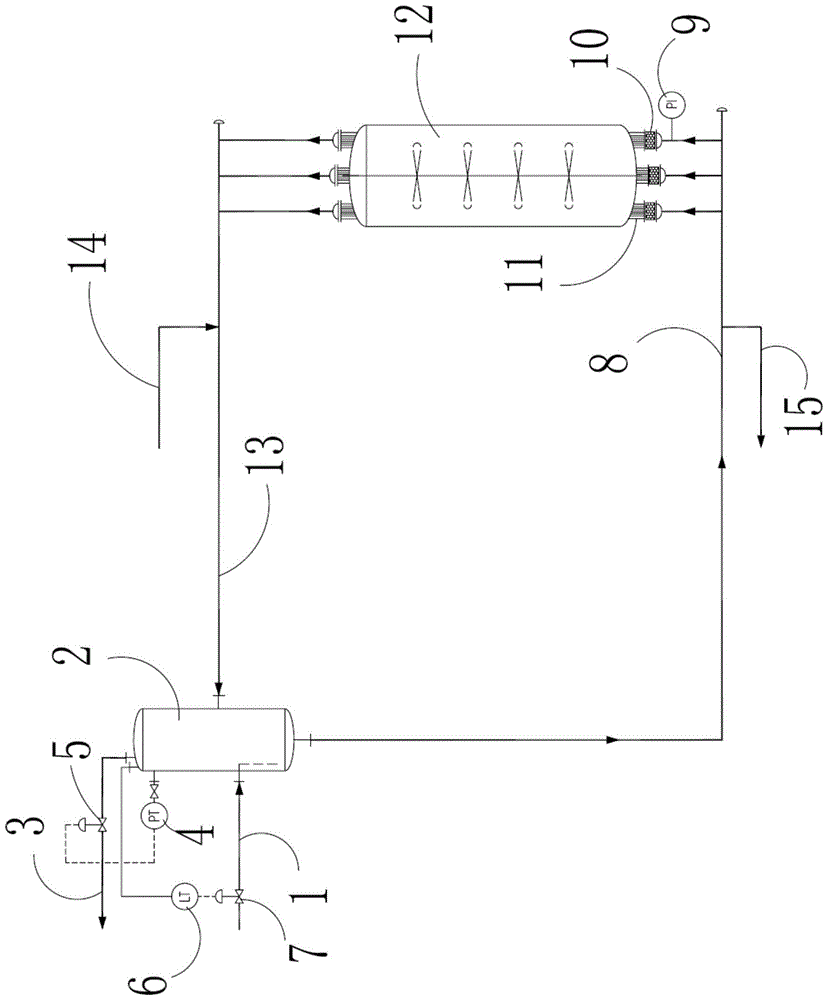

[0026] Such as figure 1 As shown, the polymerization reaction is carried out in the butyl rubber reactor 12 during industrial production of butyl rubber. The reaction heat generated in the polymerization process is absorbed by the ethylene gasification process in the heat exchange tube bundle 11 of the butyl rubber reactor and returned to the ethylene tank 2, and the gasified ethylene is sent to the ethylene compressor through the pipeline 3. The liquid level in the ethylene tank 2 is interlocked and controlled by the ethylene tank liquid level gauge 6 and the ethylene tank liquid level regulating valve 7 , and fresh liquid ethylene is supplemented by the pipeline 1 into the ethylene tank 2 . When the reaction cycle ends, the hot ethylene vapor is fed into the pipeline 14 to vaporize most of the liquid ethylene,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com