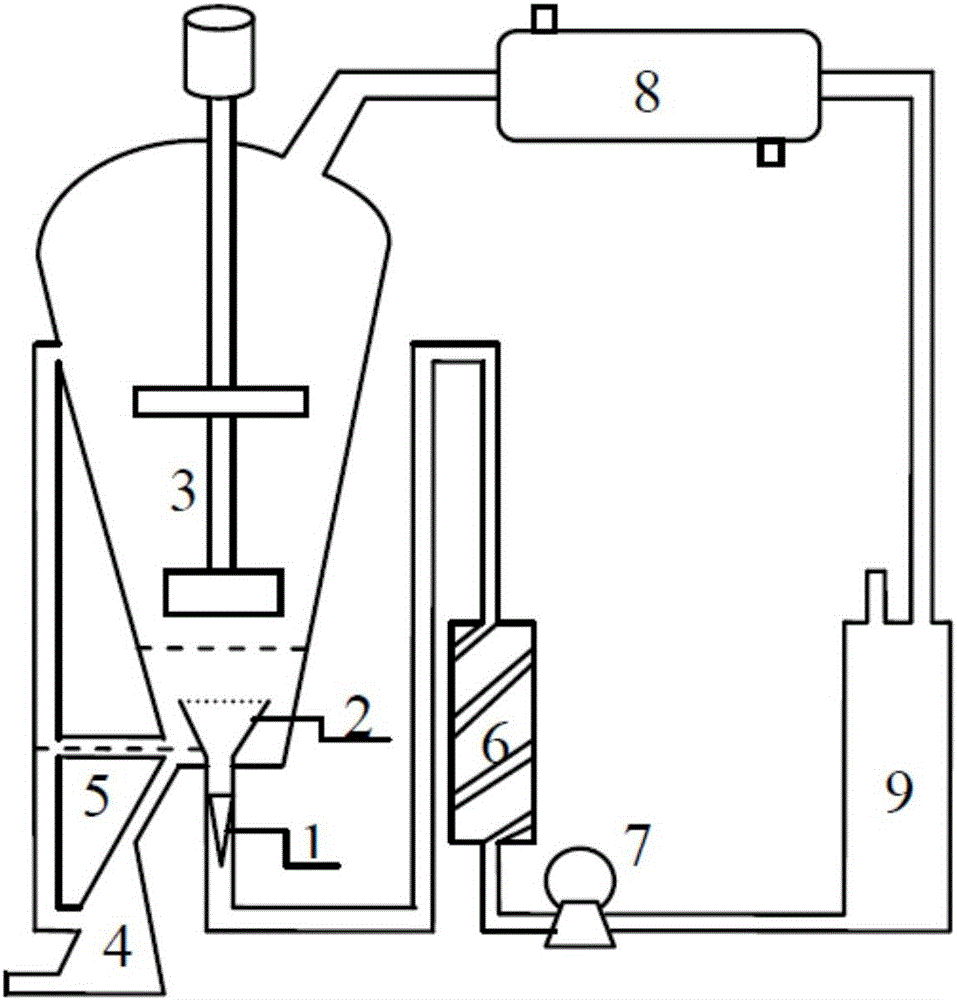

Gas-liquid two-phase ester exchange reaction equipment and method for preparing biodiesel

A technology of transesterification and biodiesel, applied in the direction of biofuel, fatty acid esterification, etc., can solve the problems of low transesterification yield, long time consumption, high energy consumption, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Raw materials: soybean oil, methanol, potassium hydroxide

[0037] Inject an appropriate amount of soybean oil and 0.8% by mass of potassium hydroxide catalyst into the reactor 3, raise the temperature to 100°C, start to inject methanol vapor from the lower end, and the temperature of the vaporizer 6 is 80°C. Sampling every half an hour, pay attention to observe the glycerin level in the glycerin separator, when it reaches the branch pipe, release an appropriate amount of glycerin; when the oil discharged from the lower end of the reactor meets the requirements, stop the methanol from entering and continue to heat and remove the reactor Methanol, open the discharge valve to obtain fatty acid methyl ester (biodiesel). The transesterification conversion rate of fats and oils was measured to reach 98.1%.

Embodiment 2

[0039] Raw materials: rapeseed oil, ethanol, sodium methoxide

[0040] An appropriate amount of rapeseed oil and 0.6% by mass sodium methoxide catalyst are injected into the reactor 3, the temperature is increased to 120°C, and ethanol vapor is injected from the lower end, and the temperature of the vaporizer 6 is 100°C. Sampling every half an hour, pay attention to observe the glycerol level in the glycerol separator, when it reaches the branch pipe, release an appropriate amount of glycerol; when the oil released from the lower end of the reactor meets the requirements, stop the ethanol from entering and continue to heat and remove the reactor Ethanol, open the discharge valve to obtain crude biodiesel product. The transesterification conversion rate of fat and oil was measured to reach 98.2%.

Embodiment 3

[0042] Raw materials: microbial grease, methanol, solid base catalyst

[0043] Into the reactor 3, an appropriate amount of microbial grease and 10% by mass of alkaline calcium bentonite supported sodium hydroxide catalyst are injected, the temperature is increased to 200°C, and methanol vapor is injected from the lower end, and the temperature of the vaporizer 6 is 80°C. Sampling every half an hour, pay attention to observe the glycerin level in the glycerin separator, when it reaches the branch pipe, release an appropriate amount of glycerin; when the oil discharged from the lower end of the reactor meets the requirements, stop the methanol from entering and continue to heat and remove the reactor Methanol, open the discharge valve to obtain fatty acid methyl ester (biodiesel). The transesterification conversion rate of fat and oil was measured to reach 95.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com