Rectification system and method of aluminium ethyl crude product

A technology of triethylaluminum and rectification system, which is applied in the system field of first filtration and then rectification, which can solve the problems of large pollution and achieve the effect of ensuring purity and convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

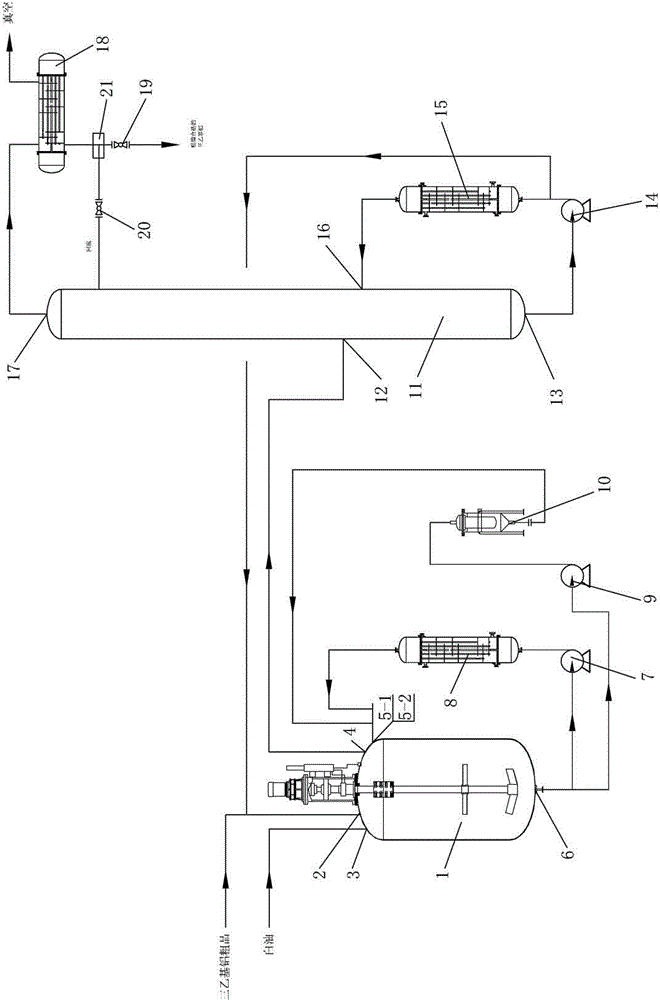

[0016] Embodiment 1 A kind of rectification system of triethylaluminum crude product

[0017] like figure 1 As shown, a rectification system for crude triethylaluminum: the upper end of the mixed still (1) is provided with an inlet for crude triethylaluminum (2), an inlet for white oil (3), and an outlet for triethylaluminum gas I (4 ), the filter circulation inlet (5-1) and the heating circulation inlet I (5-2), the lower end of the mixed still (1) is provided with the circulation outlet I (6), the circulation outlet I (6), the circulation pump I (7 ), reboiler I (8) and heating circulation inlet I (5-2) form heating circulation system I; circulation outlet I (6), circulation pump II (9), filter (10) and filtration circulation inlet (5 -1) Form a filter circulation system; the triethylaluminum gas outlet (4) is connected with the material inlet (12) of the rectification tower (11) through a pipeline; the circulation outlet II (13) at the lower end of the rectification tower ...

Embodiment 2

[0018] Embodiment 2 Triethylaluminum crude product rectification method

[0019] Adopt the rectifying system of embodiment 1, method is as follows:

[0020] 1) First add a certain amount of white oil to the mixed still (1), and raise the temperature of the white oil to 120-140°C through the reboiler I (8) in the heating circulation system I;

[0021] 2) Continuously add the crude triethylaluminum product generated by the reaction into the mixed still (1);

[0022] 3) At this time, the crude triethylaluminum added in the vacuum state is vaporized under the heating of white oil, and the gaseous triethylaluminum enters the rectification tower (11) continuously through the triethylaluminum gas outlet I (4) ); the white oil continues to stay in the mixed still (1) due to its higher boiling point;

[0023] 4) The heating circulation system I formed with the mixed still (1) heats the mixture of white oil and crude triethylaluminum; the filter circulation system formed with the mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com