Process of producing 1,4-butanediol

A technology of butanediol and dicarboxylic acid, applied in the field of production of 1,4-butanediol, can solve problems such as prolongation of polymerization time, and achieve the effect of reducing the prolongation of polymerization time and the generation of THF

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

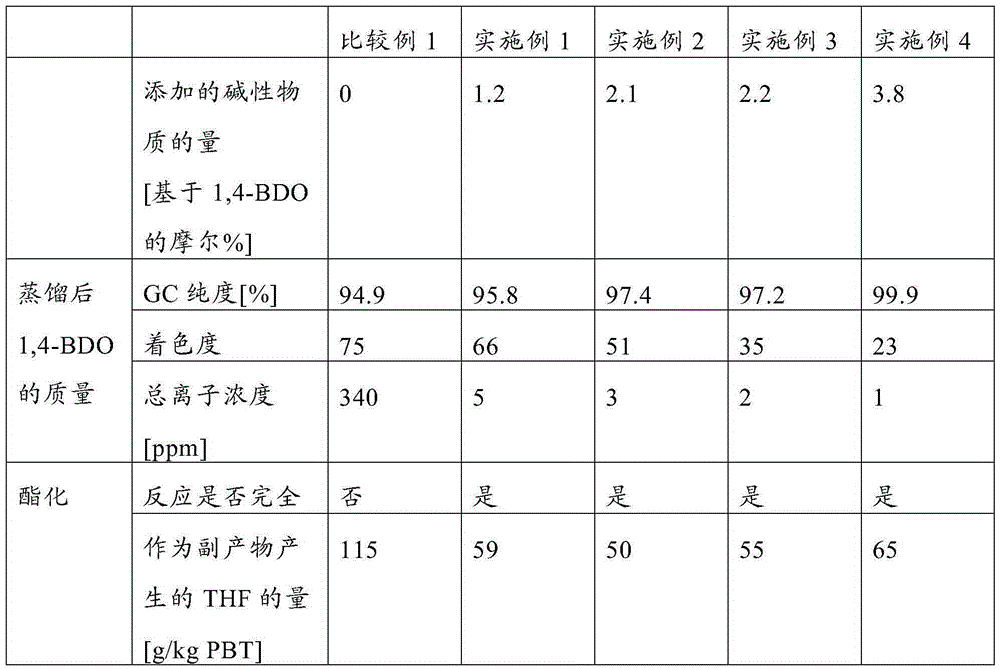

Embodiment 1 to 4 and comparative example 1

[0105] Distillation of a standard model fermentation broth with basic substances and evaluation of the esterification reaction between 1,4-butanediol and dicarboxylic acids

[0106] Preparation of Standard Simulated Fermentation Broth Containing 1,4-Butanediol

[0107] Add 1,4-butanediol, γ-butyrolactone, acetic acid, glucose, fructose, sucrose, sodium chloride, ammonium sulfate, potassium hydrogen phosphate, and hydrochloric acid to ultrapure water to prepare 1,4-butanediol aqueous solution, which was used as a standard simulated fermentation broth.

[0108] Table 1

[0109] Element

Concentration (weight%)

water

78.39

1,4-BDO

13.9

γ-butyrolactone

3.11

0.58

glucose

0.18

0.12

0.28

Na

1.57

NH 4

0.03

K

0.62

Cl

0.55

PO 4

0.62

SO 4

0.17

[0110] Distillation of standard simulated bro...

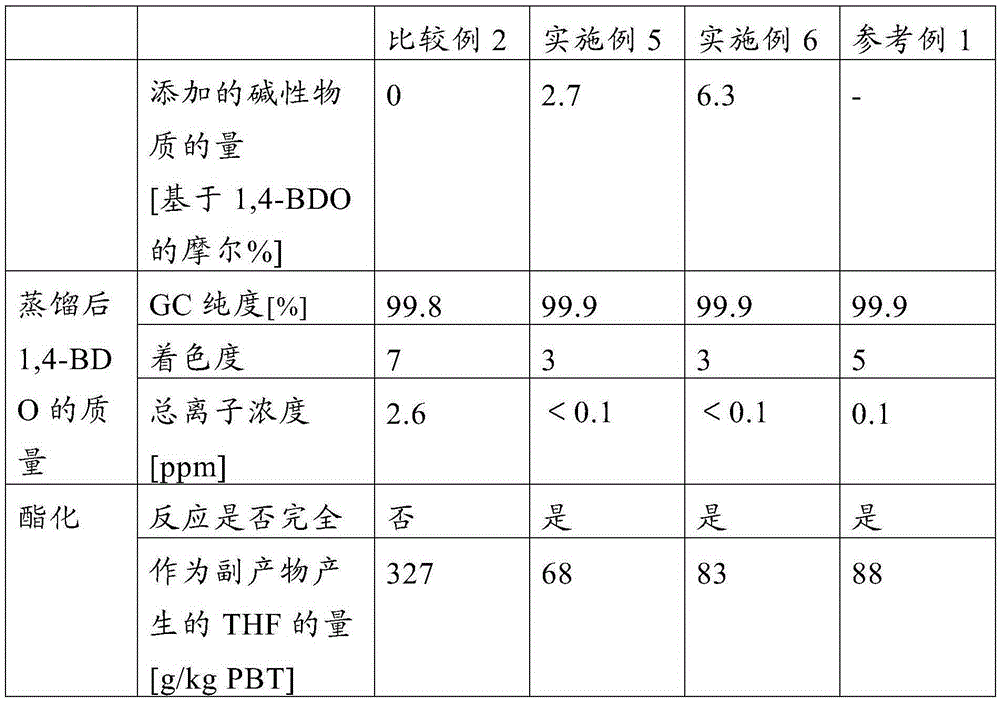

Embodiment 5 and 6, and comparative example 2

[0118] Nanofiltration membrane treatment of fermentation broth containing 1,4-butanediol, reverse osmosis membrane concentration, ion exchange treatment and purification by adding alkaline substances and distillation, and for dicarboxylic acids and the resulting 1,4 -Evaluation of the esterification reaction of butanediol

[0119] Preparation of 1,4-butanediol fermentation broth

[0120] A 1,4-butanediol-containing fermentation broth sample produced by microbial fermentation was obtained (see eg WO2008 / 115840). 27L fermentation broth was used.

[0121] Treatment of Fermentation Broth Containing 1,4-Butanediol Using Nanofiltration Membrane

[0122] use figure 1 The above fermentation broth was purified by the membrane separation device shown in . exist figure 1 Among them, symbol 1 represents the feeding tank; symbol 2 represents the container with nanofiltration membrane or reverse osmosis membrane installed; symbol 3 represents the high-pressure pump; symbol 4 represen...

Embodiment 7 and comparative example 3 and 4

[0137] Nanofiltration membrane treatment, reverse osmosis membrane concentration, ion exchange treatment and purification by addition of alkaline substances and distillation of fermented broth containing 1,4-butanediol, and for dicarboxylic acids and the resulting 1,4 -Evaluation of the esterification reaction of butanediol

[0138] Preparation of 1,4-butanediol from microbial fermentation

[0139] A 1,4-butanediol-containing fermentation broth produced by microbial fermentation is obtained (see WO2008 / 115840). The resulting fermentation broth is purified (see eg WO2010 / 141780) to obtain partially purified 1,4-butanediol.

[0140] Alkaline-added distillation of partially purified 1,4-butanediol

[0141] Water was added to the partially purified 1,4-butanediol to obtain an 80% by weight aqueous 1,4-butanediol solution. To 500g of this 1,4-butanediol solution, add 6.01g (3.4 mol % based on the amount (moles) of 1,4-butanediol, Example 7) of sodium hydroxide, and fully stir th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com