Delay type high-centipoise molecule dynamic synthesis device

A synthesis device and delayed technology, applied in the field of polymer synthesis with high centipoise, can solve the problems of destroying the reasonable molecular structure, failing to remove in time, destroying the mechanical structure of the reactor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

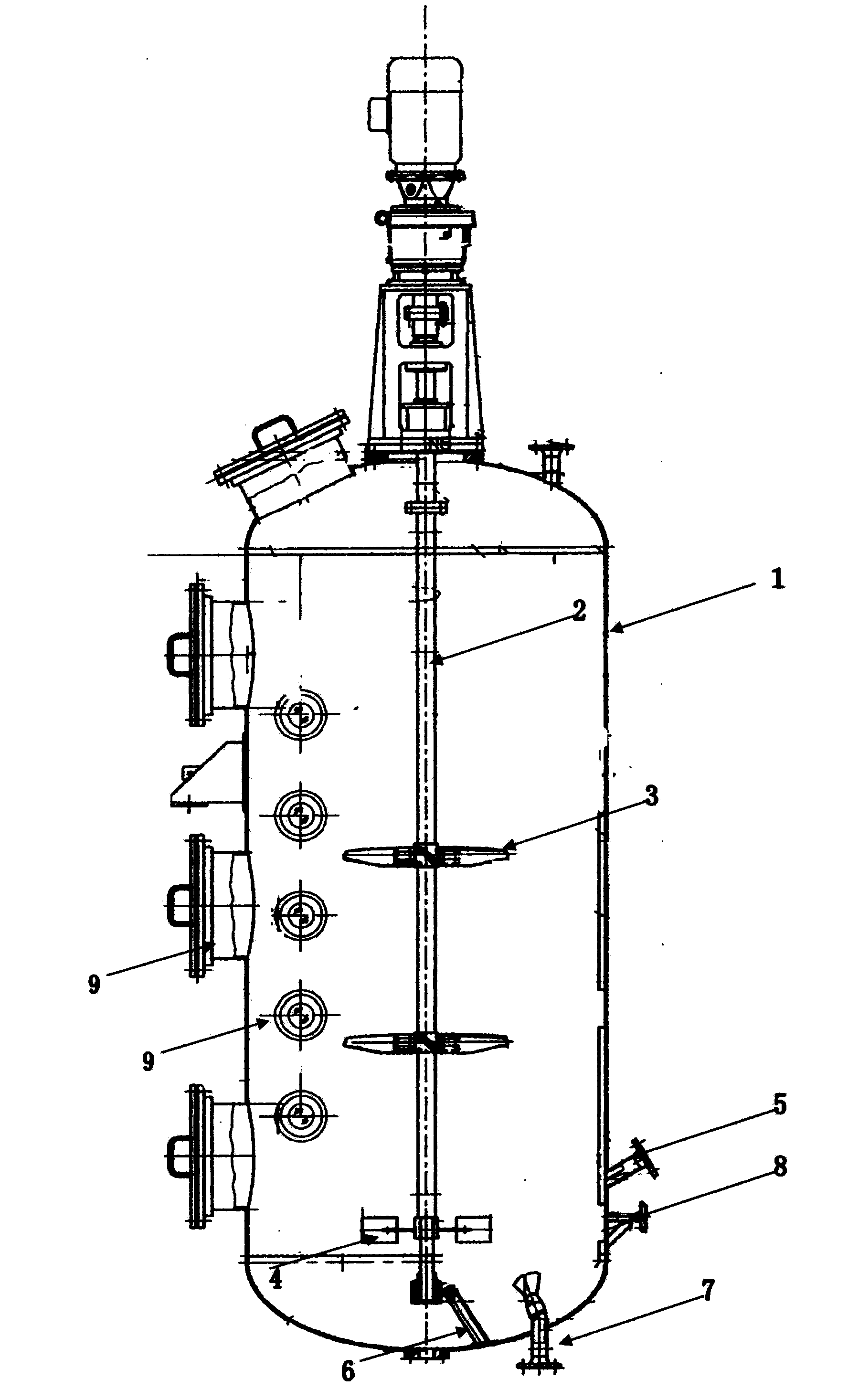

[0010] as attached figure 1 As shown, the delay type high centipoise molecular dynamic synthesis device has the following main structure: first, a stirrer is established in the dynamic synthesis device body (1), that is, the upper end of the stirring shaft (2) of the stirrer is provided with an upper lead paddle (3), the upward-leading paddle (3) is a plurality of upward-leading pitch inclined blades, placed on the stirring shaft (2);

[0011] Then at the lower end of the stirring shaft (2) of the agitator, a dispersing paddle (4) is established. mix;

[0012] Again, a monomer inlet (5), a catalyst medium inlet (6), a heating medium inlet (7), and a solvent inlet (8) are provided at the bottom of the dynamic synthesis device body (1), and the monomers to be reacted and the catalyst medium can be injected respectively. , solvent, heating medium, etc., the inlets are hollow pipes, and the ends of the pipes point to the central axis of the agitator, or point to the edge of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com