Copolyester of furandicarboxylic acid and preparation method thereof

A technology of furandicarboxylic acid copolyester and furandicarboxylic acid, which is applied in the field of materials and can solve the problems of low tensile modulus, deep color in reaction time, low molecular weight and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of furandicarboxylic acid copolyester provided by the invention may further comprise the steps:

[0032] (1) A first component, a second component and a third component are provided, wherein the first component includes at least one of furandicarboxylic acid and furandicarboxylate, and the second component Including at least one of aromatic diols and aliphatic diols, the third component includes polyols with a number of hydroxyl groups greater than or equal to 3;

[0033] (2) Mix the first component, the second component, the third component and the esterification catalyst, and react under an inert atmosphere or a nitrogen atmosphere to obtain a first intermediate product, wherein the The molar ratio of the first component, the second component and the third component is 1:(1.1~2.0):(0.0001~0.02);

[0034] (3) Under vacuum conditions, the first intermediate product is subjected to a prepolymerization reaction to obtain a second intermediate produ...

Embodiment 1

[0077] Add dimethyl 2,5-furandicarboxylate, ethylene glycol, pentaerythritol and anhydrous zinc acetate into the reaction kettle according to the molar ratio of 1:1.5:0.001:0.0015, vacuumize and replace with nitrogen three times, start stirring and gradually Raise the temperature to 180°C and react for 5h. Then add 0.15% antimony trioxide, 0.1% triphenyl phosphate, and 0.1% antioxidant-1010 in the molar weight of dimethyl 2,5-furandicarboxylate, and slowly vacuum to 600Pa~ 2000Pa, pre-polymerized at 220°C for 0.5h. Then gradually raise the temperature to 240° C., continue vacuuming to below 200 Pa and react for 3 hours to obtain bio-based furandicarboxylic acid copolyester.

[0078] From figure 1 It can be seen that the bio-based furandicarboxylic acid copolyester obtained in this example is very light yellow.

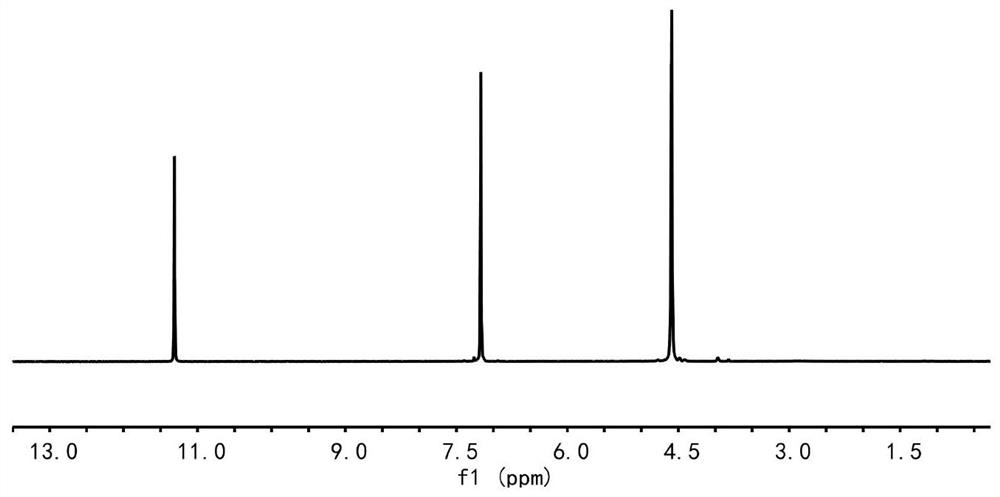

[0079] figure 2 Among them, 11.31ppm is solvent CF 3 The peak of COOD is the peak of hydrogen on the furan ring at 7.17ppm (2H), and the peak of hydrogen on the ...

Embodiment 2

[0084] Add dimethyl 2,5-furandicarboxylate, ethylene glycol, glycerol and anhydrous cobalt acetate into the reaction kettle at a molar ratio of 1:1.6:0.02:0.0005, and gradually raise the temperature to 180°C under an inert atmosphere. Reaction 4h. Then add 0.1% antimony trioxide, 0.1% triphenyl phosphate, and 0.1% antioxidant-1010 of the molar weight of dimethyl 2,5-furandicarboxylate. Pre-polymerization under the condition of ℃ for 0.5h. Then react at a temperature of 240° C. and a vacuum degree below 200 Pa for 4 hours to obtain bio-based furandicarboxylic acid copolyester.

[0085] The bio-based furandicarboxylic acid copolyester obtained in this example is very light yellow, its intrinsic viscosity is 0.80dL / g, the tensile strength is 71.8MPa, the tensile modulus is 2.2GPa, and the carbon dioxide gas barrier performance is 1.1× 10 -12 cm 3 cm / cm 2 ·s·cmHg, oxygen gas barrier performance is 1.2×10 -12 cm 3 cm / cm 2 ·s·cmHg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com