Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

149results about How to "Does not affect shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

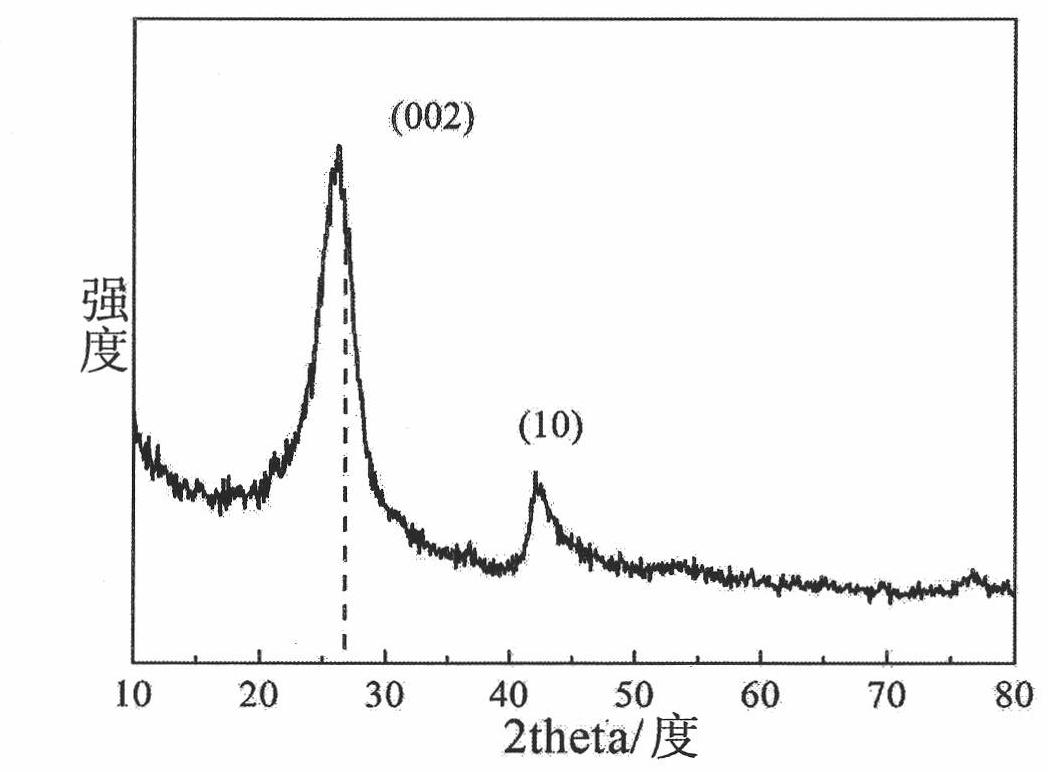

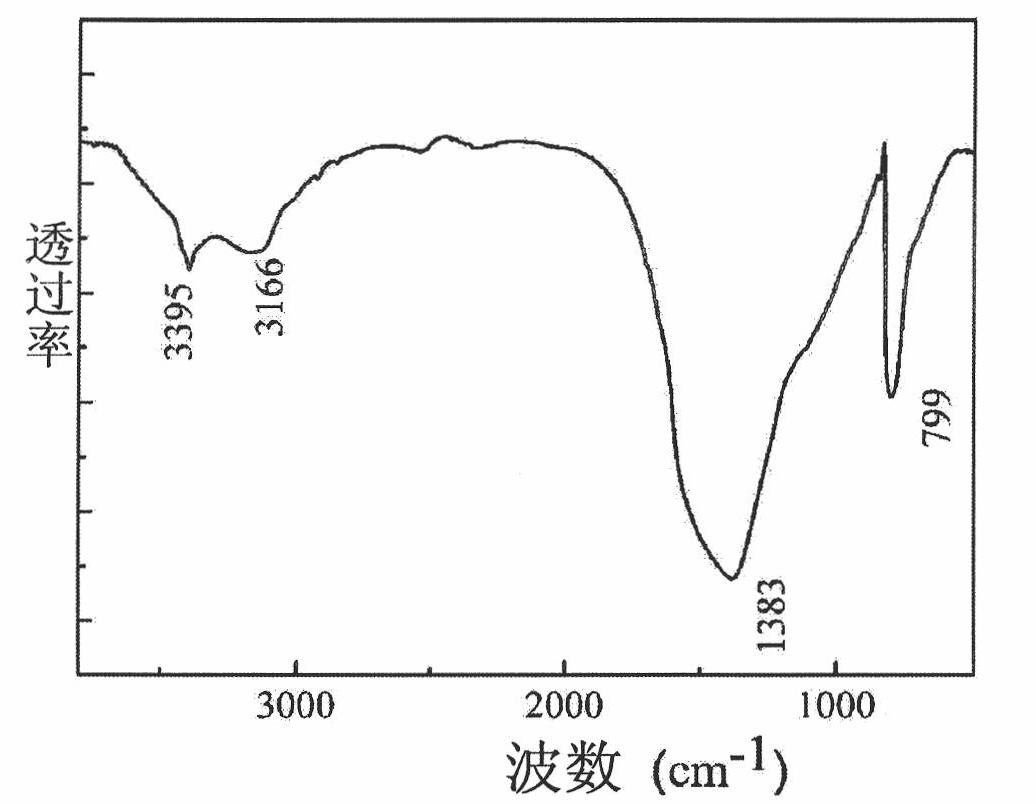

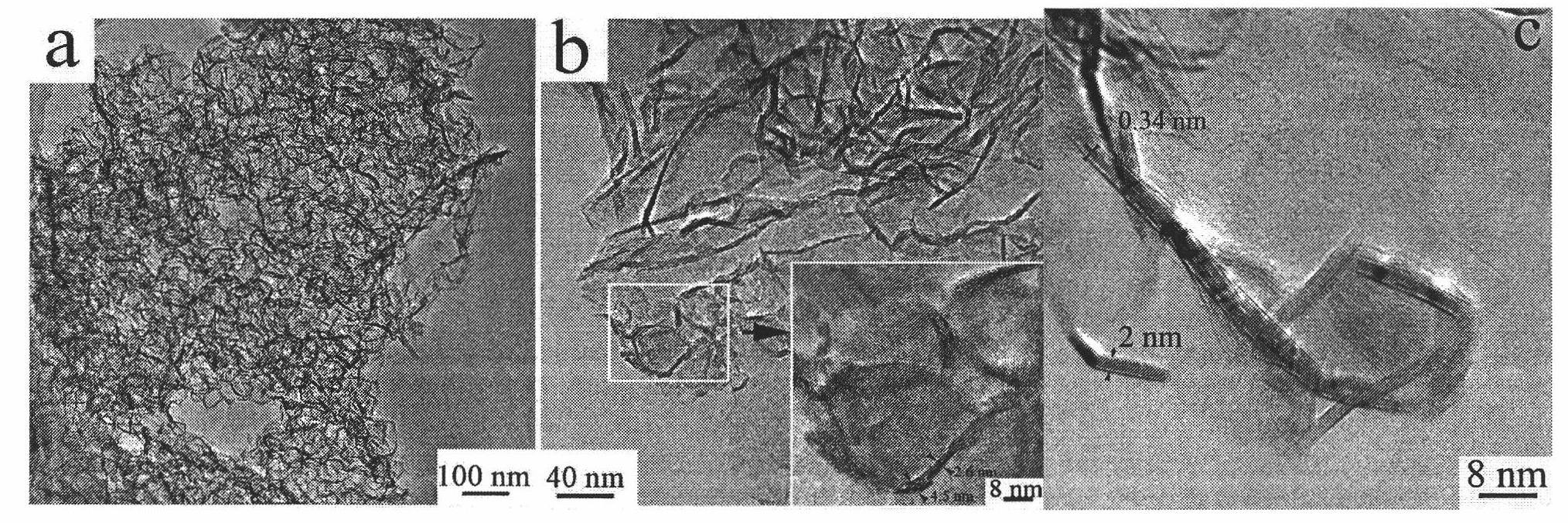

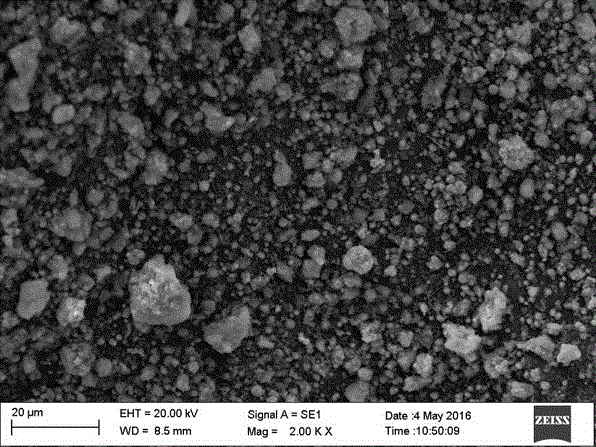

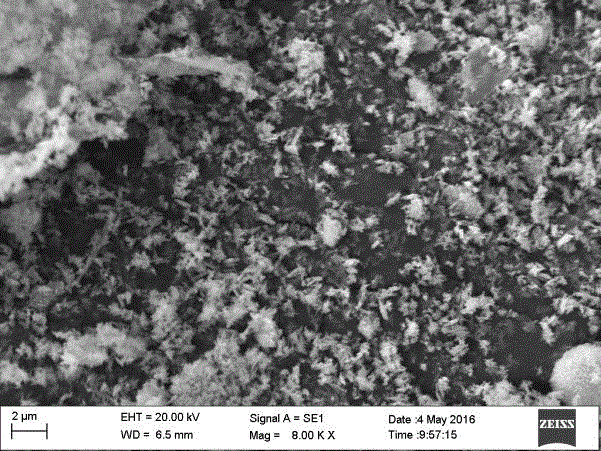

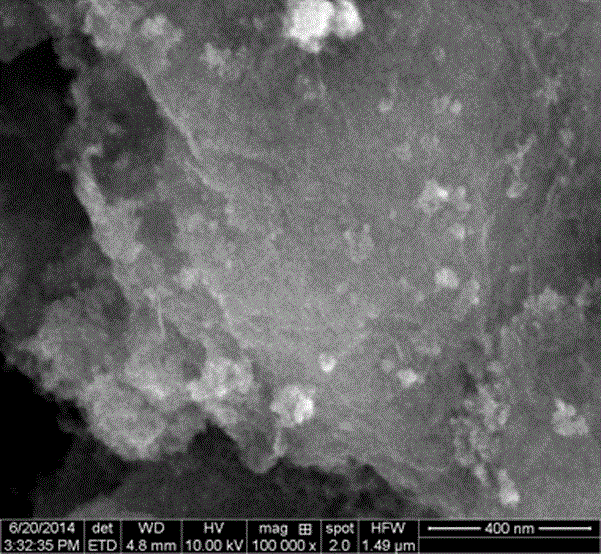

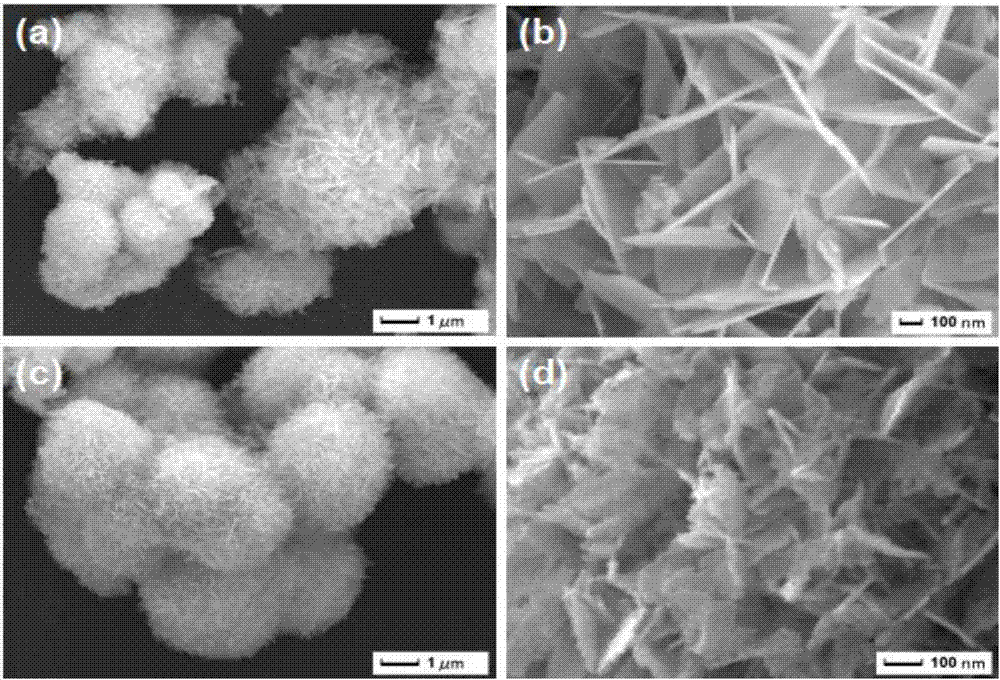

Preparation method of ultrathin boron nitride nanosheet with high specific surface area

InactiveCN101913576ALarge specific surface areaDoes not affect shapeNitrogen compoundsHydrazine compoundBoron nitride

The invention relates to a preparation method of an ultrathin boron nitride nanosheet with high specific surface area. Boron oxide, zinc oxide, iron oxide or nickel oxide reacts with hydrazine hydrochloride, ammonium chloride or ammonium bromide at a temperate temperature to prepare the boron nitride ultrathin nanometer slice with the thickness is 2-6 nm in a high temperature agitated reactor. Because of high heat stability, high specific surface area (226 m<2> / g) and larger pore volume (0.405 cm<3> / g), the ultrathin boron nitride nanosheet can be used for preparing a catalytic agent carrier and the like.

Owner:SHANDONG UNIV

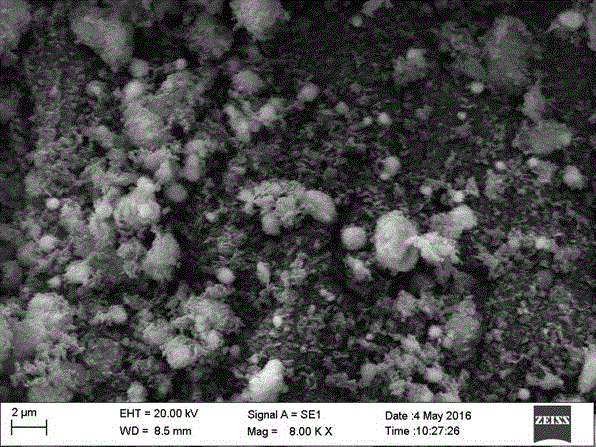

CuO-NiO/rGO composite material with efficient electro-catalysis oxygen reduction performance

The invention relates to a CuO-NiO / rGO composite material with efficient electro-catalysis oxygen reduction performance, and belonging to the technical field of electro-catalysis materials. In the CuO-NiO / rGO composite material provided by the invention, CuO-NiO nanoparticles are attached to a reduction-oxidized graphene sheet layer, a mass ratio of the CuO-NiO nanoparticles to the rGO is 100:3-5, the sizes of the CuO-NiO nanoparticles are 6-10nm, and the reduction-oxidized graphene sheet layer is a single sheet layer; and the electro-catalysis oxygen reduction performance is provided. Compared with existing oxygen reduction reaction catalysts, the CuO-NiO / rGO composite material provided by the invention is significantly reduced in cost, and is the oxygen reduction reaction catalyst with low price and excellent electro-catalysis oxygen reduction performance. The CuO-NiO / rGO composite material provided by the invention adopts copper salts, nickel salts, hydroxides and oxidized graphene as materials, deionized water and absolute ethyl alcohol as solvents, and glycol as a dispersing agent and a reducing agent, and is synthesized by using a one-pot hydrothermal method. The CuO-NiO / rGO composite material provided by the invention is low in material price, prone to get materials, simple and easy in preparation operation, simple in aftertreatment process, prone to control reaction parameters, short in flow and low in energy consumption.

Owner:UNIV OF JINAN

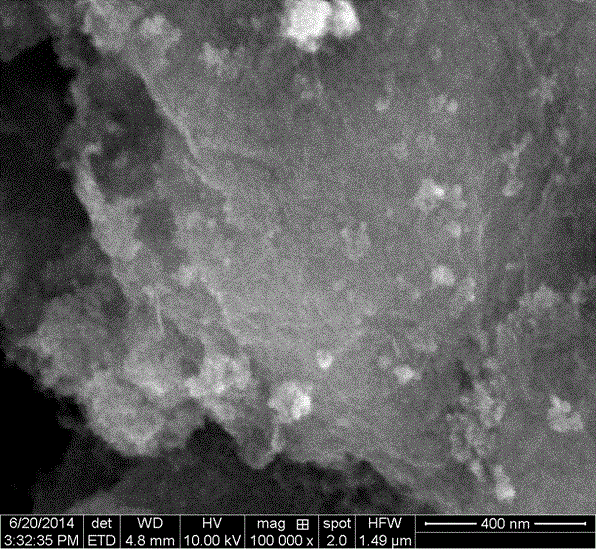

CuO/rGO composite material having efficient electrocatalysis oxygen reducing performance

InactiveCN106654304ALow priceEfficient electrocatalytic oxygen reduction performanceMaterial nanotechnologyCell electrodesSolventOxygen

The invention relates to a CuO / rGO composite material having efficient electrocatalysis oxygen reducing performance and belongs to the technical field of electrocatalysis materials. Nano CuO particles are attached onto a reduced-oxidized graphene sheet layer, a mass ratio of nano CuO and rGO is 100:3-5, size of the nano CuO particles is 6-10nm, the reduced-oxidized graphene sheet layer is a single sheet layer, and the CuO / rGO composite material has electrocatalysis oxygen reducing performance. Compared with existing oxygen reducing reaction catalysts, the CuO / rGO composite material has the advantage that cost is lowered obviously; the CuO / rGO composite material is an oxygen reducing reaction catalyst low in cost and excellent in electrocatalysis oxygen reducing performance. The CuO / rGO composite material is synthesized by taking copper salt, hydroxide and graphene oxide as raw materials, deionized water and anhydrous alcohol as solvents and ethylene glycol as a dispersant and reductant and adopting a hydrothermal one-pot process. The raw materials are low in cost and easy to obtain, preparation operation is simple and easy to implement, aftertreatment process is simple, reaction parameters are easy to control, process is short, and energy consumption is low.

Owner:UNIV OF JINAN

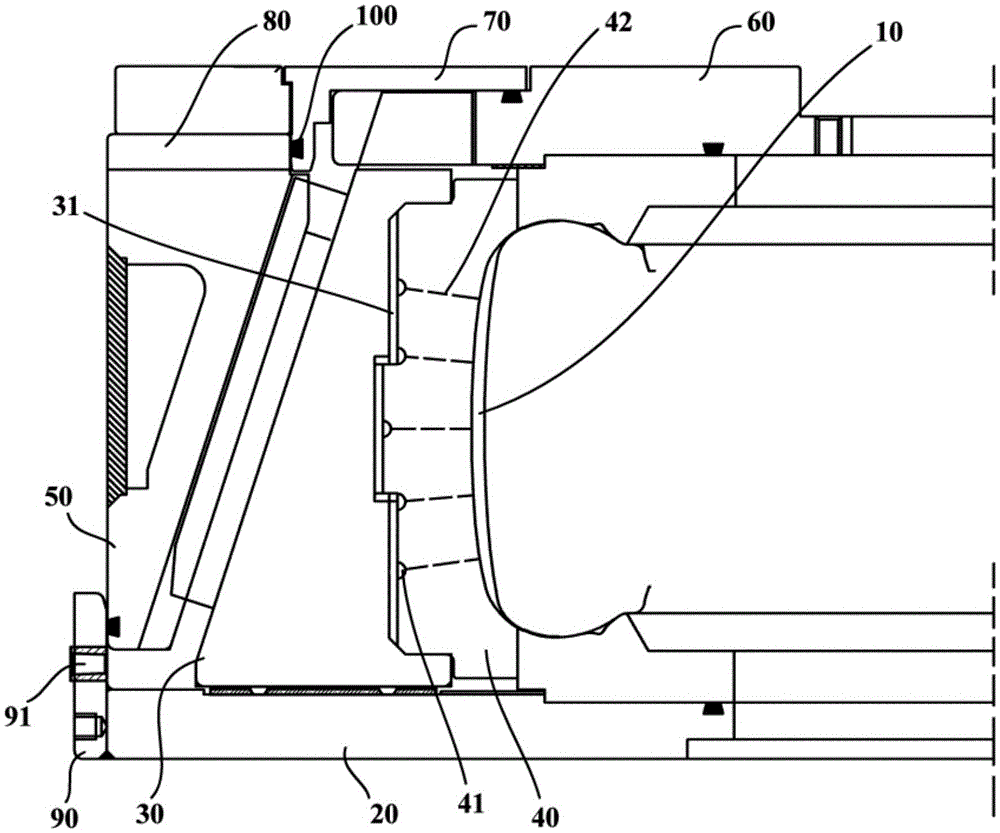

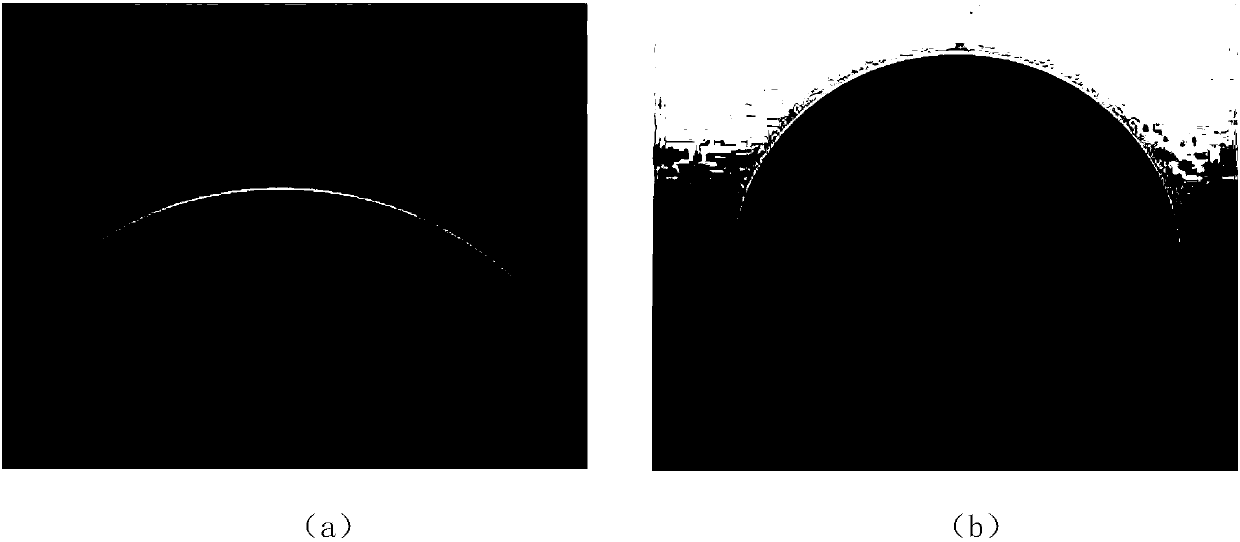

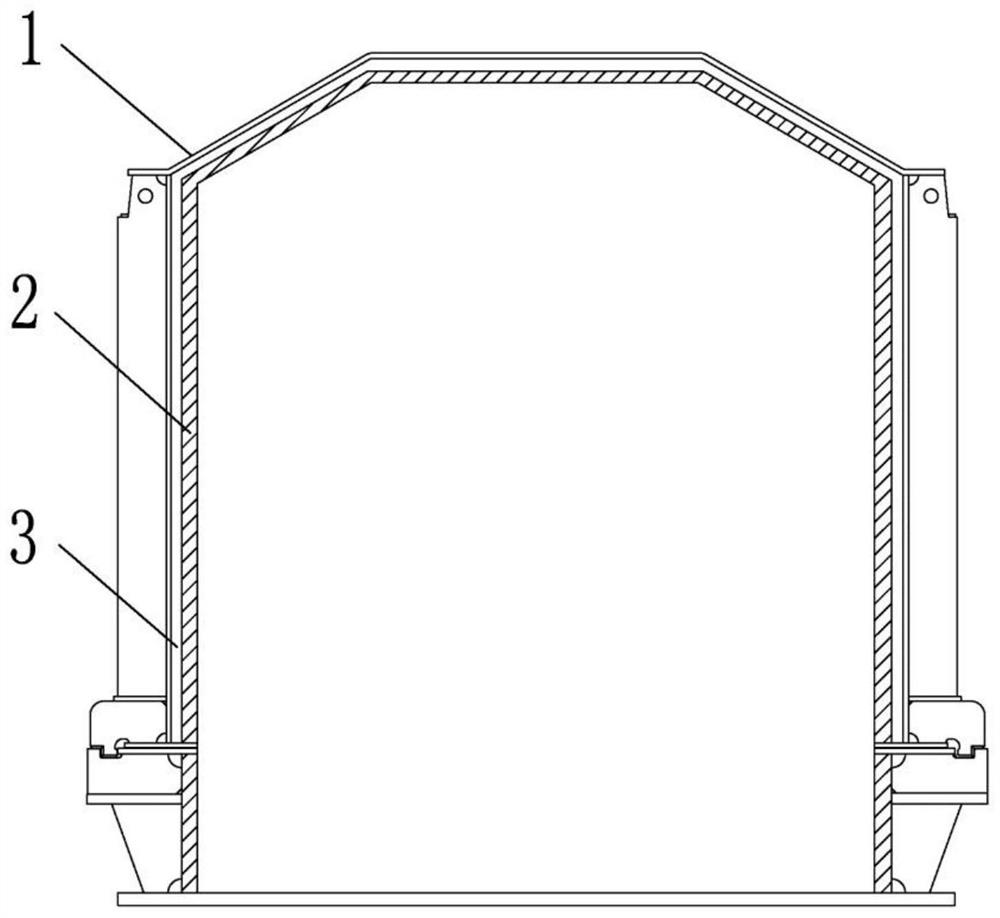

Vacuum auxiliary exhausting type segmental mold

The invention provides a vacuum auxiliary exhausting type segmental mold. The vacuum auxiliary exhausting type segmental mold comprises a bow-shaped seat and a pattern block. Multiple annular exhausting lines located at the various multiple heights and arranged coaxial with a molding cavity of the vacuum auxiliary exhausting type segmental mold and one or more flow collection exhausting lines arranged perpendicular to the annular exhausting lines are limited between the inner side face of the bow-shaped seat and the outer side face of the pattern block, wherein each flow collection exhausting line is communicated with the annular exhausting lines. The pattern block is provided with multiple air flow channel layers located at the various heights. One or more air flow channels are arranged in each air flow channel layer. The outer end of each air flow channel in each air flow channel layer is communicated with the annular exhausting line at the corresponding height and the inner end of each air flow channel in each air flow channel layer is communicated with the molding cavity. In the vulcanizing process, gas in the molding cavity, especially gas in dead corners of the mold can be exhausted smoothly. A vacuum pump is used, so that the pressure in the molding cavity is close to the vacuum degree, the shape of the molding cavity is not affected, and a formed tire can has have the advantages of being small in tire burr number and clear and attractive in pattern edge.

Owner:GUANGXI LINGLONG TIRE CO LTD

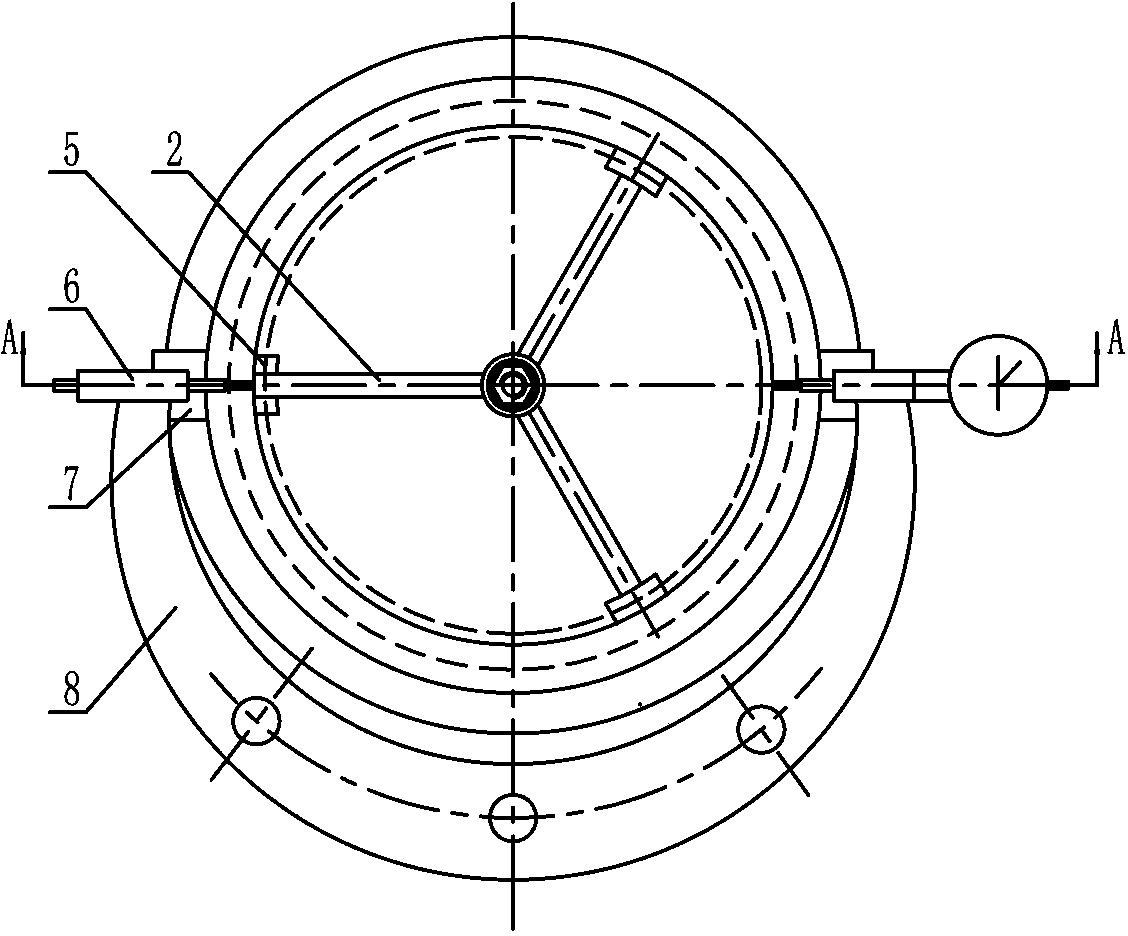

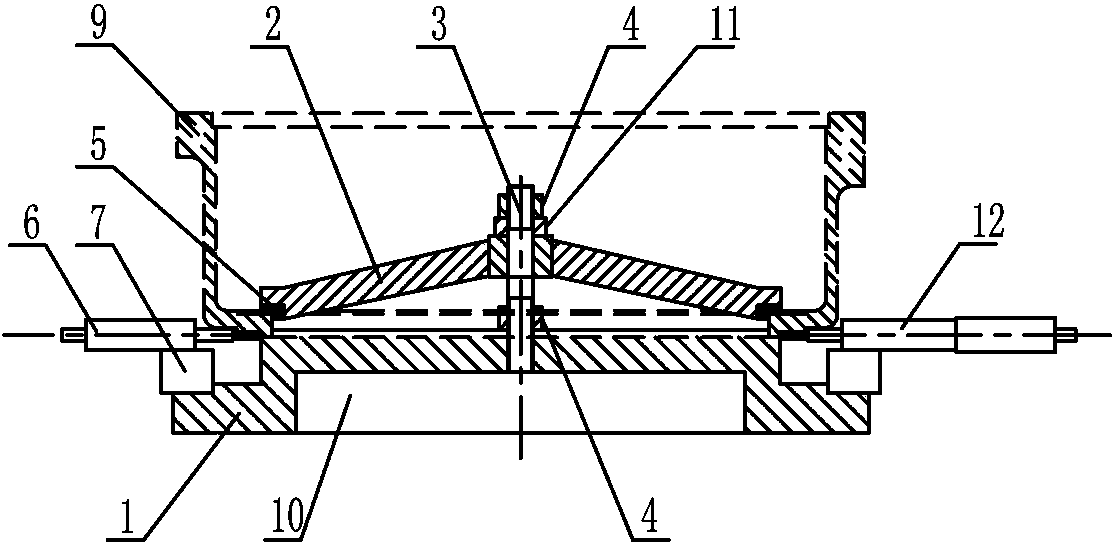

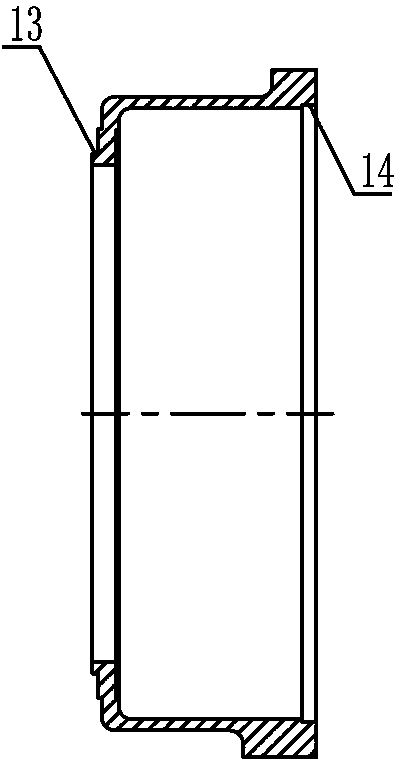

Fixture for machining connecting sleeve

InactiveCN103737397ASimple structureEasy clampingMeasurement/indication equipmentsPositioning apparatusElastic compressionCompression device

The invention discloses a fixture for machining a connecting sleeve. The fixture mainly comprises a base, an elastic claw, a compression device and a detection device. The outer end face of a small end of the connecting sleeve is abutted to the upper surface of the base, the elastic claw is pressed on the inner end face of the small end of the connecting sleeve, three 120-degree uniformly distributed pressing plates are connected to form the elastic claw, the middle of the elastic claw is arched upwards and connected with the base through the compression device, and the detection device is used for detecting the size of the connecting sleeve after machining. The fixture is simple in structure and convenient in clamping, by a three-point elastic compression method, clamping is reliable, part shapes are not affected, two ends of each part can be machined once without midway secondary clamping, machining quality is ensured, production efficiency is greatly improved, and a large number of working hours are saved for batch production of the parts.

Owner:柳江县龙满机械部件有限责任公司

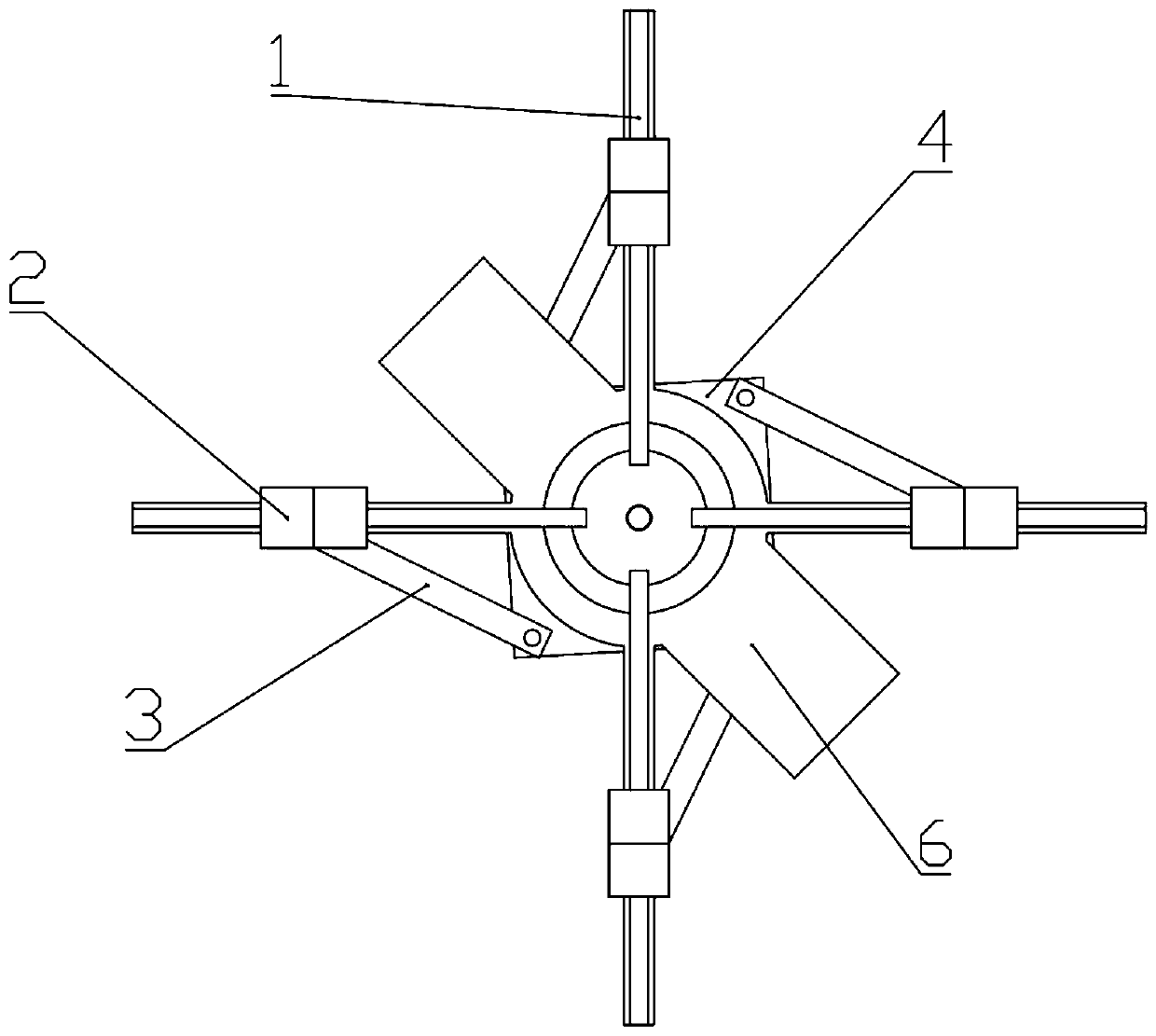

Centripetal closing type clamp mechanical gripper

The invention discloses a centripetal closing type clamp mechanical gripper. The centripetal closing type clamp mechanical gripper can achieve automatic gripping through autonomous control or parameter setting. The centripetal closing type clamp mechanical gripper comprises fixing machine frame guide rails. The lower ends of the fixing machine frame guide rails are coaxially and fixedly connectedwith a steering plate. The steering plate is coaxially and fixedly connected with a steering gear output shaft. The steering gear is connected with the fixing machine frame guide rails. The four corners of the steering plate are each hinged to one end of a connection rod. The other ends of the connection rods are hinged to four gripping jaws. The gripping jaws are connected to the guide rails. Thefour gripping jaws are arranged in four directions of the steering gear output shaft at equal intervals. The centripetal closing type clamp mechanical gripper is simple in structure, simple in control method and high in transportability. By controlling the flare angle, a spherical object can be stably gripped, and the shape of the object is not changed. During design of the centripetal closing type clamp mechanical gripper, the part wear problem is taken into full consideration, and parts are convenient to replace.

Owner:NANJING UNIV OF SCI & TECH

Heating device for pipeline

InactiveCN103453272AHigh strengthImprove heating efficiencyPipe heating/coolingHeating element shapesFastenerHeating efficiency

The invention relates to a heating device for a pipeline, which comprises an outer casing, wherein heating layers, insulating layers and heat preservation layers are arranged inside the outer casing in sequence; the outer casing adopts a split type structure, and is encircled by two semi-circular outer casings connected into a whole through a fastener; circular arc bulges are arranged on the periphery of each semi-circular outer casing; hinge connecting devices are arranged at the two ends of each bulge; the two upper and lower semi-circular outer casings are connected through a hinge. Therefore, the heating device is more fitted with the pipeline, and the heating efficiency is higher.

Owner:扬中市金元化工电力设备厂

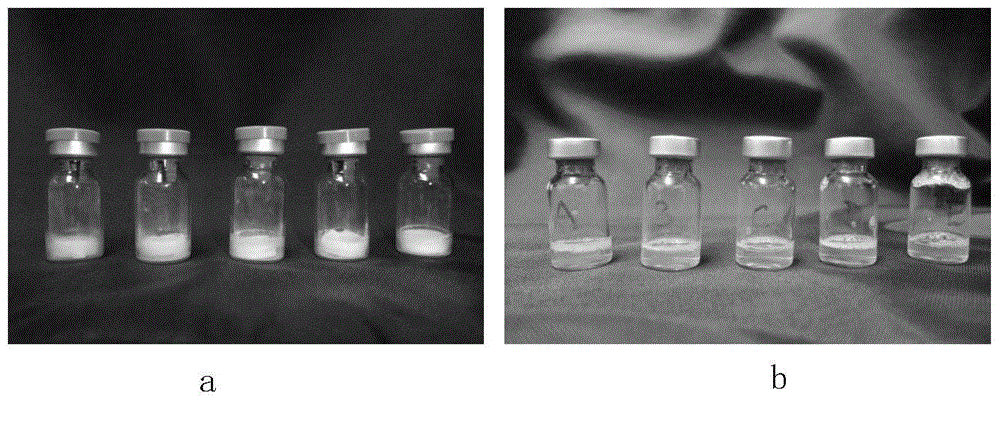

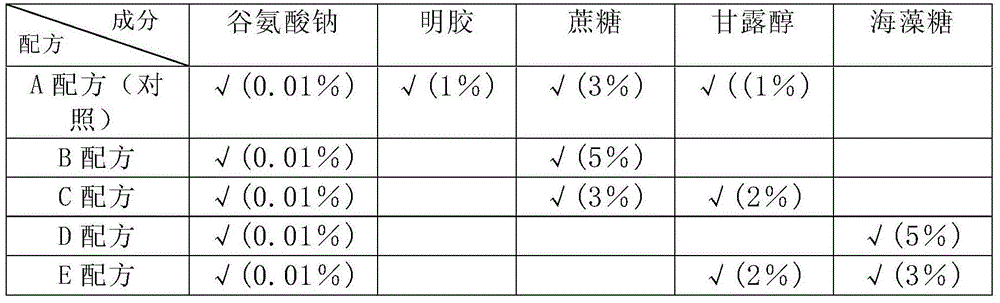

A gelatin-free varicella vaccine freeze-dried preparation and a preparing method thereof

InactiveCN105582534ADoes not affect shapeReduce adverse effectsPowder deliveryAntiviralsMonosodium glutamateSucrose

A varicella vaccine freeze-dried preparation is provided and comprises a varicella vaccine stock solution and a vaccine stabilizer. Based on the original concentration of the vaccine stock solution, the vaccine stabilizer comprises 3-10% of cane sugar and 0.01-1% of monosodium glutamate, with the balance being a buffer liquid optionally. The freeze-dried preparation is free of gelatin, dextran and / or animal-based protein. Vaccines in forms of stock solutions or freeze-dried finished products, which are prepared from the stabilizer free of the gelatin or the animal-based protein, have stability equivalent to stability of prescriptions in the prior art, and have better safety. The stabilizer is hoped to replace stabilizers containing gelatin and animal-based protein in the prior art.

Owner:SHANGHAI INST OF BIOLOGICAL PROD CO LTD

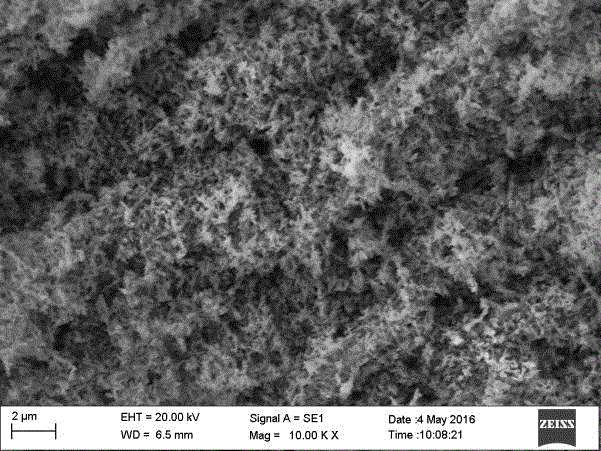

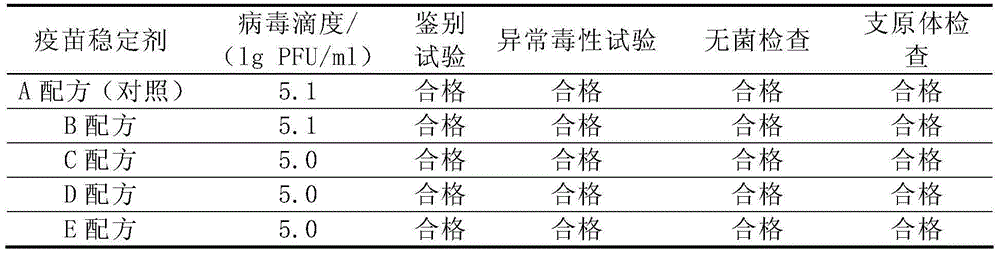

Batch-preparation and quick-separation method of iron-based coal-liquefaction nano catalyst

InactiveCN102909021AEasy to separateDoes not affect shapeLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsNano catalystPtru catalyst

The invention provides a batch-preparation and quick-separation method of an iron-based coal-liquefaction nano catalyst. The batch-preparation and quick-separation method includes utilizing 0.01-0.1mol L-1 of FeCl3 solution as a raw material, hydrolyzing the FeCl3 solution within the temperature ranging from 70 DEG C to 80 DEG C for 6-12 hours to obtain nano FeOOH colloidal solution; utilizing fulvic acid iron and sodium humate and the like as flocculant, simply separating nano particles by the aid of the flocculant and accordingly realizing batch preparation of the nano FeOOH. The batch-preparation and quick-separation method is low in cost, simple to operate, pollution-free and capable of preparing in batch. The catalyst prepared is small in particle diameter which is within nano range and uniform in particle diameter distribution, direct liquefaction activity of coal catalyzing is high, conversion rate ranging from 83-95% and oil yield rate ranging from 70-82 can be realized by direct liquefaction of Xinjiang Yili coal catalyzing, and conversion rate ranging from 85-97% and oil yield rate ranging from 65-85% can be realized by direct liquefaction of catalyzing of coal of General Temple of Xinjiang.

Owner:XINJIANG UNIVERSITY

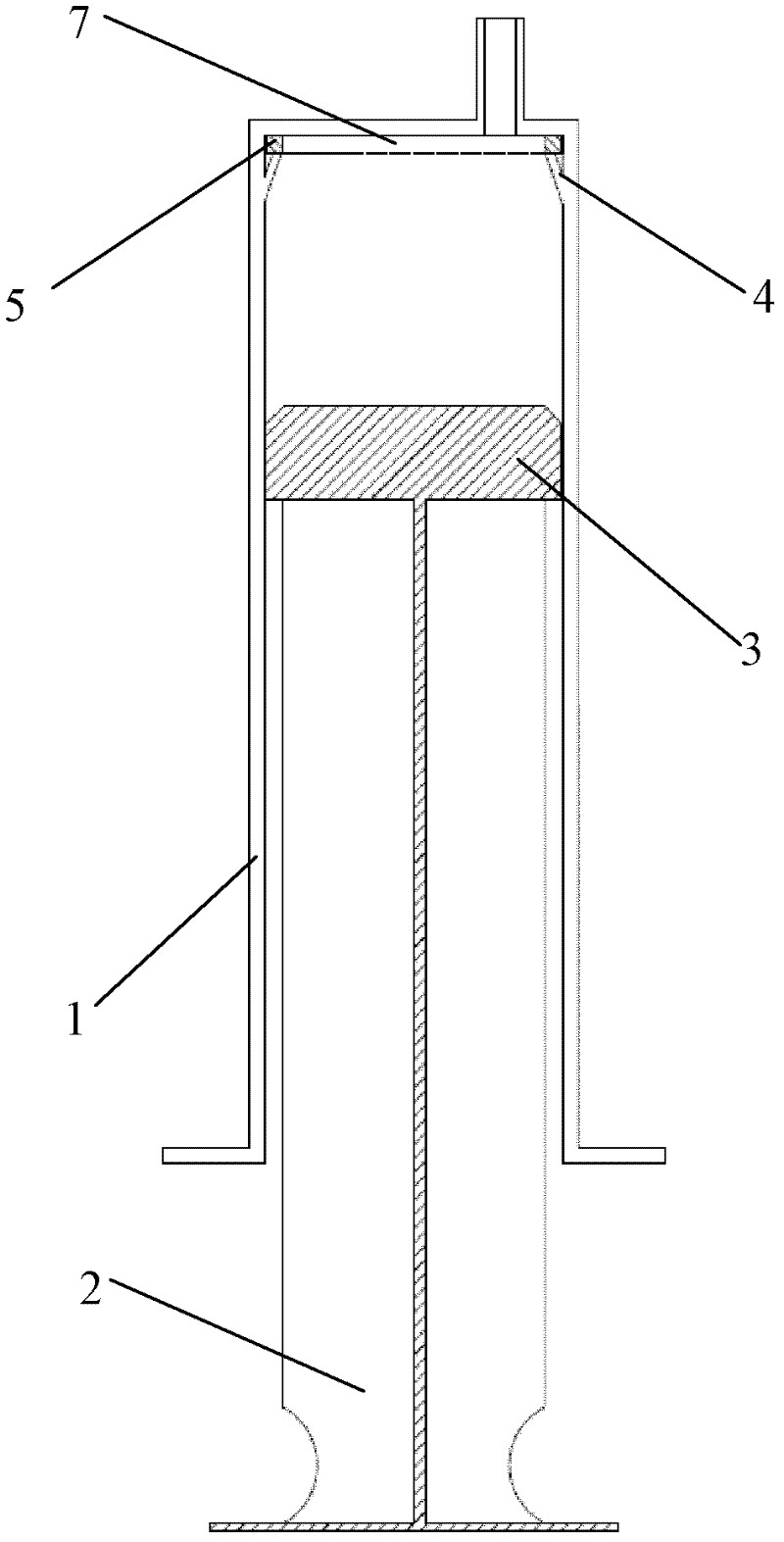

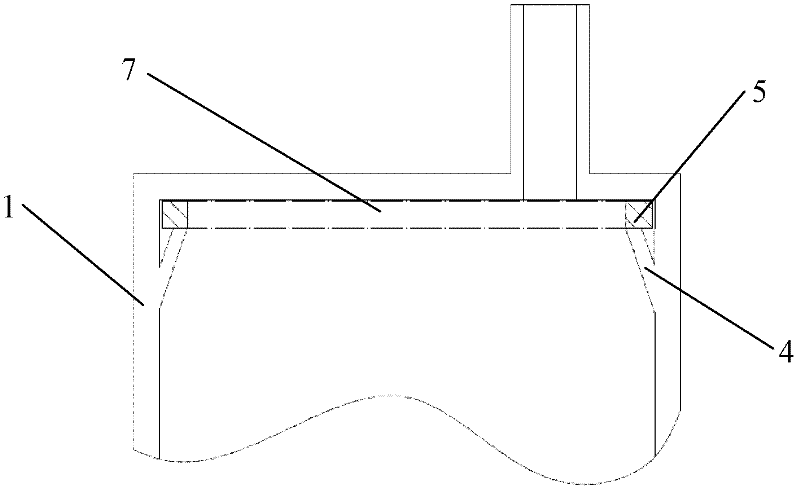

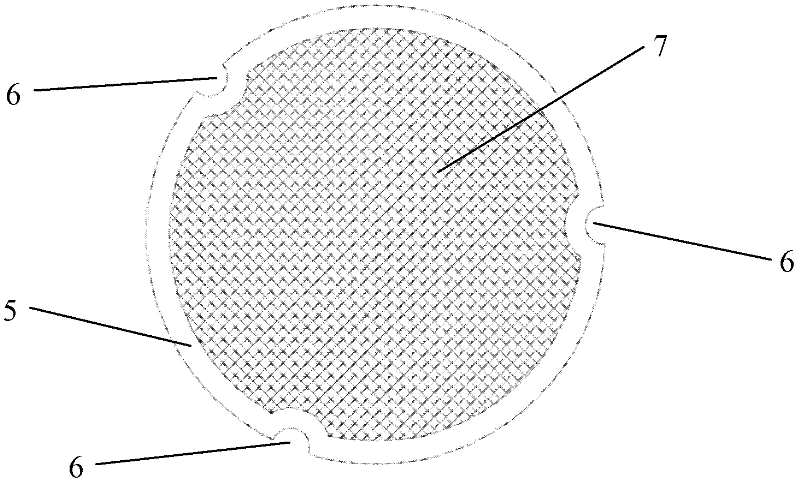

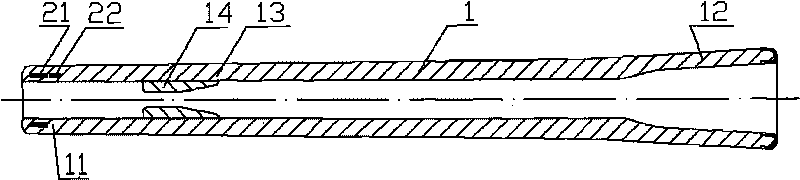

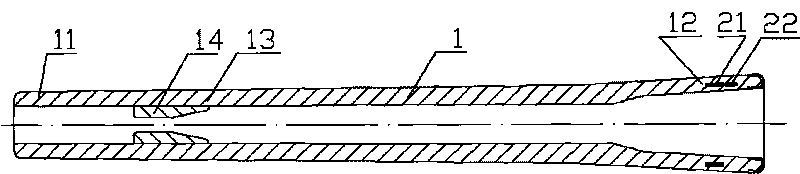

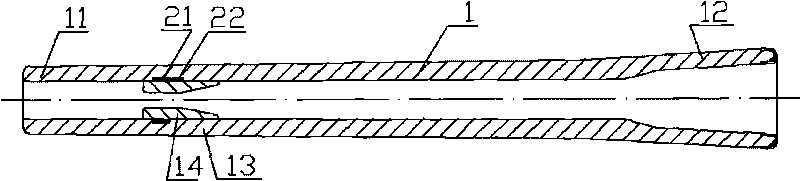

Filter type syringe

InactiveCN102406971AHarm Reduction and EliminationDoes not affect shapeInfusion syringesMedical devicesFiltrationPositive pressure

The invention discloses a filter type syringe which relates to the field of medical syringes. The filter type syringe comprises a needle cylinder, a push rod, a piston, a filter membrane device and elastic pawls, wherein the top end in the needle cylinder is provided with the filter membrane device; the inner wall of the needle cylinder is provided with a plurality of elastic pawls for ejecting the rear edge of the filter membrane device which can move along the axial direction of the needle cylinder. In the injecting process, the piston is drawn to generate negative pressure so that the filter membrane device draws back, and liquid enters the needle cylinder from a flow guide opening. The piston stops being drawn, and the filter membrane device is returned in situ under the elastic pawls. The piston is pushed to generate positive pressure, and the liquid is exhausted by a filter membrane, thereby insoluble particles in injecting liquid are removed through filtration and the damage of the insoluble particles to human bodies is eliminated and removed.

Owner:雷红力

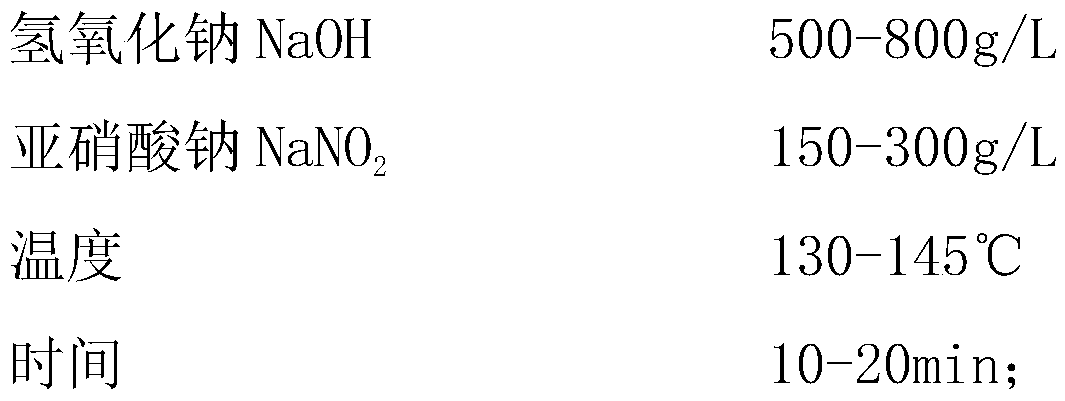

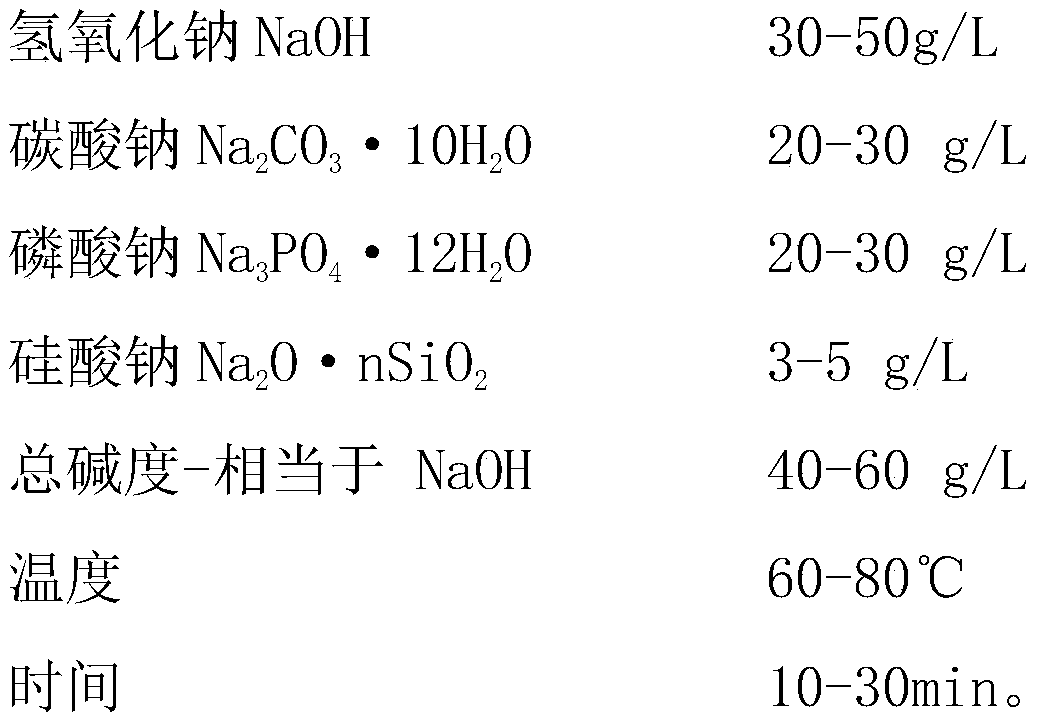

Chemical passivation process method for copper and copper alloy thin-walled part

InactiveCN110592573AImprove chemical passivation effectDoes not affect shapeMetallic material coating processesWater basedOrganic solvent

The invention discloses a chemical passivation process method for copper and a copper alloy thin-walled part. The method comprises the following steps of (1) acceptance check; (2) oil removing of an organic solvent or oil removing of a water-based washing agent; (3) installing and hanging; (4) oil removing; (5) hot water washing; (6) flow cold water washing; (7) water film continuity check; (8) alkaline washing; (9) flow cold water washing; (10) light corrosion; (11) flow cold water washing; (12) weak corrosion; (13) flow cold water washing; (14) chemical passivation; (15) flow cold water washing; (16) hot water washing; (17) drying; and (18) inspecting. The chemical passivation process method has the beneficial effects of being suitable for the chemical passivation process method for thecopper and the copper alloy thin-walled part which exist black oxide skins on the surfaces after heat treatment softening treatment, obviously improving the chemical passivation effect of the copper and the copper alloy thin-walled part, and being suitable for the chemical passivation treatment of other copper and copper alloy parts.

Owner:GUIZHOU HONGLIN MACHINERY

Spool

InactiveCN101734521ASimple structureFirm packagingRecord carriers used with machinesLow speedRadio frequency signal

The invention discloses a spool which comprises a radio frequency transponder which is mainly composed of a minitype antenna coil and a radio frequency signal receiver chip, wherein the minitype antenna coil and the radio frequency signal receiver chip are matched. The spool is characterized in that the radio frequency transponder is integrated in the body of the spool or on the top surface, and the axis of the minitype antenna coil is coincident or parallel to the axis of the spool. The integrated radio frequency transponder can normally work when the spool is in static state, moves or rotates at low speed as well as at high speed.

Owner:TIANJIN POLYTECHNIC UNIV

Hydrophobic treatment method for material surface

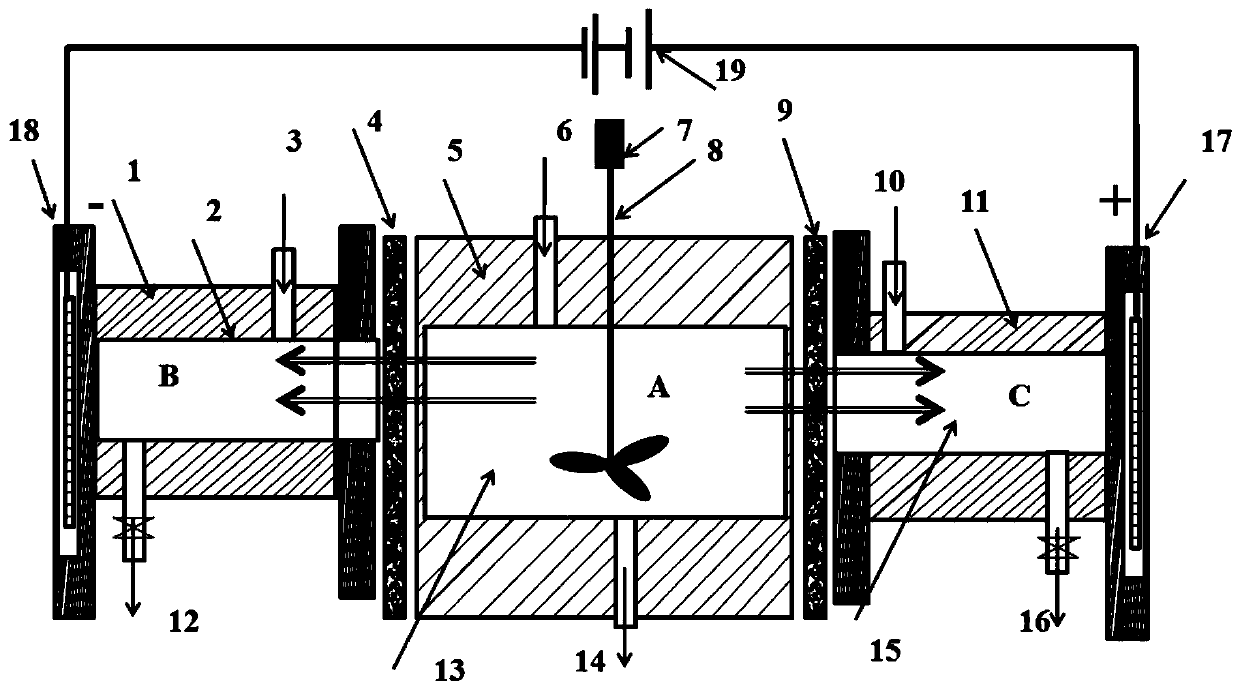

InactiveCN107723706AThickness is easy to controlDoes not affect shapeAntifouling/underwater paintsPaper coatingAlloyNanoscopic scale

The invention discloses a hydrophobic treatment method for a material surface, and relates to the technical field of surface conformal coating. The method is completed in a material microscopic surface conformal coating system and specifically comprises the steps that 1) a to-be-plated material is pretreated; 2) the to-be-plated material subjected to pretreatment is placed on a sample table; 3) acirculating water cooling system is started; 4) a vacuum control system is started; 5) an electric heating alloy wire heating system is started; and 6) an air inlet supply system is started, reactantmonomers subjected to gasification and initiators are separately introduced into a reaction chamber according to a preset flow rate, the reaction time is set, and the material surface is plated with anano-scale hydrophobic film coating through reactants. The method has the effects and the advantages that 1) the film formed by the method is nano-scale, and the thin film coating can be conformal with raw materials, is compact and uniform, and is controllable in thickness; 2) a high-vacuum environment is not needed, and the operation range is wide; 3) the operation is simple and convenient; and4) the hydrophobic modification effect is good.

Owner:DALIAN UNIV OF TECH

Electromagnetic hoisting equipment of minibus total roof skin

ActiveCN103342141AStable and convenient to lift and placeThe process link is simple and convenientVehiclesEngineeringWire rope

The invention relates to electromagnetic hoisting equipment of a minibus total roof skin, which comprises a hanger assembly, four steel wire ropes, four electromagnets and four fixing blocks, wherein the hanger assembly is a rectangular framework; hooks are respectively arranged at the four corners of the hanger assembly; the steel wire ropes are in one-to-one correspondence with the hooks; the first end part of each steel wire rope is connected with the corresponding hook; each electromagnet is connected with the second end part of the corresponding steel wire rope; the fixing steel blocks are arranged on the upper surface of the roof skin; and the fixing steel blocks are in one-to-one correspondence with the electromagnets in position. The electromagnetic hoisting equipment of a minibus total roof skin with the structure can hoist the roof skin assembly by use of the electromagnetic adsorption principle; when the roof skin is hoisted, greater deformation is avoided, and the surface smoothness of the skin is not damaged; and moreover, the equipment realizes stable and convenient hoisting and placing processes, is favorable for assembly, and has a simple structure and a wider application range.

Owner:JIANGXI B ENERGY SHANGRAO COACH

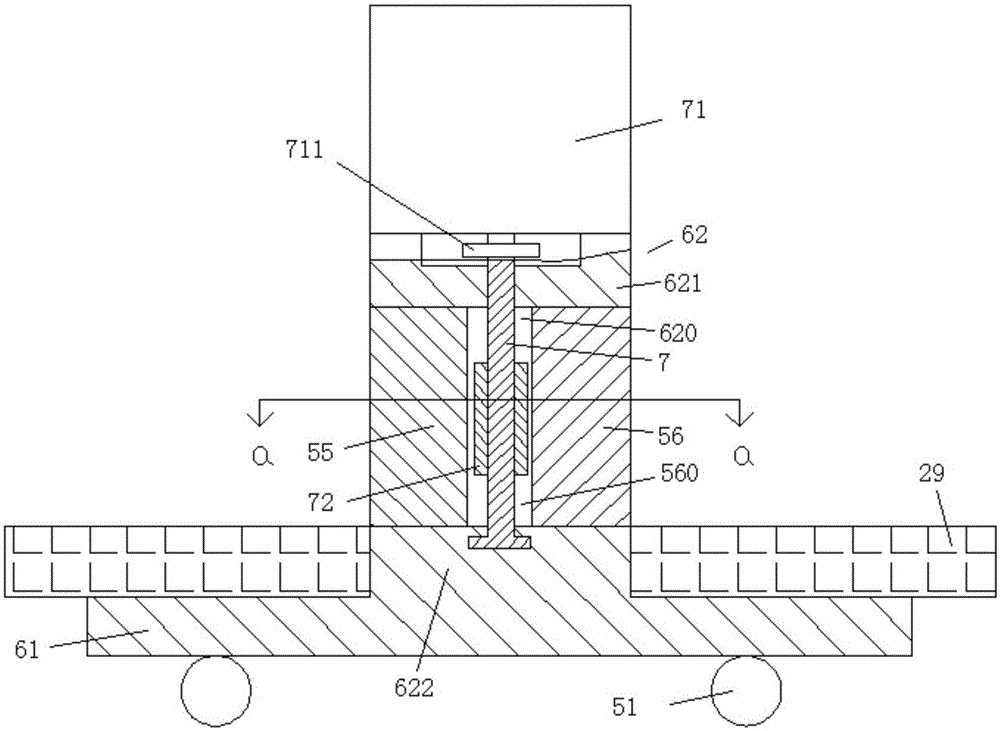

Movable plate fixing device used for welding and adopting solar energy for power supply

InactiveCN105108426AGuaranteed to fallUnified operation is convenientWelding/cutting auxillary devicesAuxillary welding devicesArchitectural engineeringSolar energy

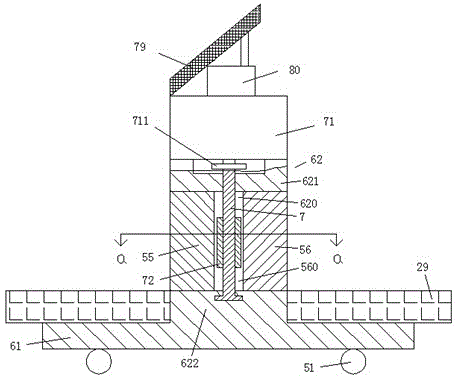

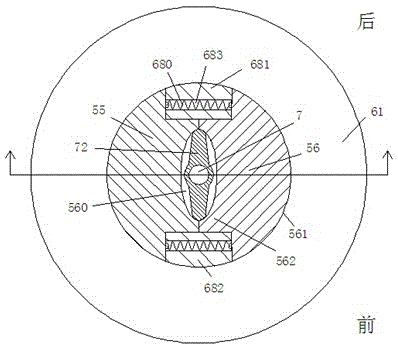

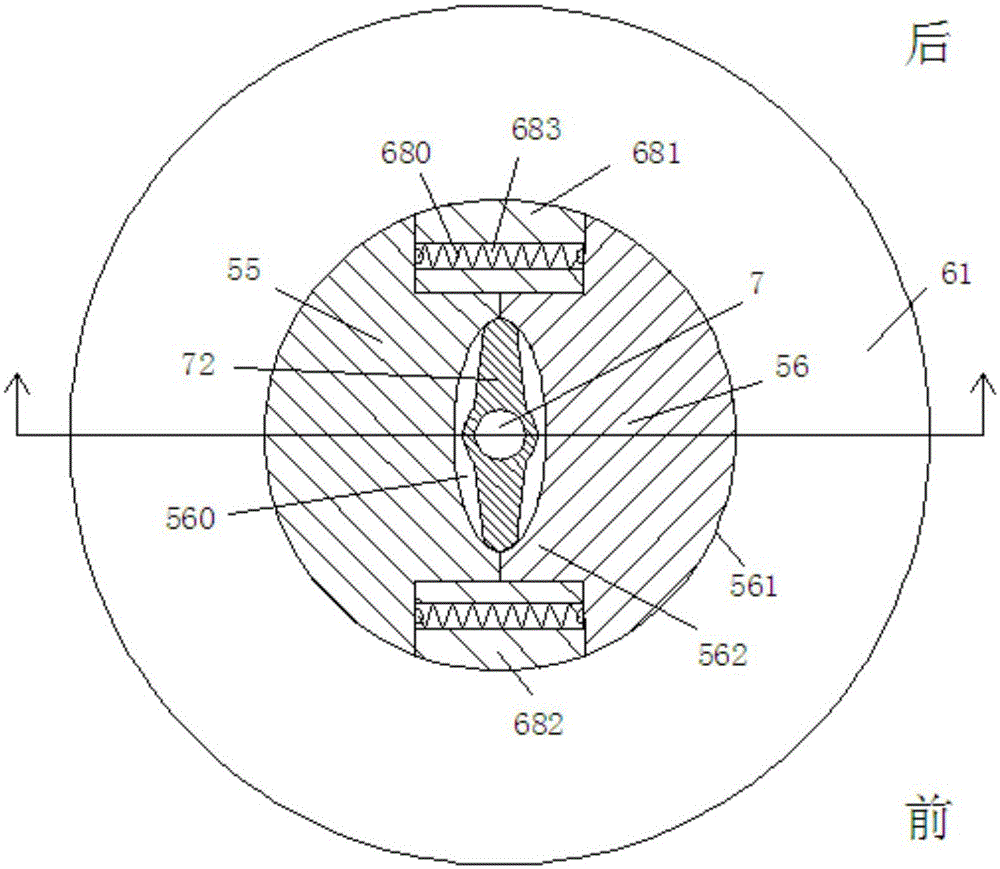

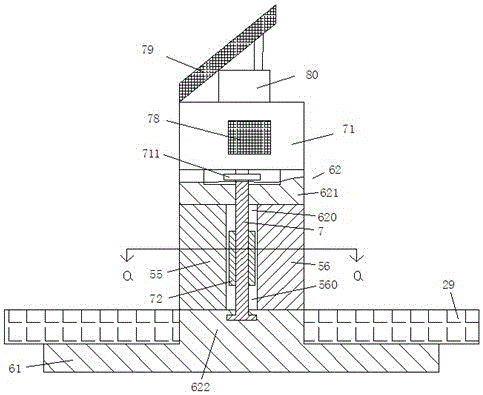

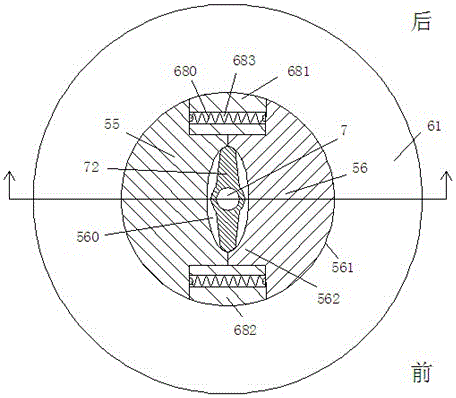

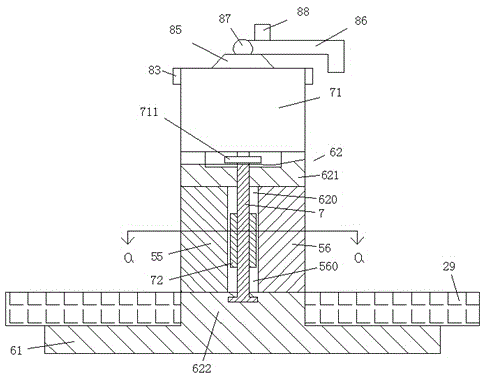

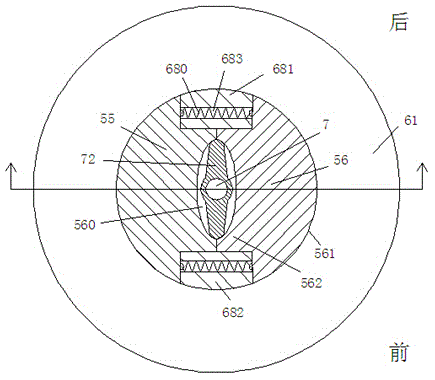

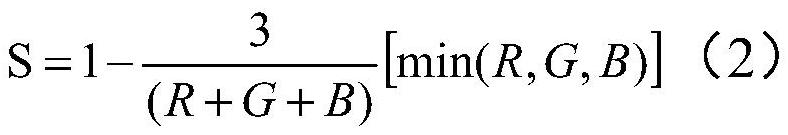

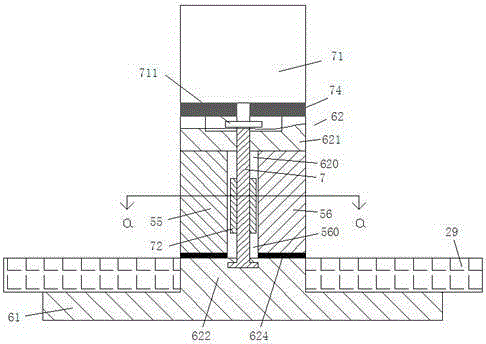

A movable plate fixing device used for welding and adopting solar energy for power supply comprises a bearing base plate (61) for bearing a to-be-welded plate (29) and a fixed cylinder assembly (62) which is fixedly connected with the bearing base plate (61) and extends in the vertical direction, wherein the fixed cylinder assembly (62) comprises two fixed columns (681 and 682), a top wall part (621) fixedly connected with the upper ends of the two fixed columns (681 and 682) and a cylinder root part (622) fixedly connected with the lower ends of the two fixed columns (681 and 682), the two fixed columns (681 and 682) extend in the vertical direction and are opposite in the diameter direction, and two locking sliders (55 and 56) symmetric to a central axis of the fixed cylinder assembly (62) are glidingly arranged in a telescopic channel (620) extending in the horizontal direction between the two fixed columns (681 and 682).

Owner:广州御晟能源科技有限公司

Electrode formation method for solar battery

ActiveCN106952973AGood removal effectDoes not affect shapeFinal product manufacturePhotovoltaic energy generationElectrical batteryConductive materials

The invention provides a method for producing a solar battery. The method comprises the steps that an upper surface of a silicon wafer with T-shaped via holes is pasted on a back of a battery piece, wherein the via holes correspond to positions at which front electrodes and back electrodes of the solar battery are about to be formed; and coating and annealing of a conductive material are carried out on a backlight surface of the battery piece by taking the silicon wafer as a mask, and the silicon wafer is removed to form a first T-shaped electrode.

Owner:JIANGSU FOCUS NEW ENERGY TECH

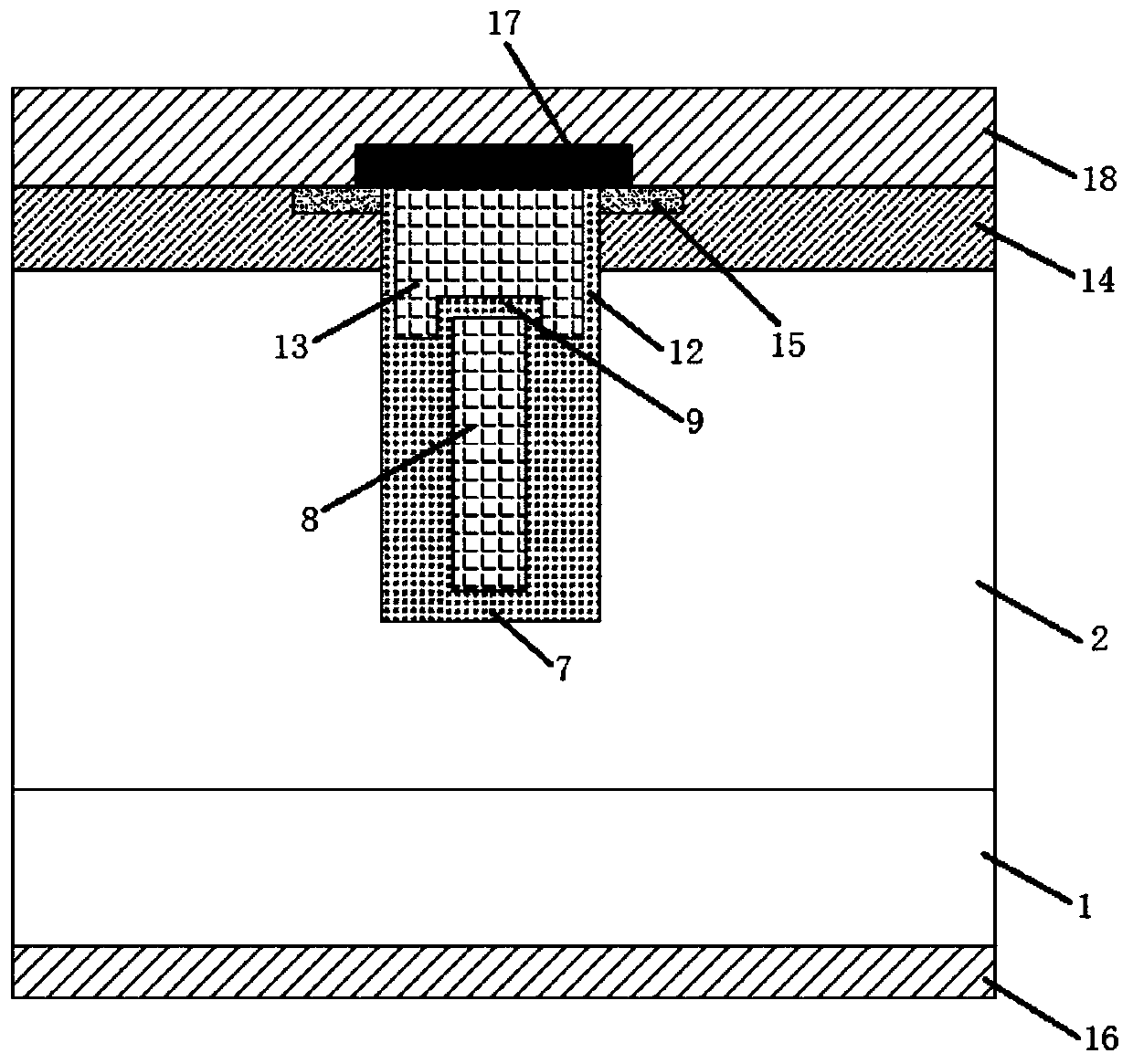

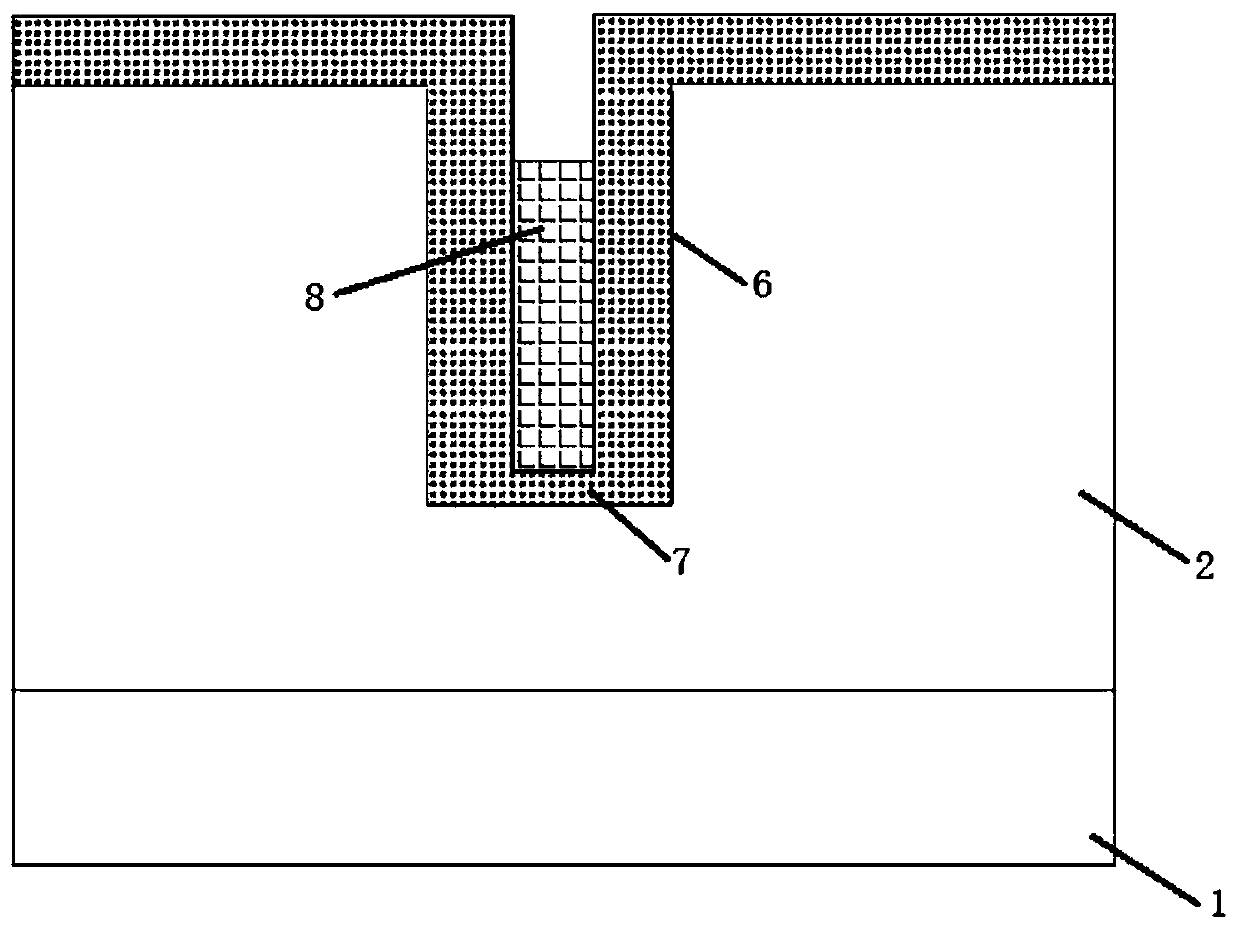

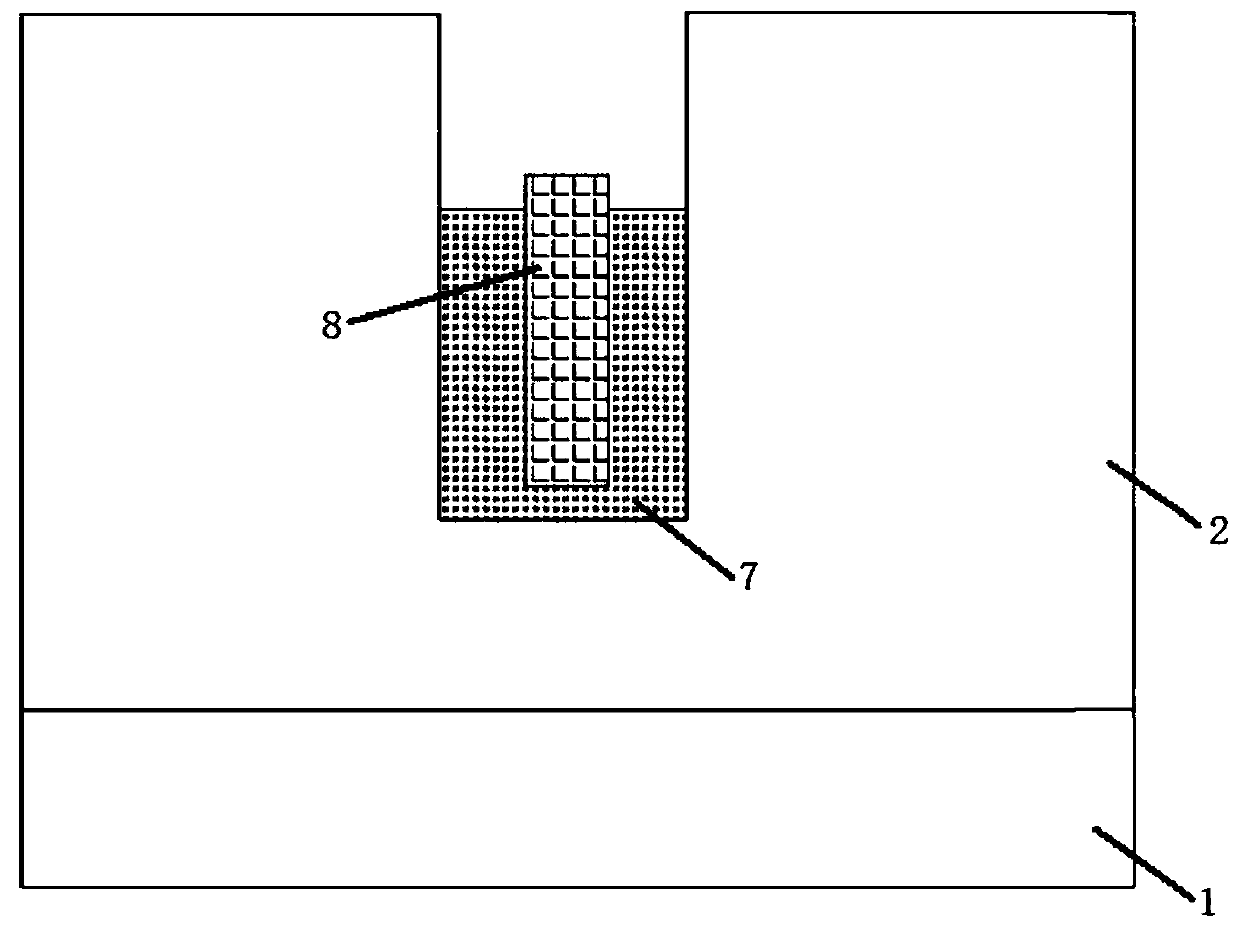

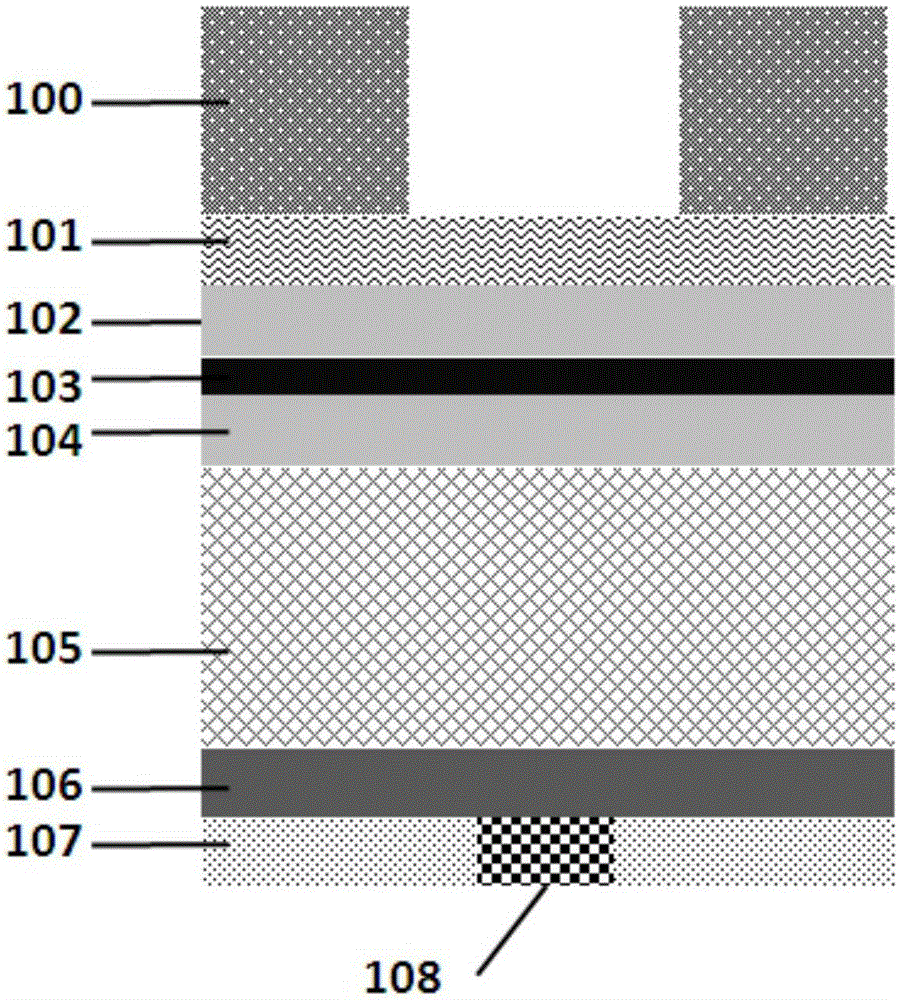

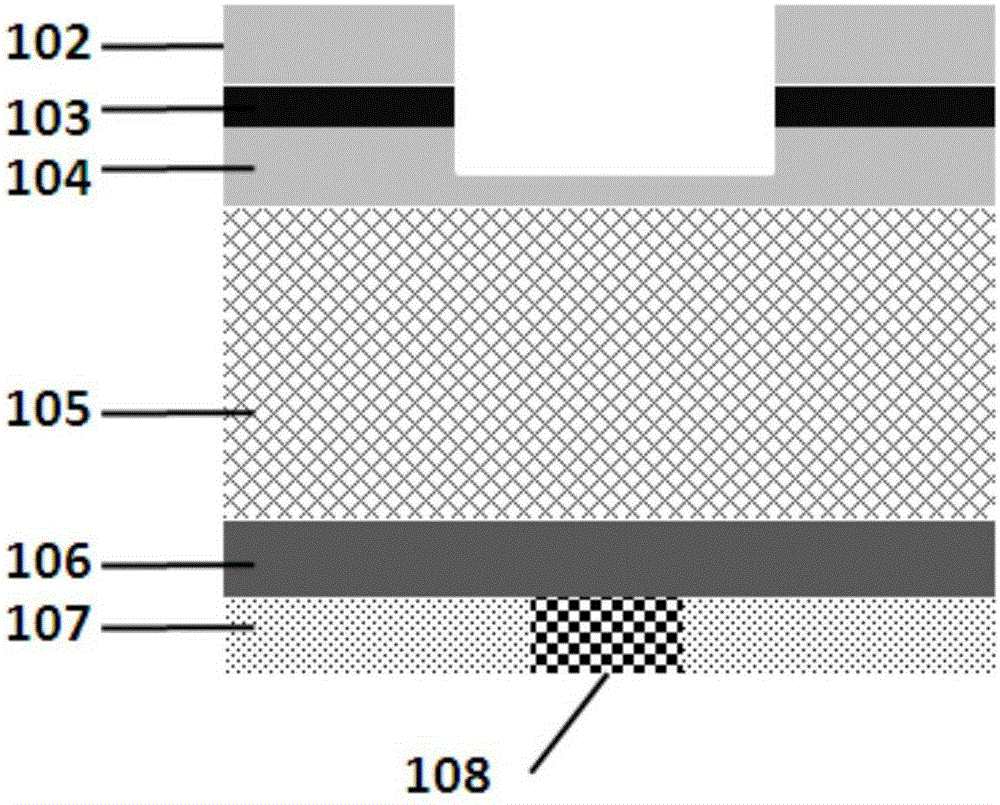

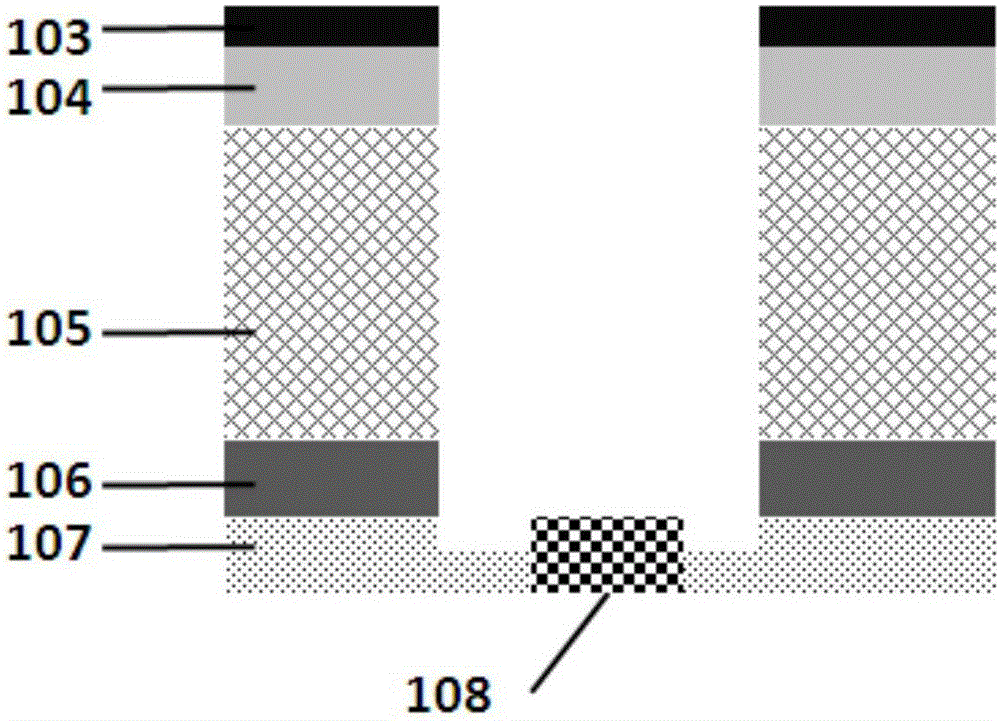

Manufacturing method of split gate MOSFET

ActiveCN111415868APrecise thickness controlEfficient removalSemiconductor/solid-state device manufacturingSemiconductor devicesMOSFETHigh density

The invention discloses a manufacturing method of a split gate MOSFET. The manufacturing method comprises the following steps: 1, forming an epitaxial layer on a substrate; 2, depositing an ONO structure on a first main surface; 3, performing etching to form a groove; 4, removing a second oxide layer; 5, forming a third oxide layer in a trench; 6, forming separation gate polycrystalline silicon inthe trench; 7, removing a third oxide layer on a side wall of the upper part of the trench, so that the top of the separation gate polysilicon is higher than the reserved third oxide layer; 8, forming an inter-polysilicon isolation oxide layer in a high-density plasma chemical vapor deposition mode, forming a side wall oxide layer on the side wall of the trench, and forming a thick oxide layer onthe first nitride layer; 9, removing a side wall oxide layer; 10, removing the first nitride layer so as to peel off the thick oxide layer. According to the method, the inter-polycrystalline siliconisolation oxide layer meeting the process requirements is formed on the separation gate polycrystalline silicon at a time in an HDPCVD mode, and the thickness of the inter-polycrystalline silicon isolation oxide layer can be accurately controlled.

Owner:捷捷微电(上海)科技有限公司

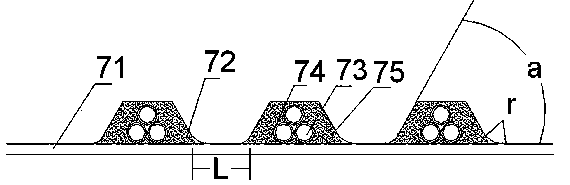

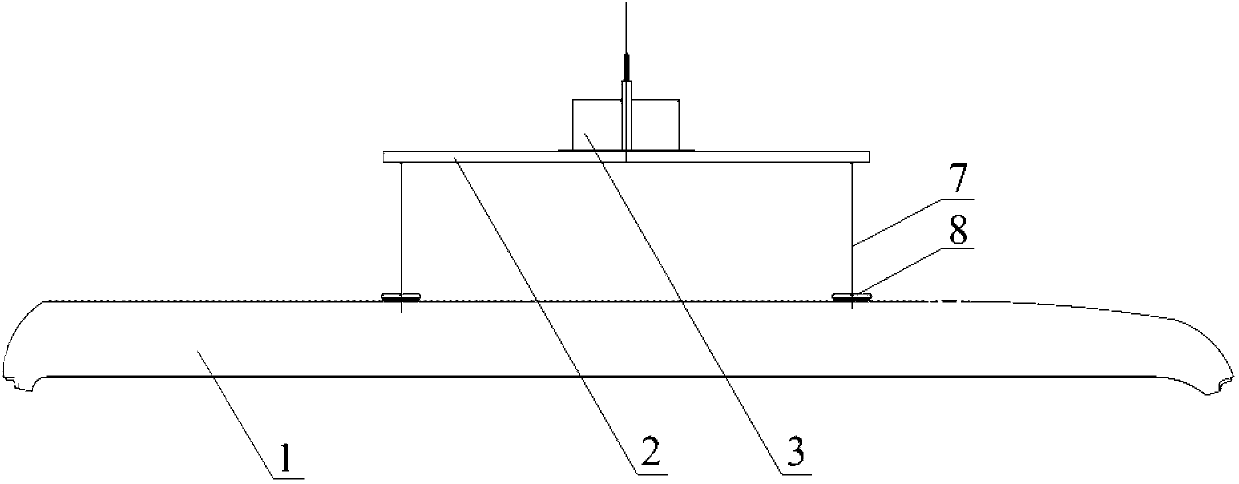

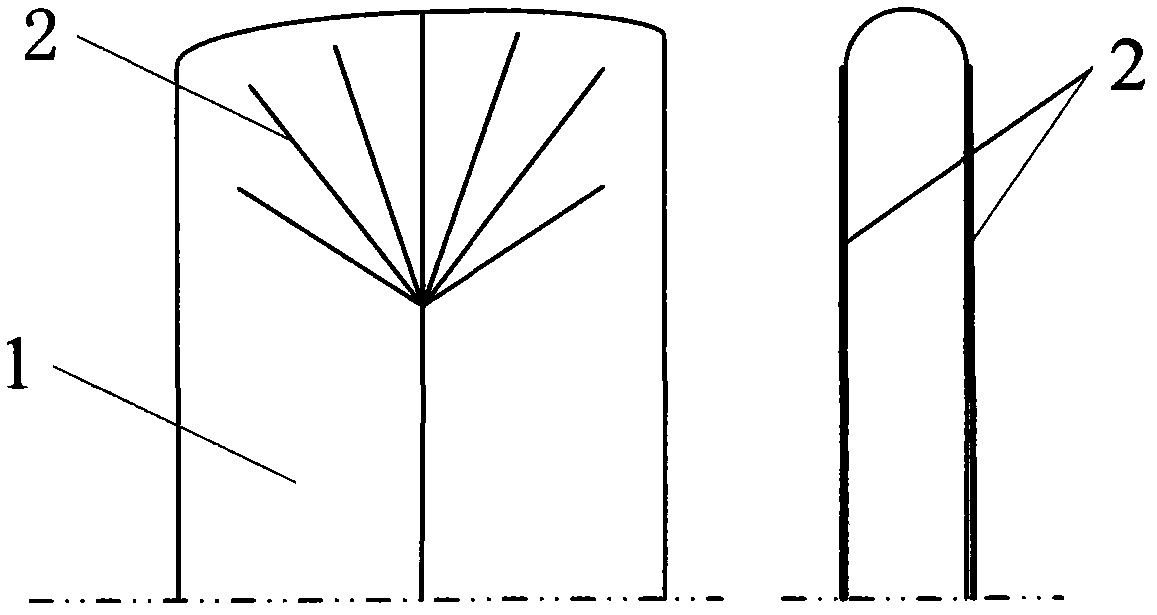

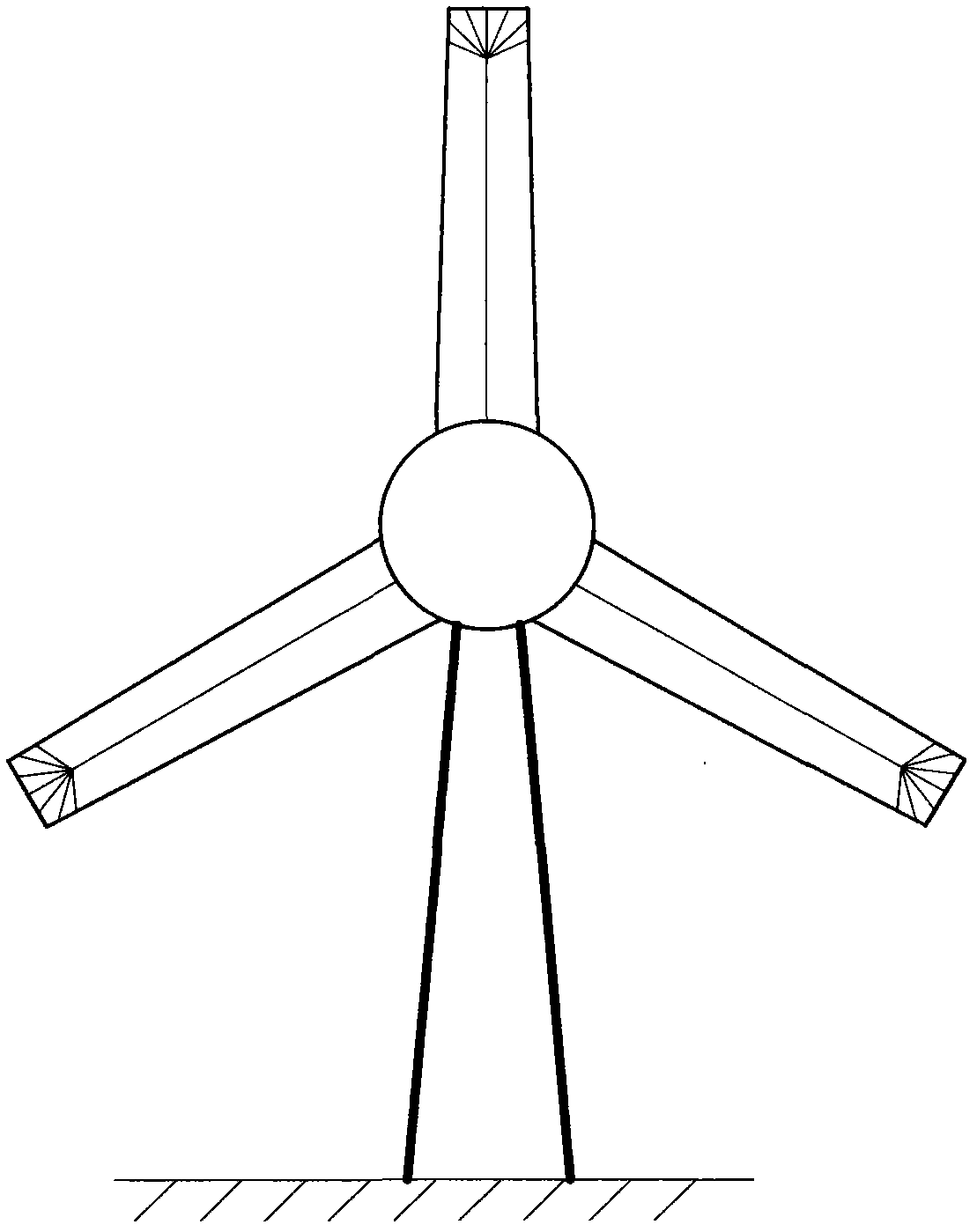

Lightning disaster-reducing method applicable to wind power generating unit

InactiveCN103184970ALightning Disaster ReductionDoes not affect shapeMachines/enginesWind energy generationWind forceDistribution rule

The invention relates to the field of lightning protection in wind power generation, in particular to a lightning disaster-reducing method applicable to a wind power generating unit. Radial conductive needle-shaped metal or radial conductive needle-shaped coatings are installed on the two surfaces of the upper end of a blade of the wind power generating unit, wherein (1) is the blade; and (2) is a radial conductive needle. By the method, before thundercloud performs electrical discharge on the wind power generating unit, the distribution rule of space charges in an electrical field of the thundercloud is distorted, so that the discharge voltage of lightning on an object is changed.

Owner:王鹏

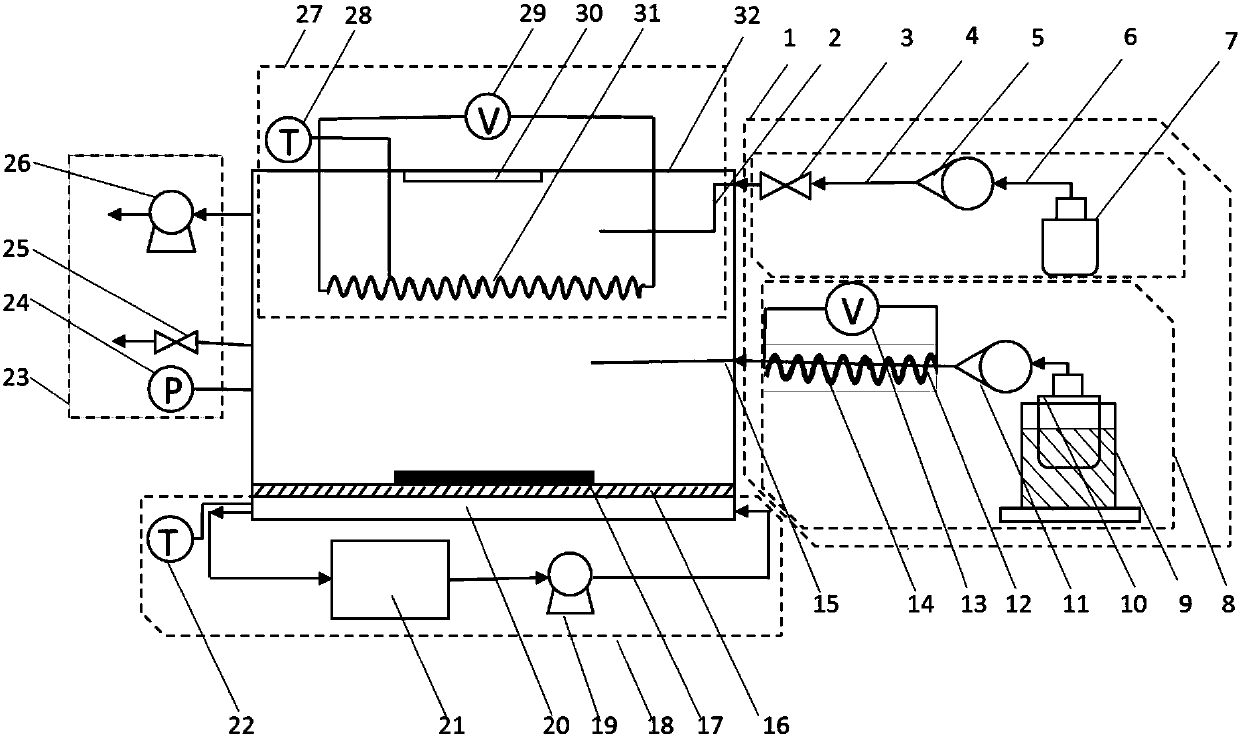

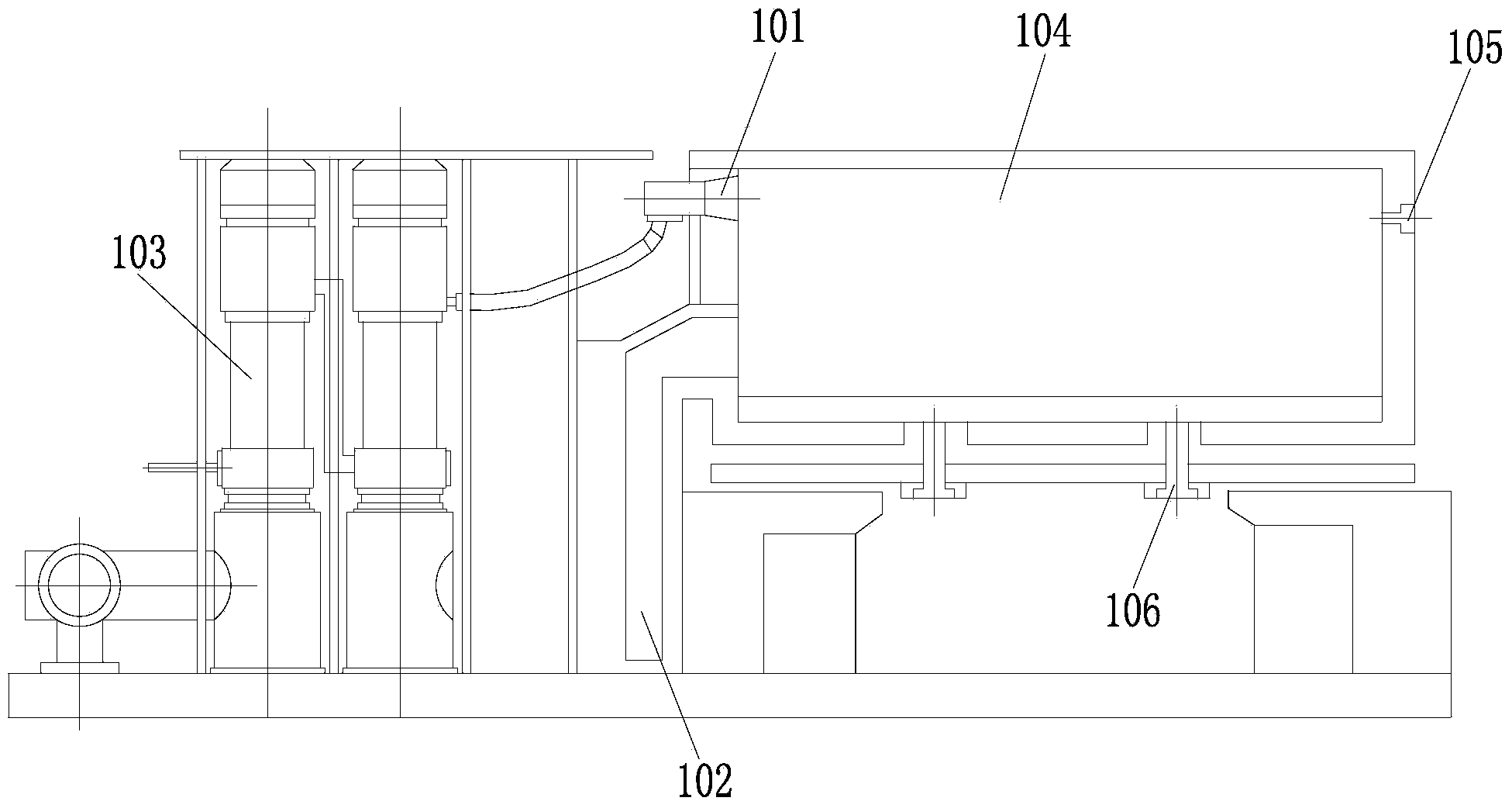

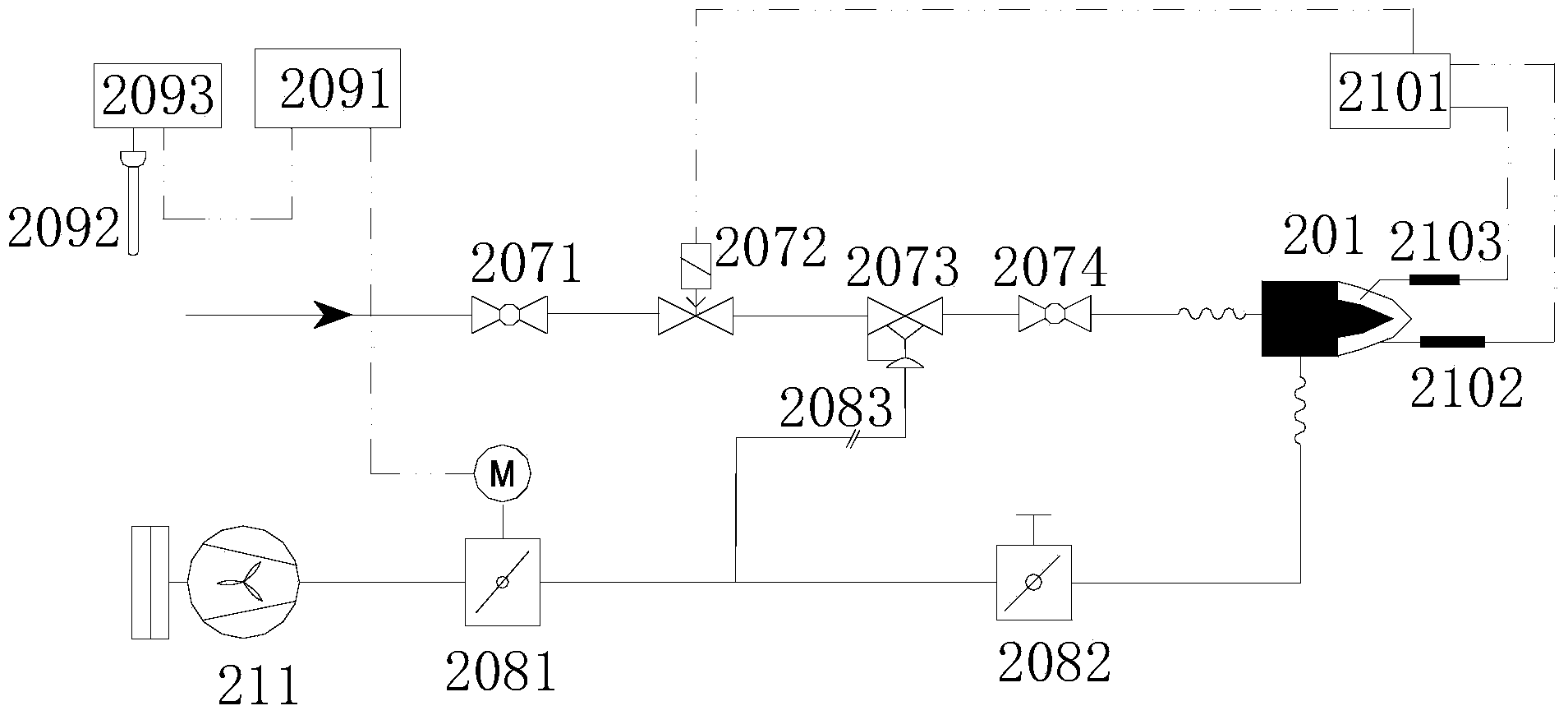

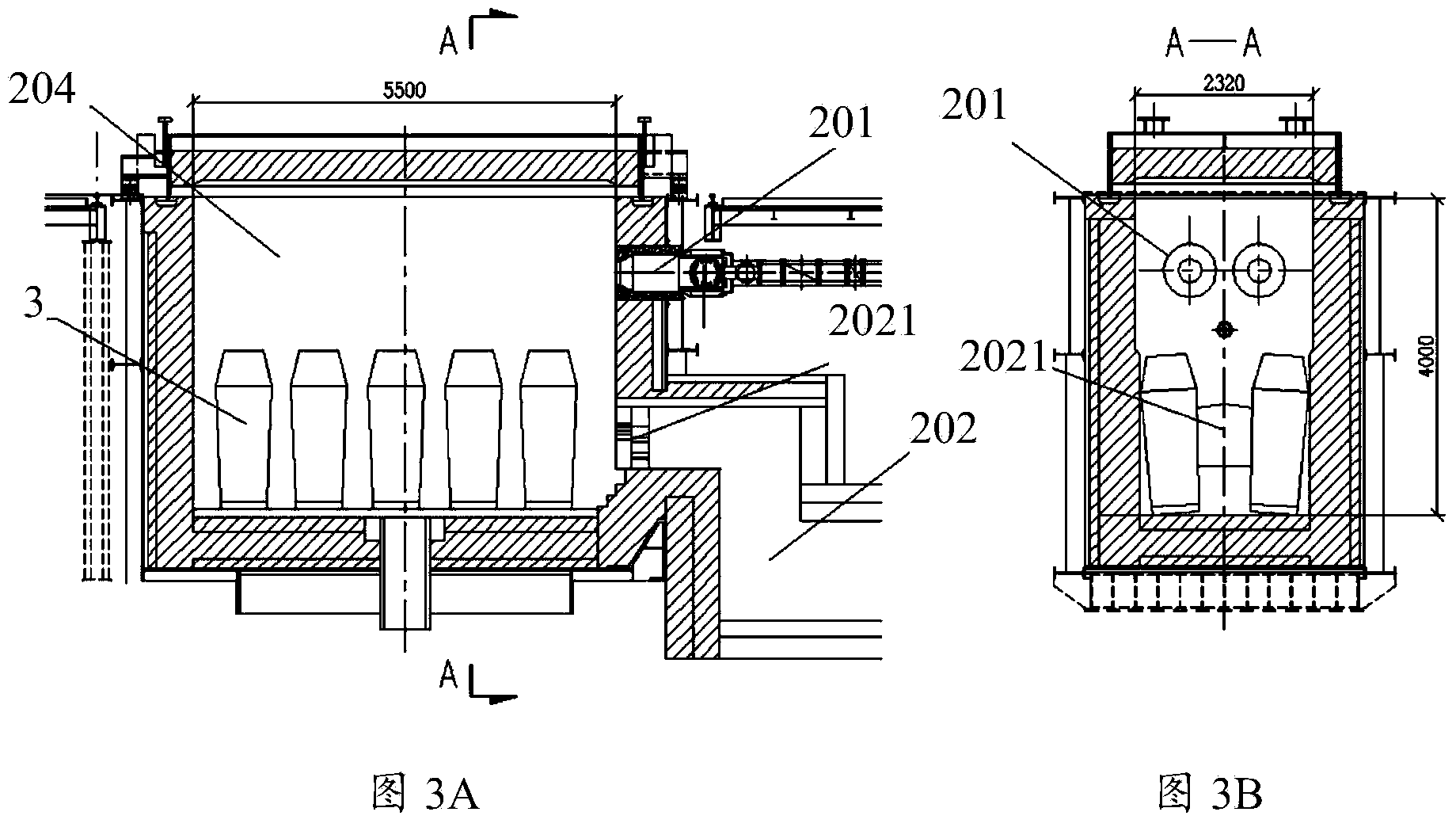

Heat supply system and heat supply method for soaking pit furnace

ActiveCN103725866ADoes not affect shapeDoes not affect performanceFurnace typesHeat treatment process controlAutomatic controlHearth

The invention discloses a heat supply system and a heat supply method for a soaking pit furnace. A long coal gas flame burner is replaced by a high velocity burner, and double-cross limit control is replaced by pulse control. The heat transfer mode between a steel ingot and burner gas is changed due to the high velocity burner, the traditional single heat transfer mode of heating the steel ingot by flame radiation of the burner is changed into convection and radiation two heat transfer modes, so that the steel ingot heating time is shortened, hot furnace gas in a hearth is intensively disturbed by the high-velocity hot air sprayed from the high-velocity burner, so that the furnace air in the furnace can be more uniform, the temperature field of the hearth can be more uniform, and the heating quality of the steel ingot can be improved. Due to the pulse control, full-automatic operation, full-automatic ignition, automatic flame monitor, flameout alarm cutoff and automatic temperature control can be realized on the high-velocity burner, the high-velocity burner can be in an optimized work state, hot air intensive disturbance, intensified convection and radiation heat transfer can be guaranteed, the burner is guaranteed to be in an optimized work station in each startup, the shape and performance of flame cannot be influenced by regulation of heat supply amount, and uneven temperature field in the furnace cannot happen.

Owner:BERIS ENG & RES CORP

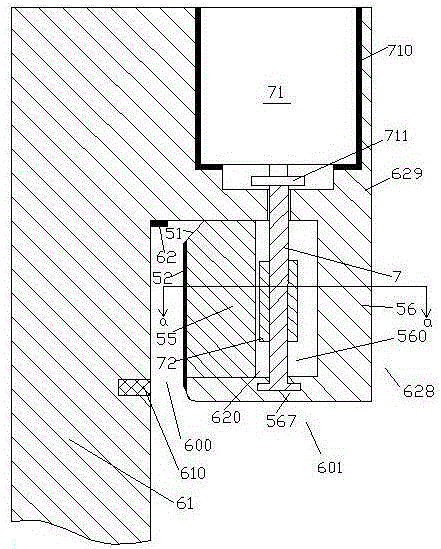

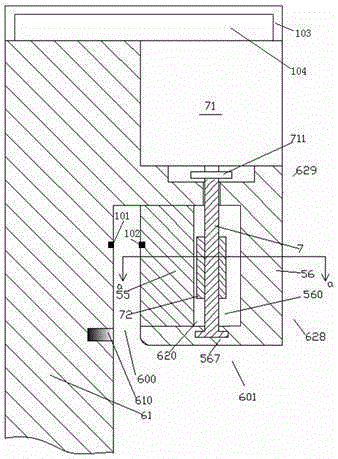

Device for reading medical film

InactiveCN105182541AImprove work efficiencyGuaranteed flatnessOptical elementsEngineeringDrive motor

The invention discloses a device for reading a medical film, and the device comprises a backlight plate frame body (61) with a backlight source. The backlight source is used for illuminating the medical film for reading, and the upper side edge of the backlight plate frame body (61) is provided with a clamping convex strip part (601) extending horizontally. The clamping convex strip part (601) comprises an upper bearing frame body (629) and at least one lower bearing frame room (628), wherein the upper bearing frame body (629) is integrated with the backlight plate frame body (61) and is used for bearing a drive motor (71), and the lower bearing frame room (628) is in integrated connection with the upper bearing frame body (629).

Owner:吴刚

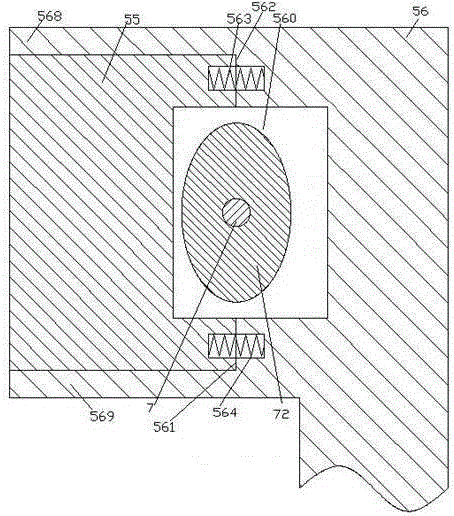

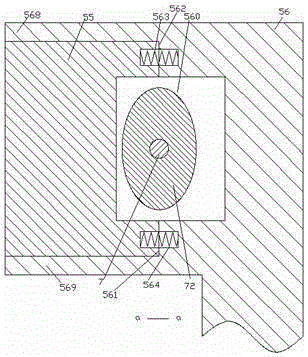

Mobile plate fixing device for welding

InactiveCN105108435AGuaranteed to fallUnified operation is convenientWelding/cutting auxillary devicesAuxillary welding devicesEngineeringStructural engineering

A mobile plate fixing device for welding comprises a bearing base plate (61) used for bearing a welded plate (29) and a fixing column component (62) which is fixedly connected with the bearing base plate (61) and extends in the vertical direction, wherein the fixing column component (62) comprises two fixing columns (681 and 682) which are opposite to each other in the diameter direction and extend in the vertical direction, a top wall part (621) fixedly connected with the upper ends of the two fixing columns (681 and 682) as well as a column root part (622) fixedly connected with the lower ends of the two fixing columns (681 and 682); two locking sliding blocks (55 and 56) which are symmetric about the center axis of the fixing column component (62) are glidingly arranged in a telescopic channel (620) extending in the horizontal direction between the two fixing columns (681 and 682).

Owner:广东高航知识产权运营有限公司

Intelligent plate fixing device for welding

InactiveCN105108434AGuaranteed to fallUnified operation is convenientWelding/cutting auxillary devicesAuxillary welding devicesStructural engineering

An intelligent plate fixing device for welding comprises a bearing base plate (61) for bearing a to-be-welded plate (29)and a fixing column component (62) which is fixedly connected with the bearing base plate (61) and extends in the vertical direction, wherein the fixing column component (62) comprises two fixing columns (681 and 682) which are opposite to each other in the diameter direction and extend in the vertical direction, a top wall part (621) fixedly connected with the upper ends of the two fixing columns (681 and 682) as well as a column root part (622) fixedly connected with the lower ends of the two fixing columns (681 and 682); two locking sliding blocks (55 and 56) which are symmetric about the center axis of the fixing column component (62) are glidingly arranged in a telescopic channel (620) extending in the horizontal direction between the two fixing columns (681 and 682); each of the two locking sliding blocks (55 and 56) has an external circumferential part (561) and an internal bulged part (562).

Owner:陈晗

Plate fixing device for welding which is capable of water-cooling and is provided with LED lamps

ActiveCN105290672AGuaranteed to fallUnified operation is convenientLighting elementsWelding/cutting auxillary devicesLED lampArchitectural engineering

The invention discloses a plate fixing device for welding which is capable of water-cooling and is provided with LED lamps. The plate fixing device comprises a bearing chassis (61) which is used for bearing a to-be-welded plate (29) and a fixed cylindrical component (62) which is fixedly connected with the bearing chassis (61) and extends in the vertical direction; the fixed cylindrical component (62) comprises two fixed posts (681 and 682) which extend in the vertical direction and are opposite in the diameter direction, a top wall part (621) which is fixedly connected with the upper ends of the two fixed posts (681 and 682) and a post root part (622) which is fixedly connected with the lower ends of the two fixed posts (681 and 682); and a telescopic passage (620) which extends in the horizontal direction between the two fixed posts (681 and 682) is internally and slidably provided with two locking sliding blocks (55 and 56) which are symmetrical about the central axis of the fixed cylindrical component (62).

Owner:NANTONG FUQIANG LIGHTING TECH

First layer metal trench etching method

ActiveCN105226014AGood lookingConducive to loadSemiconductor/solid-state device manufacturingDry etchingMetal

The invention provides a first layer metal trench etching method. The ILD dielectric of a contact hole layer in a wafer front-layer process is SiO2, and contact hole WCMP is completed. The method comprises the steps that etching stop layers are deposited; a Low-k dielectric layer is deposited; by introducing the mask plate and the shrinkage plate of a first layer metal trench, metal hard mask etching and Low-k dielectric layer etching are separated; by using the difference between etching selection ratio of different materials, two times of etching stop at the etching stop layers which are respectively located at the top and the bottom of the Low-k dielectric layer; and great uniformity of wet etching is used to reduce an etching loading effect. Compared with a first layer metal trench dry etching method in the prior art, the method provided by the invention has the advantages that a better optimization loading effect is realized without affecting the morphology of the first layer metal trench; the consistency of process parameters of first layer metal is ensured; and the uniformity of process parameters of the whole device is optimized.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

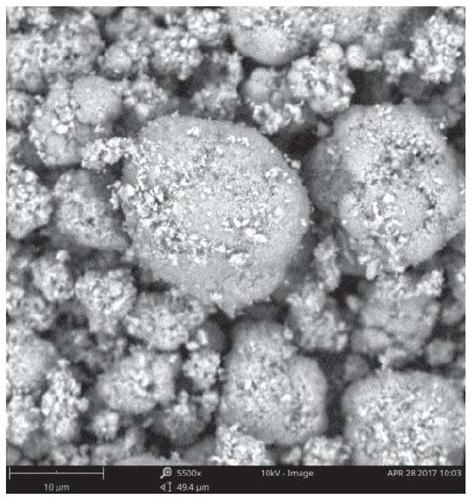

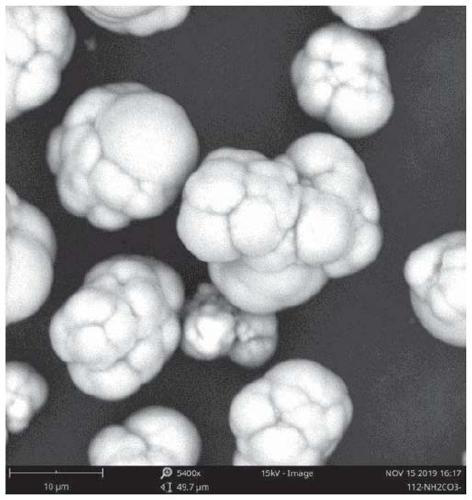

Method for washing positive electrode material precursor

ActiveCN111217409AReduce manufacturing costDoes not affect shapeCell electrodesNickel compoundsPoly ether ether ketonePervaporation membrane

The invention provides a method for washing a positive electrode material precursor. The method comprises the following steps: putting a positive electrode material precursor containing impurity ionsinto a washing device, and treating to obtain a positive electrode material precursor slurry of which the impurity ion concentration meets the requirement, wherein the washing device comprises a cathode chamber, a mixture chamber and an anode chamber which are sequentially separated by a cation selective permeable membrane and an anion selective permeable membrane; the cation selective permeable membrane is selected from a sulfamide polypyrrole and polyether-ether-ketone permeable membrane or a sulfamide polypyrrole permeable membrane; and the anion selective permeable membrane is selected from a polyethersulfone permeable membrane. When the precursor is washed by adopting the method, the morphology and components of the precursor are not influenced, and meanwhile, impurities Na<+> and SO4<2-> of the precursor can be reduced to be 100 ppm or less, so that the excellent electrochemical performances of the precursor after the material is sintered in the later period are ensured; and according to the method, a large amount of water is saved, meanwhile, byproducts Na<+> and SO4<2-> can be recycled respectively, and the production cost of the material is reduced by washing with the method.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

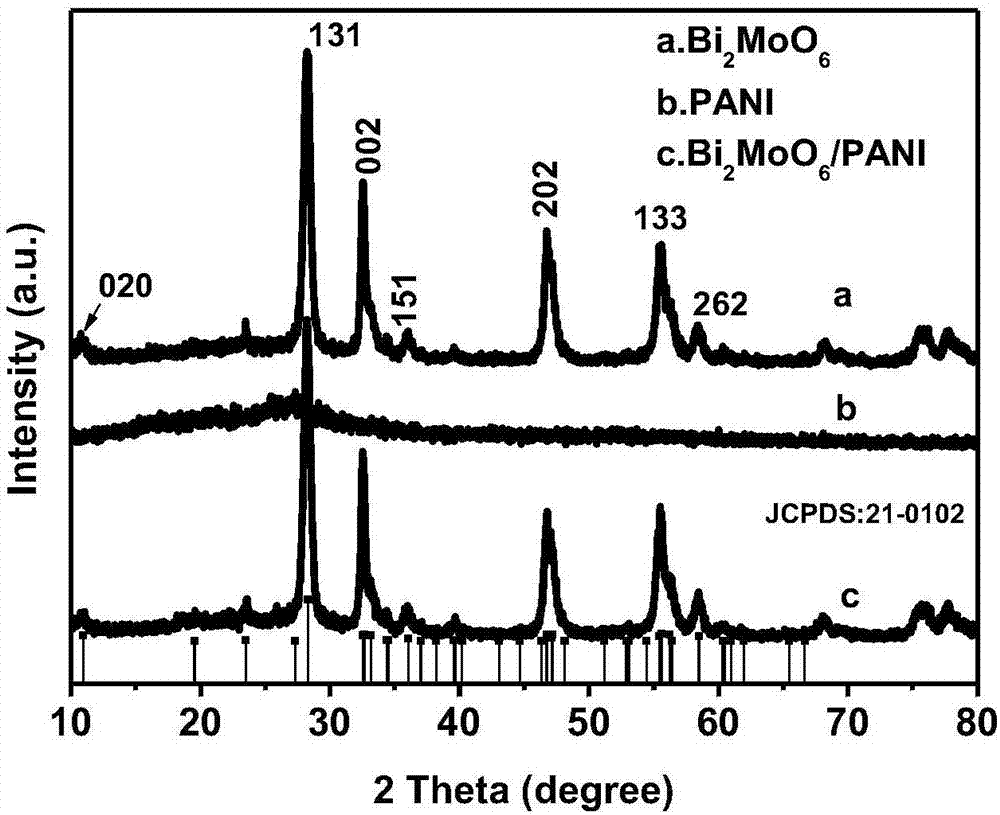

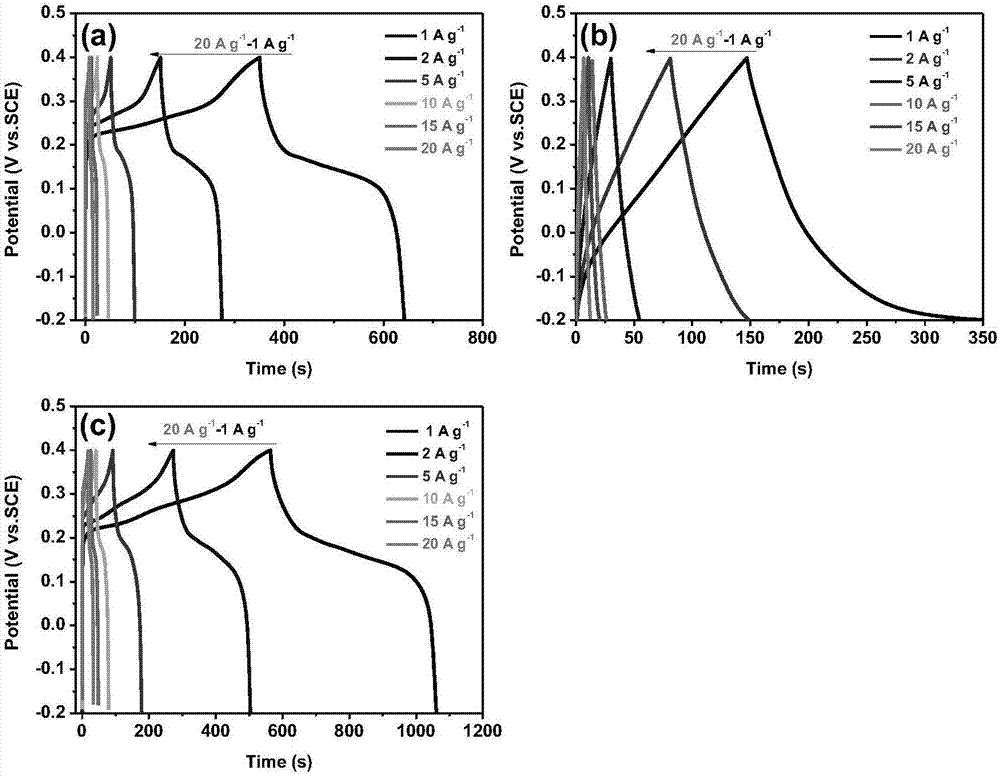

Preparation method for bismuth molybdate/polyaniline composite supercapacitor electrode material

InactiveCN106981369ACapacitive increaseSimple methodHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceSolvent

The invention provides a preparation method for a bismuth molybdate / polyaniline composite supercapacitor electrode material. The preparation method comprises the following steps of dissolving bismuth nitrate and sodium molybdate into ethylene glycol at a molar ratio at a room temperature to obtain a mixed solution A, and performing ultrasonic uniformity and adding a mixed solution of urea and absolute ethyl alcohol; stirring continuously and uniformly and then pouring the mixed solution into a polytetrafluoroethylene stainless steel hydrothermal reaction kettle, sealing and performing a solvothermal reaction; after naturally cooling, performing washing and drying to obtain bismuth molybdate; performing ultrasonic dispersion of bismuth molybdate and lignin sodium sulfonate into deionized water to obtain a mixed solution, then adding an aniline monomer and p-toluenesulfonic acid, and then changing into ice- bath stirring, after the aniline is dispersed, obtaining a mixed solution B; and slowly dropwise adding an ammonium persulfate solution to the mixed solution B, and after the ice-bath reaction is completed, performing washing and drying to obtain the bismuth molybdate / polyaniline composite material. The method is simple, and the capacitance performance of the prepared bismuth molybdate / polyaniline composite material is greatly improved.

Owner:JIANGSU UNIV

Low-noise transformer oil tank

PendingCN112750595AReduce deliveryDoes not affect shapeTransformers/inductances coolingTransformers/inductances casingsLow noiseEngineering

The invention provides a low-noise transformer oil tank. The oil tank comprises an oil tank inner wall, an oil tank outer wall and a noise reduction interlayer arranged between the oil tank inner wall and the oil tank outer wall, wherein the noise reduction interlayer comprises an interlayer structure used for transmitting noise vibration energy and mass blocks located on the two sides of the interlayer structure, and the mass block is used for converting and consuming noise energy so as to reduce noise pollution. The oil tank can reduce outward propagation of sound waves, reduces noise transmitted by the tank wall of the oil-immersed transformer, is low in cost, does not affect the overall appearance shape of the tank wall, and can be used for a long time without maintenance.

Owner:CHINA ELECTRIC POWER RES INST +2

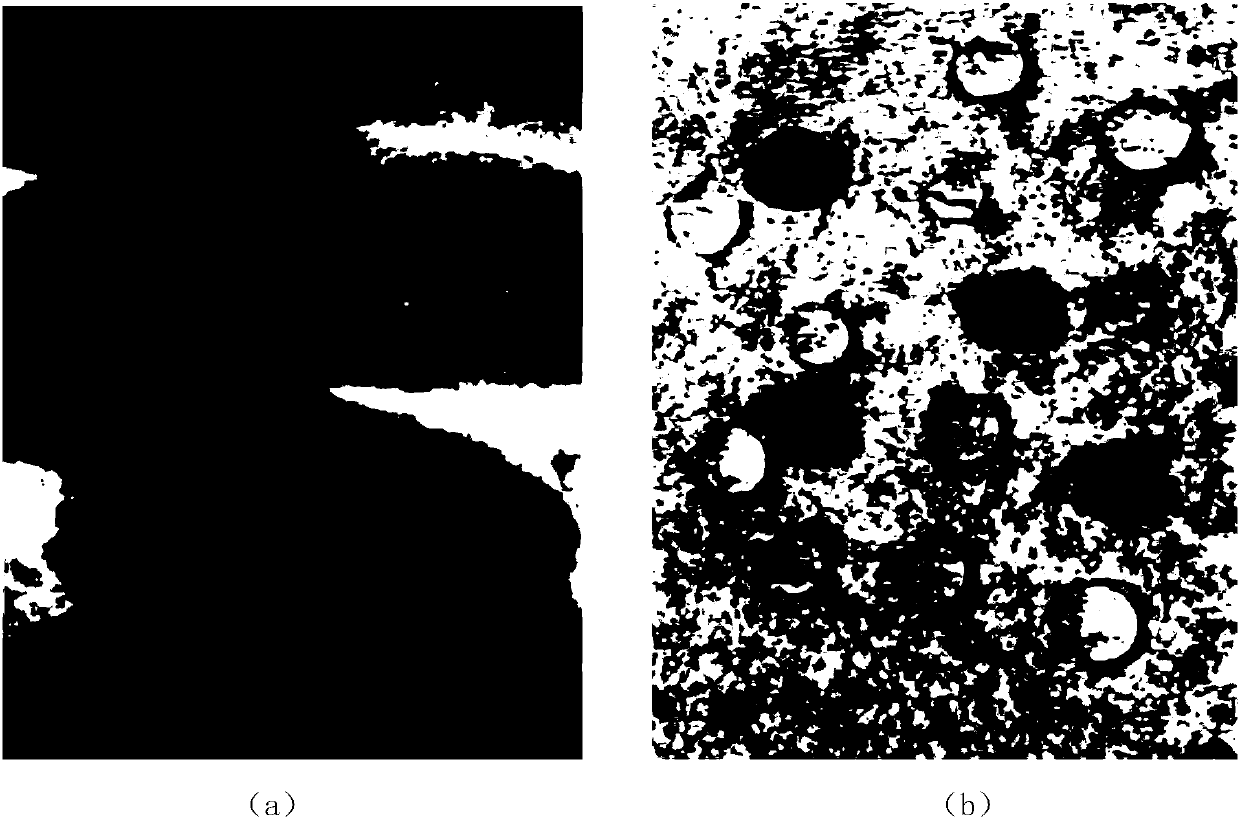

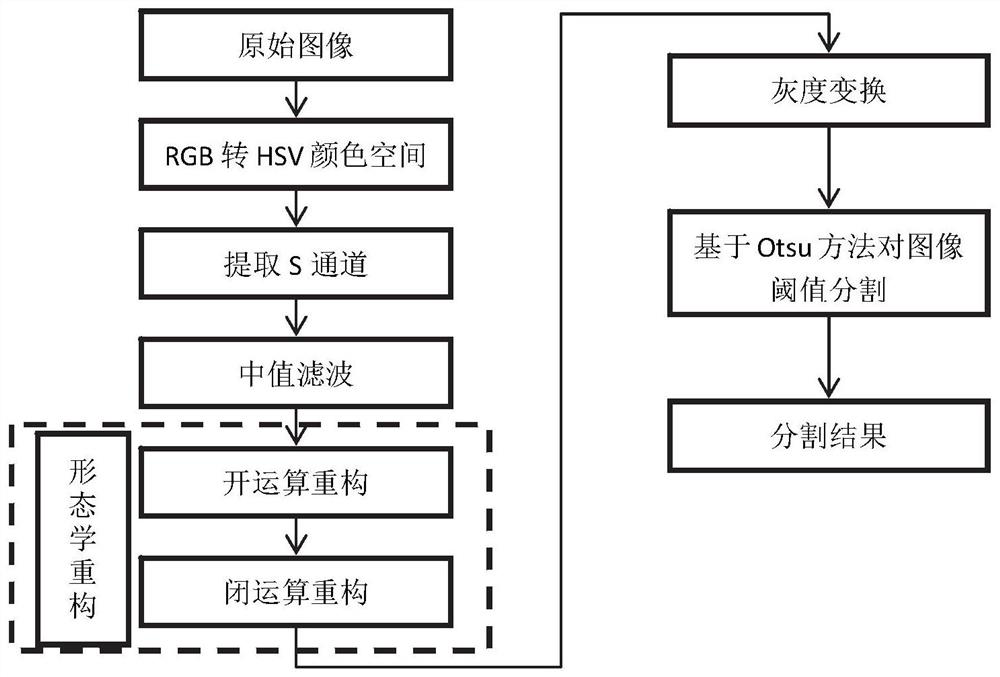

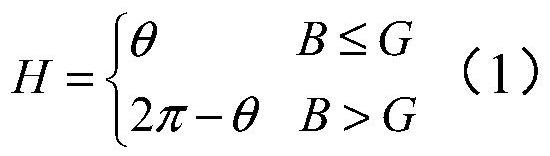

Cotton image segmentation method and system based on morphological reconstruction and adaptive threshold

PendingCN112862841AGood distinctionEffective segmentationImage enhancementImage analysisGray levelDark spot

The invention discloses a cotton image segmentation method and system based on morphological reconstruction and an adaptive threshold. The method comprises the steps of obtaining a to-be-processed cotton image; converting the to-be-processed cotton image from an RGB color space to an HSV color space; extracting a saturation S component of the cotton image of the HSV color space; performing filtering processing on the saturation component image to remove random noise in the image; performing morphological reconstruction on the filtered image to remove dark spots and flaws in the image; carrying out gray level transformation on the image after morphological reconstruction processing so as to enhance the contrast ratio between the cotton area and the background area; and carrying out threshold segmentation on the image after gray level transformation to obtain a segmentation result of the cotton image. And the segmentation precision of the cotton in the natural environment is improved.

Owner:SHANDONG UNIV +1

Fixing device with protective paint layer and shock absorption function for welding plate

InactiveCN105195944AGuaranteed to fallUnified operation is convenientWelding/cutting auxillary devicesAuxillary welding devicesLacquerChassis

The invention discloses a fixing device with a protective paint layer and a shock absorption function for a welding plate. The fixing device comprises a bearing chassis (61) and a cylindrical fixing component (62), wherein the bearing chassis (61) is used for bearing a plate (29) to be welded, and the cylindrical fixing component (62) is fixedly connected with the bearing chassis (61) and extends in the vertical direction. The cylindrical fixing component (62) comprises two fixing columns (681 and 682), a top wall portion (621) and a column root portion (622), wherein the two fixing columns (681 and 682) extend in the vertical direction and are opposite in the diameter direction, the top wall portion (621) is fixedly connected with the upper ends of the two fixing columns (681 and 682), and the column root portion (622) is fixedly connected with the lower ends of the two fixing columns (681 and 682). Two locking sliding blocks (55 and 56) symmetrical about the center axis of the cylindrical fixing component (62) are arranged in an extensible channel (620) in a slidable mode, wherein the extensible channel (620) is arranged between the two fixing columns (681 and 682) and extends in the horizontal direction.

Owner:柳州市鸿福机械制造有限公司

Over-travel-proof and convenient medical film reading device

InactiveCN105182540AImprove work efficiencyGuaranteed flatnessOptical elementsDrive motorEngineering

The invention discloses an over-travel-proof and convenient medical film reading device, and the device comprises a backlight plate frame body (61) with a backlight source. The backlight source is used for illuminating a medical film for reading, and an upper side edge of the backlight plate frame body (61) is provided with a clamping convex strip part (601) extending horizontally. The clamping convex strip part (601) comprises an upper bearing frame body (629) which is integrated with the backlight plate frame body (61) and used for bearing a drive motor (71), and also comprises at least one lower bearing frame room (628) which is in integrated connection with the upper bearing frame body (629).

Owner:田晓青

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com