Batch-preparation and quick-separation method of iron-based coal-liquefaction nano catalyst

A nano-catalyst and coal liquefaction technology, applied in chemical instruments and methods, preparation of liquid hydrocarbon mixtures, physical/chemical process catalysts, etc., can solve the problems of difficult scale-up of preparation methods, difficulty in batch preparation, and high cost of waste treatment. Achieve the effect of low raw material price, high direct liquefaction activity and uniform shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

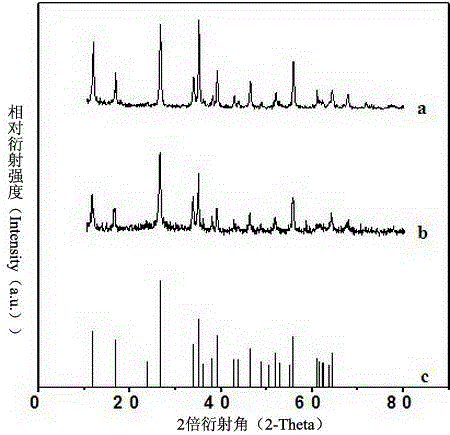

[0024] with FeCl 3 ·6H 2 O was used as raw material to prepare iron oxyhydroxide nanoparticles. Prepare 0.02 mol·L -1 FeCl 3 ·6H 2 O solution 2 L, at 76 o C and stirred for 10 hours to obtain a yellow opaque homogeneous liquid containing ferric oxyhydroxide nanoparticles, and the mixed liquid was not coagulated. Weigh 0.07 g ferric fulvic acid and prepare it into 10 ml aqueous solution. Add the prepared ferric fulvic acid solution into the reaction liquid after the reaction is completed under the condition of stirring, resulting in a large amount of precipitation. Leave to separate layers and remove the supernatant. The precipitate was filtered, washed three times with distilled water and three times with ethanol. The product was dried at room temperature to obtain iron oxyhydroxide nanoparticles.

Embodiment 2

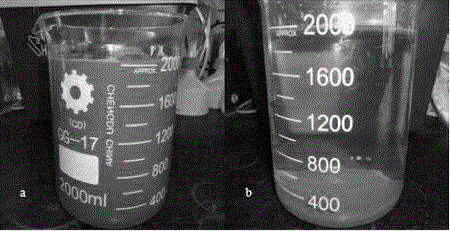

[0026] with FeCl 3 ·6H 2 O as a raw material to prepare iron oxyhydroxide nanoparticles in large quantities. Prepare 0.04 mol·L -1 FeCl 3 ·6H 2 O solution 150 L, at 76 o C and stirred for 10 hours to obtain a yellow opaque homogeneous liquid of ferric oxyhydroxide nanoparticles, and the mixed liquid was not coagulated. Weigh 10 g of ferric fulvic acid and prepare 600 ml of aqueous solution. Add the prepared ferric fulvic acid solution into the reaction liquid after the reaction is completed under the condition of stirring, resulting in a large amount of precipitation. Leave to separate layers and remove the supernatant. The precipitate was filtered, washed three times with distilled water and three times with ethanol. The product was dried at room temperature to obtain 422 g of iron oxyhydroxide nanoparticles.

Embodiment 3

[0028] The direct liquefaction of Xinjiang Yili coal and Xinjiang Jiangjunmiao coal was catalyzed by nano-iron oxyhydroxide prepared in large quantities. Load the reaction materials in the high-pressure reactor according to the following material ratio: 30 g dry basis coal, 0.3 g elemental sulfur, 60 g hydrogen-donating solvent tetrahydronaphthalene, and the amount of catalyst input is 3% of the dry basis coal weight in which the iron content is % meter, pass hydrogen to make the initial pressure of the reactor 6.5MPa; react according to the following reaction conditions: the reaction temperature is 420 o C, the reaction time is 75 min; after the reaction is over, the product is extracted with n-hexane, toluene, and tetrahydrofuran through a Soxhlet extractor to obtain oil soluble in n-hexane, bitumen insoluble in n-hexane but soluble in toluene Pre-asphaltenes and tetrahydrofuran-insoluble liquefaction residues that are insoluble in alkene and toluene but soluble in tetrahydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com