Preparation method of ultrathin boron nitride nanosheet with high specific surface area

A technology of boron nitride and nanosheets, applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve the problems of few products, difficult to obtain, and limit the application of BNNSs, and achieve large pore volume, high thermal stability, high The effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In a typical synthesis, 20 mmol B 2 o 3 , 130mmol zinc powder and 50mmol N 2 h 4 2HCl was mixed evenly and placed in a 20mL reaction kettle. Seal the reaction kettle, raise the temperature from room temperature to 500°C at a rate of 10°C / min in an electric furnace, and keep it at 500°C for 12 hours, then cool naturally, and the initial product is treated with diluted hydrochloric acid overnight to remove by-products. It was then filtered and dried at 80°C. The product is about 0.33g.

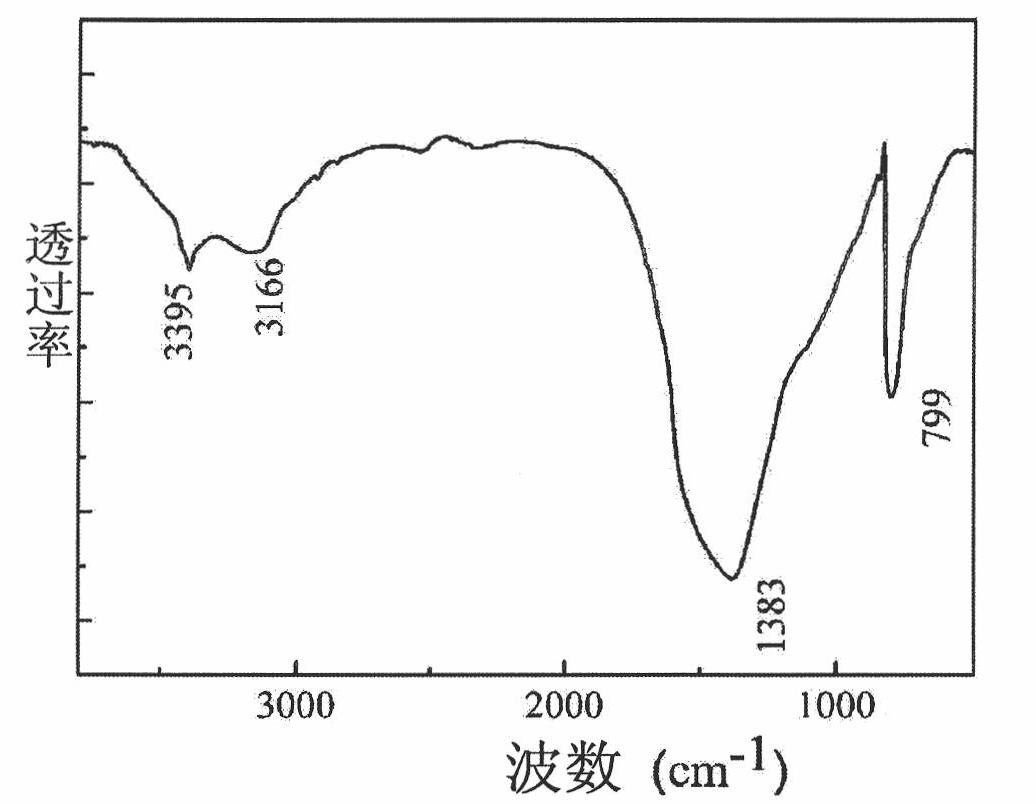

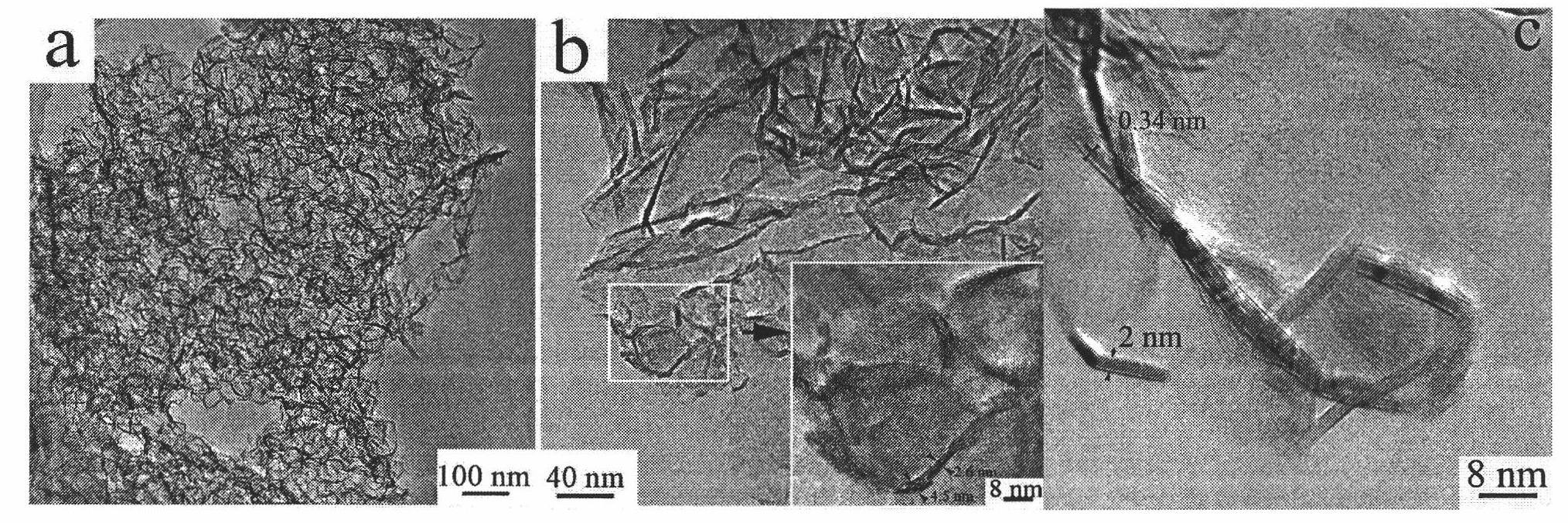

[0035] Using infrared spectrometer, X-ray powder diffractometer, transmission electron microscope (TEM, Hitachi H-7000), high resolution transmission electron microscope (HRTEM, JEOL-2100, 200kV), thermogravimetric analyzer, specific surface area and pore distribution instrument (NAVA2000e) in 77K for nitrogen adsorption-desorption analysis.

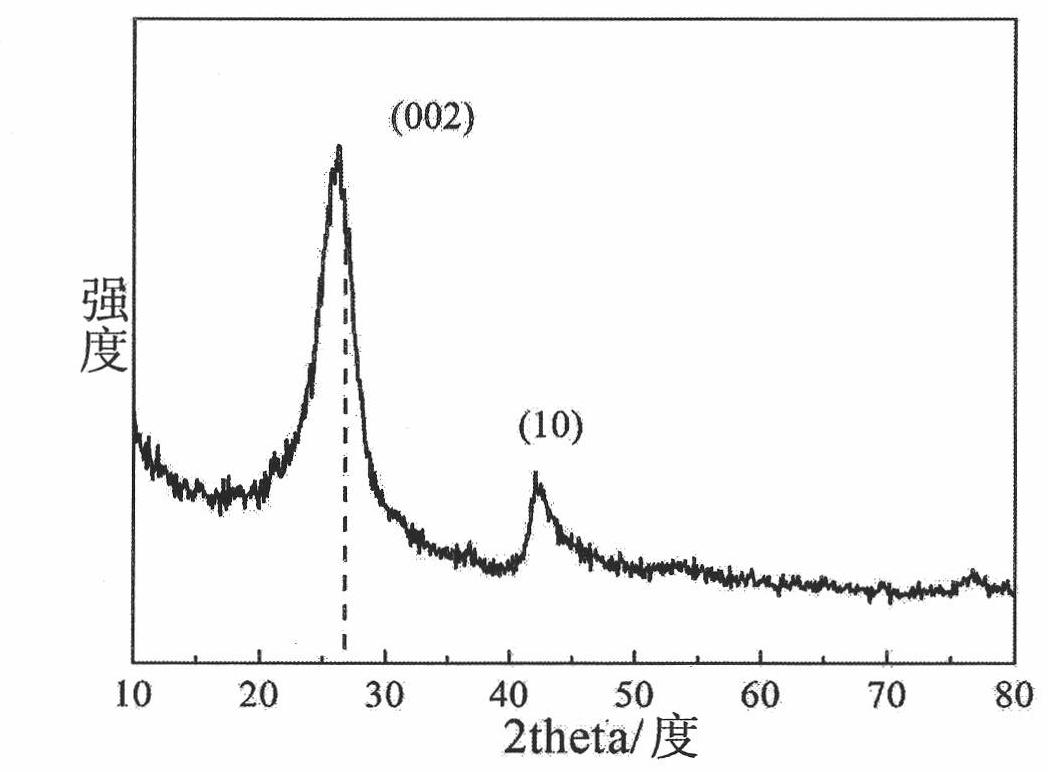

[0036] The obtained samples were first characterized by powder diffraction, as figure 1 , at 26.24 (3.394 ) and 42.08° (2.145 ) have two...

Embodiment 2

[0045] As described in Example 1, the difference is:

[0046] 40mmol B 2 o 3 , 200mmol zinc powder and 50mmol N 2 h 4 2HCl was mixed evenly and placed in a 20mL reactor, reacted at 500°C for 6h, and dried to obtain 1g of the product. The obtained XRD is as Figure 6 shown.

Embodiment 3

[0048] As described in Example 1, the difference is that Zn is replaced by equimolar magnesium powder, and the obtained product is mainly flakes with a diameter of more than 10 nm. Such as Figure 7 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com