Fixture for machining connecting sleeve

A technology for connecting sleeves and fixtures, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems affecting the mass production requirements of parts, the difficulty of ensuring the processing quality of the fixture, and the easy deformation of the clamp, and achieves a simple structure and economical efficiency. The effect of working hours and convenient clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

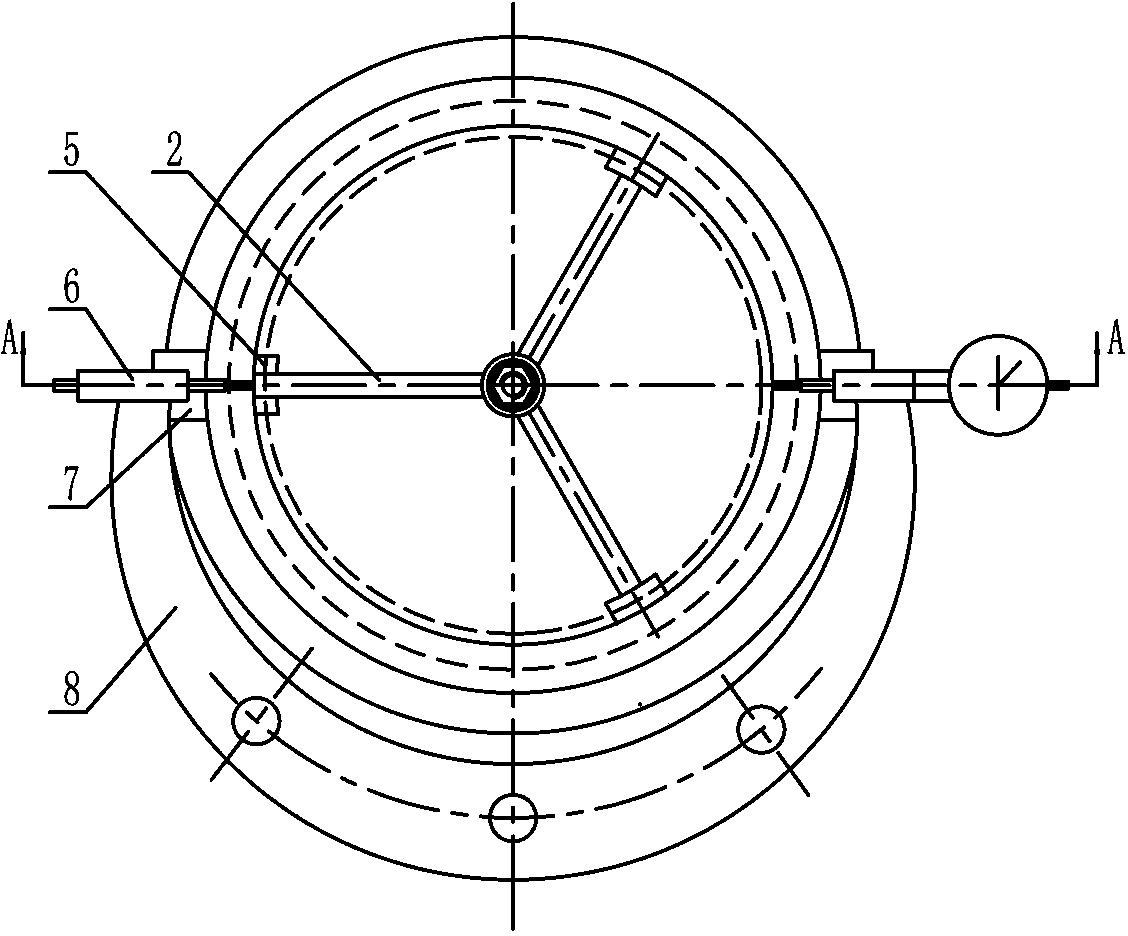

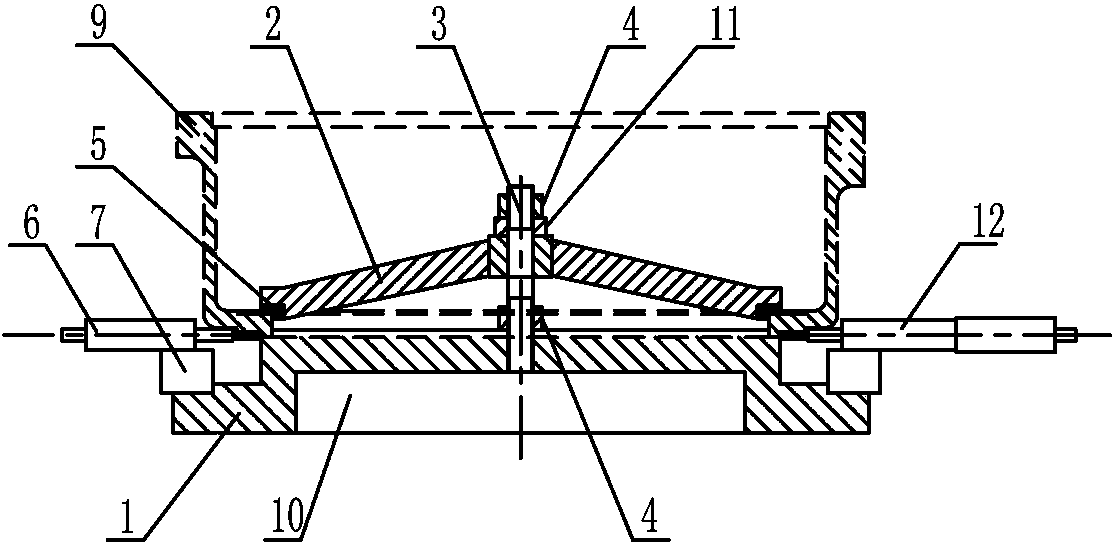

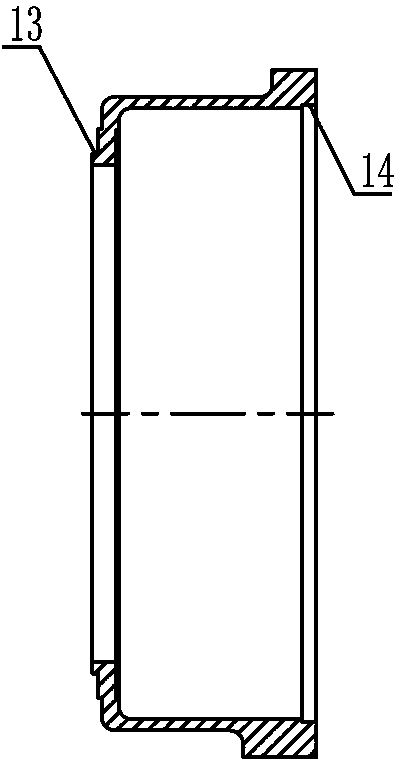

[0017] Such as Figure 1-3 As shown, a clamp for processing a connecting sleeve described in the embodiment of the present invention is mainly used for processing the small end processing surface 13 and the large end processing surface 14 of a connecting sleeve 9 for assembly and clamping. The clamp mainly includes a base 1 , elastic claw 2, pressing device and detection device, the outer end surface of the small end of the connecting sleeve 9 is attached to the upper surface of the base 1, the elastic claw 2 is pressed on the inner end surface of the small end of the connecting sleeve 9, and the elastic claw 2 It is formed by connecting three pressure plates evenly distributed at 120°. The middle of the elastic claw 2 arches upwards and is connected with the base 1 through a pressing device. Since the distance between the processing surface 13 of the small end and the base 1 is very close, there is a certain difficulty in detection, so a separate detection device is designed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com