Spool

A technology inside the bobbin and tube wall, which is applied in the field of textile devices, can solve the problems of easy wear and tear, waste of energy, and influence on bobbin forming, etc., and achieve the effect of firm packaging, long life and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

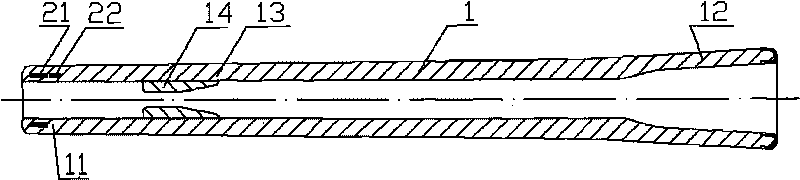

[0028] The coil 21 is integrated in the spun bobbin at the bobbin head end 11 (see figure 1 ).

[0029] The coil 21 is designed as an annular flat coil with an inductance of 3.45mH, an outer diameter of 10mm, and an inner diameter of 8mm; The axes are coincident; the chip 22 is selected from the EM4100 chip that matches the coil 21, and the chip 22 is placed in the tube wall 1 below the coil 2 at the head end 11 of the bobbin. After being electrically connected with the coil 21, they are connected to the bobbin by injection molding. The raw materials are integrated into bobbins of the present invention.

[0030] The spinning test is carried out with the bobbin of this embodiment. When the spinning spindle speed reaches 15,000 rpm, the radio frequency reader can still communicate with the radio frequency transponder 2 (or bobbin) normally.

Embodiment 2

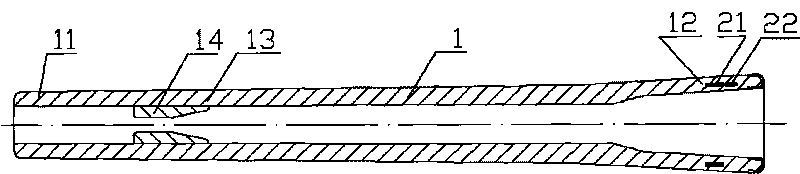

[0034]The coil 21 is integrated into the spun yarn bobbin at the bottom end 12 of the bobbin (see figure 2 ).

[0035] The packaging position of the radio frequency transponder 2 is at the bottom 12 of the spun bobbin, and the axis of the coil 21 coincides with the axis of the bobbin 1; the inner diameter of the coil 21 is 19 mm, the outer diameter is 23 mm, and the chip 22 is selected It is TK4100 chip. The rest are the same as embodiment 1.

Embodiment 3

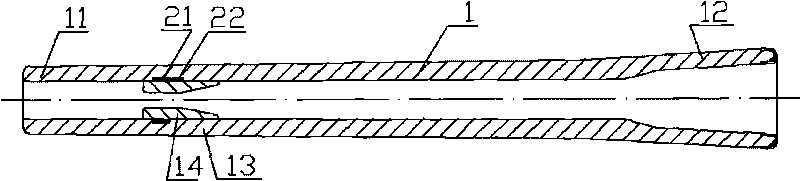

[0037] The coil 21 is integrated into the spun bobbin at the positioning ring 14 in the bobbin (see image 3 ).

[0038] The encapsulation position of the radio frequency transponder 2 is at the inner positioning ring 14 of the spun bobbin, and the axis of the coil 21 coincides with the axis of the bobbin 1; The radio frequency transponder chip 22 (produced in my country's Taiwan), the rest is the same as the embodiment 1.

[0039] The method of this embodiment is more convenient to embed and fix the radio frequency transponder 2 therein during the injection molding process of the bobbin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com