Hydrophobic treatment method for material surface

A treatment method and hydrophobization technology, applied in fiber raw material treatment, fiber treatment, metal material coating process, etc., can solve problems that are not conducive to the control of surface hydrophobic modification conditions and modification costs, the inability to precisely control the chemical structure of the film, Functional groups are not easy to preserve and other problems, to achieve the effect of good hydrophobic modification, good hydrophobic effect and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

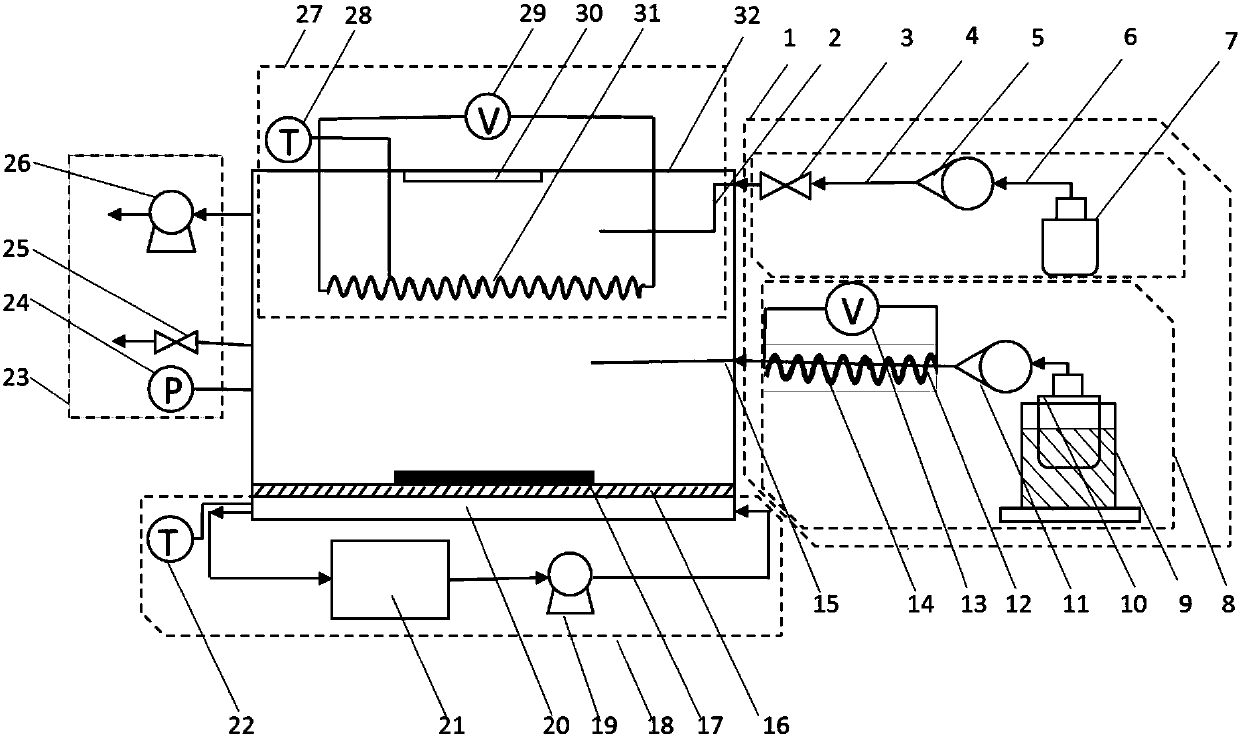

Method used

Image

Examples

Embodiment 1

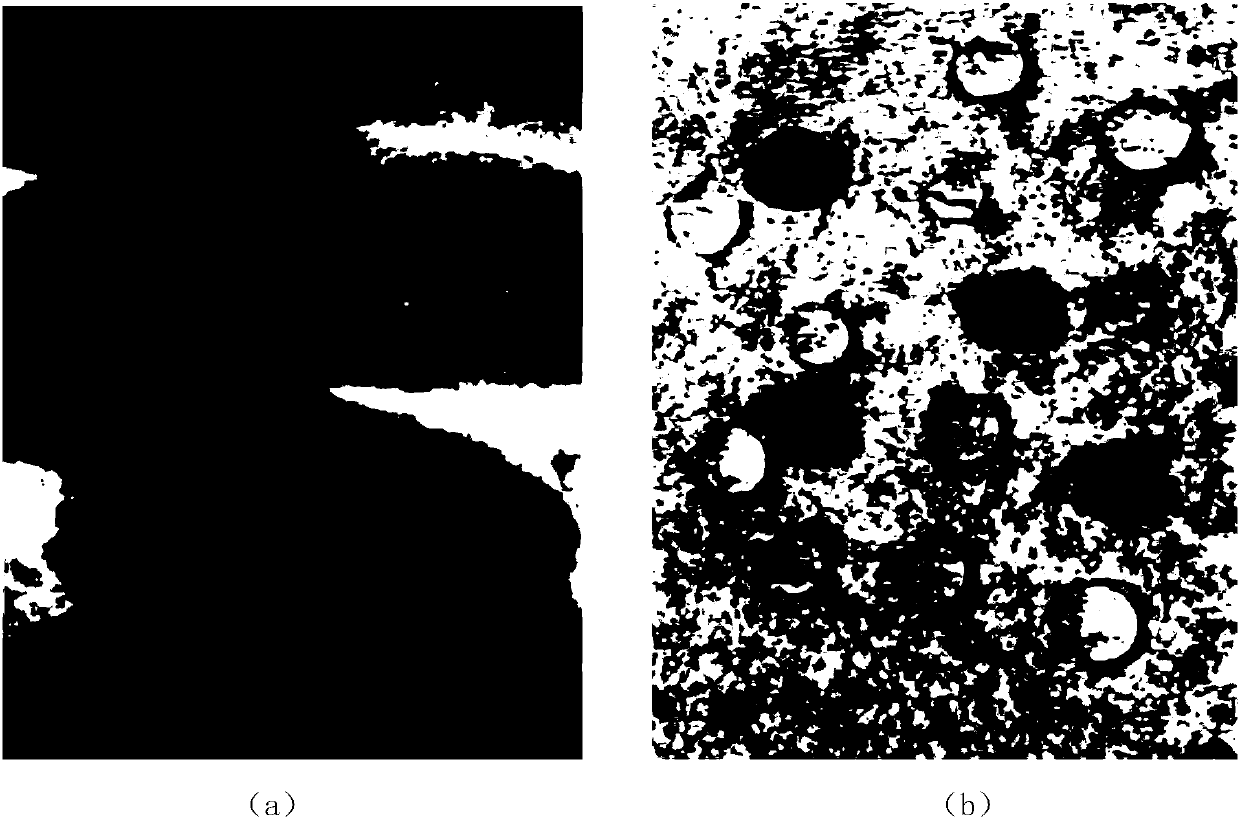

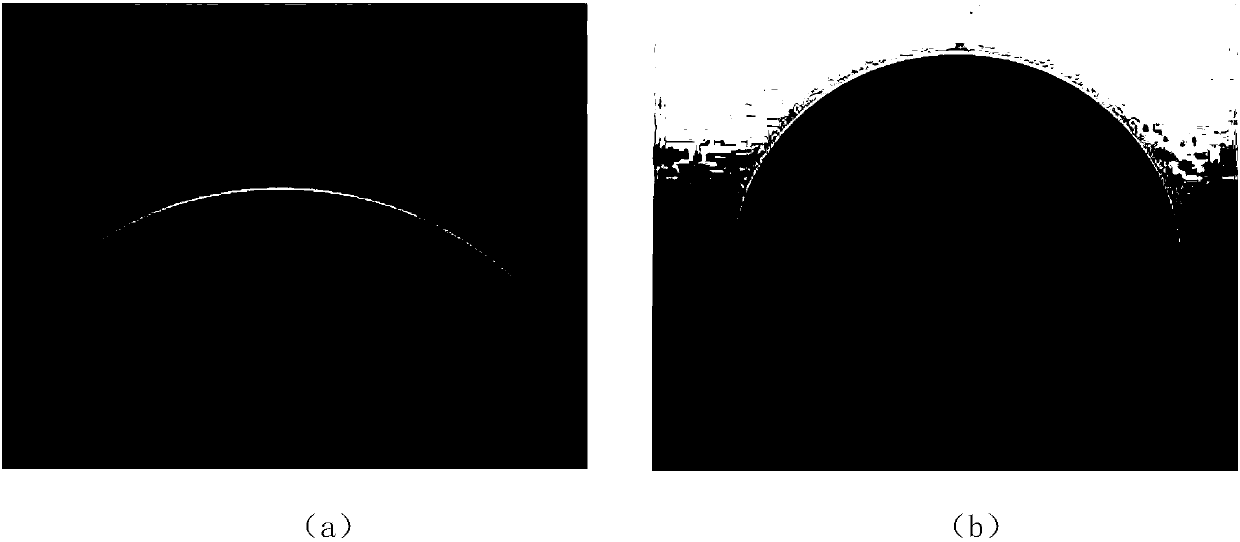

[0045] The laboratory dust-free paper is used as the material of the coating to be plated in this embodiment. Put the 21.5cm*11cm dust-free paper into the incubator for drying treatment, and then place it on the sample stage of the conformal coating system for the microscopic surface of the material. The initiator is di-tert-butyl peroxide, the molecular formula is C 8 h 18 o 2 ; The reactant monomer is perfluorodecanoic acid (PFDA), and the molecular formula is C 10 HF 19 o 2 . The pressure of the control reaction chamber is 1200Pa; the temperature of the initiator container is kept at room temperature; the DC power supply current of the reactant monomer inlet device is adjusted to 0.7A, and the voltage is 7.1V; the temperature of the reactant monomer water bath heating device is controlled to be 82 °C; adjust the DC power supply current of the electrothermal alloy wire heating system to 3.6A, the voltage to 19.0V, and control the temperature of the electrothermal alloy...

Embodiment 2

[0048] A flat glass sheet is used as the material to be coated in this embodiment. Wash the 7.5cm*2.5cm glass piece and put it into the incubator for drying treatment, and then place it on the sample stage of the nanoscale thickness conformal hydrophobic film coating device. The initiator is di-tert-butyl peroxide, the molecular formula is C 8 h 18 o 2 ; The reactant monomer is perfluorodecanoic acid (PFDA), and the molecular formula is C 10 HF 19 o 2 . The pressure of the reaction chamber is controlled at 3200Pa, and the temperature of the initiator container is kept at room temperature; the DC power supply current of the reactant monomer inlet device is adjusted to 0.7A, and the voltage is 7.5V; the temperature of the reactant monomer water bath heating device is controlled at 83 ℃; adjust the DC power supply current of the electrothermal alloy wire heating system to 3.8A, the voltage to 19.5V, and the temperature of the electrothermal alloy wire is controlled at 225 °...

Embodiment 3

[0051] A single crystal silicon wafer is used as the material of the coating to be plated in this embodiment. A 0.5cm*1.5cm single crystal silicon wafer is washed with absolute ethanol, dried naturally, and then placed on the sample stage of a nanoscale thickness conformal hydrophobic film coating device. The initiator is di-tert-butyl peroxide, the molecular formula is C 8 h 18 o 2 ; The reactant monomer is perfluorodecanoic acid (PFDA), and the molecular formula is C 10 HF 19 o 2 . The pressure of the reaction chamber is controlled at 2700Pa, the temperature of the initiator container is controlled at room temperature, the DC power supply current of the reactant monomer inlet device is adjusted to 0.60A, and the voltage is 7.5V; the temperature of the reactant monomer water bath heating device is controlled at 81 ℃, adjust the DC power supply current of the electrothermal alloy wire heating system to 3.5A, the voltage to 18.0V, the temperature of the electrothermal all...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com