Method for preparing complex film of proton exchange film for fuel cell

A proton exchange membrane and fuel cell technology, applied in fuel cells, fuel cell parts, solid electrolyte fuel cells, etc., can solve the problems of composite membranes, difficulty in making compactness, etc., and achieve flexibility, mechanical strength, The effect of easy control of immersion amount and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: Cut a piece of 10×11cm 2 Polytetrafluoroethylene (PTFE) porous membrane with a thickness of 30 μm (SEM scanning electron micrographs are shown in the attached figure 1 ), soak in ethanol solution to remove organic matter on the surface. Then spread the PTFE porous membrane on a flat glass, Nafion (R) The solution was mixed with DMSO at a ratio of 1:8 (volume), and 17.6 g of the solution was dropped onto the surface of the porous membrane. Put it on a 50°C hot stage, and after 1 hour, the temperature is raised to 75°C, and after 1 hour, the temperature is raised to 120°C. Take it off the hot table, put it in a vacuum oven at 100°C for 12 hours, cool it down to room temperature and take it out to get Nafion (R) / PTFE composite membrane (film thickness 45μm). Put it into double distilled water, take out the membrane, and save it in deionized water for later use.

[0034] Porous gas diffusion electrodes were prepared using carbon paper, polytetrafluoroethyl...

Embodiment 2

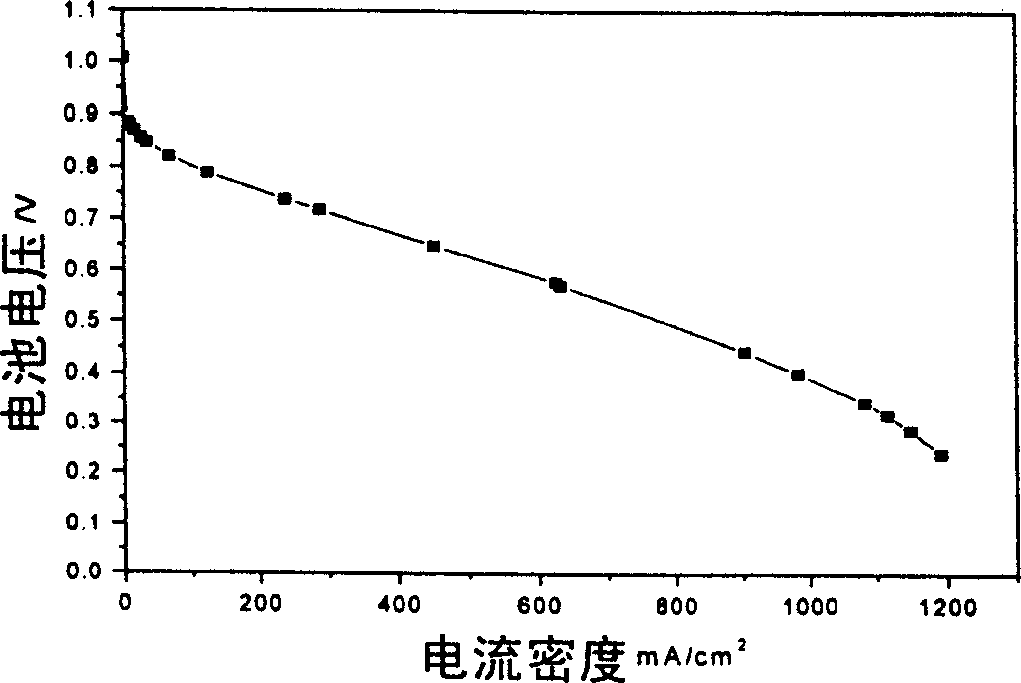

[0037] Embodiment 2: Prepare perfluorosulfonic acid Nafion by using the method of Example 1 (R) / PTFE composite membrane and membrane electrode three-in-one, PTFE porous membrane adopts 15μm thick film (10×11cm 2 ), its SEM photo is shown in the attached image 3 . in Nafion (R) DMF was added to the solution at a ratio of 1:8 (volume ratio). 28 g of the mixed solution was added dropwise on the surface of the porous membrane. The prepared composite film was placed in a vacuum oven at 150°C overnight. Preparation of Nafion (R) The thickness of the / PTFE composite membrane is 70 μm, and the membrane electrode three-in-one is prepared by hot pressing this membrane. The assembled PEMFC was tested for battery performance on a single-cell evaluation device. The polarization curve of the test battery is attached Figure 4 . The operating conditions of the battery are the same as in Example 1.

Embodiment 3

[0038] Embodiment 3: Use the mixed solvent of low molecular weight alcohols and water to dissolve perfluorosulfonic acid Nafion in a closed reactor (R) Membrane corner material, made of Nafion (R) solution. With this solution, adopt example 1 method to prepare perfluorosulfonic acid composite membrane and membrane electrode three-in-one, PTFE porous membrane adopts 15 μ m thick film (10 * 11cm 2 ), its SEM photo is shown in the attached image 3 . in Nafion (R) DMAC was added to the solution at a ratio of 1:8 (volume ratio). 14.6 g of the mixed solution was added dropwise on the surface of the porous membrane. The prepared composite film was placed in a vacuum oven at 200°C overnight. Preparation of Nafion (R) The thickness of the / PTFE composite membrane is 25 μm, and the membrane electrode three-in-one is prepared by hot pressing this membrane. The assembled PEMFC was tested for battery performance on a single-cell evaluation device. The polarization curve of the te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com