Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

55results about How to "Close the loop" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

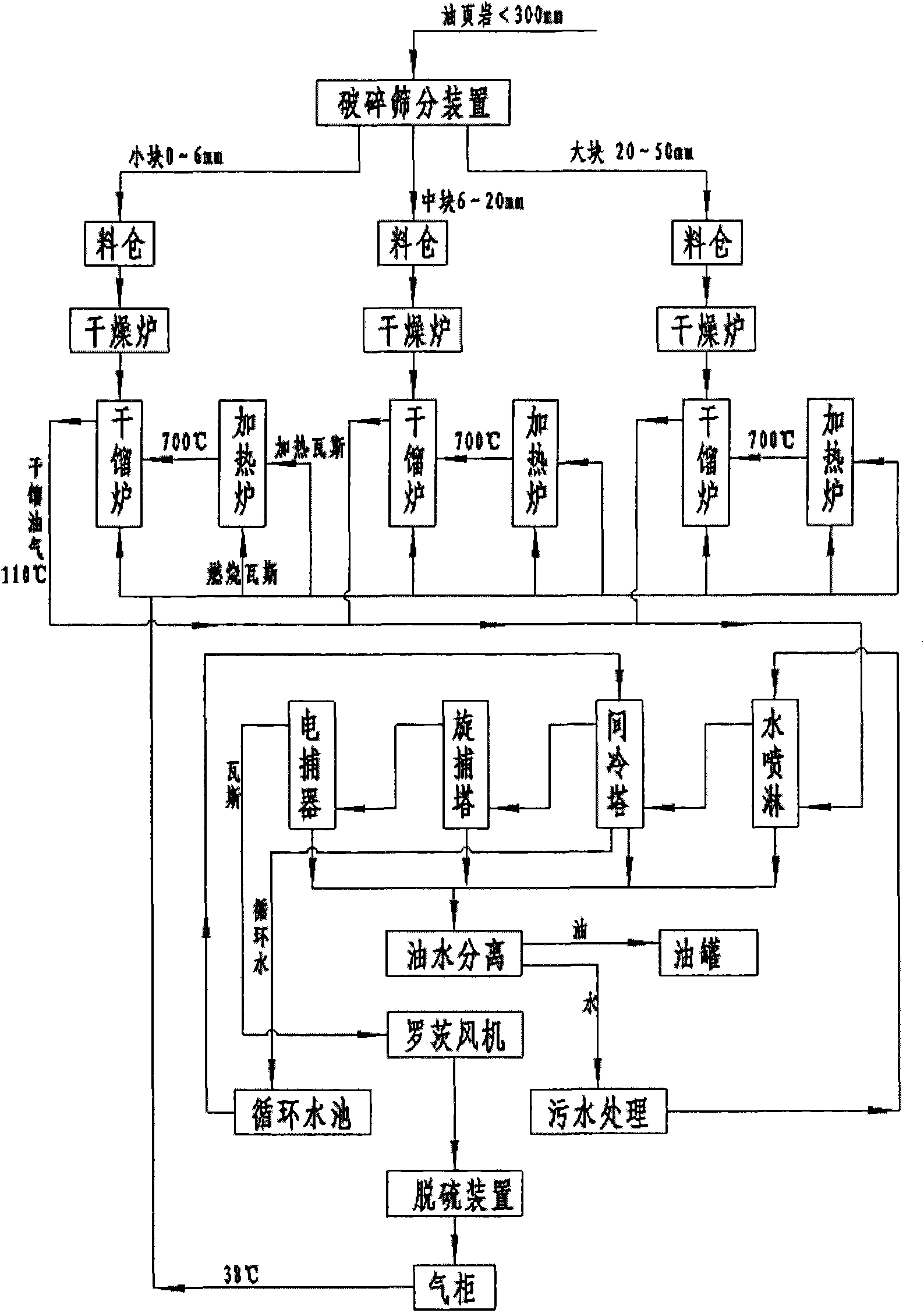

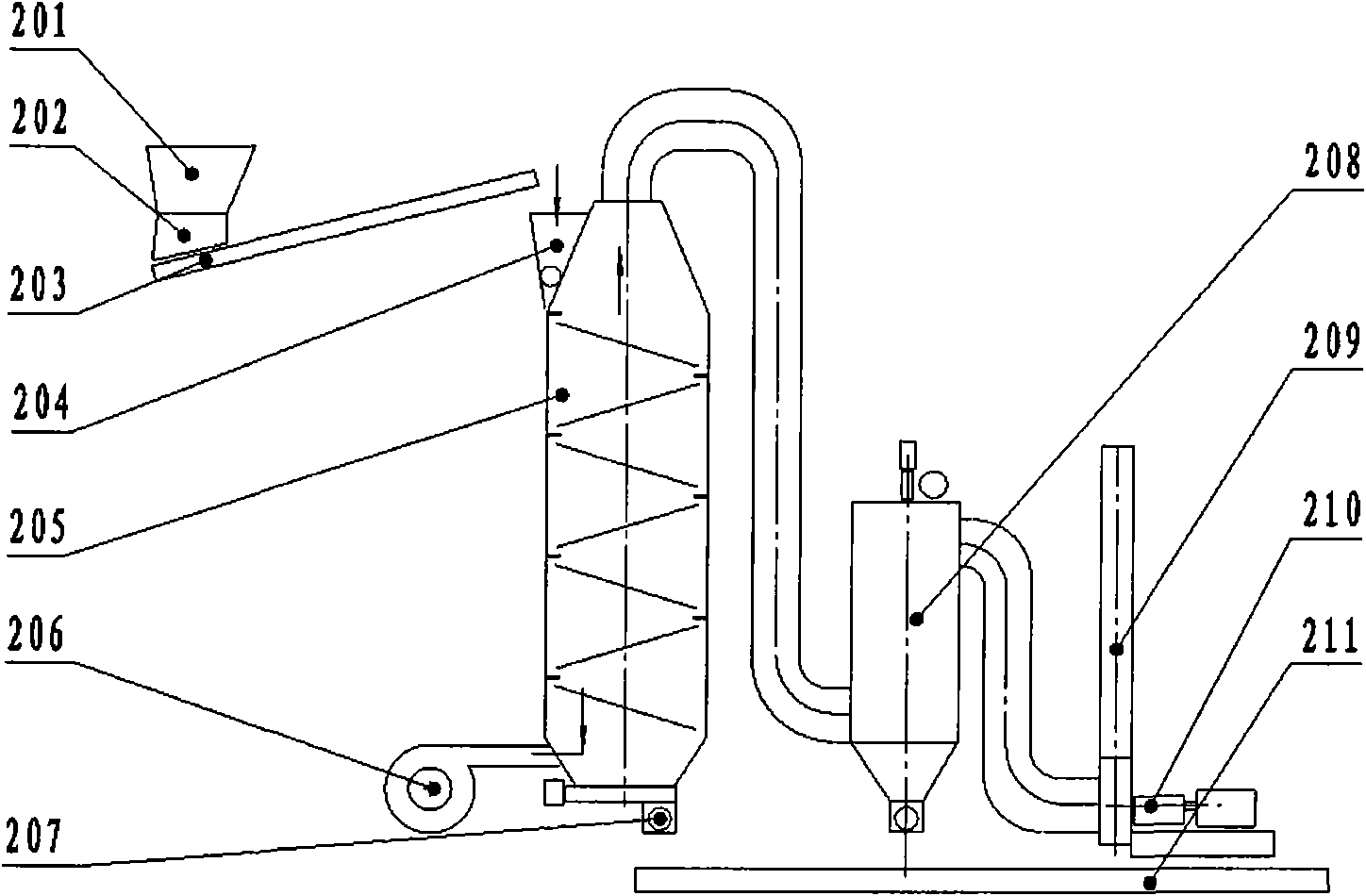

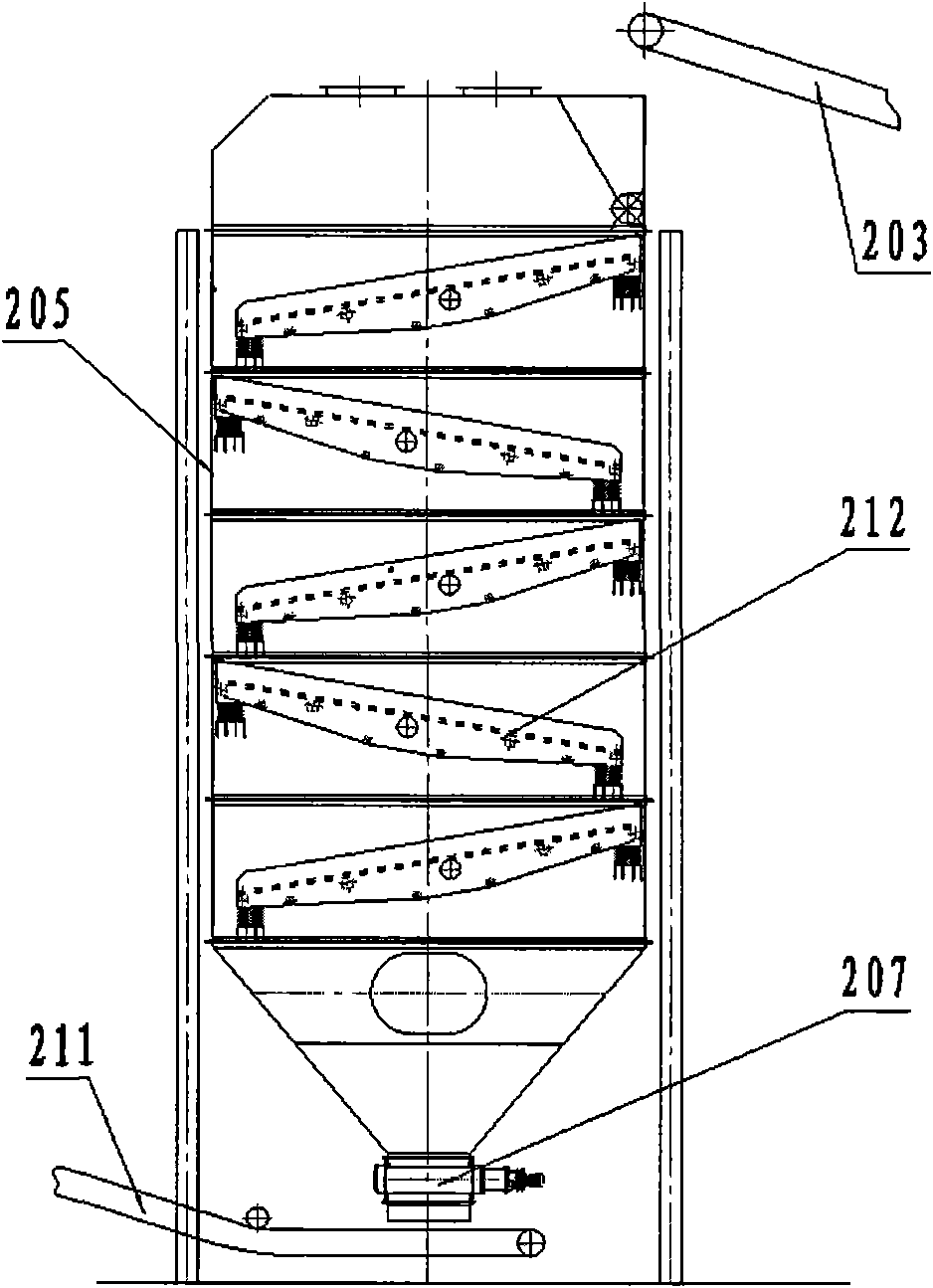

Huadian type process and device for dry distillation of oil shale

ActiveCN101942313AGuaranteed to be heatedGuaranteed temperature requirementsDirect heating destructive distillationCombustible gas purificationHeat carrierCooling tower

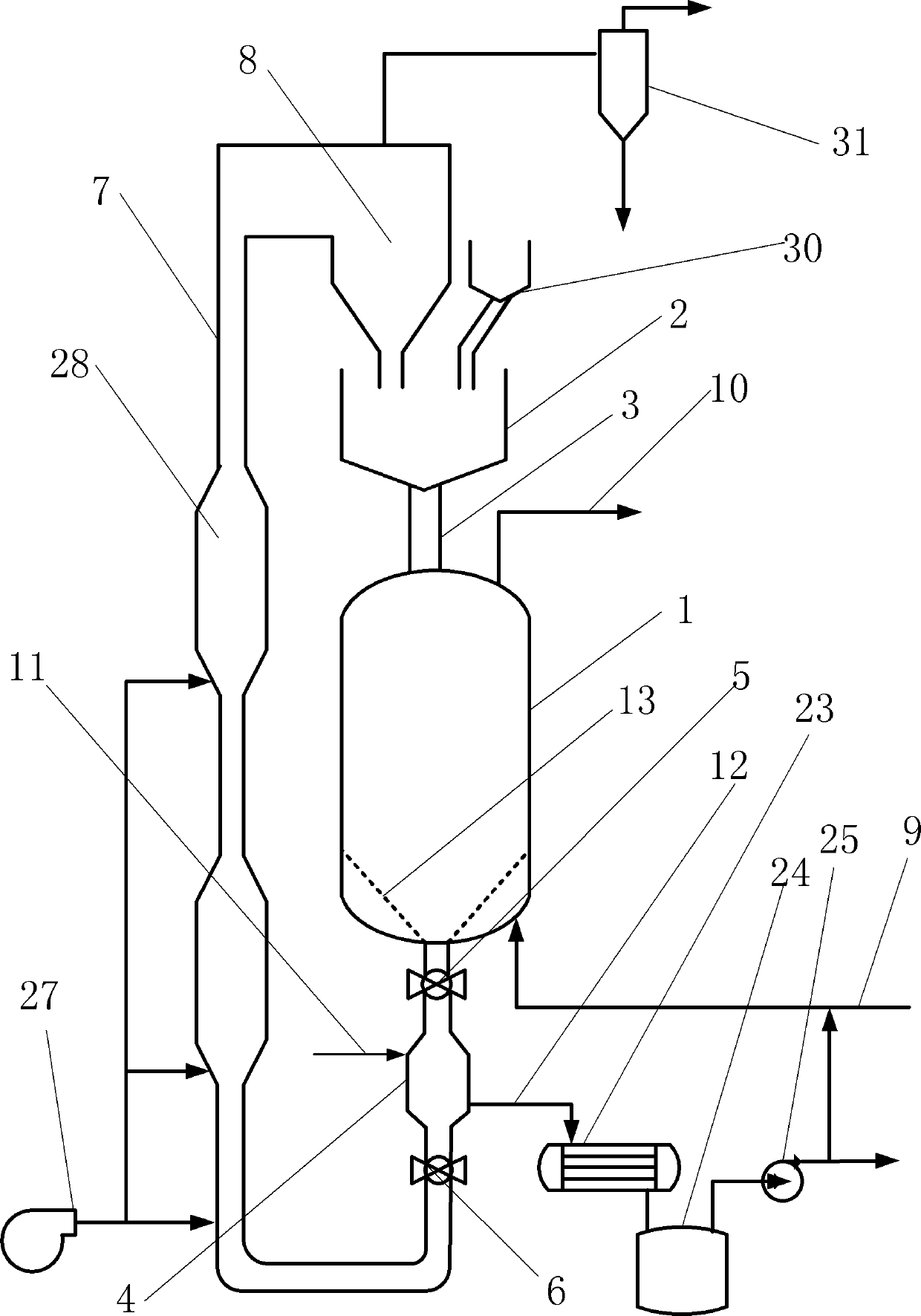

The invention provides a process and device for carrying out stage dry distillation on oil shale under the state of full recycle, with the gas as the heat carrier. The oil shale is divided into three different sizes (such as 0-6mm, 6-20mm and 20-50mm) through crushing and screening, and the oil shale is firstly dried and heated to the temperature between 50 DEG C and 150 DEG C by the waste smoke exhausted from gas heating furnaces and then enters into the different sizes of furnaces for dry distillation to undergo dry distillation. After being treated by water spraying and an indirect cooling tower, a rotary trapper and an electric trapper for oil collection, the dry distillation oil and gas undergo oil-gas-water separation, and after separation, the oil enters into a storage tank, the water enters into a circulating water tank and the first part of gases serves as the heat carrier and is recycled, the second part of gases is used as the fuels for the heating furnaces and the third part of gases is used as the fuel gases for power generation.

Owner:辽宁成大能源科技有限公司

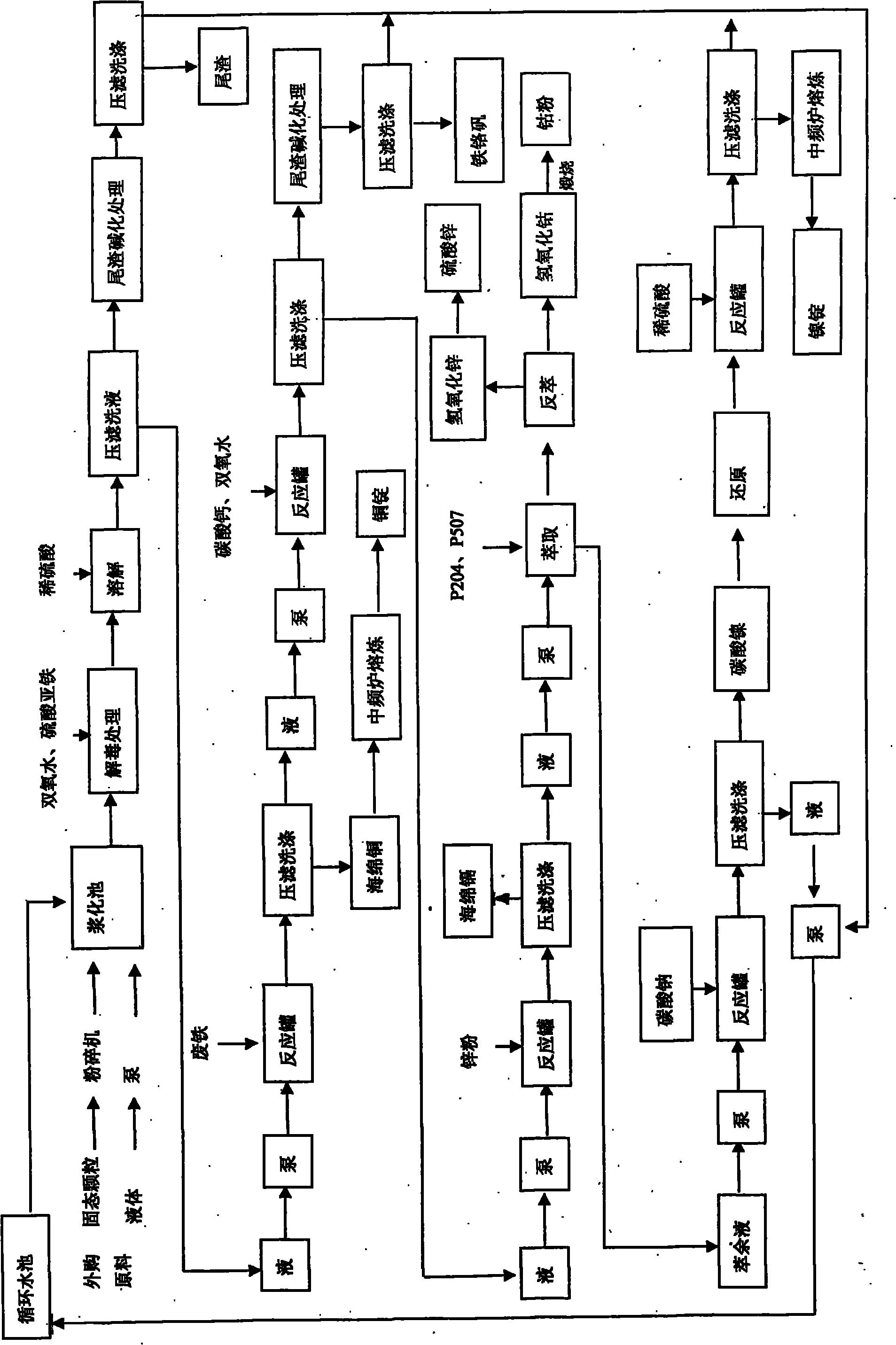

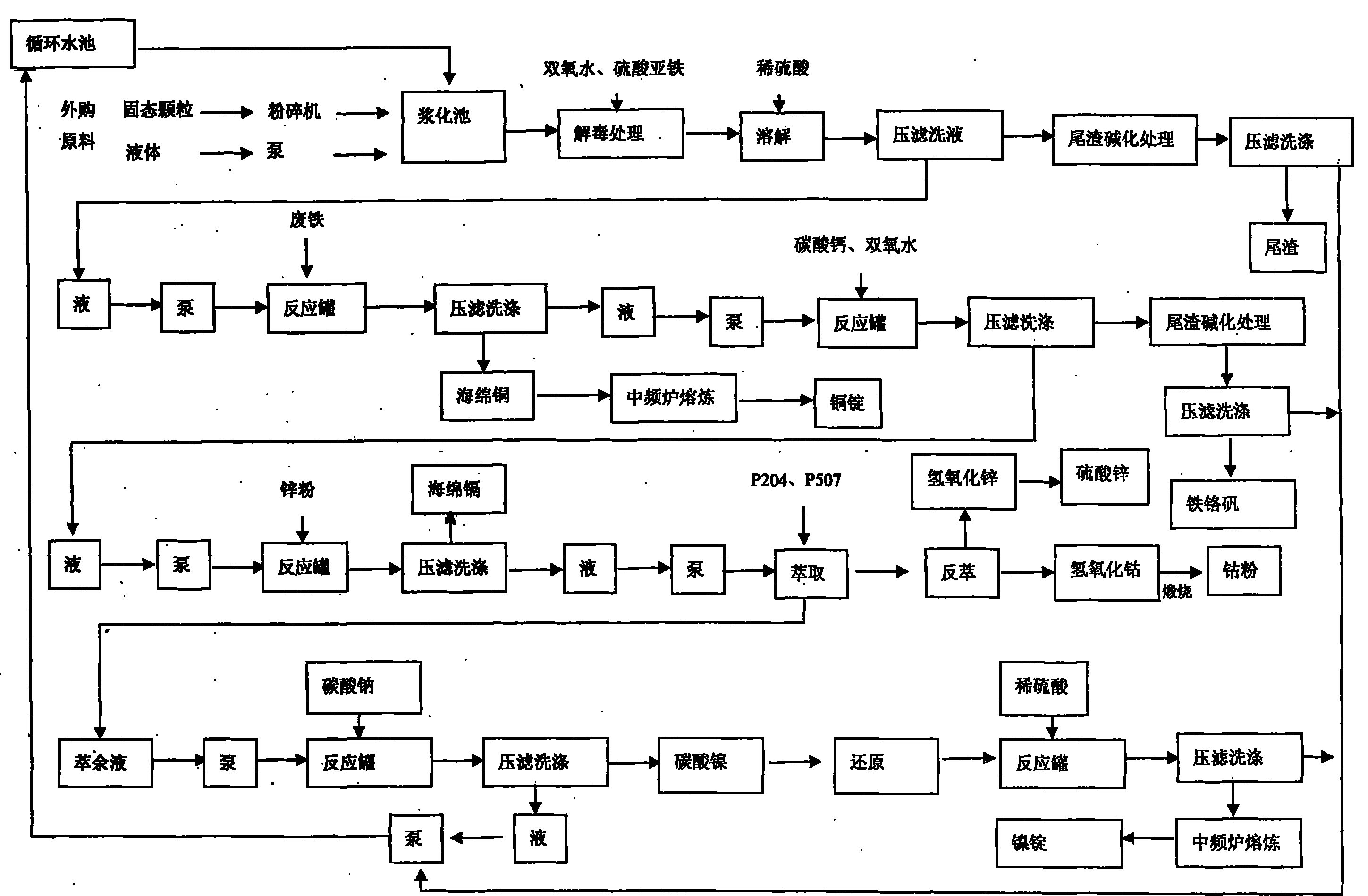

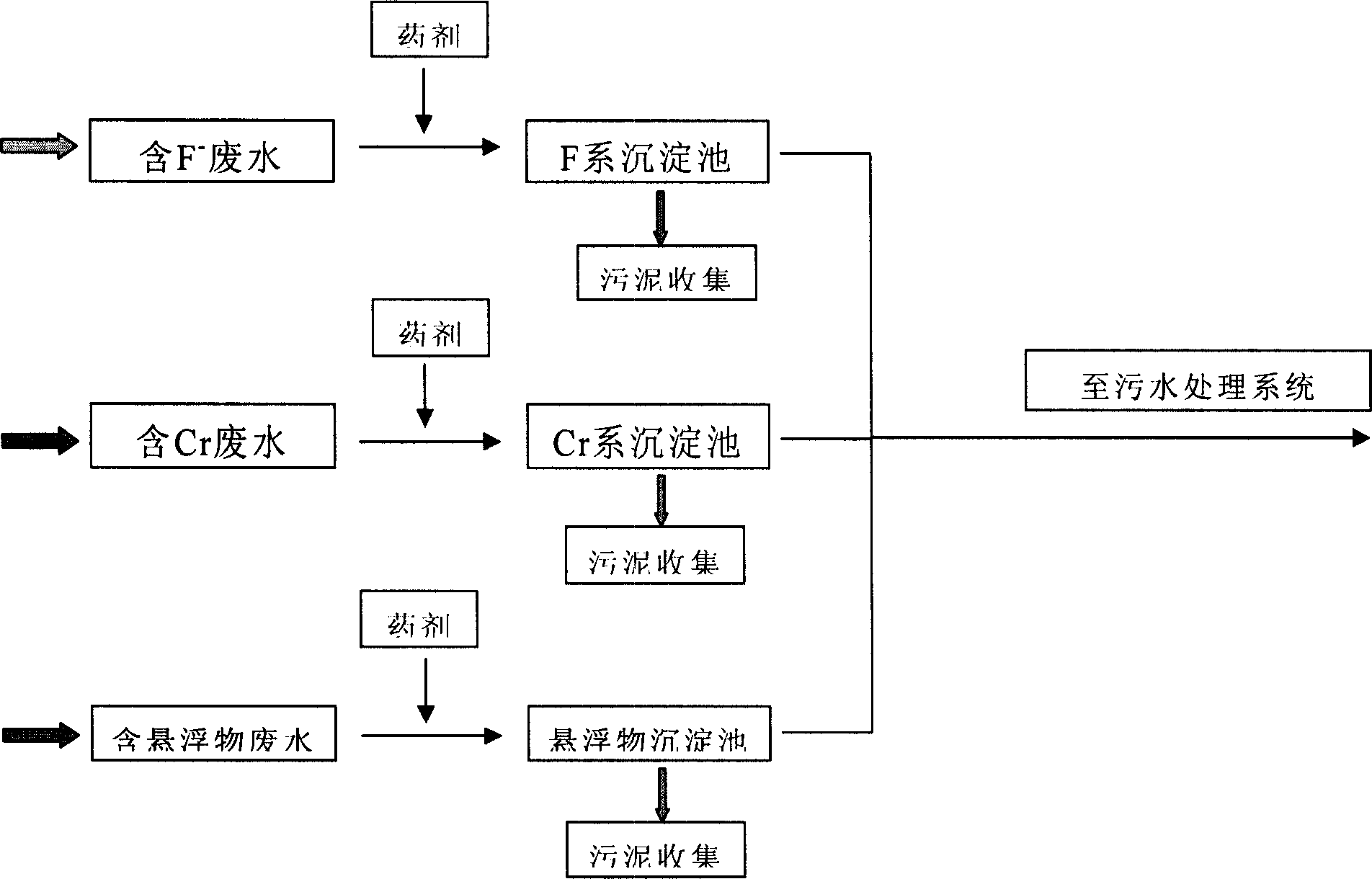

Method for recycling heavy metal pollution wastes

InactiveCN101871046AWide process adaptabilityRealize the purpose of resource utilizationProcess efficiency improvementChemistryCopper

The invention discloses a method for recycling heavy metal pollution wastes, which comprises the following steps of: 1) the pulping of raw materials; 2) acid leaching, namely, adding pulp obtained in the step 1 into a dilute sulphuric acid for filtration, and taking filter residues as the raw materials of bricks or cement; 3) copper displacement, namely, displacing copper out of filtrate in the step 2 with iron; 4) the preparation of ferrum-chrome-alum, namely, adding alkaline substances and an oxidant into the filtrate obtained in the step 3, adjusting a PH value, and precipitating and filter-pressing the mixed solution to obtain the ferrum-chrome-alum; and 5) the preparation of sponge cadmium, namely, displacing cadmium out of the filtrate obtained in the step 4 with zinc. The process has the advantages of suitability for the treatment of waste residues and waste liquor in a plurality of industries of electroplating, surface treatment, heavy metal smelting, chemical engineering and the like, no need of heating liquid-phase materials, the realization of closed cycle, and the capacity of extracting a plurality of valuable metals, such as Cu, Cr, Cd, Ni, Co, Zn and the like, directly taking the wastes obtained after the metal separation as the raw materials of the bricks or cement, and saving coal and electricity amounting to 20,000 T standard coal and 40,000-ton water per year for enterprises recycling 5,000-ton metals per year.

Owner:青川县天运金属开发有限公司

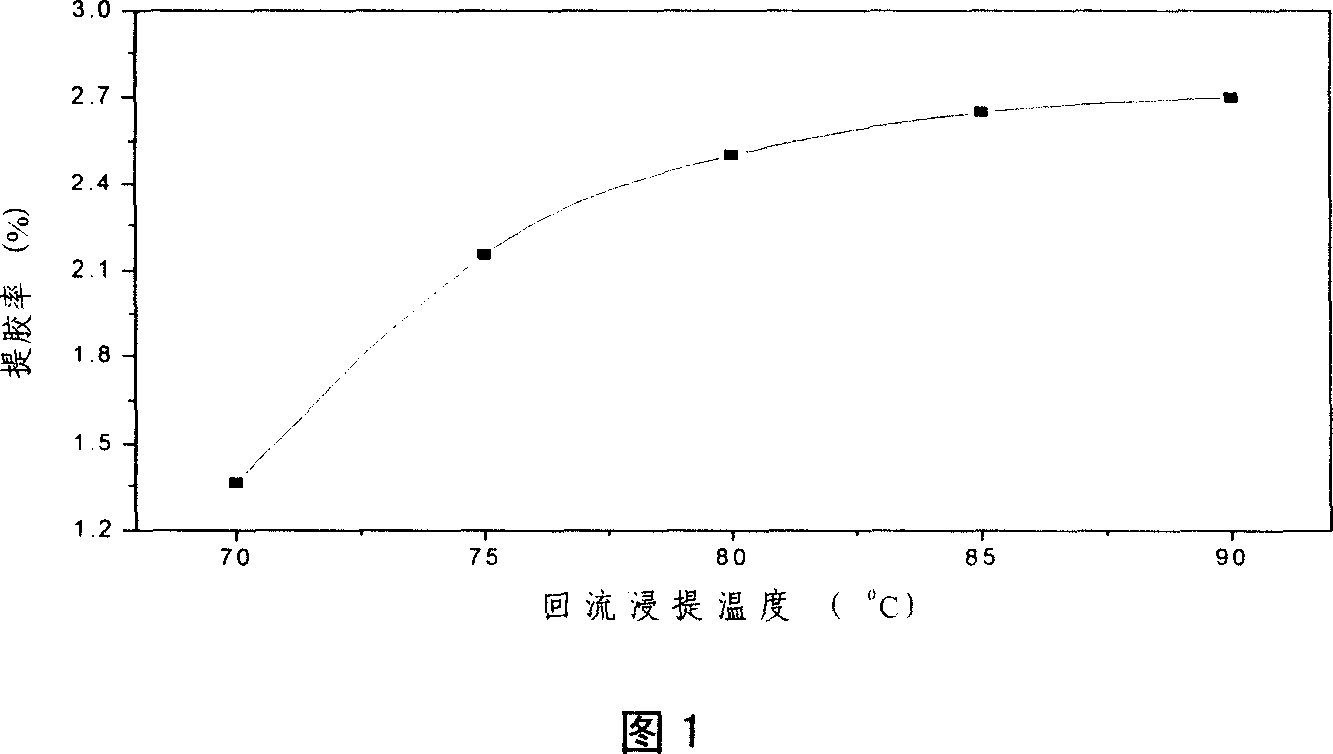

Method of extracting gutta percha by solvent circulation

This invention provides a solvent circulate extraction of gutta percha, and the ligarine is used for extraction of gutta percha from folium eucommiae or skin eucommiae. Its craft includes: (1)The raw material is through circulation drying in baking oven, and then shatterred by crusher, cribration. (2)The ligarine is added in accordance with dosage liquor ratio, refluxing in hot bath water. (3)Filtering as hot as possible, segregating its dregs and collecting the filtrate. (4)The filtrate is filtered after water cooling and hypothermy cold storage to reclaim gutta percha solid and filtrate separately. (5)The filtrate degelatinized mixes again with dregs, and then refluxing. (6)Crude product is obtained by combining gutta percha after conducting repetitive operation twice. (7)The ligarine reclaimed still can be used for extraction of gutta percha.

Owner:GUIZHOU UNIV

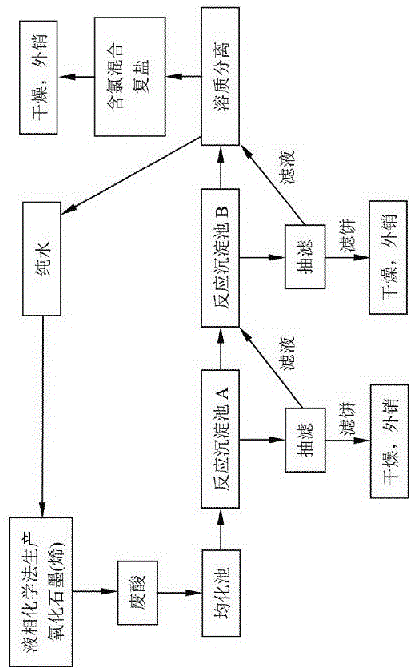

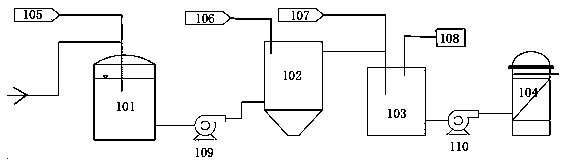

Recycling method for waste acid generated during preparation of graphite oxide through liquid-phase chemical method

ActiveCN106396227ASimple procedureEasy to operateCalcium/strontium/barium sulfatesTreatment involving filtrationManganese oxideGypsum

The invention provides a recycling method for waste acid generated during the preparation of graphite oxide through the liquid-phase chemical method. The method comprises the steps of homogenizing the waste acid: pumping the waste acid into a homogenization tank by an acid-resistant pump to homogenize the waste acid; recycling sulfate: adding a precipitant in the homogenization tank according to the molar weight of sulfate ions in the waste acid, conducting the stirring reaction and recycling gypsum (CaSO4*2H2O); recycling manganese ions: adding an inorganic base to adjust the pH value so as to form a manganese hydroxide, then adding an oxidant to react with the manganese hydroxide so as to form a manganese oxide, recycling the manganese hydroxide / manganese oxide or the mixture of the manganese hydroxide and the manganese oxide; conducting the separation and purification operation; recycling chloride ions; and recycling the water. Conventional methods for preparing graphene are mainly divided into physical methods and chemical methods. The physical methods are composed of a micro-mechanical stripping method, a high-energy ball milling method and the like. The above methods are low in yield and are not suitable for large scale production. The method of the present invention is applied to the clean production of graphite oxide and the comprehensive utilization of waste acid resources.

Owner:HARBIN UNIV OF SCI & TECH

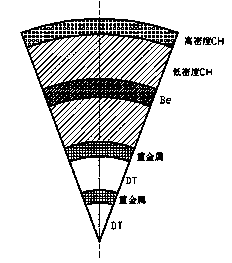

Z-pinch driven fusion-fission hybrid energy reactor

InactiveCN104240772AReasonable designGuarantee continuous and stable operationNuclear energy generationThermonuclear fusion reactorFusion fissionNuclear engineering

The invention discloses a Z-pinch driven fusion-fission hybrid energy reactor. The Z-pinch driven fusion-fission hybrid energy reactor comprises a Z-pinch inertial confinement fusion reactor core, a subcritical fission cladding and energy output system, and a tritium production cladding and deuterium-tritium circulation system. The fusion reactor core comprises a fusion load, fusion targets, a fusion driver and a fusion target chamber supporting continuous operation of fusion. The subcritical fission cladding and energy output system comprises a subcritical cladding, a cooling loop, a steam generator and a voltage stabilizer. The tritium production cladding and deuterium-tritium circulation system comprises a tritium production cladding, a reactor core residual tritium recovery system and an out-of-reactor tritium factory. According to the Z-pinch driven fusion-fission hybrid energy reactor, the inertial confinement fusion reactor core scheme based on the integrated ignition technology is high in realizability and reliable in performance, depleted uranium and thorium can be fully utilized, and therefore the fission resource utilization efficiency is improved; the whole fusion-fission hybrid energy reactor is reasonable and balanced in design, the subcritical cladding is driven through the Z-pinch fusion reactor core, and long-term sufficient clean electrical energy can be provided.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

Dechlorination method of zinc sulfate solution

InactiveCN103572051AHigh efficiency removalExpand sourceProcess efficiency improvementEthyl ChlorideCuprous chloride

The invention discloses a dechlorination method of a zinc sulfate solution, which comprises the steps that sulfuric acid is added to a zinc sulfate solution containing 100-150g / L zinc and 0.5-5.0g / L chlorine; an acid solution with the sulfuric acid concentration of 20-75g / L is obtained; the acid solution is subjected to selective electrodialysis in four diaphragm electrolytic cells at a room temperature and at the current density of 50-200A / m<2>; a low-chlorine solution containing 0.1-0.3g / L chlorine and a high-chlorine solution containing 5-20g / L chlorine are obtained; the low-chlorine solution is used for producing electric zinc; the high-chlorine solution is subjected to chlorine precipitation by a cuprous chloride method; a chlorine precipitation solution containing 0.4-1.0g / L chlorine is obtained; zinc powder is added to the chlorine precipitation solution for replacing and removing copper; a copper removal solution containing 0.4-1.0g / L chlorine is produced; the copper removal solution is returned for acid addition, and subjected to the selective electrodialysis. With the adoption of the method, chloride ions in the zinc sulfate solution can be removed at low cost and high efficiency.

Owner:吴鋆

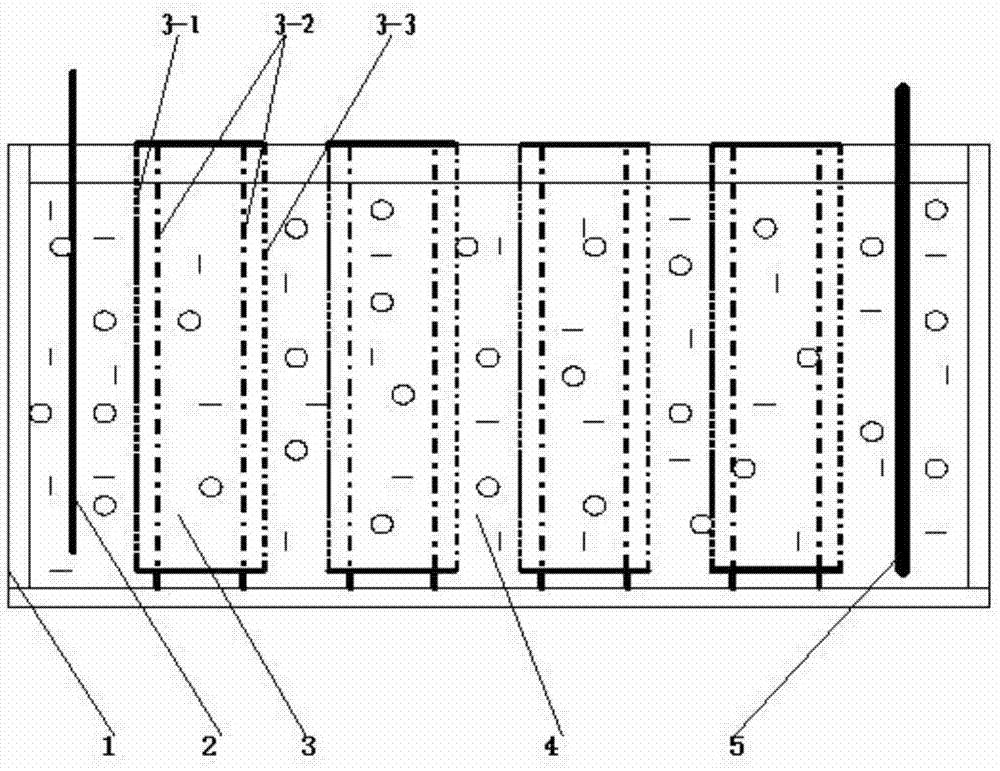

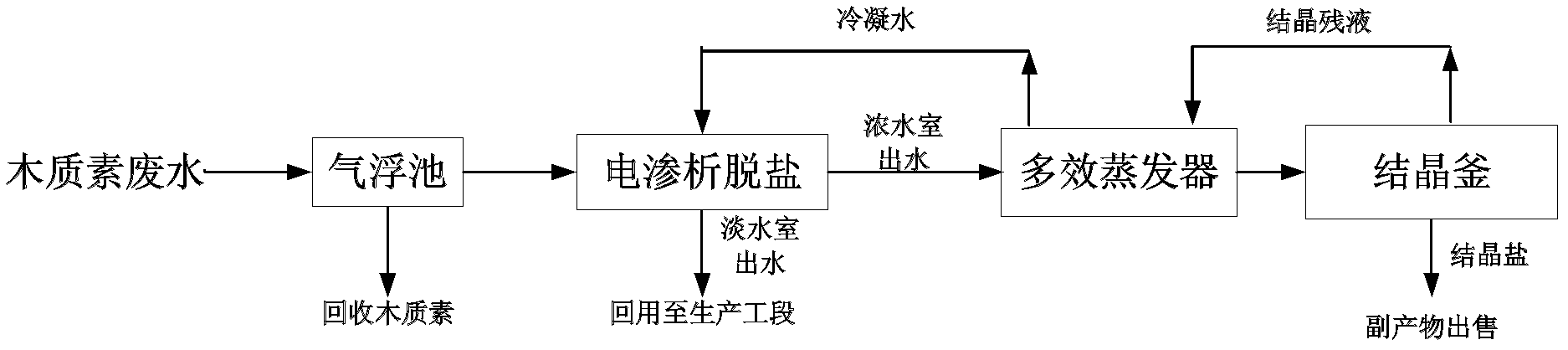

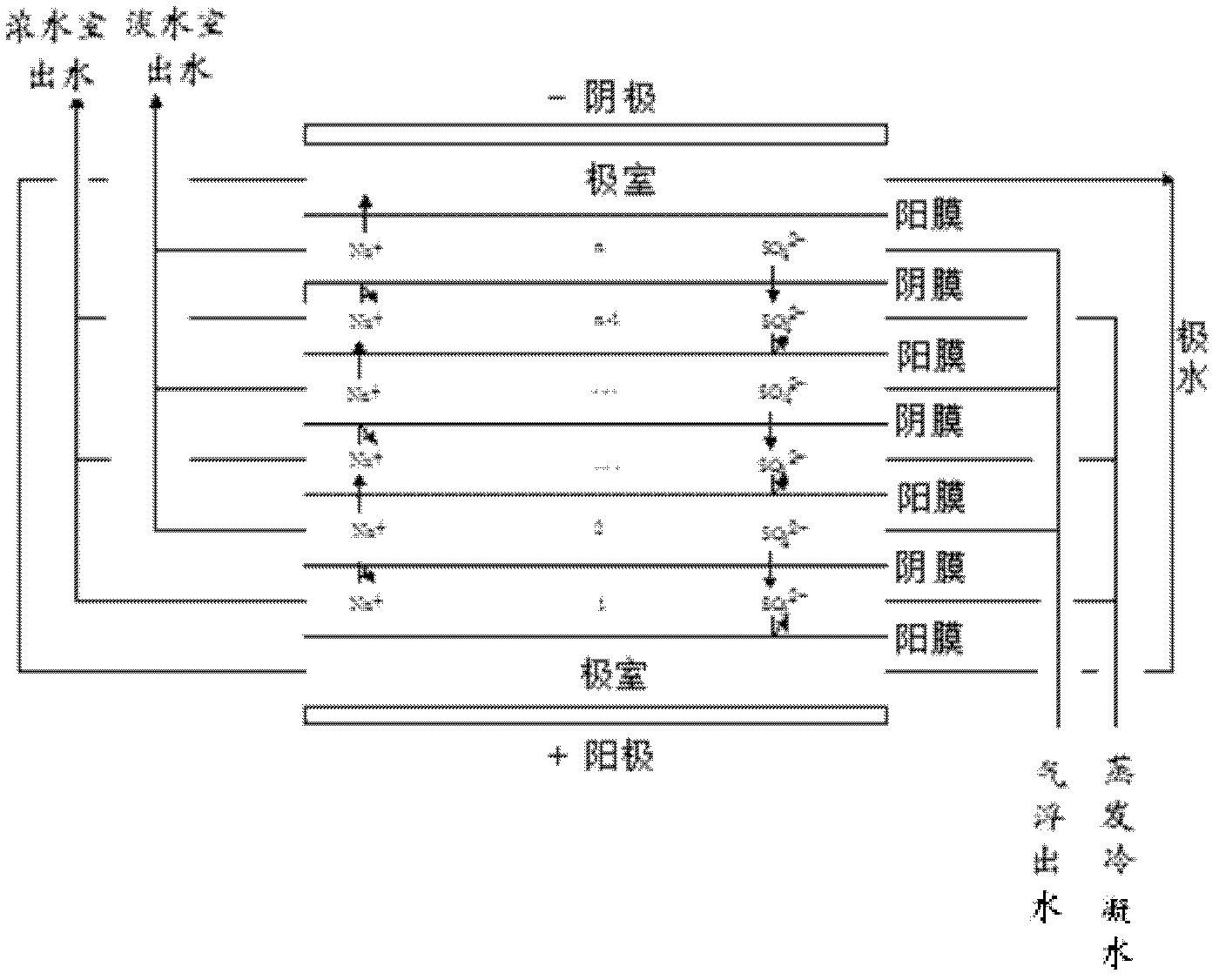

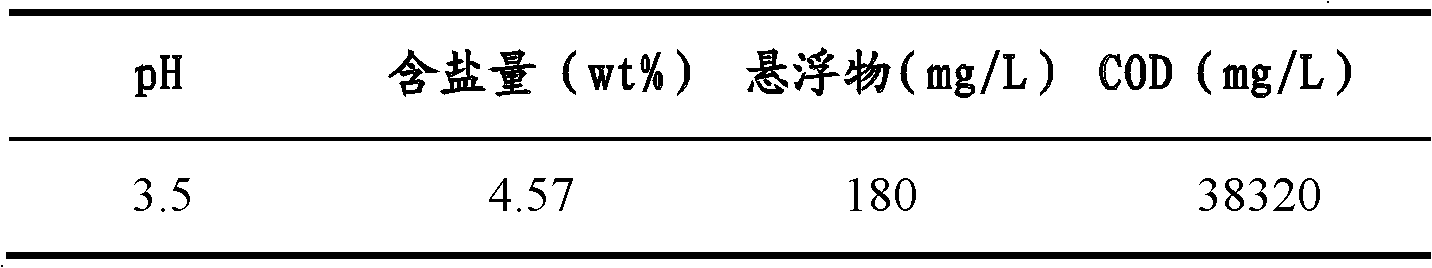

Treatment method of lignin production waste water

InactiveCN103172212AGuaranteed purityGuaranteed qualityGeneral water supply conservationDispersed particle separationElectricityInduced gas flotation

The invention relates to a treatment method of lignin production waste water, which comprises the following steps of: treating and recovering lignin residues in lignin waste water through a gas floatation method at first; respectively feeding gas floatation water and condensate water in a multi-effect evaporation stage into an electro-osmosis desalting device to obtain lignin waste water containing no salt basically and highly saline concentrated water; and recovering the lignin waste water containing no salt basically as supplementary water in the lignin production process, feeding the highly saline concentrated water into a multi-effect evaporation device to concentrate and crystallize, recovering the obtained evaporation condensate water in the electro-osmosis desalting device, and directly selling the obtained high-purity solid salt. Due to the process, resource recycling of waste water is realized; closed cycle of water is realized, so that the pollution abatement cost is reduced; organic combination of the electro-osmosis technology, multi-effect evaporation and the crystallization technology is sufficiently embodied; and the treatment method disclosed by the invention is a high-efficiency and economical treatment method.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

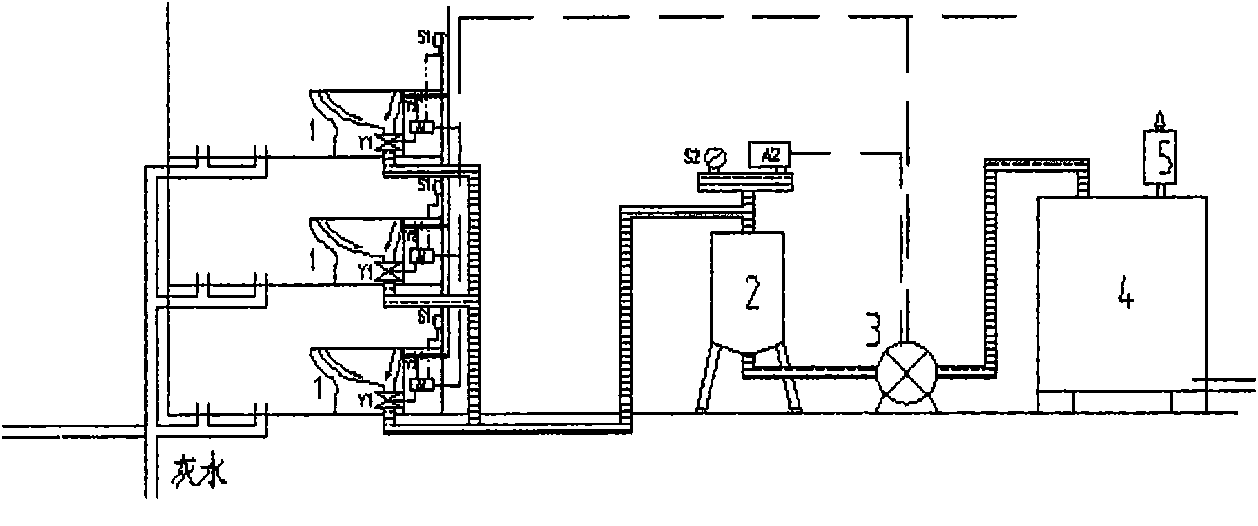

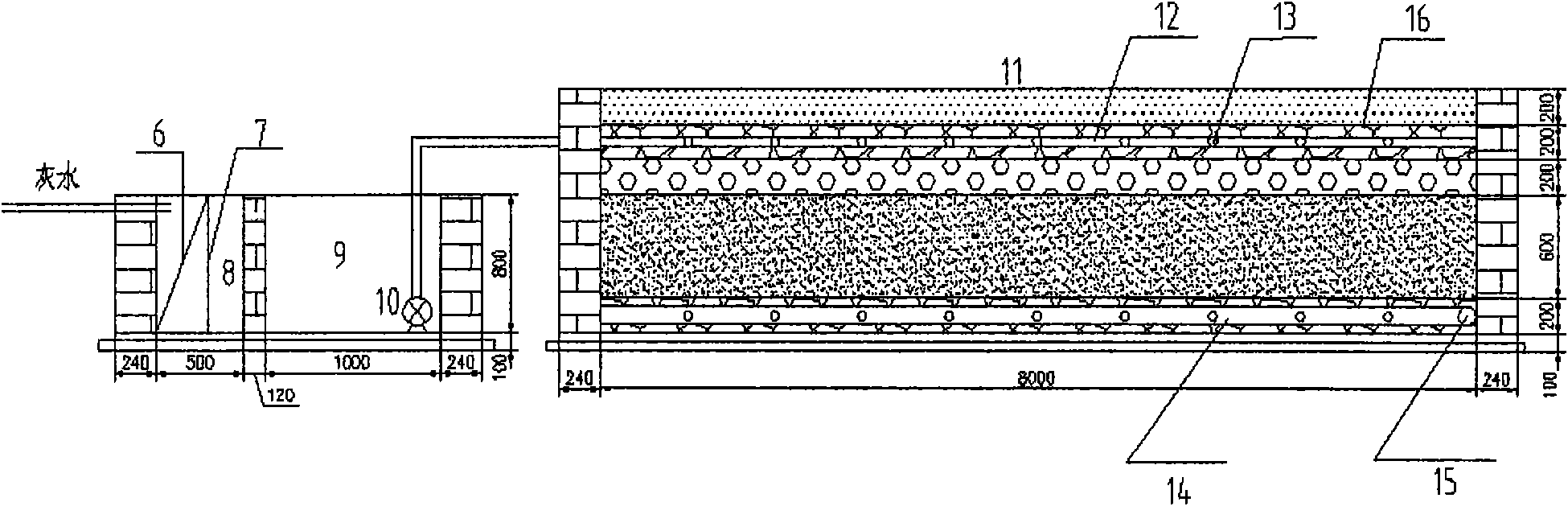

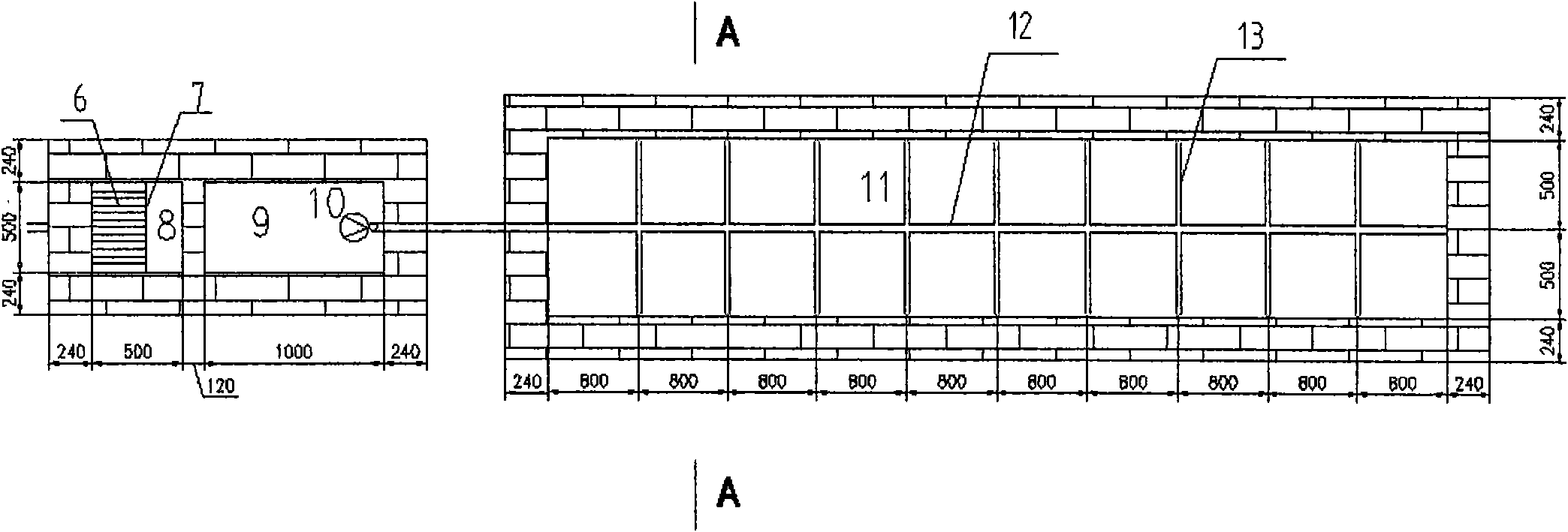

Distributed domestic sewage source separation treatment and reclamation method

InactiveCN101928093APollution controlClose the loopFatty/oily/floating substances removal devicesWater closetsCollection systemSmall footprint

The invention discloses a distributed domestic sewage source separation treatment and reclamation method, relating to the technology of environmental protection, wherein the method uses a black and gray water separation and collecting system, a black and gray water processing system, and a black and gray water reclamation use system. The technology of the black water system comprises the followings: black water, vacuum water-saving toilet, vacuum pump, vacuum tank, black water collecting box, fermentation, and reclamation; and the technology of the gray water system comprises the followings: gray water, pretreatment, land processing system, water discharge, and reuse. The method uses distributed domestic sewage to separate, process and recycle at the source, which can save water, solves the problem of random discharge of distributed domestic sewage in the town, improves the environment, and realizes the recycling use of domestic sewage; and the method has the advantages of low building cost, simple and convenient construction, small occupied area, low operation cost and simple maintenance, and has strong practical and popularization values.

Owner:GRADUATE SCHOOL OF THE CHINESE ACAD OF SCI GSCAS

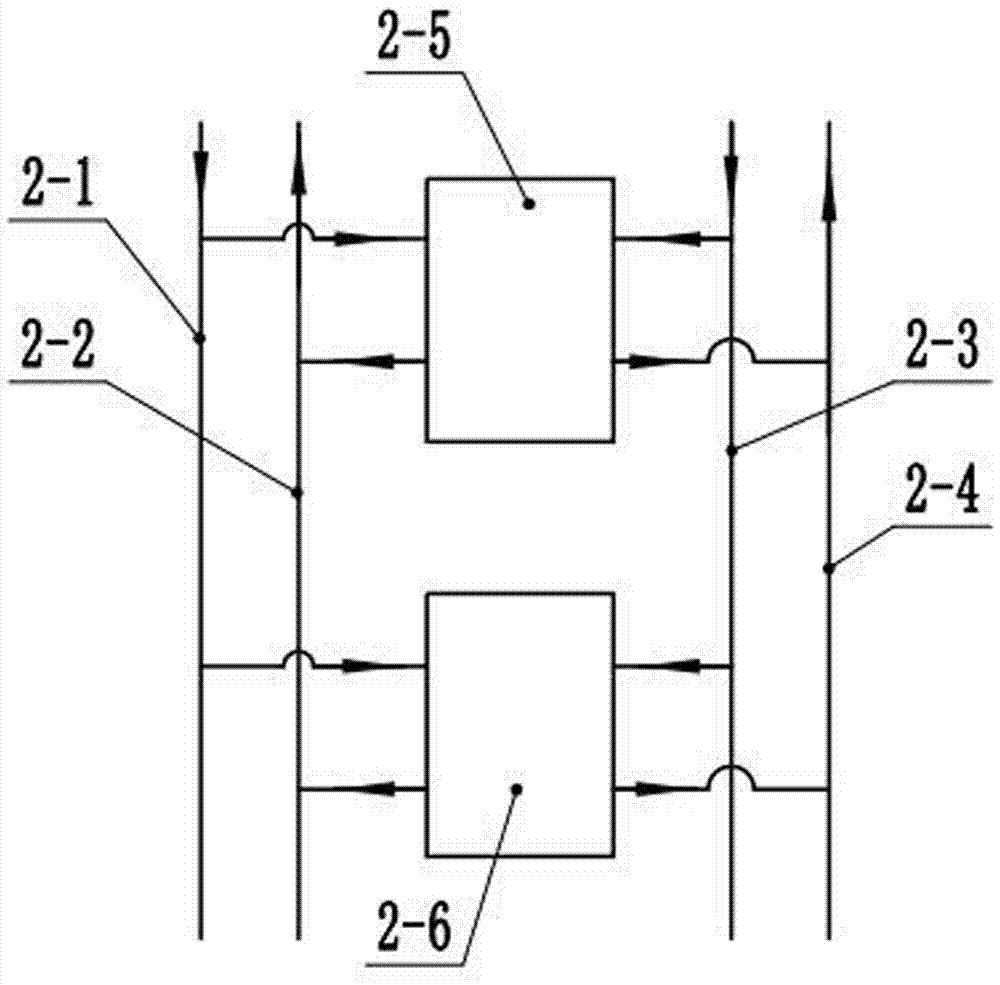

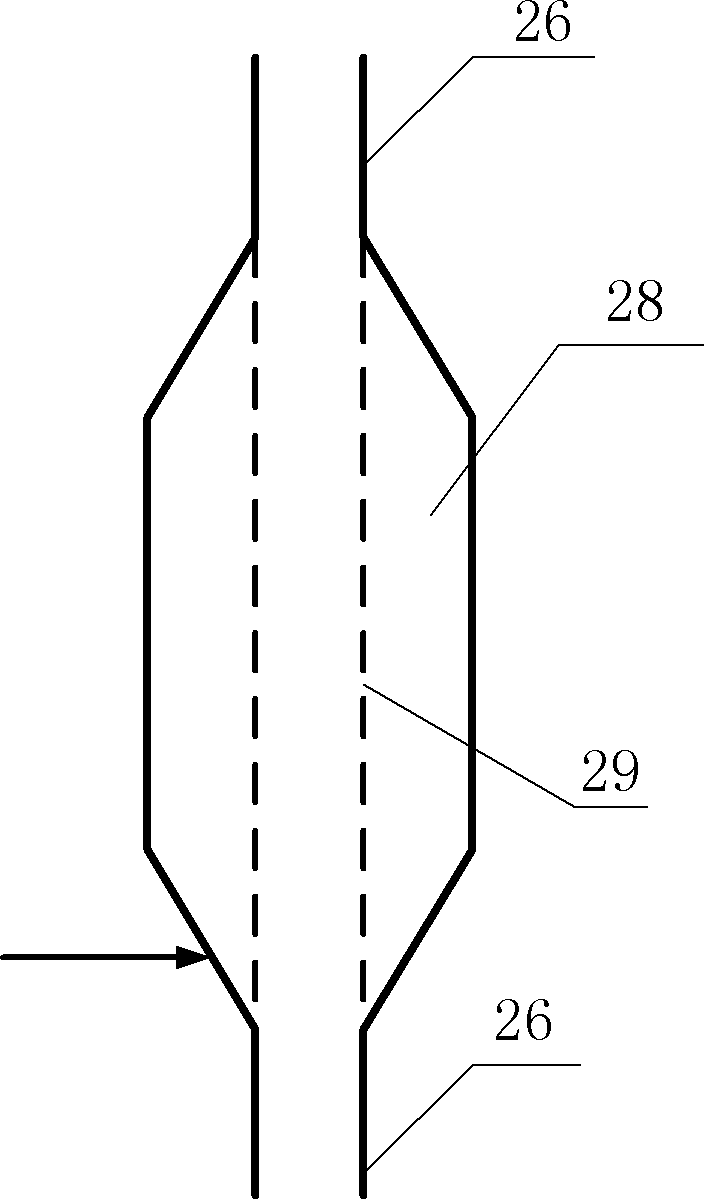

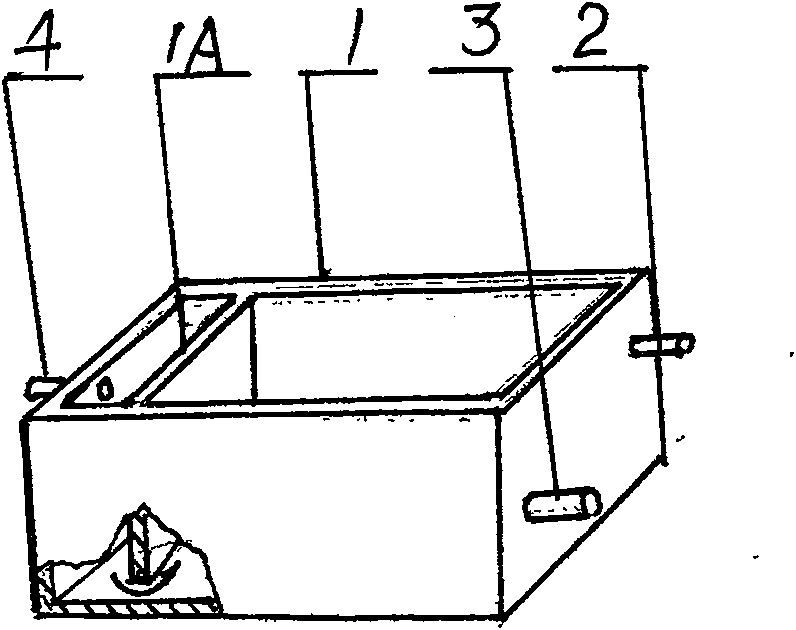

Processing method of wastewater in the sebacic acid production and special extractor thereof

ActiveCN101139148AEnergy savingReduce processing costsMultistage water/sewage treatmentWater/sewage treatment by neutralisationChemistryInterphase

The present invention relates to a wastewater treatment method of decanedioic acid production and special extraction plant. The method includes solid and liquor separation in a sedimentation pond, neutralization process pH value regulating, extracting agent extracting forbidden discharge matters and separation between the forbidden discharge matters and discharge water. The key scheme of the method is that a ricinoleic acid is adopted as the extracting agent to extract and separate the forbidden discharge matter hydroxybenzene in the wastewater of decanedioic acid production and the detail step of combined and repeat application of the extracting agent and the extractive matters is adopted. A matched special extraction plant is applied to carry through the operation of multilevel extracting forbidden discharge matters to realize the closed recycling of the forbidden discharge matters in a production system. The extraction plant consists of an extraction separation chamber, a compound emulsification pump arranged between two neighboring or interphase extraction separation chambers and a pipeline connected between the compound emulsification pump and the extraction separation chambers at two sizes that are arranged in order. An oil inlet of each matched compound emulsification pump is communicated with a fat phase exit of the back level extraction separation chamber. An inlet is communicated with a water phase exit of the front level extraction separation chamber. An exit of the compound emulsification is communicated with a fluid infusion opening extracted from a flow regulation chamber of the front level extraction separation chamber.

Owner:韩厚义

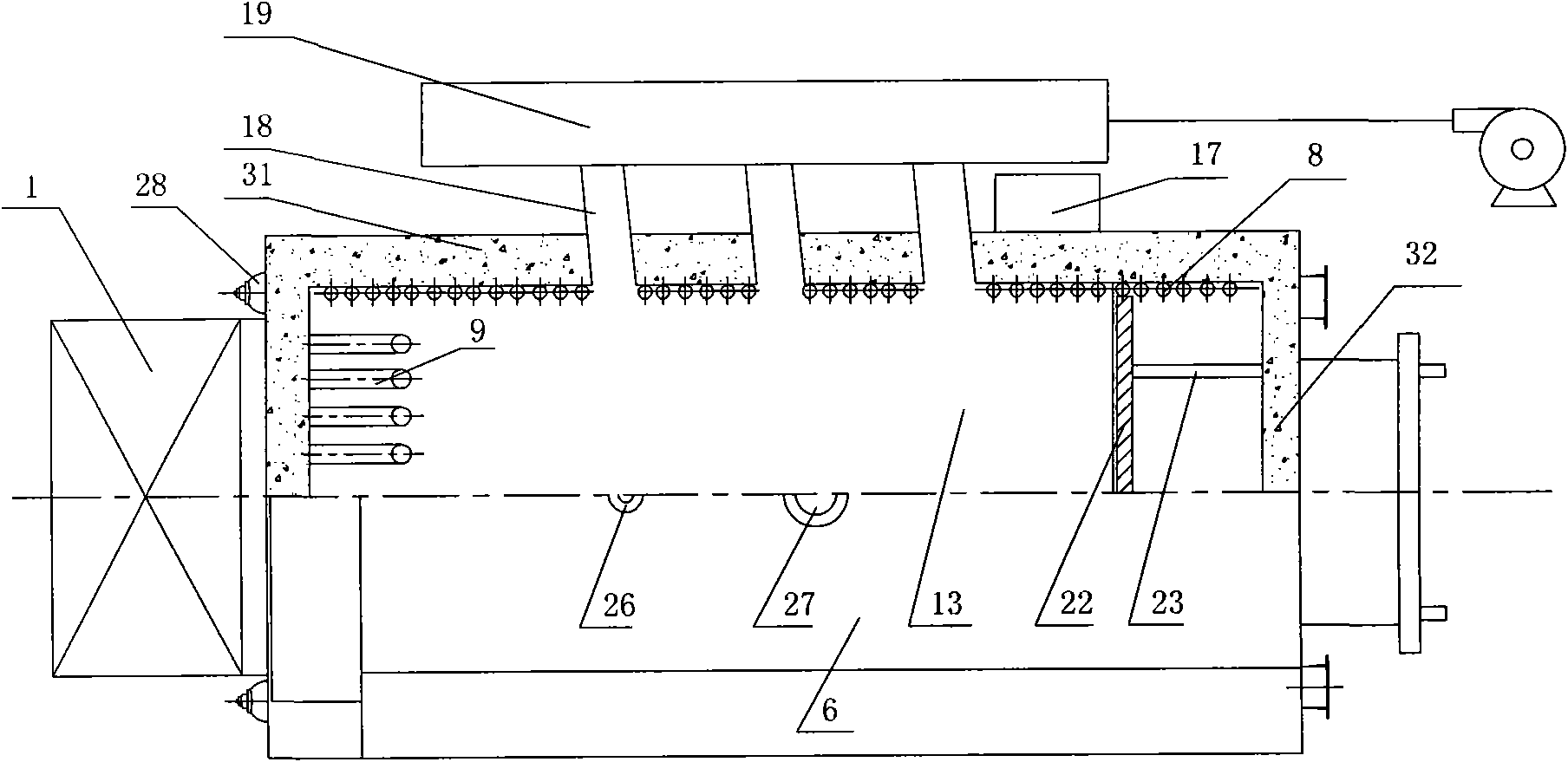

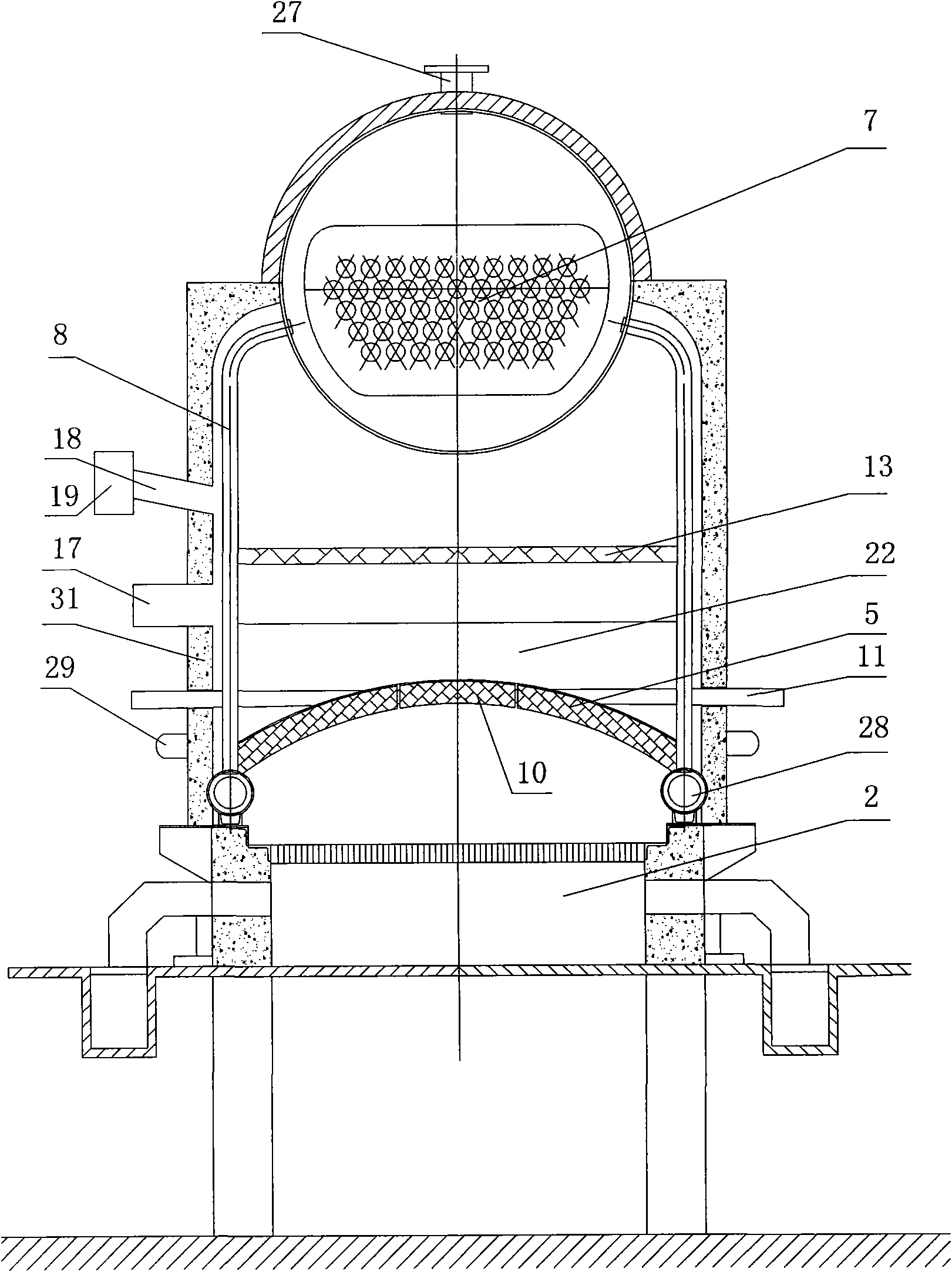

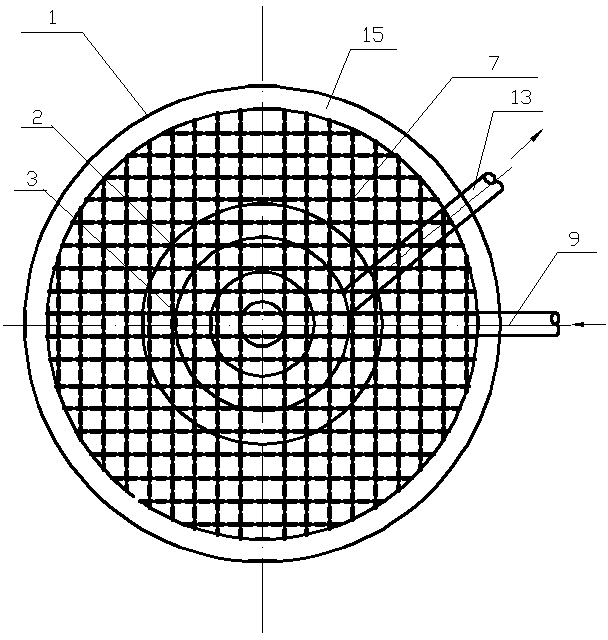

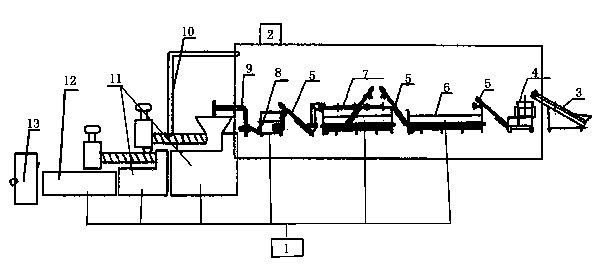

Industrial boiler for burning bio-briquettes

ActiveCN101818891AEfficient and stable combustionFast startupSolid fuel combustionCasings/liningsCombustion chamberEngineering

Owner:ZHEJIANG JINGUO BOILER

Aerobic granular sludge integrated sewage treating device and method

ActiveCN104310584ASimple structureEasy constructionBiological treatment apparatusTreatment with aerobic and anaerobic processesWater dischargeAeration system

An aerobic granular sludge integrated sewage treating device is disclosed. The device comprises a water feeding pipe, aeration systems and a sludge discharging perforated pipe. The device also comprises a cylindrical tank body. The center of the cylindrical tank body is provided with a cone reaction drum. The periphery of the cone reaction drum is provided with cylindrical separation plates. The cone reaction drum is the first reaction chamber. The space between the cone reaction drum and the cylindrical separation plates is the second reaction chamber. The space between the cylindrical separation plates and the cylindrical tank body is the third reaction chamber. Each reaction chamber is provided with a plurality of layers of mesh plates which are arranged horizontally. The bottom of the cone reaction drum is provided with a water-gas mixing short pipe. The water-gas mixing short pipe is connected to a gas feeding pipe. The lower end of the water-gas mixing short pipe is provided with a frustum cone-like water feeding cavity. The outlet of the water feeing pipe is horizontally arranged, is in the frustum cone-like water feeding cavity, and is provided with a nozzle. The lower end of the cylindrical tank body is provided with a cone. The bottom of the cone is connected to the sludge discharging perforated pipe. The top edge of the inner wall of the cylindrical tank body is provided with a water discharging groove. The device has characteristics of simple configuration, construction convenience, small occupied space, convenient running, good quality of discharged water, low manufacturing cost, and low running cost.

Owner:中国市政工程西北设计研究院有限公司

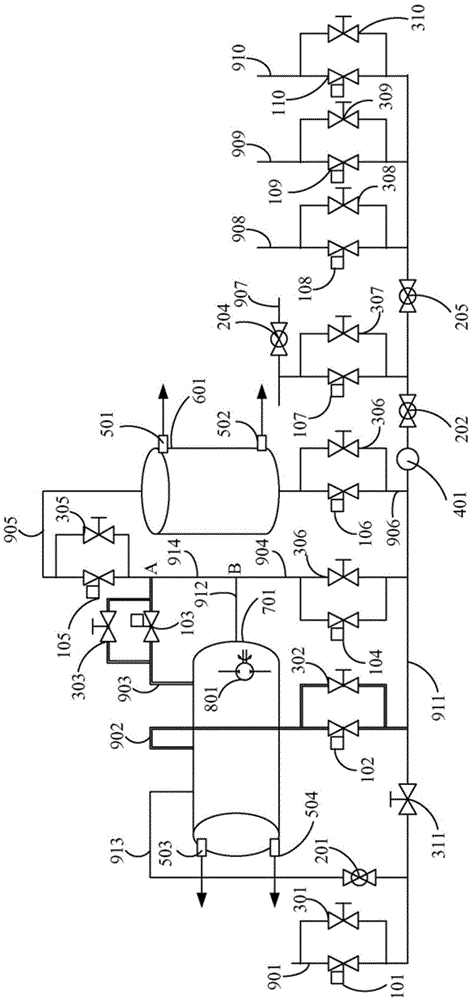

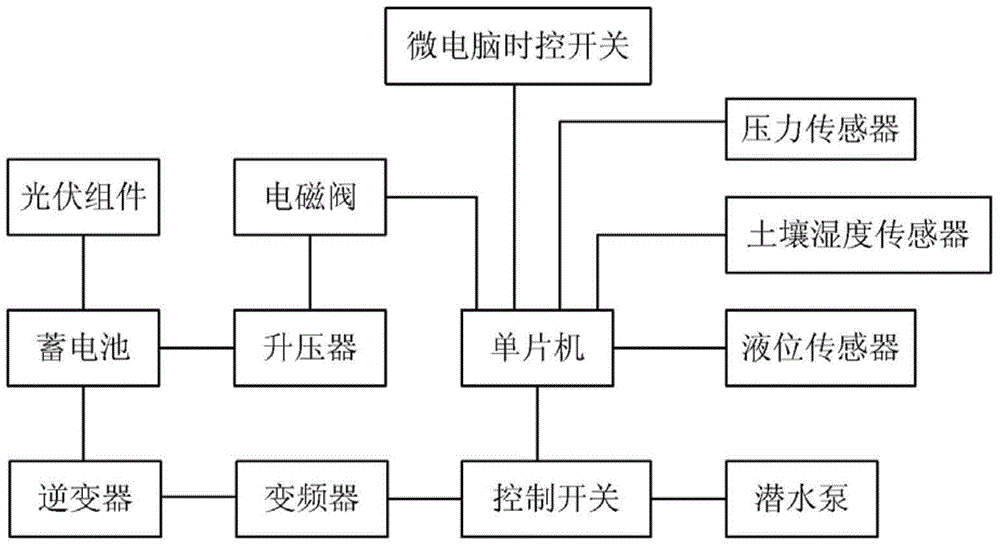

Photovoltaic time-controlled automatic irrigation system

InactiveCN104584990AReduce water consumptionImprove stabilitySelf-acting watering devicesWatering devicesSupply energyIrrigation

The invention discloses a photovoltaic time-controlled automatic irrigation system which comprises a photovoltaic device, an irrigation device, an irrigation pipeline, a switching assembly and a control device, wherein the photovoltaic device comprises a photovoltaic assembly, an accumulator, an inverter, a frequency converter and a voltage booster; the irrigation device comprises a water storage container; the irrigation pipeline is connected with an external water source and the water storage container, so as to irrigate; the switching assembly is arranged on the irrigation pipeline, and different water flow paths are formed in the irrigation pipeline by opening and closing the switching assembly; the control device comprises a controller and a microcomputer time-controlled switch, the controller is used for controlling the switching assembly to open or close, power is supplied to the irrigation device and the control device by the photovoltaic device, and the microcomputer time-controlled switch is connected to the controller, so as to control the irrigation device to start and stop in multiple time periods. According to the photovoltaic time-controlled automatic irrigation system, solar energy is reasonably utilized, and unattended operation, automatic energy supply, closed cycle and automatic irrigation of crops are realized.

Owner:INNER MONGOLIA KESHENG SOLAR ENERGY TECH

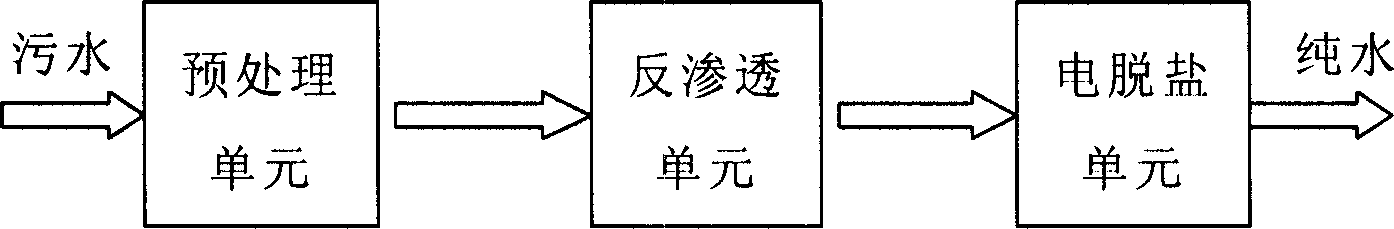

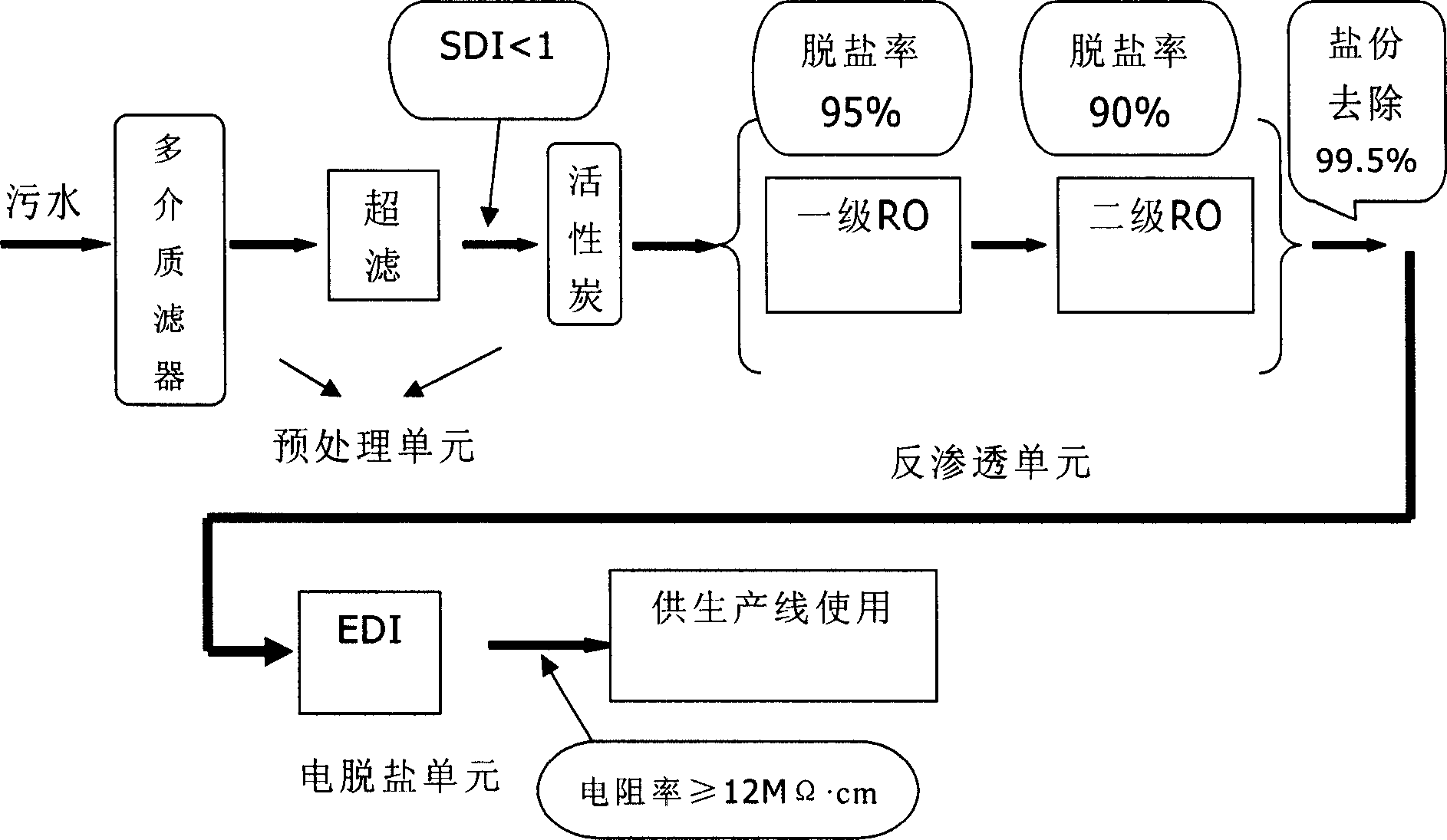

Technological process of treating sewage into pure water

InactiveCN1810662AHigh purityClose the loopScale removal and water softeningWater/sewage treatment by magnetic/electric fieldsActivated carbon filtrationWater resources

The technological process of treating sewage into pure water is completed in a pre-treating unit, a reverse osmosis unit and an electric desalting unit, and features that collected sewage is first treated in the pre-treating unit through its multiple medium filter, ultrafilter and active carbon filter, then treated in the reverse osmosis unit with double-stage reverse osmosis device, and finally electrically desalted in the electric desalting unit to obtain pure water. The technological process can treat sewage into pure water in high efficiency, and may be used in industrial production to realize the closed circulation of sewage to lower the water resource consumption greatly.

Owner:BEIJING MATSUSHITA COLOR CRT CO LTD

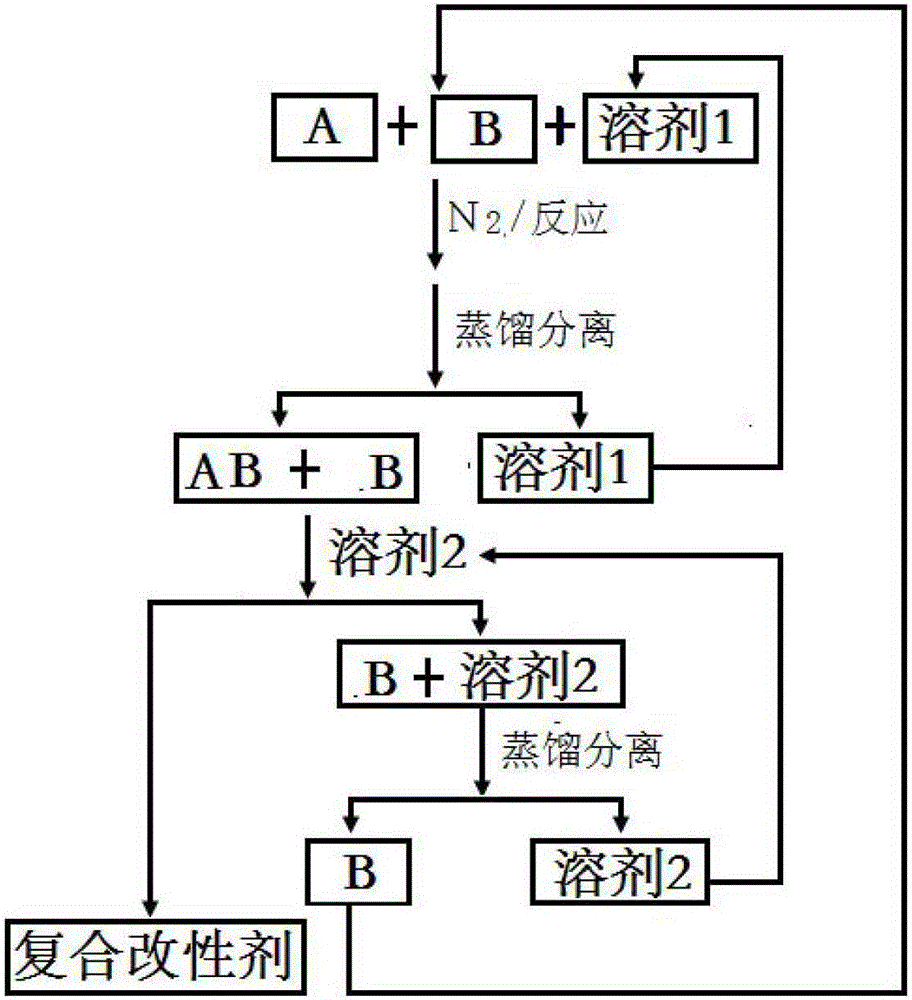

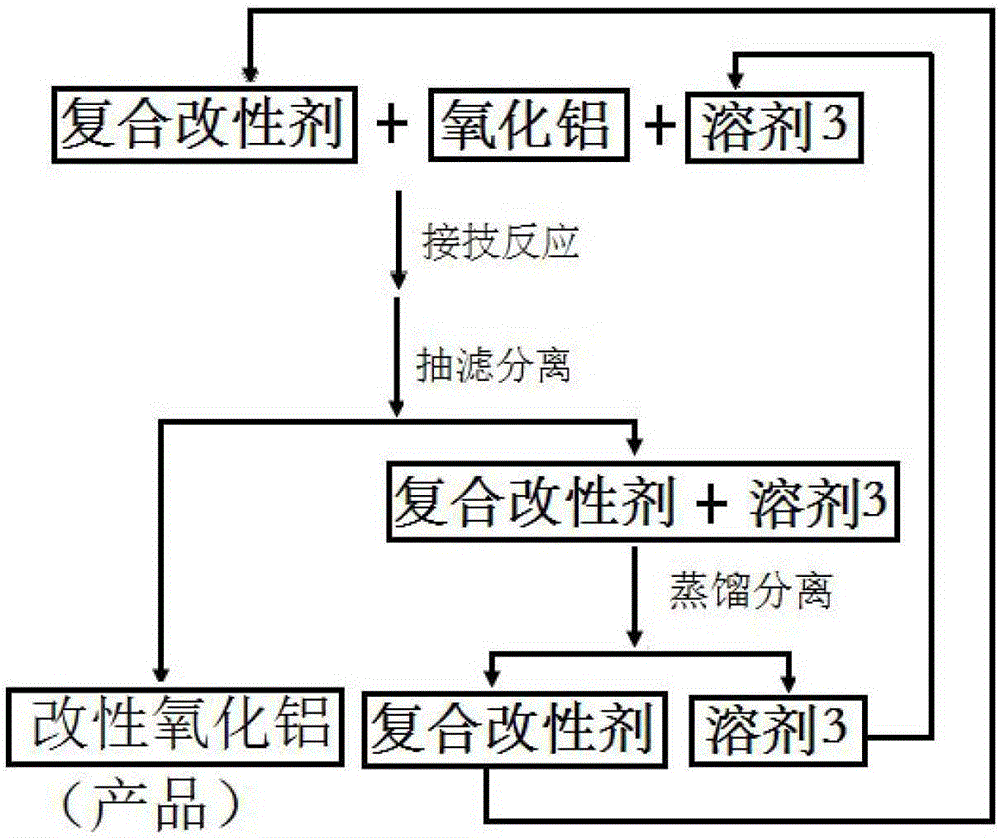

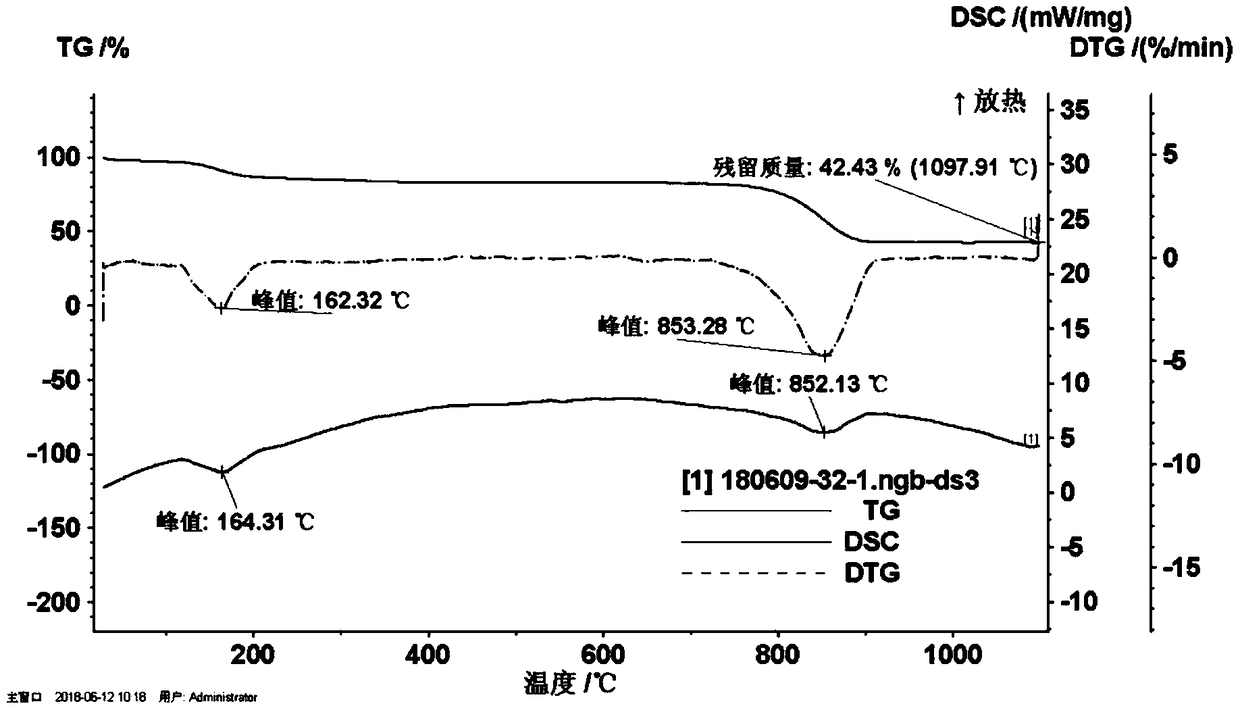

Recycling surface modification method for aluminum oxide powder high in water dispersion stability

ActiveCN106590067AAvoid condensation reactionsClose the loopPigment treatment with organosilicon compoundsDispersion stabilitySolvent

The invention belongs to the technical field of materials and discloses a recycling surface modification method for aluminum oxide powder high in water dispersion stability. According to the method, compound modifier generation reaction and grafting reaction of aluminum oxide powder are both carried out in organic solvents, condensation reaction of a silane coupling agent is effectively prevented, aluminum oxide surface modified molecular layers are more regular, and accordingly surface coating rate and surface modification effects of the aluminum oxide powder are controllable; aiming at waterborne media different in property, favorable compatibility and dispersion stability of the modified aluminum oxide powder in water or waterborne media can be achieved through compound modifier molecular design; appropriate solvents are selected to realize recovery and recycling of residual compound modifier, reactants and solvents, and material closed cycle, cleanness and environment friendliness (namely freeness of waste liquid generation and discharge) in a whole surface modification process are realized.

Owner:溧阳极盾新材料科技有限公司

Treatment method for resource utilization of waste liquid in production of graphene oxide

ActiveCN109319999AClose the loopZero pollutionTreatment involving filtrationSulfur-trioxide/sulfuric-acidResource utilizationSulfate

The invention relates to a treatment method for resource utilization of waste liquid in production of graphene oxide. The treatment method comprises the following steps of (1) pretreating the wastewater, so as to obtain wastewater A; (2) evaporating and crystallizing the wastewater A, and filtering, so as to obtain crystals, condensate water I and wastewater B; washing and drying the crystals, soas to obtain manganese sulfate crystals; (3) distilling and concentrating the wastewater B under a vacuum condition, so as to obtain condensate water II and recycled acid; returning the condensate water I, the condensate water II and the recycled acid back into the production technology for recycling. The treatment method for the resource utilization of the waste liquid in the production of the graphene oxide has the advantages that the characteristic of dissolving degree of the manganese sulfate in sulfuric acid is utilized, and the crystals are removed by the evaporation and crystallizationtechnology, so as to obtain the manganese sulfate; the obtained wastewater in the separating process is concentrated into finished acid, and the finished acid and the condensate water produced in theevaporation process are returned back into the production process for recycling, so as to realize the purposes of zero drainage and high-efficiency recycling of the wastewater in the production process of the graphene oxide.

Owner:新疆烯金石墨烯科技有限公司

Heat pipe system for boiler

InactiveCN1111715CClose the loopImprove heat absorption efficiencyIndirect heat exchangersHot-water central heatingAutomatic controlSystem pressure

A heat pipe system is composed of boiler body and partition type heat-consuming equipment and is especially suitable for the condition that the heat supply equipment is far from the heat consuming equipment. The steam branch has regulating valve. In cold liquid channel, there are steam / liquid separating tank, delivery pump of liquid, liquid level regulator and inertial gas exhauster. It has not only the unique advantage of heat pipe in heat transfer, but also has the functions of system pressure and temp. indication, automatic control, and alarm. Its advantages are locally regulated heat consumption, long service life, high efficiency and safety, and saving energy.

Owner:陈烈涛

Electrolysis recovery device for copper-containing waste liquid of printed circuit board

PendingCN112080763AExtend the electrolysis timeImprove replacement efficiencyElectrolysis componentsPhotography auxillary processesThermodynamicsElectrical connection

The invention relates to the technical field of copper waste liquid electrolysis recovery devices, in particular to an electrolysis recovery device for copper-containing waste liquid of a printed circuit board. The electrolysis recovery device comprises a pretreatment unit and an electrolysis unit, wherein the pretreatment unit comprise a header tank, a blow-off pipe and a chemical adding pipe, aheating plate and stirring blades are installed at the bottom of the header tank, the blow-off pipe is connected with the header tank in a penetrating manner, the chemical adding pipe is installed atthe top of the header tank, a nanofiltration membrane is arranged between a concentration cavity and a circulating cavity, the electrolysis unit comprises a tubular electrolytic cell and a power supply, a base is arranged in the tubular electrolytic cell and used for placing an anode metal bar and a cathode metal bar, and the anode metal bar and the cathode metal bar are electrically connected with the power supply to form a closed loop. According to the electrolysis recovery device for the copper-containing waste liquid of the printed circuit board, the problems of lower recovery rate, shortcontact time and low replacement efficiency of the copper-containing waste liquid of the printed circuit board in the prior art are solved, and an electrolysis recovery device has the advantages of high electrolysis efficiency, high recycling material utilization rate and high replacement efficiency.

Owner:昆山卫司特环保设备有限公司

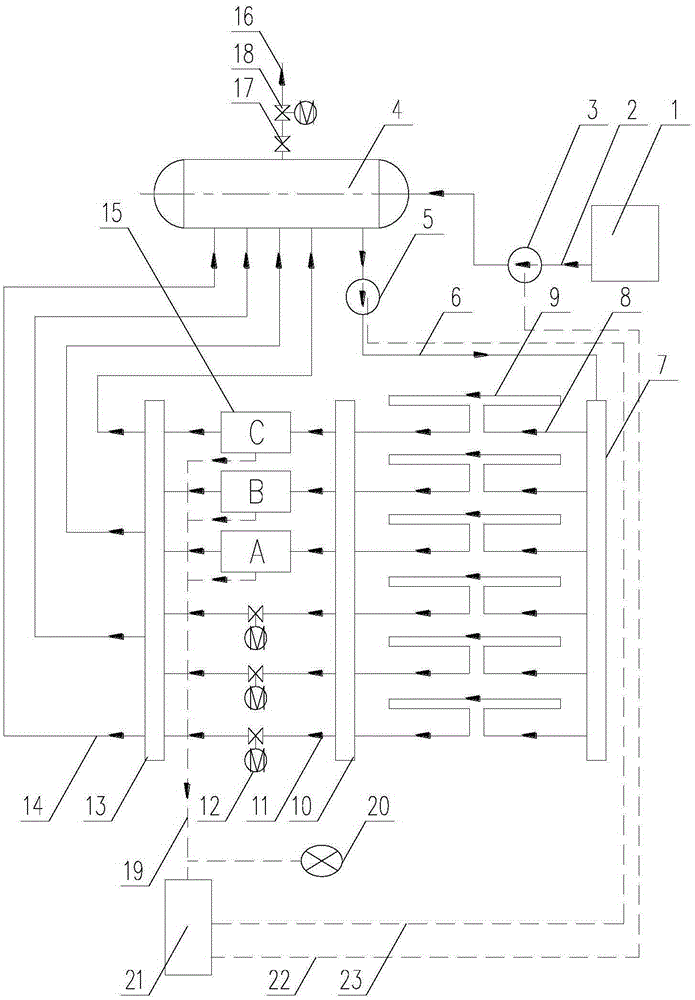

System for recycling waste heat of nuclear power plant

ActiveCN107166479AMeet Cooling NeedsStable temperatureMechanical apparatusHeat pumpsNuclear powerEvaporation

The invention discloses a system for recycling waste heat of a nuclear power plant. The system comprises a nuclear power plant steam condenser (1) and further comprises a heat pump system (2) and a heat use system (3). The cooling water output end of the steam condenser (1) is connected with the input end of the evaporation side of the heat pump system (2), and the cooling water input end of the steam condenser (1) is connected with the output end of the evaporation side of the heat pump system (2). The hot water supply input end of the heat use system (3) is connected with the output end of the condensation side of the heat pump system (2), and the hot water supply output end of the heat use system (3) is connected with the input end of the condensation side of the heat pump system (2). The heat pump system is directly connected with a cooling water way of the steam condenser, closed circulation of cooling water is achieved, on one hand, recycling of the heat is achieved, and on the other hand, output of the heat is reduced, and heat pollution to the environment is avoided.

Owner:YANTAI ZHUOYUE NEW ENERGY TECH +1

Preparation method of high-bulkiness super-sensitive paper

InactiveCN109468880AIncrease bulkStrong sense of fiber on paper surfaceCoatings with pigmentsPaper/cardboardFiberPapermaking

The invention relates to the technical field of papermaking, in particular to a preparation method of high-bulkiness super-sensitive paper: base paper is dried, coiled and split after being coated, and a coating method is to coat each of two sides with an air knife. The invention provides a method for preparing the high-bulkiness super-sensitive paper by air knife coating. A coating used for coating is prepared from a polystyrene pigment, a mineral pigment, an adhesive and other coating aids, and the obtained super-sensitive paper is strong in surface fiber sense and high in bulkiness; the process is low in production energy consumption, and equipment is simple and easy to obtain; a process flow is simple, and batch production can be realized; and furthermore, the whole flow is completelyimplemented in a closed cycle without pollution.

Owner:QILU UNIV OF TECH

Bleaching method of bagasse pulp

The invention discloses a bagasse pulp bleaching method, including the steps: preprocessing unbleached pulp by H2SO4 to reduce the content of transition metal ions; adding in a proper amount of H2O2, Mg2+ and DTPA; adding in NaOH and Na2SiO3; adding in O2 for bleaching. The invention can make the Soda-AQ processed bagasse pulp reach 79.26% ISO whiteness by single-stage bleaching, the experiment verifies that the whiteness reaches 79.92% ISO whiteness, reaching the level of C-E-H tri-stage bleaching.

Owner:SOUTH CHINA UNIV OF TECH

Waste plastic treatment system

InactiveCN105500554AReduce COD concentrationClose the loopGas treatmentUsing liquid separation agentWater treatment systemFiltration

The invention discloses a waste plastic treatment system. The waste plastic treatment system comprises a shredding mechanism, a cleaning mechanism, a dewatering mechanism, an extrusion forming mechanism, a storage mechanism and conveying mechanisms arranged between the mechanisms, wherein the shredding mechanism, the cleaning mechanism, the dewatering mechanism, the extrusion forming mechanism and the storage mechanism are arranged in sequence. The waste plastic treatment system further comprises a waste water treatment system and a waste gas treatment system. Waste water and waste gas generated by the mechanisms of the waste plastic treatment system are gathered and then discharged into the waste water treatment system and the waste gas treatment system respectively to be treated. The waste water treatment system comprises a regulation tank, a precipitation tank, an air flotation tank and a multi-medium filtration tank which are connected in sequence. Homogenization and flow regulation of the waste water can be achieved when the waste water passes through the regulation tank, precipitable substances are removed when the waste water passes through the precipitation tank, non-precipitable suspended substances and soluble impurities are removed when the waste water passes through the air flotation tank, and finally the waste water is further filtered and clarified when passing through the multi-medium filtration tank. By carrying out specific technological treatment on the waste water and the waste gas, pollutants are well removed, the pollutant treatment effect is good, and closed circulation of the water in the waste plastic treatment process is achieved.

Owner:沈永灶

Method for achieving filter liquor circulation, recovering waste lead plaster through wet process and preparing high-purity red lead

ActiveCN109868366AClose the loopAchieve directional separationProcess efficiency improvementOrganic acidLead carbonate

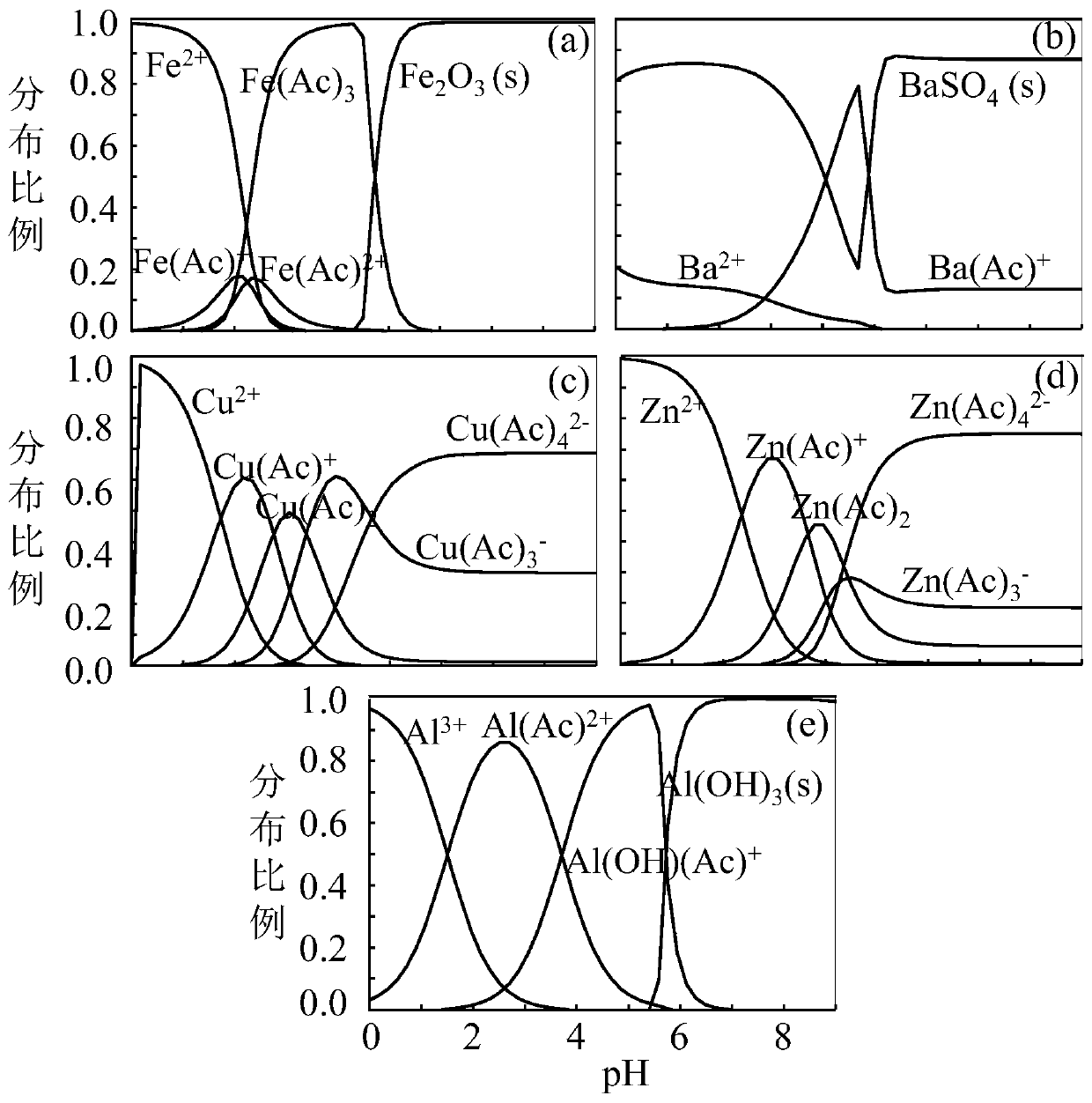

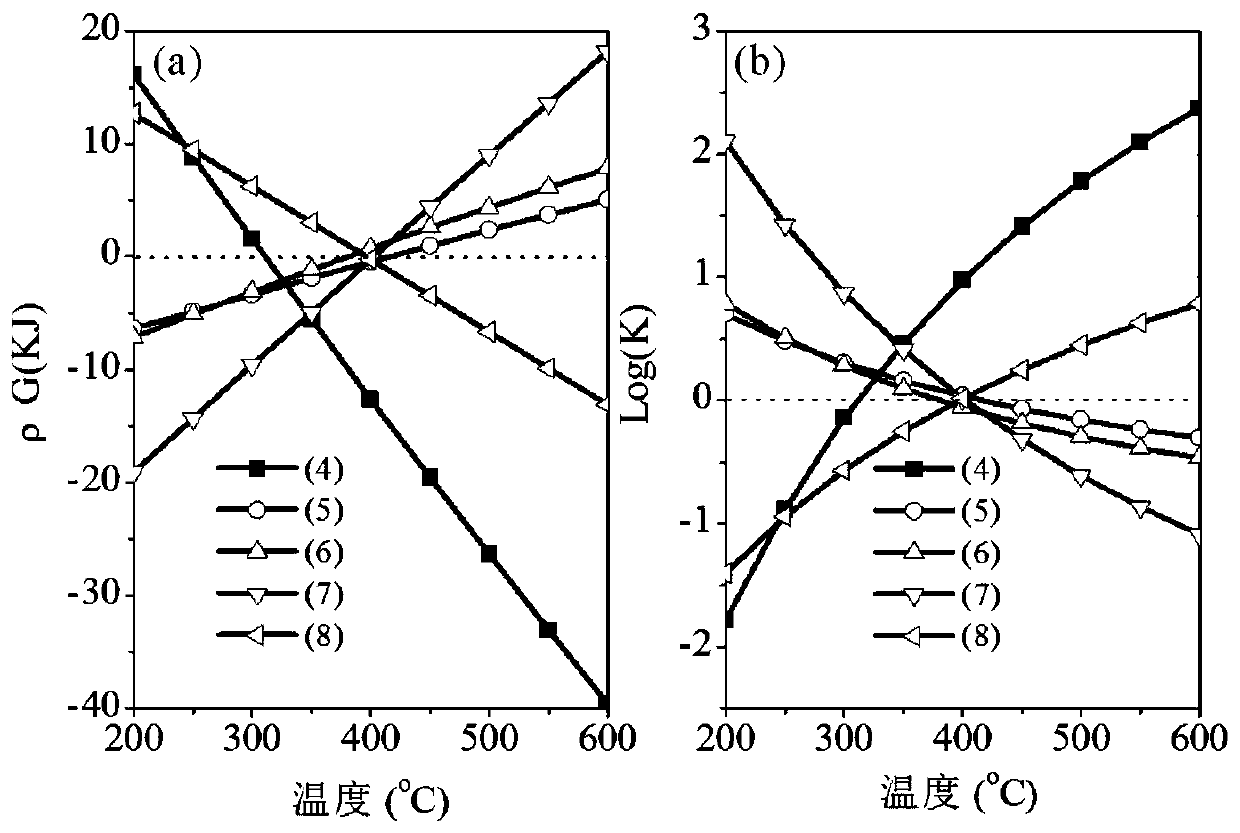

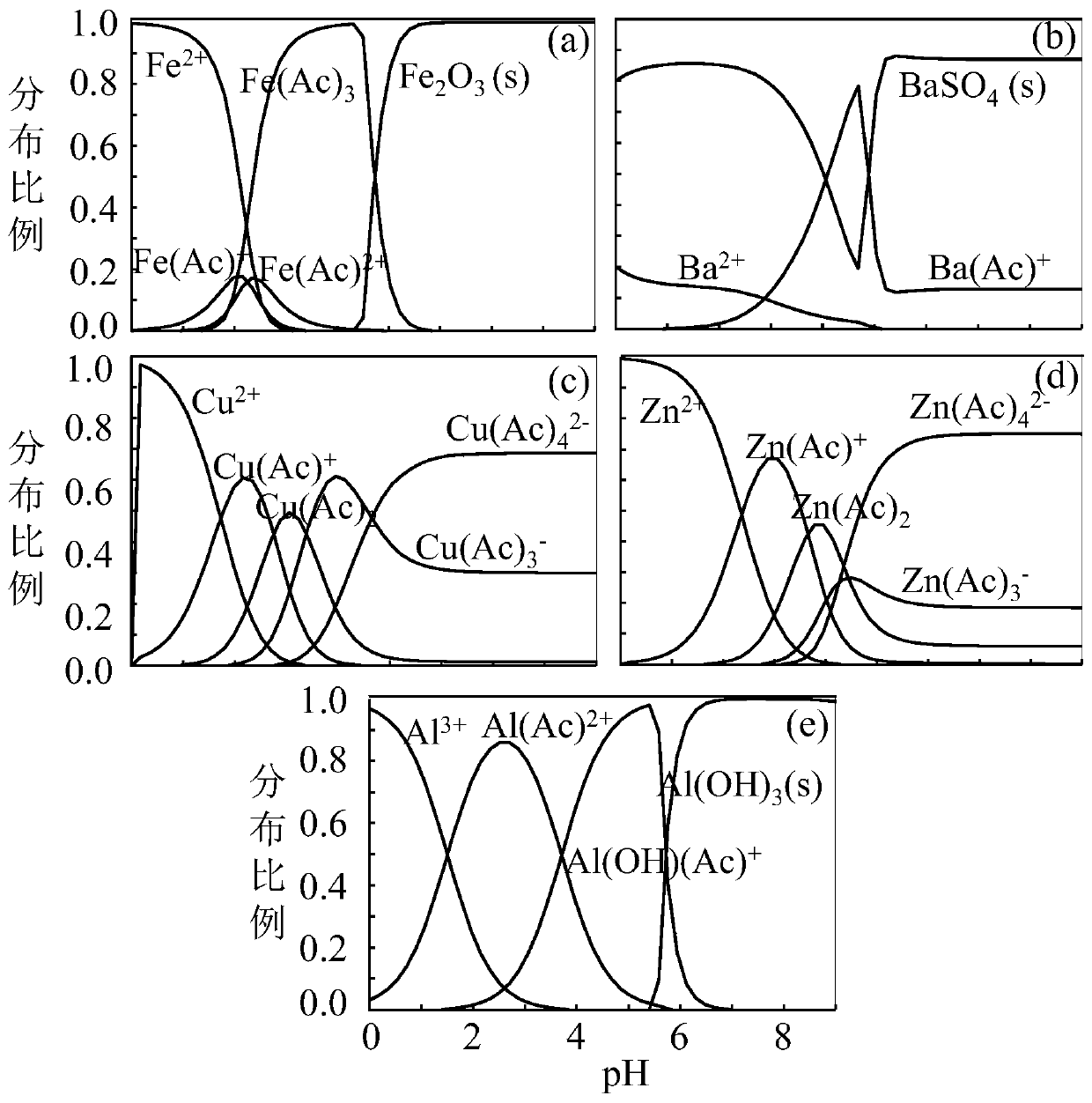

The invention discloses a method for achieving filter liquor circulation, recovering waste lead plaster through a wet process and preparing high-purity red lead and relates to the technical field of waste lead-acid cell lead plaster wet process recovery and red lead preparation. The method comprises the following steps that 1, organic acid salt, organic acid and reducer mixed liquor are utilized for leaching out the waste lead plaster, and after solid and liquid are separated, lixivium is obtained; 2, a carbonate solution is added to the lixivium, the reaction pH is regulated, and solid and liquid separating is carried out to obtain lead carbonate sediment and filter liquor; and 3, lead carbonate is roasted in the aerobic atmosphere, and the high-purity red lead with low impurity content is prepared. The prepared red lead product is high in purity and low in impurity content, the content of main impurities Ba and Fe is smaller than 10 mg / kg, the content of Cu, Zn and Al impurity elements is smaller than 1 mg / kg, the filter liquor can achieve closed circulation of organic acid radical ligand in a leaching system, and the use efficiency of a leaching agent is improved remarkably.

Owner:HUAZHONG UNIV OF SCI & TECH

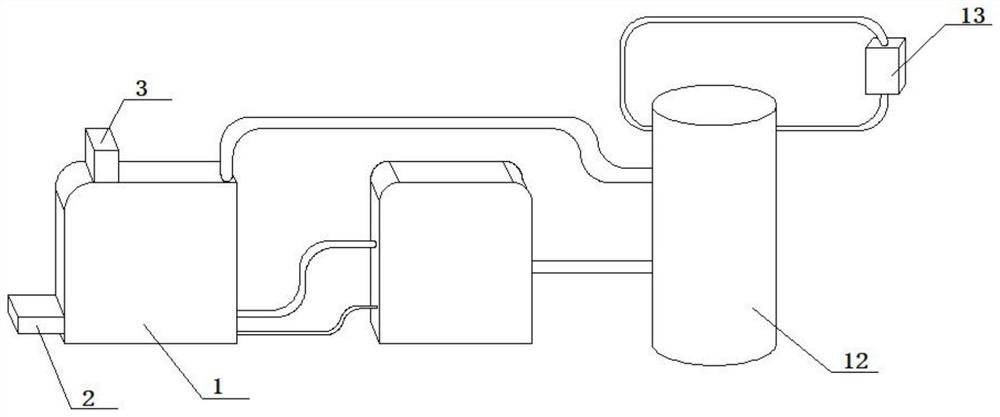

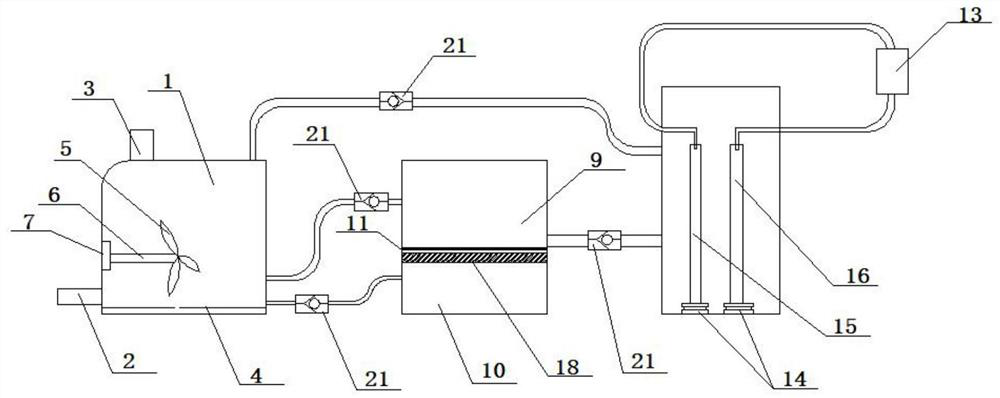

Self-recovery system for cooling energy medium of heating furnace

ActiveCN104359323AClose the loopAchieving complete self-recyclingIncreasing energy efficiencyFurnace coolingSelf recoveryEngineering

The invention discloses a self-recovery system for a cooling energy medium of a heating furnace. The system is mainly designed by aiming at the situation that the cooling energy medium is not fully utilized by an existing heating furnace cooling system. According to the self-recovery system for the cooling energy medium of the heating furnace, a first outlet distribution header is connected to an outlet of an in-furnace water beam and is connected with a second outlet distribution header through a pipeline group; a generator set is arranged on the pipeline group; a vapor water mixture in the first outlet distribution header is conveyed to the pipeline group; the vapor water mixture in the pipeline group supplies energy required by the operation of the generator set and is output to the second outlet distribution header through the generator set. According to the self-recovery system for the cooling energy medium of the heating furnace, the vapor water mixture formed by vaporizing saturated water through the in-furnace water beam is converted into the saturated water through the generator set, the saturated water is recycled, and electric energy generated by the generator set can be used for the self-operation of the system.

Owner:HUATIAN ENG & TECH CORP MCC

A method for preparing high-purity red lead by reclaiming waste lead plaster by wet method with filtrate circulation

ActiveCN109868366BClose the loopAchieve directional separationProcess efficiency improvementOrganic acidLead carbonate

Owner:HUAZHONG UNIV OF SCI & TECH

Activated carbon continuous sorption-desorption device for movable bed

The invention discloses an activated carbon continuous sorption-desorption device for a movable bed. The device comprises an adsorber filled with granular active carbon, wherein an aggregate bin is in communication with the adsorber through an upright material sealing pipe, and continuously and slowly provides the granular active carbon into the adsorber; a regenerator is arranged below the adsorber by communicating with the adsorber through a first star-type material feeder; the granular activated carbon at the bottom of the adsorber continuously and slowly flows into the regenerator; the regenerator is in communication with a lifting pipe dryer by a second star-type material feeder; a first cyclone separator placed at the upper part of the aggregate bin is arranged at the upper end of the lifting pipe dryer; the granular activated carbon at the bottom of the regenerator is lifted by the lifting pipe dryer so as to continuously flow into the aggregate bin via the first cyclone separator; a waste gas inlet pipe and a waste gas outlet pipe are arranged on the adsorber; and a steam inlet pipe and a steam outlet pipe are mounted on the regenerator. By using the activated carbon continuous sorption-desorption device disclosed by the invention, the sorption-desorption process can be continuously carried out, thereby improving the sorption-desorption efficiency.

Owner:SHANDONG UNIV OF SCI & TECH

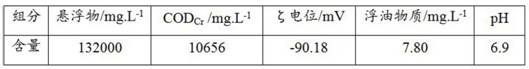

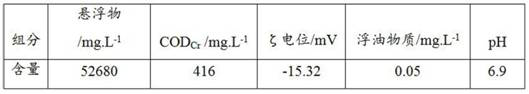

Waste water treatment method in preparation of para-aminophenol by electrolytic process

InactiveCN1450000AAchieve recyclingClose the loopWater/sewage treatment by heatingWater/sewage treatment by sorptionAmmonium sulfateChemistry

The present invention discloses a method for treating waste water produced by p-aminophenol process by electrolysis method. Said method adopts the fruit shell active carbon to make adsorption to remove P-aminophenol, then makes the waste water be evaporated and concentrated to recover industrial-grade ammonium sulfate, the recovery rate of the ammonium sulfate is greater than 98%. The evaporation-obtained water can be used for preparing sulfuric acid aqueous solution whose concentration is 18%, and can be used as electrolyte and fed into electrolytic bath to implement closed circulation of water. The fruit shell active carbon in which the p-aminophenol is adsorbed can be regenerated by using 18 wt% sulfuric acid aqueous solution as desorption agent, and the desorption liquid can be returned into electrolytic bath to participate in electrolysis reaction.

Owner:EAST CHINA UNIV OF SCI & TECH

A device for efficient and clean treatment of coal washing water without chemicals

ActiveCN114394691BReduce operating costsMeet environmental protection requirementsTreatment involving filtrationMultistage water/sewage treatmentTreatment pondPre treatment

The invention relates to a device for efficient and clean treatment of coal washing water without chemicals, comprising a pretreatment tank, a clarification tank, a coarse filter, an ultrafilter, a sedimentation tank and a coal slime dehydrator; a baffle is arranged in the middle of the pretreatment tank, The coal washing water inlet pipe is arranged above the pool wall of the pretreatment tank, and the aeration inlet pipe is connected to the coal washing water inlet pipe along the vertical direction; the floating substance overflow pipe is arranged on the top of the pool wall of the pretreatment tank; Inclined tube sedimentation tank. The main feature of this invention is that it adopts a brand-new water treatment concept, and after carefully analyzing the characteristics of coal washing water, it proposes a chemical-free and efficient clean treatment process. The water treatment speed is dozens of times that of the traditional process, and the occupied area is less than 50% of the traditional process. It is especially suitable for the purification treatment equipment of coal washing water and mine water. Using the device of the present invention to treat coal washing water does not require adding any chemicals, which will inevitably help enterprises reduce operating costs, help enterprises meet environmental protection requirements, and truly realize zero sewage discharge.

Owner:TAIYUAN UNIV OF TECH

Waste water treatment method in preparation of para-amiophenyl by electrolytic process

InactiveCN1199868CAchieve recyclingClose the loopNature of treatment waterWater/sewage treatment by heatingDesorptionClosed loop

The invention discloses a wastewater treatment method in an electrolysis process of p-aminophenol. In the method, the p-aminophenol is removed by adsorption of fruit shell activated carbon, and then the waste water is evaporated and concentrated to recover industrial-grade ammonium sulfate, and the recovery rate of the ammonium sulfate is greater than 98%. The evaporated water is used to prepare 18% sulfuric acid aqueous solution and enters the electrolytic cell as electrolyte to realize the closed circulation of water. The fruit shell activated carbon that adsorbs p-aminophenol can use 18 (wt)% sulfuric acid aqueous solution as a desorption agent to regenerate the activated carbon (the unit consumption of activated carbon is about 50 kg / ton PAP), and the desorption solution can be returned to the electrolytic cell to participate in electrolysis reaction, therefore, the waste water treatment method of the present invention is a zero discharge, environmentally friendly waste water treatment method.

Owner:EAST CHINA UNIV OF SCI & TECH

Processing method of wastewater in the sebacic acid production and special extractor thereof

ActiveCN100569674CClose the loopSave energyMultistage water/sewage treatmentWater/sewage treatment by neutralisationEmulsionWastewater

The invention relates to a treatment method for sebacic acid production wastewater and a special extraction device thereof. The method includes solid and liquid separation in settling tanks, neutralization method Ph value adjustment, extractant extraction of forbidden substances, and separation of forbidden substances and discharge water. The key idea is to use ricinoleic acid as the extraction agent to extract and Separation of prohibited discharge phenol in sebacic acid production wastewater, and the specific steps of mixing and reusing the extractant and extract were adopted. With the help of the supporting special extraction device, the multi-stage extraction operation of forbidden substances is carried out to realize the closed circulation of forbidden substances in the production system. The extraction device is composed of extraction and separation tanks arranged in sequence, a mixing emulsification pump arranged between two adjacent or interphase extraction and separation tanks, and a pipeline connected between the mixing emulsification pump and the extraction and separation tanks on both sides. The oil inlet of a matching mixed emulsification pump is connected with the oil phase outlet of the subsequent stage extraction and separation tank, the water inlet is connected with the water phase outlet of the front stage extraction and separation tank, and the outlet of the mixed emulsion is connected with the steady state of the previous stage extraction and separation tank. The rehydration port drawn from the flow chamber is connected.

Owner:韩厚义

Heating furnace cooling energy medium self-recovery system

ActiveCN104359323BClose the loopAchieving complete self-recyclingIncreasing energy efficiencyFurnace coolingSelf recoveryEnergy recovery

The invention discloses a self-recovery system for a cooling energy medium of a heating furnace. The system is mainly designed by aiming at the situation that the cooling energy medium is not fully utilized by an existing heating furnace cooling system. According to the self-recovery system for the cooling energy medium of the heating furnace, a first outlet distribution header is connected to an outlet of an in-furnace water beam and is connected with a second outlet distribution header through a pipeline group; a generator set is arranged on the pipeline group; a vapor water mixture in the first outlet distribution header is conveyed to the pipeline group; the vapor water mixture in the pipeline group supplies energy required by the operation of the generator set and is output to the second outlet distribution header through the generator set. According to the self-recovery system for the cooling energy medium of the heating furnace, the vapor water mixture formed by vaporizing saturated water through the in-furnace water beam is converted into the saturated water through the generator set, the saturated water is recycled, and electric energy generated by the generator set can be used for the self-operation of the system.

Owner:HUATIAN ENG & TECH CORP MCC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com