Recycling surface modification method for aluminum oxide powder high in water dispersion stability

A technology of alumina powder and dispersion stability, applied in the field of materials, can solve the problems of complicated, difficult and low efficiency of powder surface modification process, and achieve controllable surface coverage and surface modification effect, preventing Effects of condensation reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

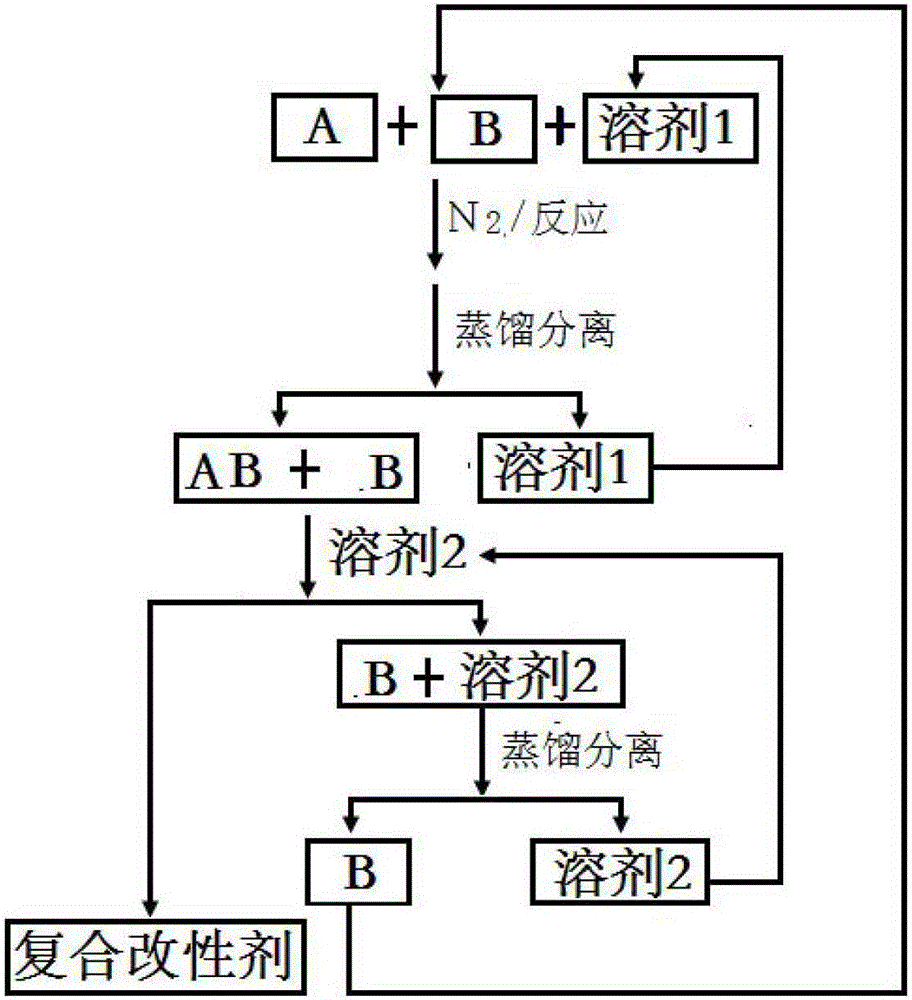

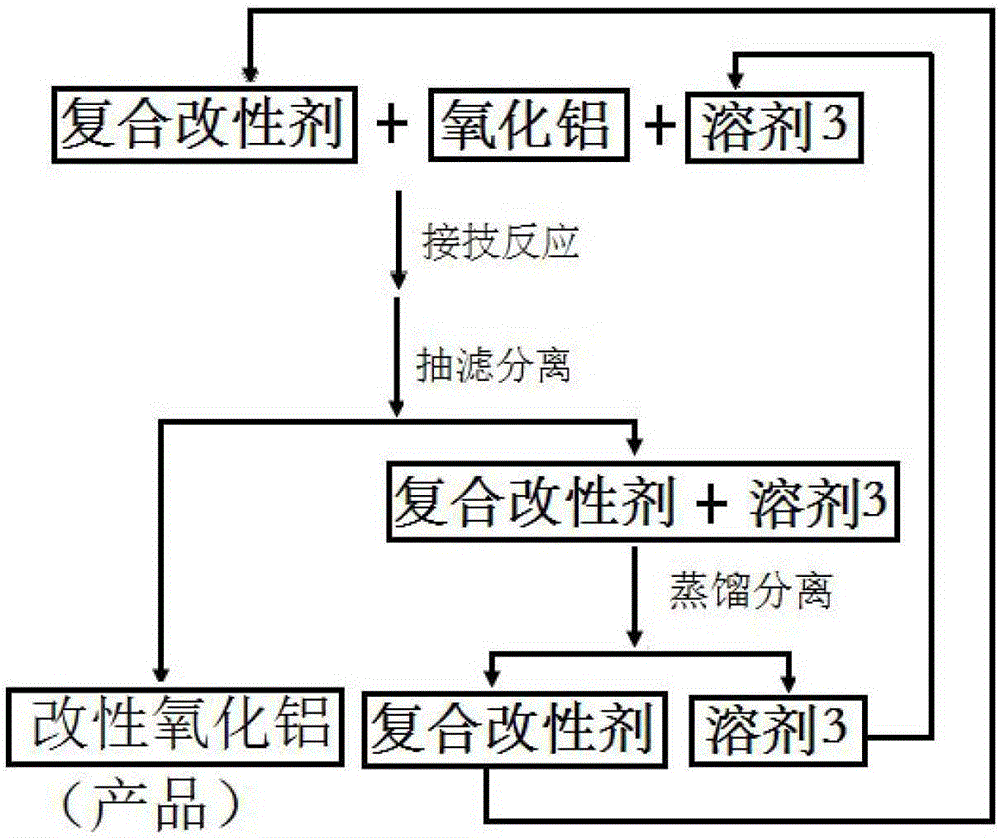

Embodiment 1

[0054] First dissolve methyl polyethylene glycol formate (n=10) in toluene, then add 3-aminopropyltriethoxysilane, the molar ratio of the two is 1:3. Nitrogen, 80 ℃ reaction 10h. The solvent toluene is separated and recovered by distillation under reduced pressure, and the precipitating agent acetone is added to the mixed solution to obtain composite modifier 1. The remaining liquid is distilled and separated to recover the precipitating agent acetone and excess 3-aminopropyltriethoxysilane. Dissolve 1g of composite modifier 1 in absolute ethanol, then add 10g of alumina powder and a small amount of acetic acid, and stir and react at 55°C for 24h. Separation by suction filtration to obtain modified oxygen oxide powder (sample 1, coverage rate 1.51%). The residual liquid is distilled and separated to recover the solvent ethanol, and the residual liquid is the excess composite modifier. The separated and recovered solvent toluene, ethanol, precipitant acetone, excess 3-aminopr...

Embodiment 2

[0056] Dissolve methyl polyethylene glycol formate (n=10) in tetrahydrofuran first, then add bis(trimethoxysilylpropyl)amine, the molar ratio of the two is 1:2. Nitrogen, 80 ° C reaction for 12h. The solvent tetrahydrofuran is separated and recovered by distillation under reduced pressure, and the precipitating agent cyclohexanol is added to the mixed solution to obtain the composite modifier 2. amine. Dissolve 1g of composite modifier 2 in toluene, then add 10g of alumina powder and a small amount of acetic acid, and stir and react at 55°C for 30h. Separation by suction filtration to obtain modified oxygen oxide powder (sample 2, coverage rate 1.75%). The residual liquid is distilled under reduced pressure to separate and recover the solvent toluene, and the residual liquid is the excess composite modifier. The separated and recovered solvent tetrahydrofuran, toluene, precipitant cyclohexanol, excess bis(trimethoxysilylpropyl)amine and excess composite modifier 2 can all b...

Embodiment 3

[0058] Dissolve polyethylene glycol (n=50) in toluene, and then add ethyltriethoxysilane cyanate, the molar ratio of the two is 1:3. Nitrogen was passed, and the reaction was carried out at 50°C for 24h. The solvent toluene is separated and recovered by distillation under reduced pressure, and the precipitating agent cyclohexane is added to the mixed solution to obtain the compound modifier 3. The remaining liquid is distilled under reduced pressure, separated and recovered, the precipitating agent cyclohexane and excess ethyltriethoxysilane cyanate . Dissolve 1g of composite modifier 3 in tetrahydrofuran, then add 10g of alumina powder, and stir and react at 50°C for 20h. Separation by suction filtration to obtain modified oxygen powder (sample 3, coating rate 2.35%). The residual liquid is distilled and separated to recover the solvent tetrahydrofuran, and the residual liquid is the excess compound modifier. The separated and recovered solvent toluene, tetrahydrofuran, pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com