Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

65results about How to "Realize the purpose of resource utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

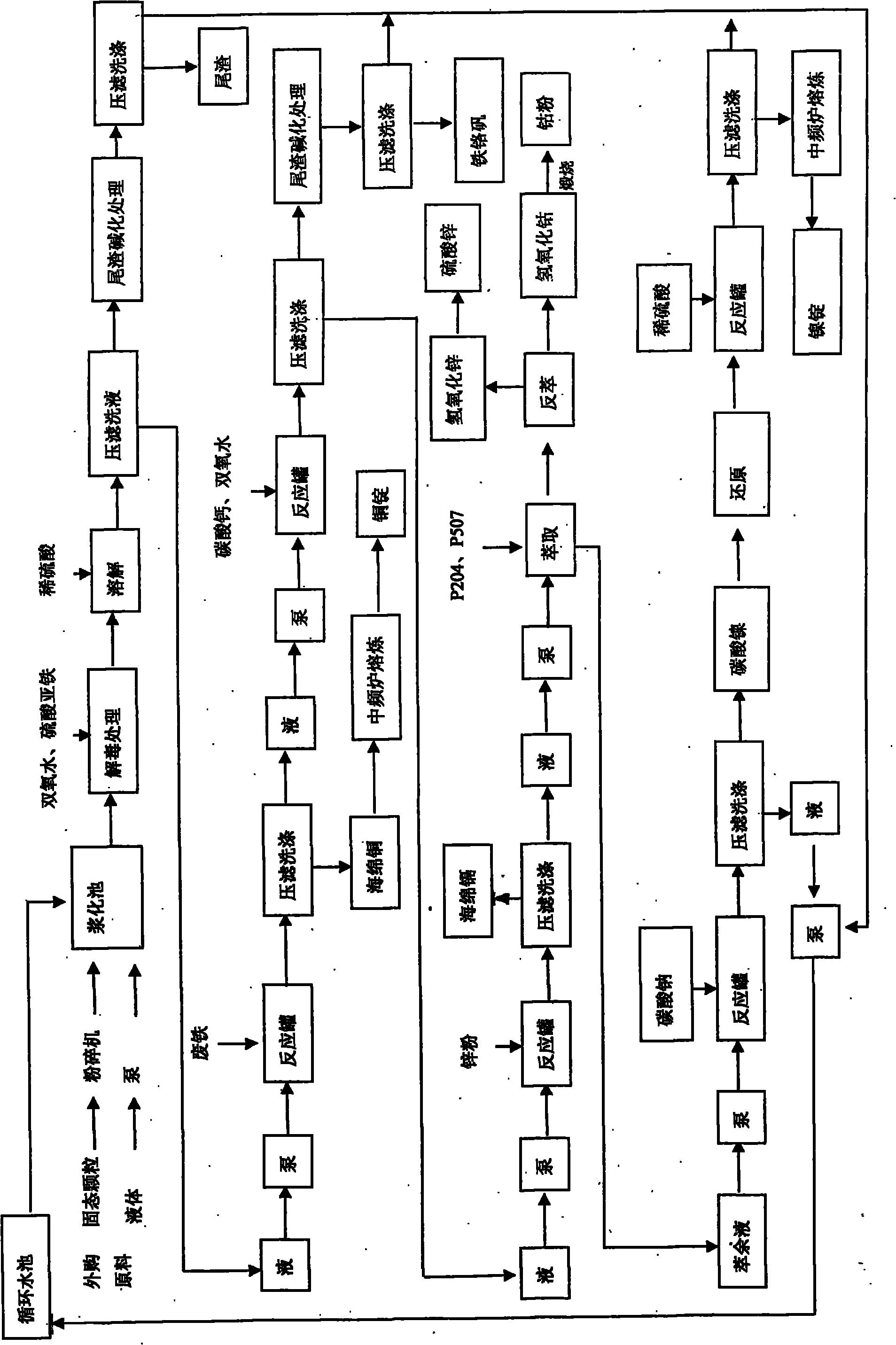

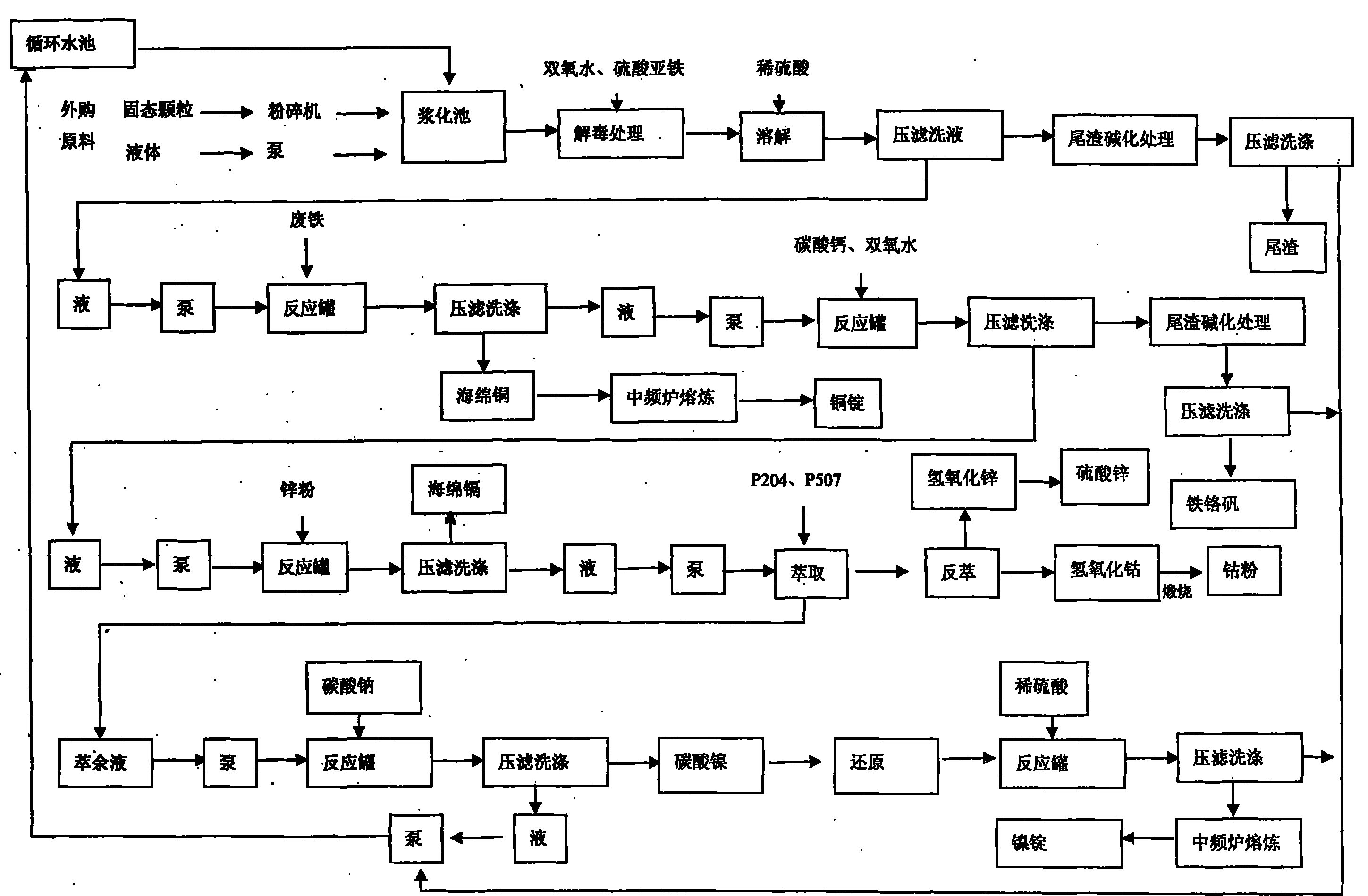

Method for recycling heavy metal pollution wastes

InactiveCN101871046AWide process adaptabilityRealize the purpose of resource utilizationProcess efficiency improvementChemistryCopper

The invention discloses a method for recycling heavy metal pollution wastes, which comprises the following steps of: 1) the pulping of raw materials; 2) acid leaching, namely, adding pulp obtained in the step 1 into a dilute sulphuric acid for filtration, and taking filter residues as the raw materials of bricks or cement; 3) copper displacement, namely, displacing copper out of filtrate in the step 2 with iron; 4) the preparation of ferrum-chrome-alum, namely, adding alkaline substances and an oxidant into the filtrate obtained in the step 3, adjusting a PH value, and precipitating and filter-pressing the mixed solution to obtain the ferrum-chrome-alum; and 5) the preparation of sponge cadmium, namely, displacing cadmium out of the filtrate obtained in the step 4 with zinc. The process has the advantages of suitability for the treatment of waste residues and waste liquor in a plurality of industries of electroplating, surface treatment, heavy metal smelting, chemical engineering and the like, no need of heating liquid-phase materials, the realization of closed cycle, and the capacity of extracting a plurality of valuable metals, such as Cu, Cr, Cd, Ni, Co, Zn and the like, directly taking the wastes obtained after the metal separation as the raw materials of the bricks or cement, and saving coal and electricity amounting to 20,000 T standard coal and 40,000-ton water per year for enterprises recycling 5,000-ton metals per year.

Owner:青川县天运金属开发有限公司

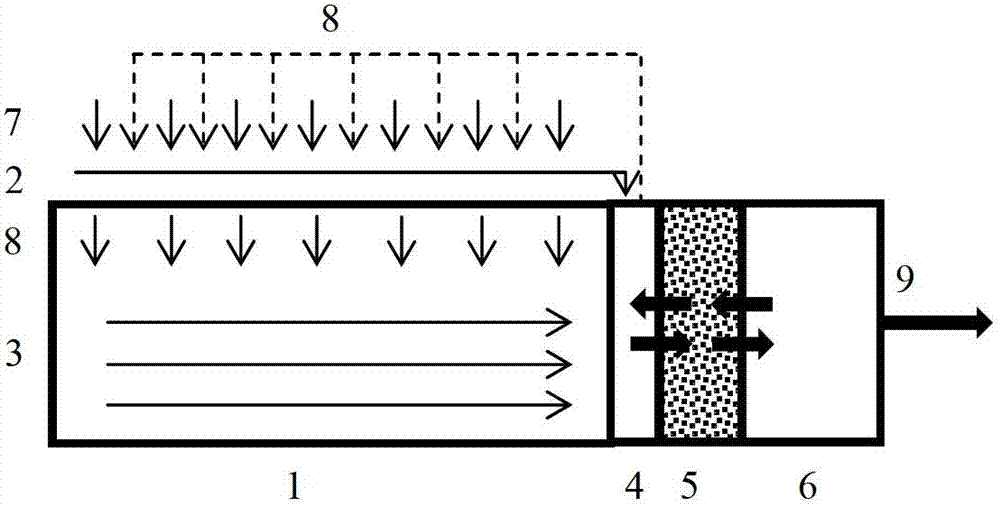

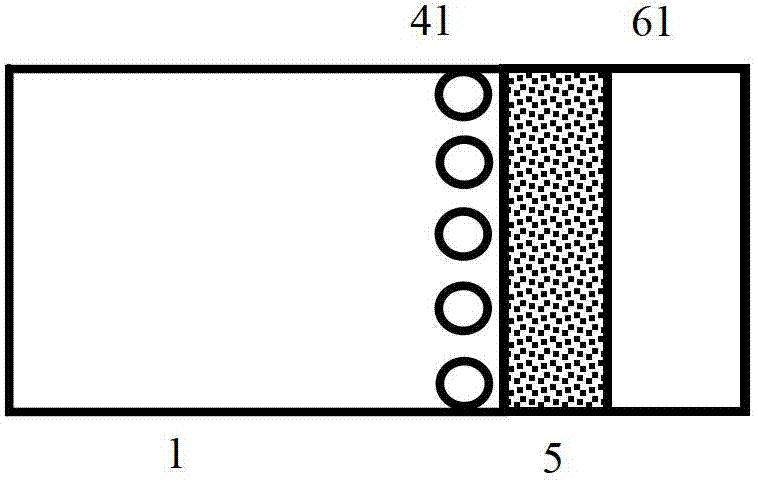

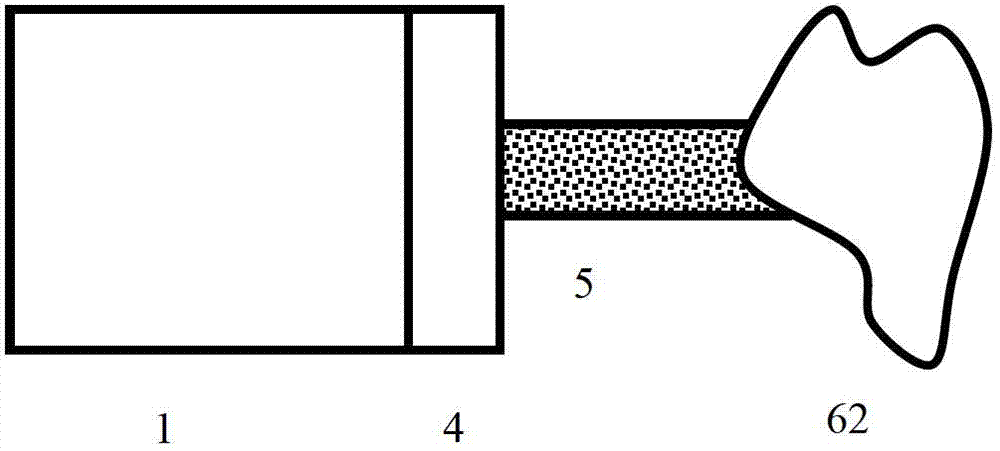

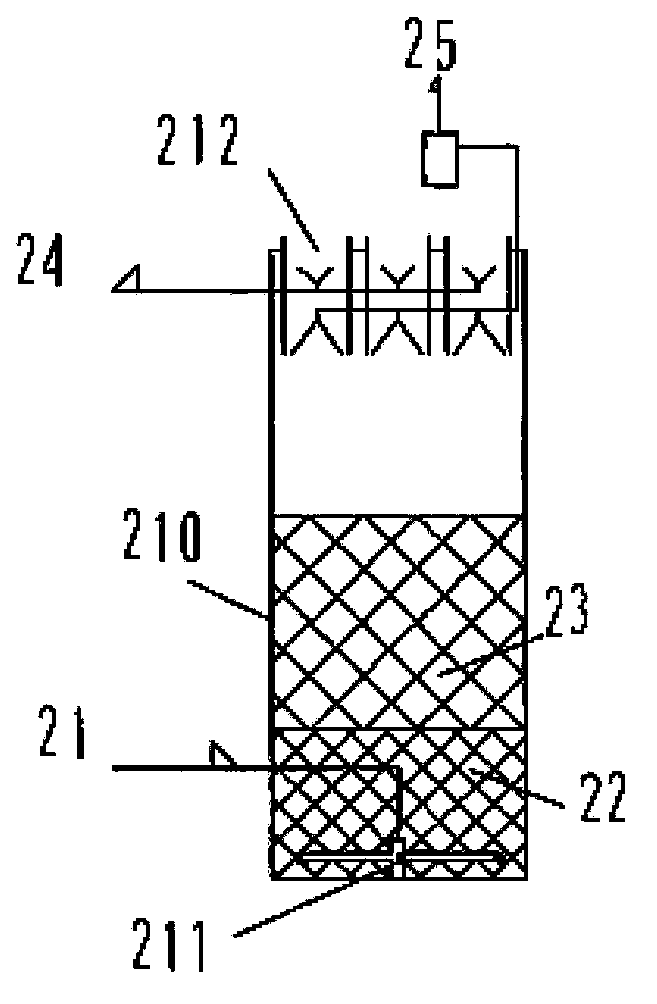

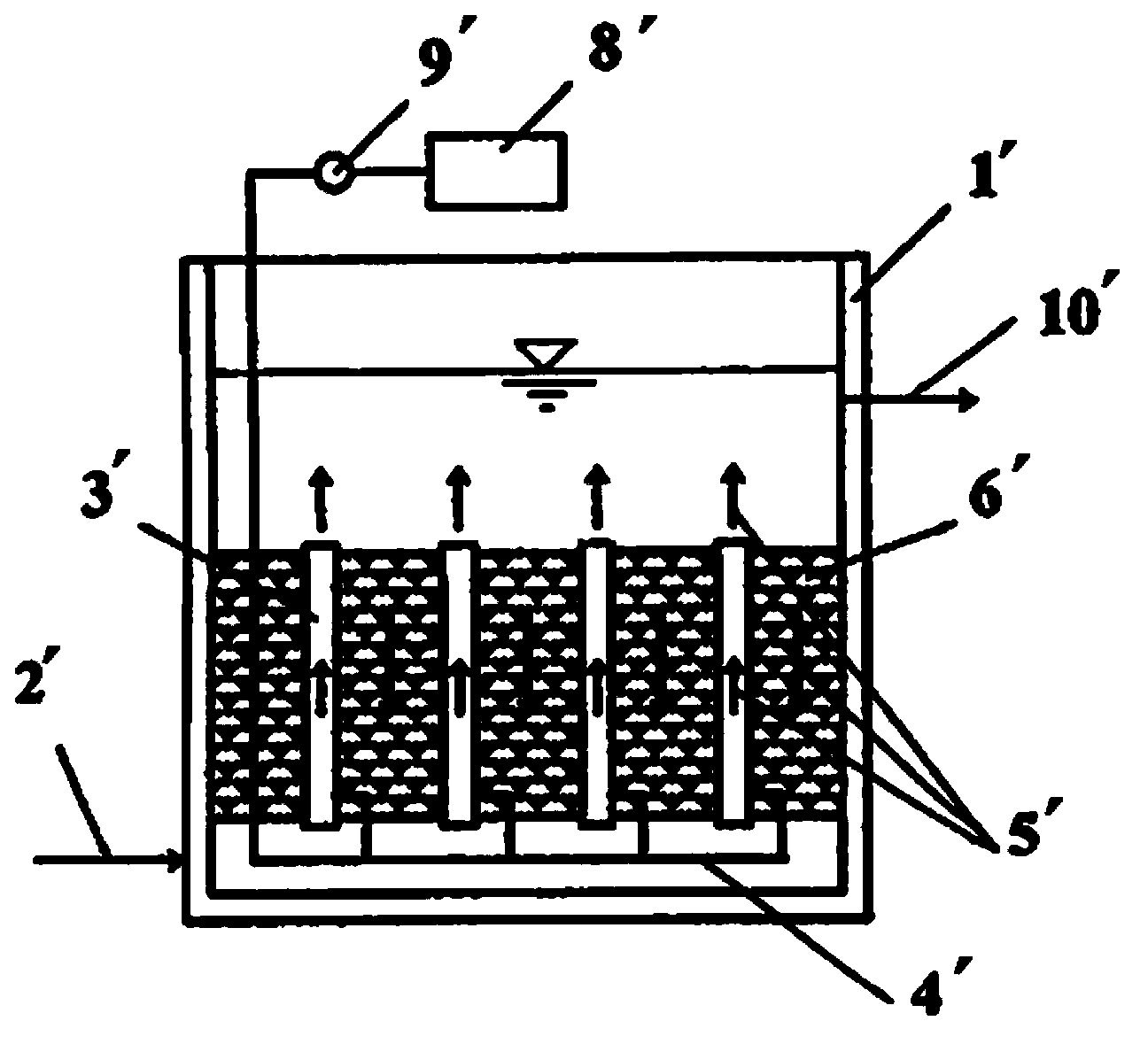

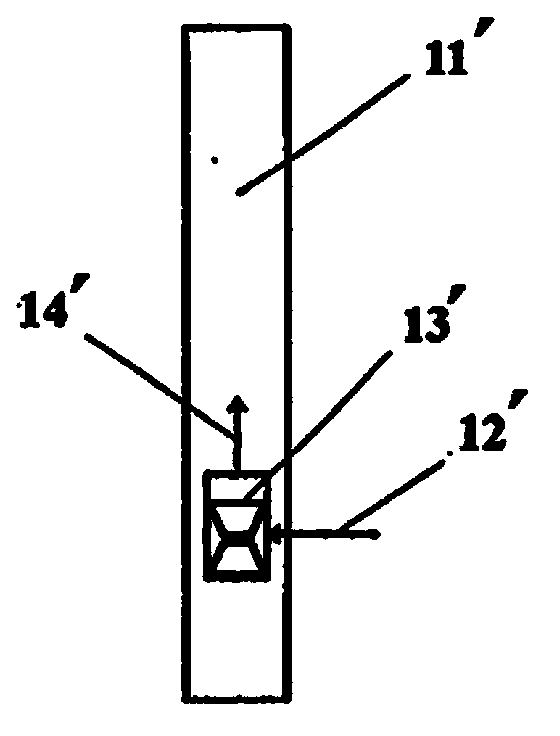

Farmland nitrogen and phosphorous non-point source pollution control and recycle system, and method thereof

ActiveCN102786110AAvoid enteringPrevent eutrophicationSewerage structuresWater/sewage treatment by sorptionDesorptionNitrogen

The invention relates to a farmland nitrogen and phosphorous non-point source pollution control and recycle system, and a method thereof. The system comprises a water collector, an adsorption unit and a water store which are sequentially arranged from the upstream to the downstream according to farmland surface runoff and underground runoff paths. The water collector, the adsorption unit and the water store are sequentially transversely arranged according to the farmland surface runoff and underground runoff paths, so when rain falls or irrigation is carried out, the farmland water is surplus, meets in the water collector through the farmland surface runoff and underground runoff, the water in the collector continuously downward flows and goes through the adsorption unit, nitrogen (N) and phosphorous (P) are adsorbed, the purified farmland drainage enters the water store, and the superfluous purified drainage is discharged to a river and a lake; and when farmland recharging is carried out, the water which reversely flows goes through the adsorption unit for the N and P desorption, and the desorbed N and P enter the water collector with the water flow, afresh enter the farmland and are adsorbed and utilized by crops. Compared with the prior art, the method has the advantages of pollution control, recycle, fertilizing cost saving and the like.

Owner:SHANGHAI JIAO TONG UNIV

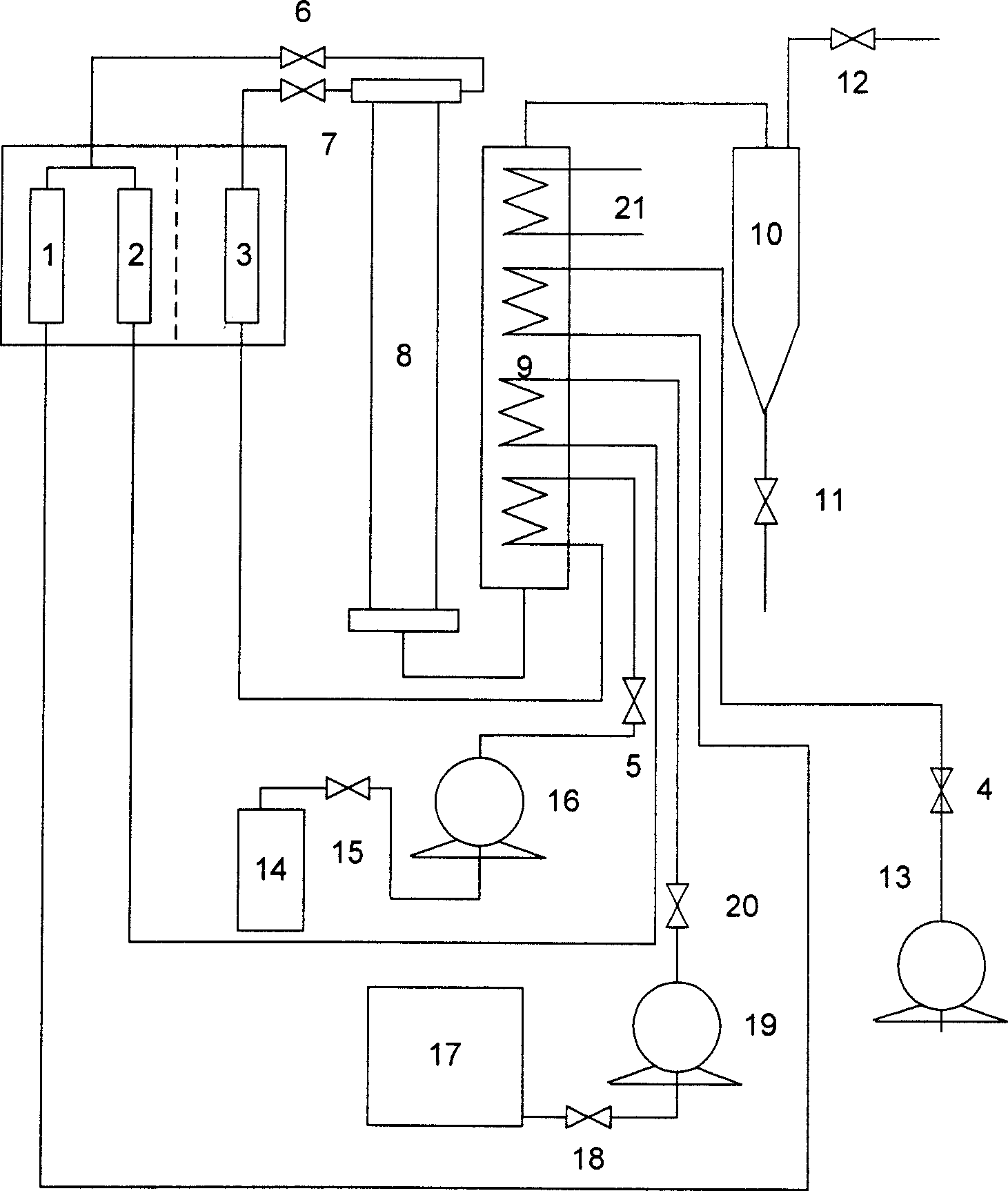

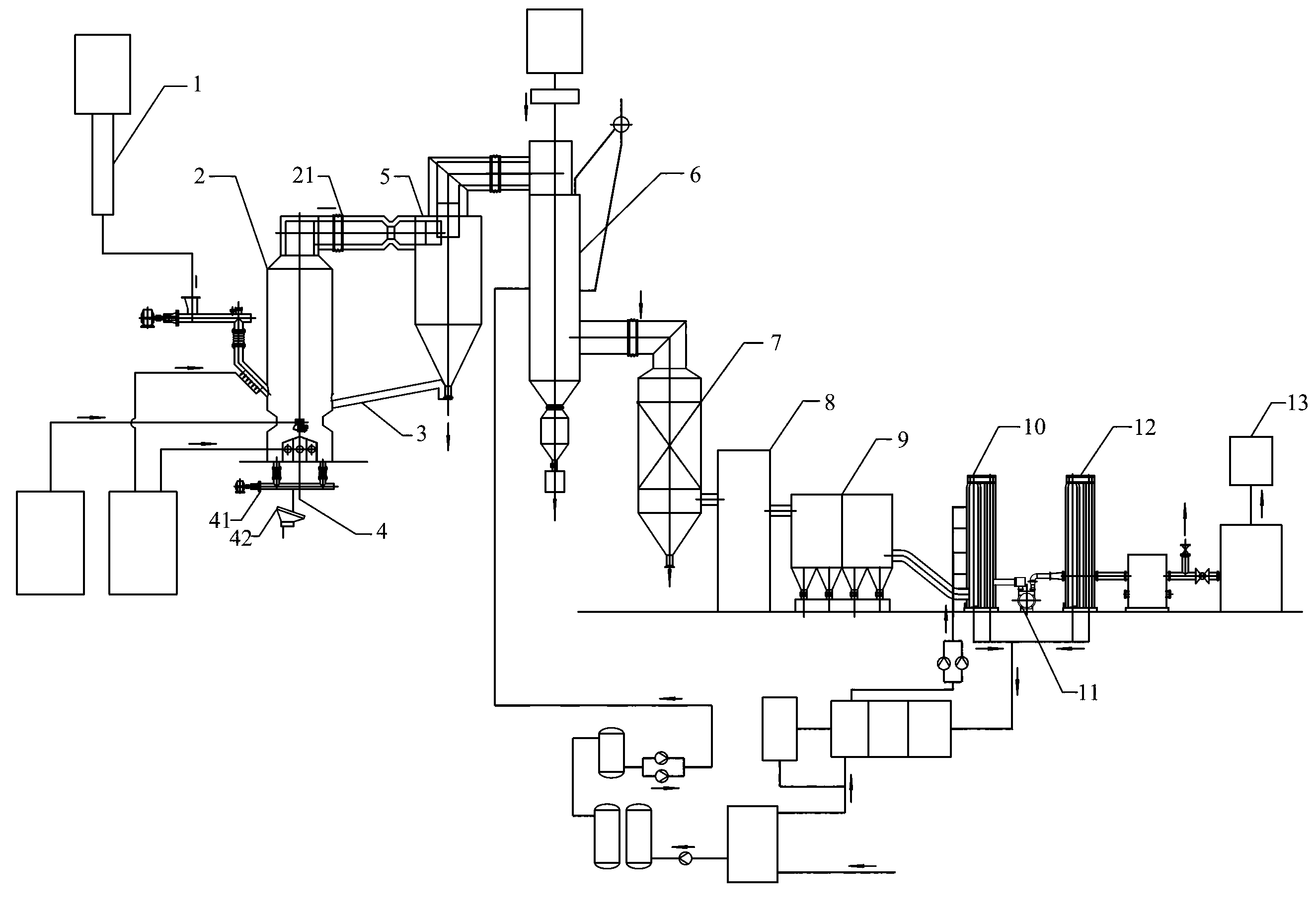

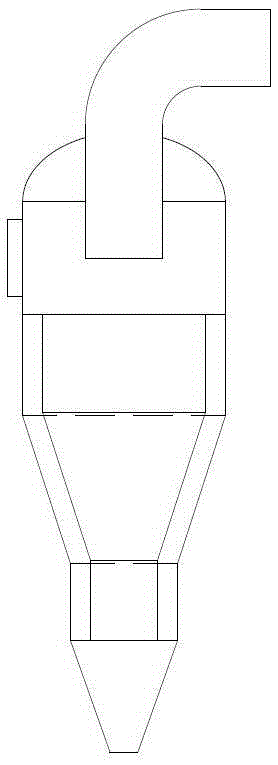

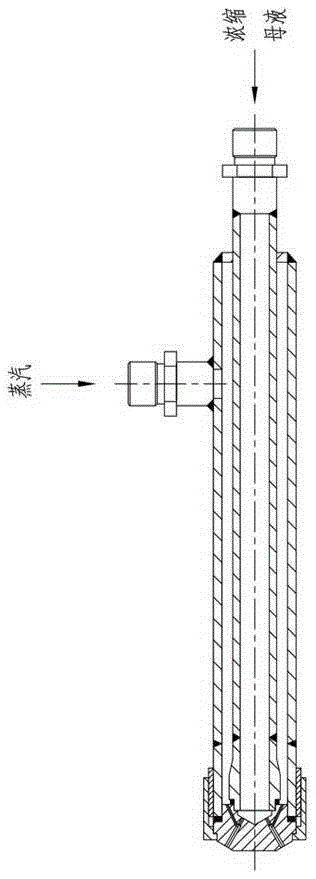

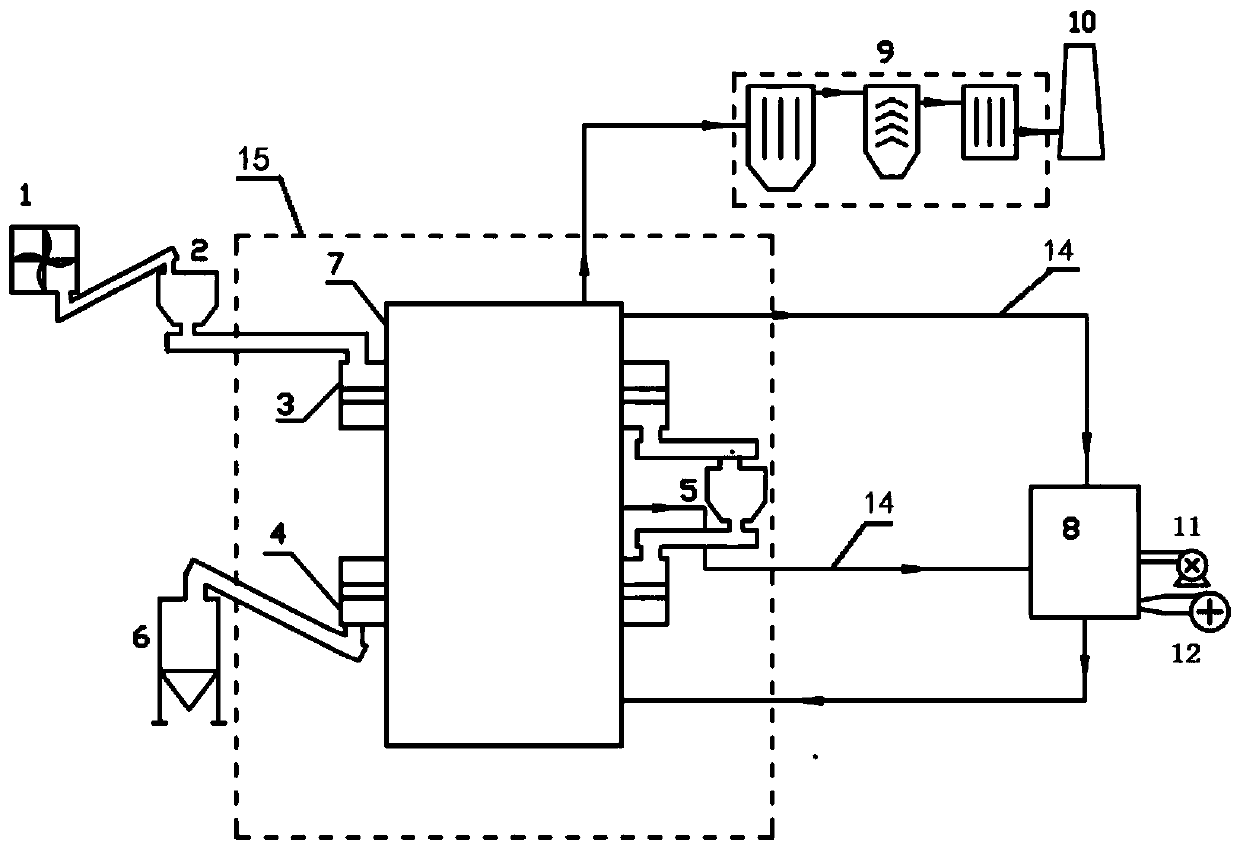

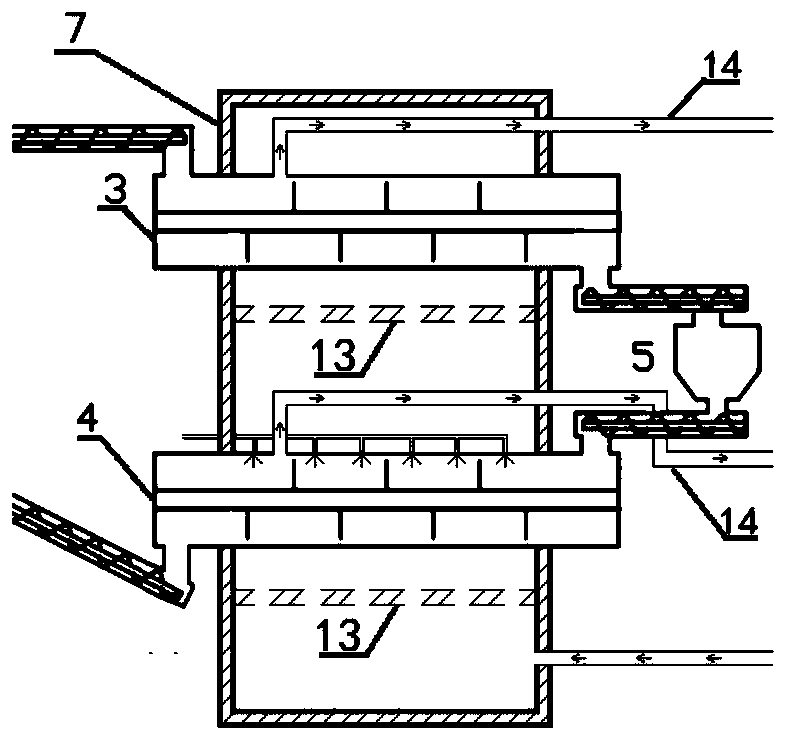

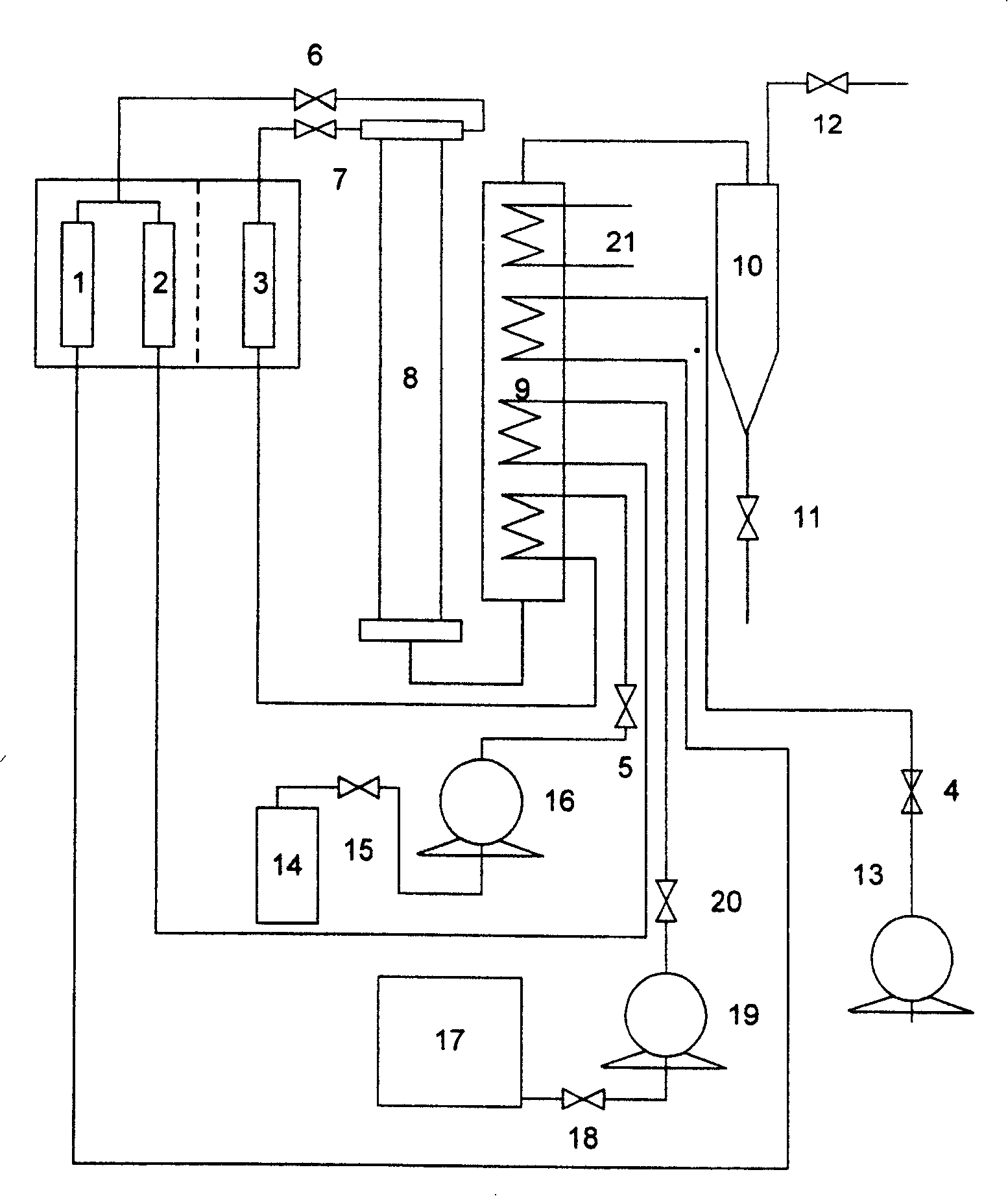

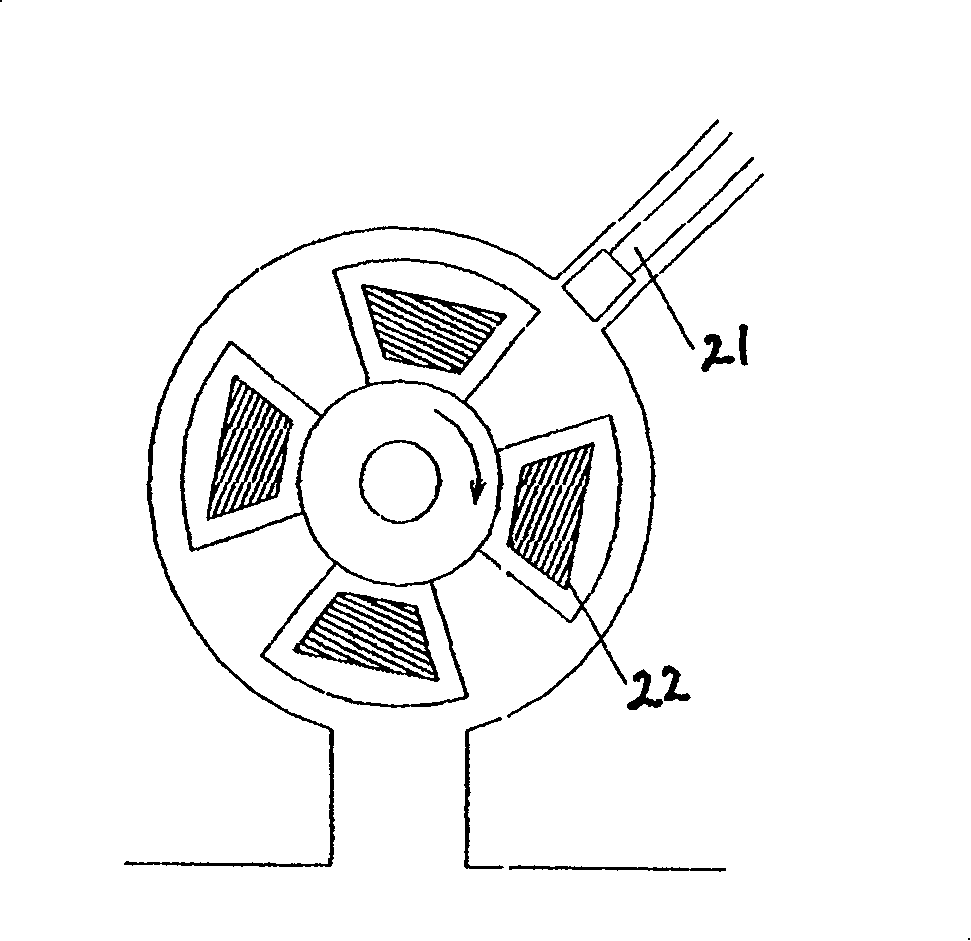

Super critical water treatment system of waste organic liquid pollution less discharge and resources utilization

InactiveCN1868915AWarm up fastAvoid cloggingWater/sewage treatment by heatingWater/sewage treatment by oxidationWater treatment systemResource utilization

A supercritical water treating system for reclaiming the rejected organic sewage and recovering its energy without draining of pollutants features that it has three preheaters (gas preheater, liquid preheater and material preheater) for respectively preheating the gas oxidant, liquid oxidant (or reaction medium) and material to suppress the generation of tar and coke and simplifying the design of reactor, and the oxidizing reaction and gasifying reaction are simultaneously preformed in this system.

Owner:XI AN JIAOTONG UNIV

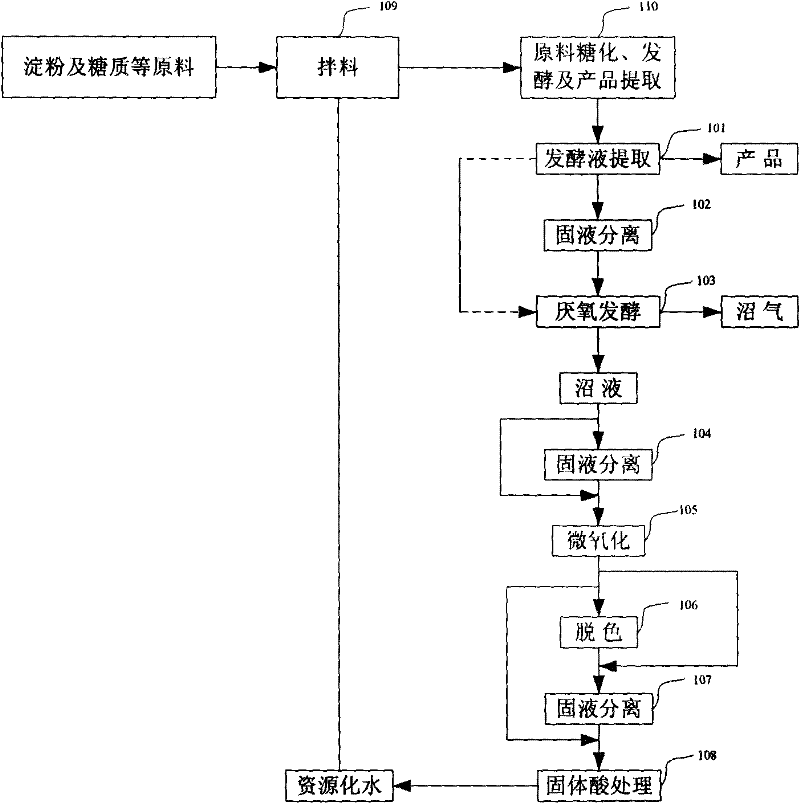

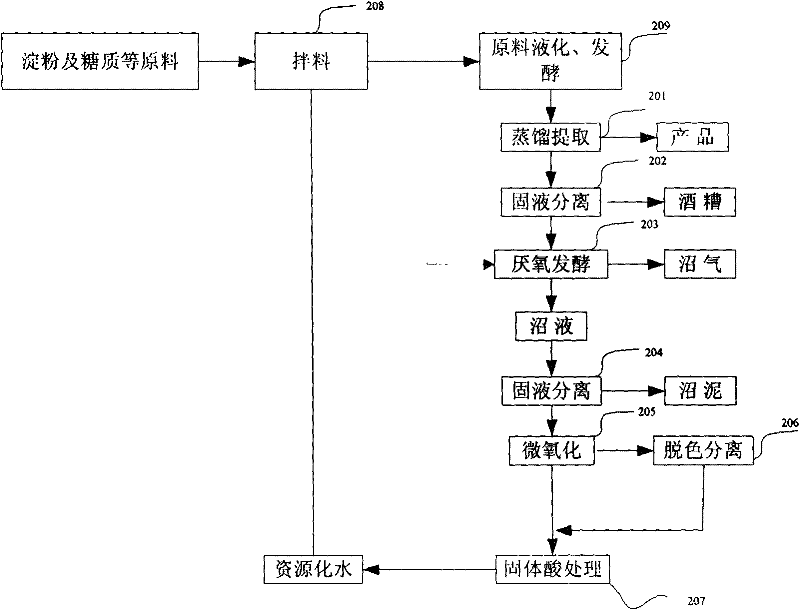

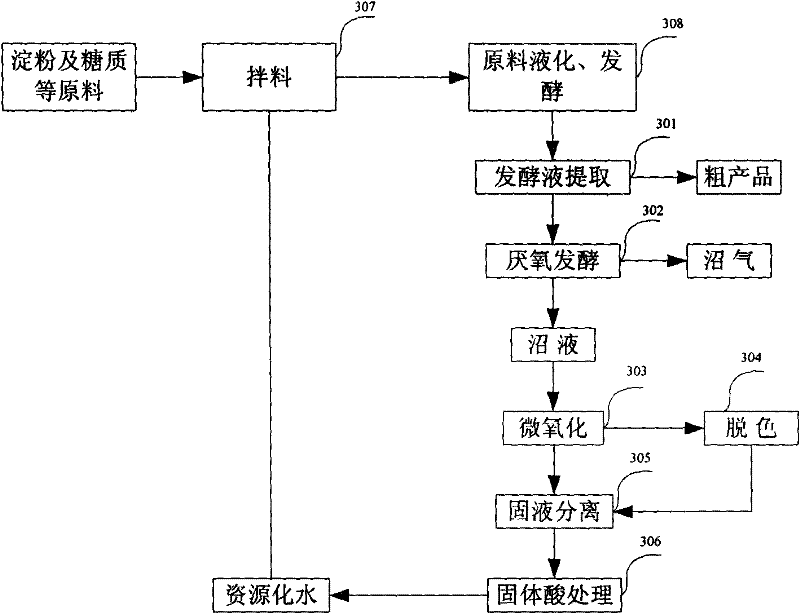

Method for realizing biogas slurry reutilization by recycling biogas slurry

ActiveCN102503019AThere are many means of resource utilizationRealize the purpose of resource utilizationOrganic compound preparationBiofuelsBiogasLiquefaction

The invention relates to a method for realizing biogas slurry reutilization by recycling biogas slurry. The method is characterized by comprising the following steps: enabling extracted waste liquor subjected to or not subjected to solid-liquid separation to enter an anaerobic biogas fermentation tank for biogas fermentation, conducting micro-oxygenation, decolorization, solid acid treatment and other processes on the biogas slurry, recycling and using the processed biogas slurry as water for mixing when the processed biogas slurry meets the requirements of process water, conducting liquefaction, saccharification, fermentation, extraction and other regular production processes on the processed biogas slurry, obtaining fermentation products, and enabling the extracted waste liquor to enter the next recirculation. According to the method, the following advantages can be achieved: the biogas slurry can be recycled all the time, not only can the waste water pollution in the traditional fermentation product process can be obviated, but also the biogas slurry reutilization can be realized, a large amount of valuable water resources can be saved, aerobic process is abandoned, and the production cost is lowered.

Owner:JIANGNAN UNIV

Treatment method of heavy metals in desulfurization waste water

InactiveCN103332810AAvoid secondary pollutionAvoid leachingMultistage water/sewage treatmentFerrous saltsSorbent

The invention discloses a treatment method of heavy metals in desulfurization waste water, and belongs to the technical field of waste water treatment. A combination method of chemical precipitation and physical adsorption treatment is adopted to remove the heavy metals in the desulfurization waste water. The chemical precipitation method uses a ferrite precipitation method that a process condition is controlled by adding ferric and ferrous salts into desulfurization slurry, so that various metal ions such as Cd, Pb, Hg, Cu, Zn, Cr and Ni in the waste water form an insoluble composite ferrite; after aging for a period of time, a solid-liquid separation means is used to achieve the object of removing the heavy metal ions; a natural adsorbent is used for adsorbing the residual heavy metals in the desulfurization waste water, therefore the discharge standard of the heavy metal ions in the desulfurization waste water is achieved. The method has the advantages of simple process, good sediment stability, high removal efficiency of heavy metals and good environmental benefits, and effectively solves the secondary pollution problem of heavy metals.

Owner:WUHAN UNIV

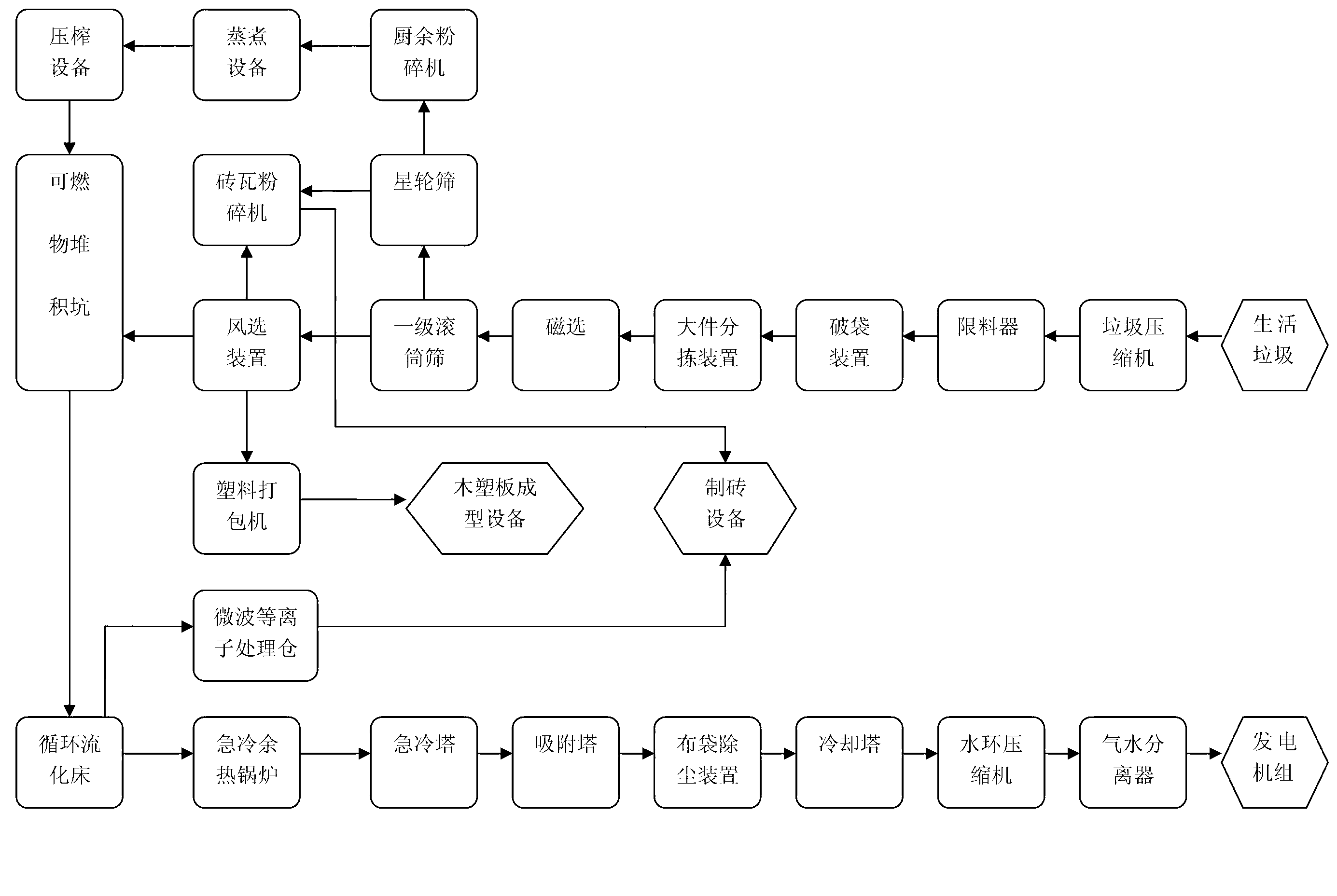

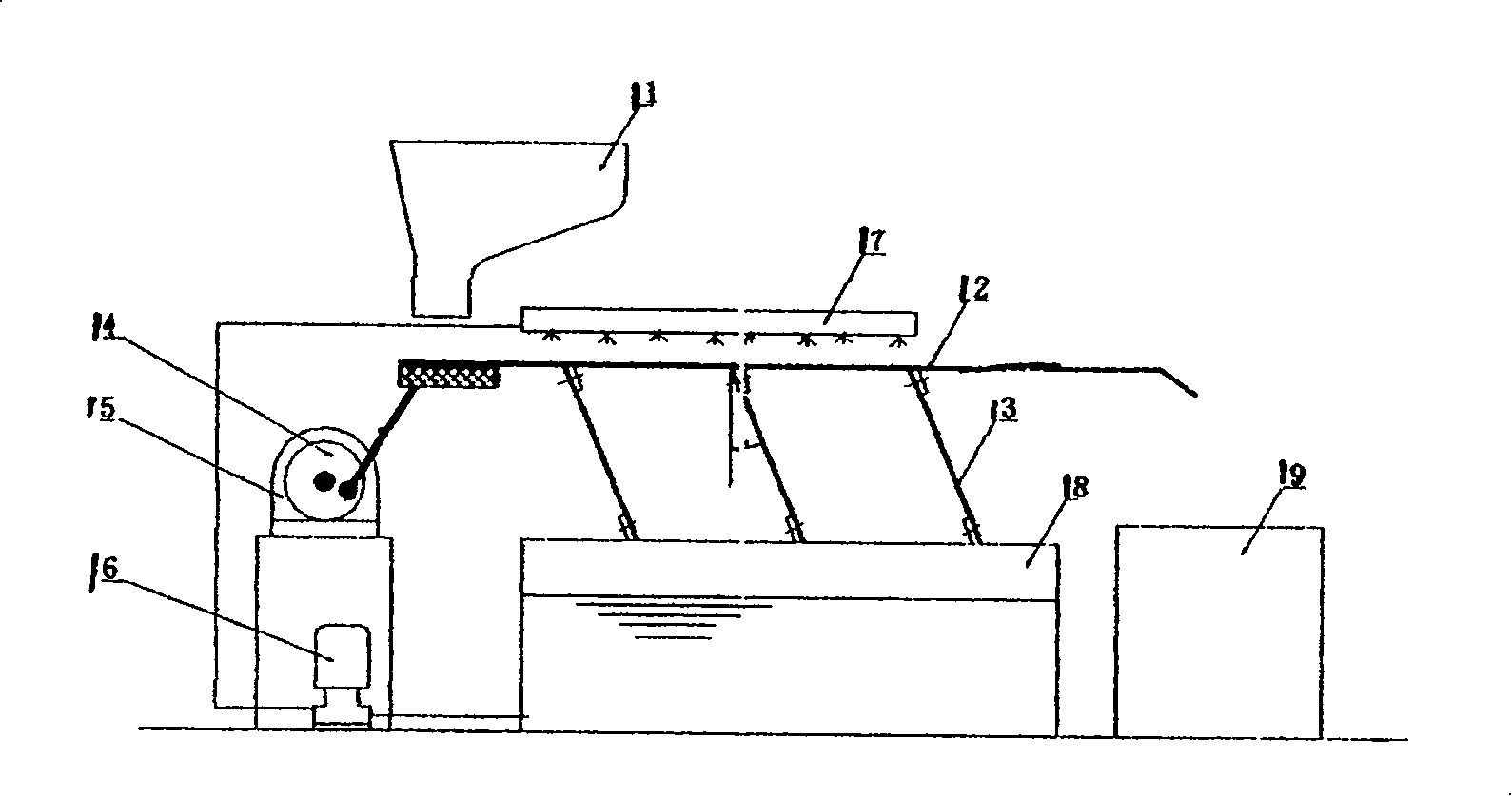

Method for treating household garbage

InactiveCN102836862AGood hygieneReduce odorSolid waste disposalFurniture waste recoveryWaste treatmentElectricity

The invention discloses a method for treating household garbage, which comprises a pre-treating step, a plastic product treating step, a sand treating step and a combustible material treating step, wherein, according to the method, the household garbage is divided into five kinds of material, namely ferromagnetic material, plastic products, sands, light combustible material and kitchen waste; the five kinds of material are used for manufacturing wood-plastic boards, bricks and generating electricity by gasification and the like, respectively; the method disclosed by the invention has the advantages of simple operation, strong practicability, high automatic degree, safe and controllable use; a circular fluidized bed with relatively high gasification efficiency is used for light combustible material and kitchen waste treatment; the circular utilization degree of the household garbage such as gasified mixing gas treatment and the like except dioxin is increased; secondary pollution is avoided; and the method can be widely suitable for household garbage treatment of all scales.

Owner:张建超 +1

Kitchen waste treatment method by utilizing mealworms

The invention discloses a kitchen waste treatment method by utilizing mealworms, which comprises the following steps: collecting kitchen waste, artificially sorting and rejecting large bones, plastic bags, tissues, toothpicks and bamboo chopsticks; washing the kitchen waste with water, crushing the washed kitchen waste into fine pulp, subjecting the crushed chicken waste to high-temperature steam sterilization, drying the waste at a high temperature, and obtaining chicken waste dry powder; mixing 60% to 90% of the chicken waste dry powder with 10% to 40% of wheat bran to obtain mealworm culture medium; the percentage is a percentage accounting for the total weight of the mealworm culture medium; and using the mealworm culture medium to feed the mealworms. According to the kitchen waste treatment method, kitchen waste is sterilized and is produced into dry powder, not only purposes of convenient transportation and long time preservation are achieved, but also reduction and harmlessness treatments of the kitchen waste are achieved; and the mealworm culture medium mixed by the kitchen waste dry powder and the wheat bran is used to cultivate mealworms, thereby not only placement problem of the kitchen waste is solved, but also the kitchen waste is changed into treasure, and reutilization of the kitchen waste is achieved.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Harmless treatment method for urban domestic garbage and its novel use

InactiveCN1701865ASimple processCrushing requirements are not highSolid waste disposalEngineeringLow calorie

New method and application of innocent energylization treatment for urban house garbage. Separate the house garbage, break up; add lime, binding agent and burning-rate accelerator, finally, form, solidify and dry; the product can be used to low-calorie fuels for cement manufacture. This invention needs low cost, simple to operate and provides new resource and application for building material.

Owner:长沙紫宸科技开发有限公司

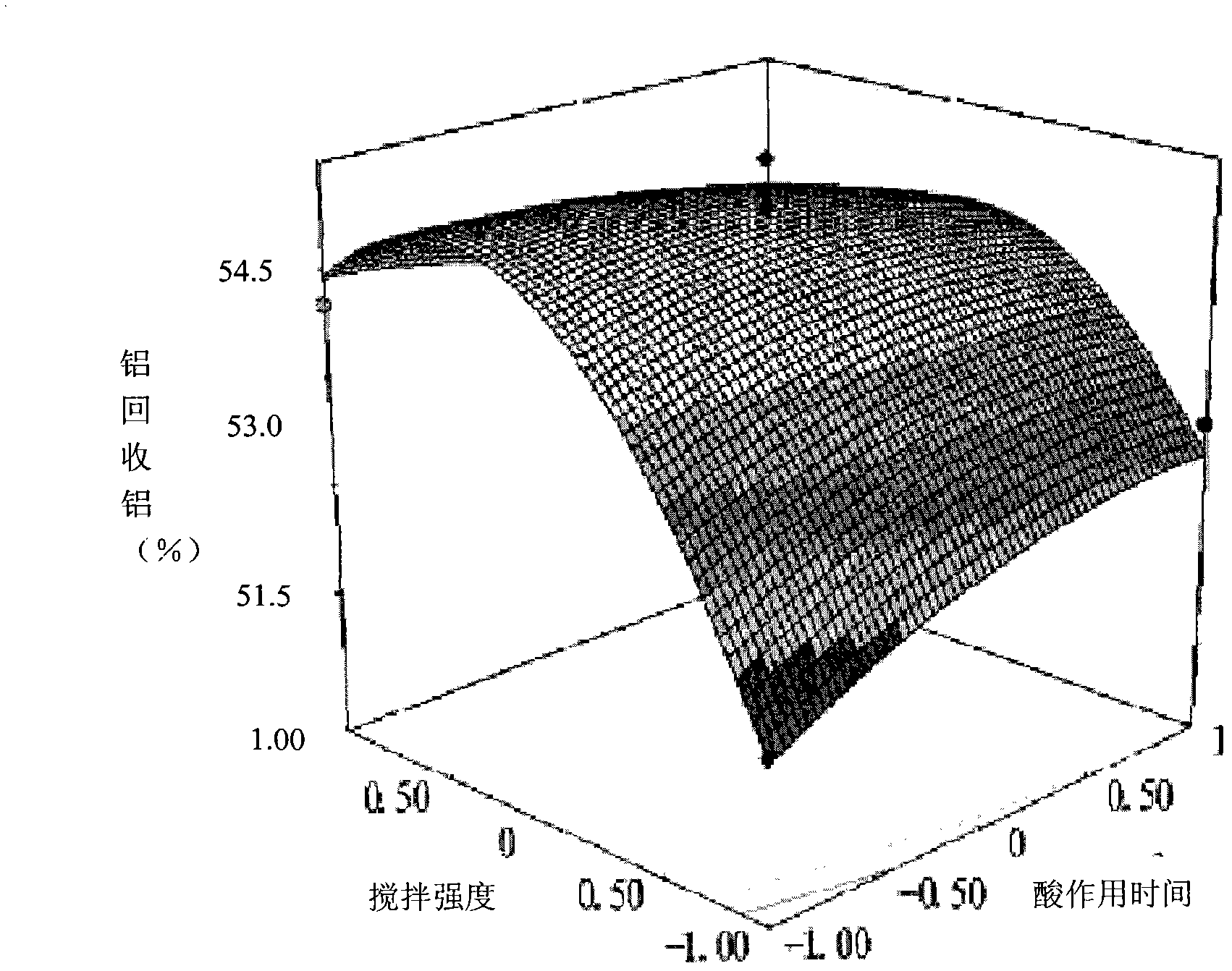

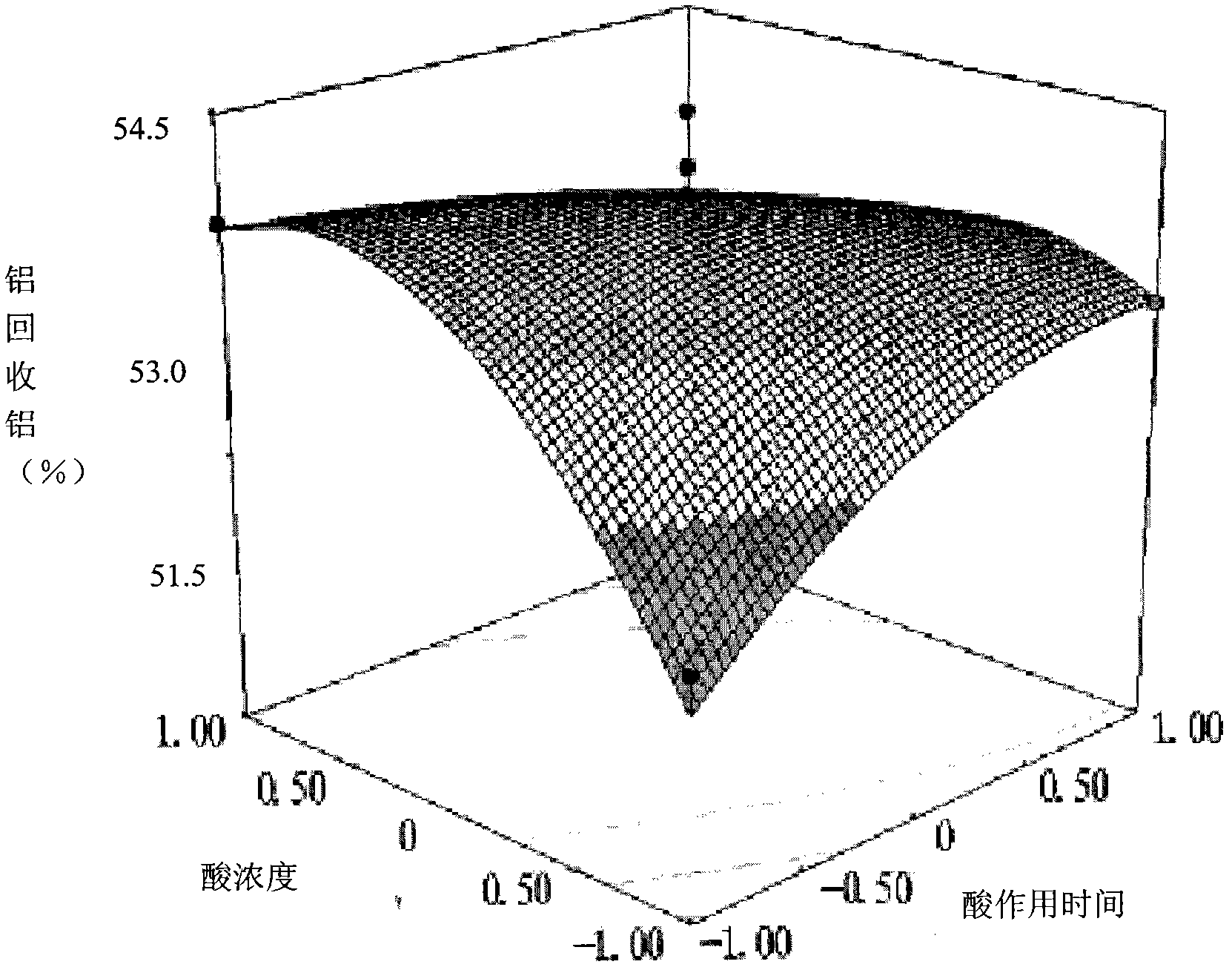

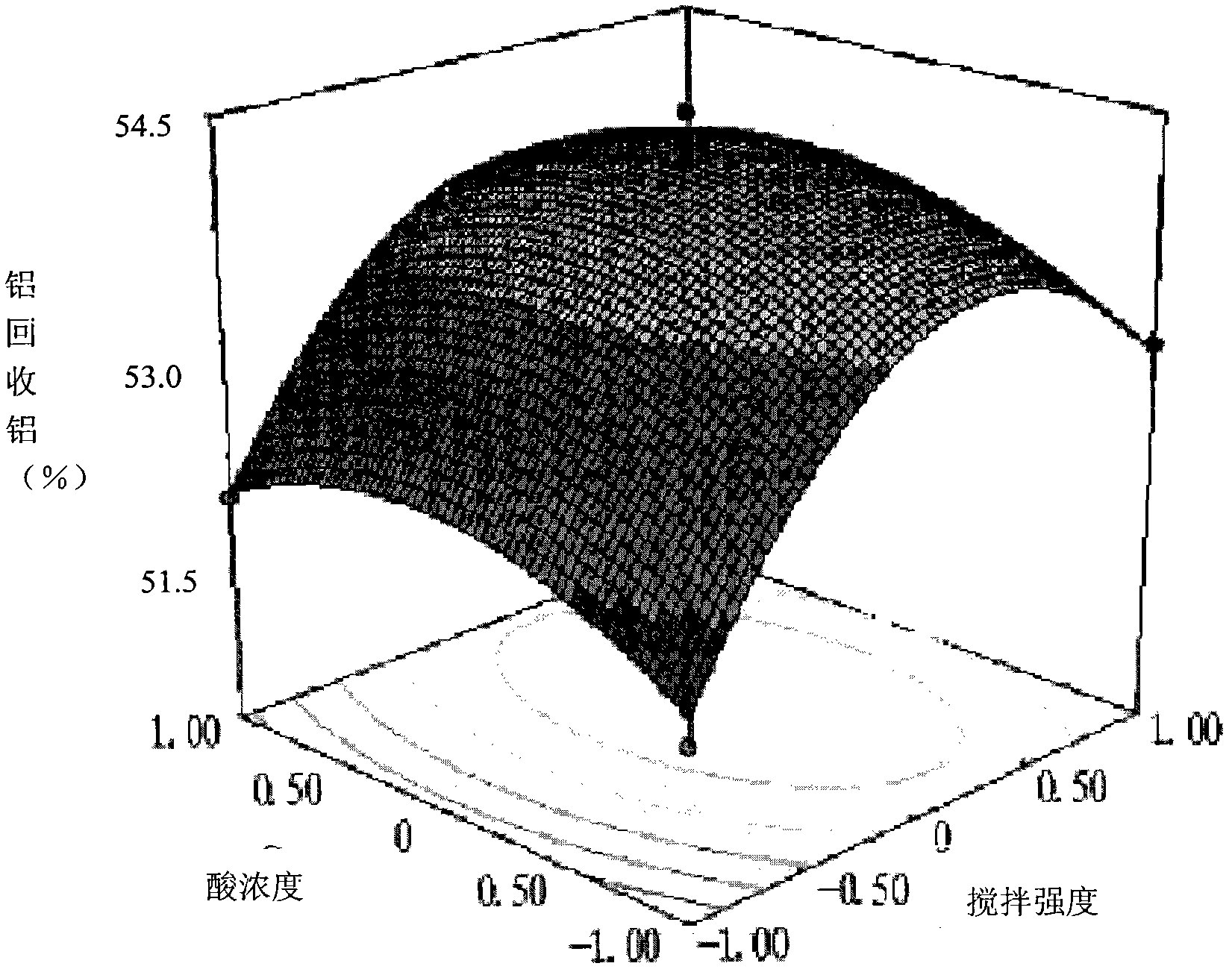

Acid lixiviation based recycling treatment method of aluminum circulating coagulation sludge

InactiveCN102583951ALower Disposal CostsEasy to recycleSludge treatment by de-watering/drying/thickeningAluminium compoundsFlocculationChemical oxygen demand

The invention provides an acid lixiviation based recycling treatment method of aluminum circulating coagulation sludge. The method is characterized by comprising the following steps of: dehydrating sludge to reduce water content of the aluminum circulating coagulation sludge to be lower than 80%; drying and baking; carrying out acidifying treatment: adding mixture of water and acid to adjust pH value of sludge slurry to 3, controlling reaction temperature to be 38 DEG C and agitating sludge and acid in mixed liquid so that the sludge and the acid sufficiently contacts; separating and purifying; and finally, filtering, evaporating and crystallizing to obtain crystal aluminum salt with a flocculation effect. According to the acid lixiviation based recycling treatment method of the aluminum circulating coagulation sludge, a large part of water and aluminum in the sludge is converted into a flocculating agent and impurities are further removed by separating to purify the flocculating agent, thereby improving the recycling of an aluminum salt flocculating agent, greatly reducing sludge disposal cost and further reducing COD (Chemical Oxygen Demand), pH value, residual organic matters and chromaticity of the sludge wastewater; and therefore, the aim of recycling is realized, the subsequence biochemical treatment is easy to implement and the damage of wastewater discharging to the environment is reduced.

Owner:NANJING UNIV

Method and device for removing SO2 in flue gas with copper extracting tailings and recycling copper extracting tailings

ActiveCN106422716AWith spray densityIncrease contact areaGas treatmentDispersed particle separationMetasilicateAmmonium sulfide

The invention relates to a method and device for removing SO2 in flue gas with copper extracting tailings and recycling the copper extracting tailings, and belongs to the technical field of environmental protection. Ferrous metasilicate (Fe2SiO4), magnesium ferrite (MgFe2O4), hedenbergite (CaFeSi2O6) and other sulfur removal active substances in the copper extracting tailings are used for reacting with SO2 in the flue gas in an aqueous solution to generate sulfite, then sulfate is generated under the action of oxygen in the flue gas, the SO2-containing flue gas makes contact with copper extracting tailing slurry, SO2 is absorbed, and thus the flue gas is purified; by adding ammonium sulfide, ammonium bicarbonate and lime milk step by step, iron ions, zinc ions, copper ions, ammonium ions and other ions in the sulfur removal slurry can be resourcelized to be reused.

Owner:KUNMING UNIV OF SCI & TECH

Method for making organic fertilizer for Clivia miniata

InactiveCN102674918AEfficient killingRealize the purpose of resource utilizationBio-organic fraction processingOrganic fertiliser preparationClivia miniataFermentation

The invention discloses a method for making an organic fertilizer for Clivia miniata and relates to a method for making an organic fertilizer. The invention solves the technical problems that the conventional fertilizer which is composted by using manure of livestock and poultry and a common carbon source is weakly alkaline, is not suitable for the growth of the Clivia miniata, and is long in composting time. The method comprises the following steps of: 1, uniformly mixing fish scale or fishbone dust, leaves or straws, manure of livestock and poultry and soil, spraying a microbial fermentation inoculum, and regulating the moisture to obtain a material; 2, piling the material into a windrow, covering a plastic film on the surface layer of the windrow, and composting; and 3, drying and crushing to obtain the organic fertilizer for the Clivia miniata. By the method, the composting time is shortened from 15 months to 4 months; and the prepared organic fertilizer for the Clivia miniata is weakly acidic and meets requirement on the pH value of the soil for the growth of the Clivia miniata.

Owner:NORTHEAST INST OF GEOGRAPHY & AGRIECOLOGY C A S

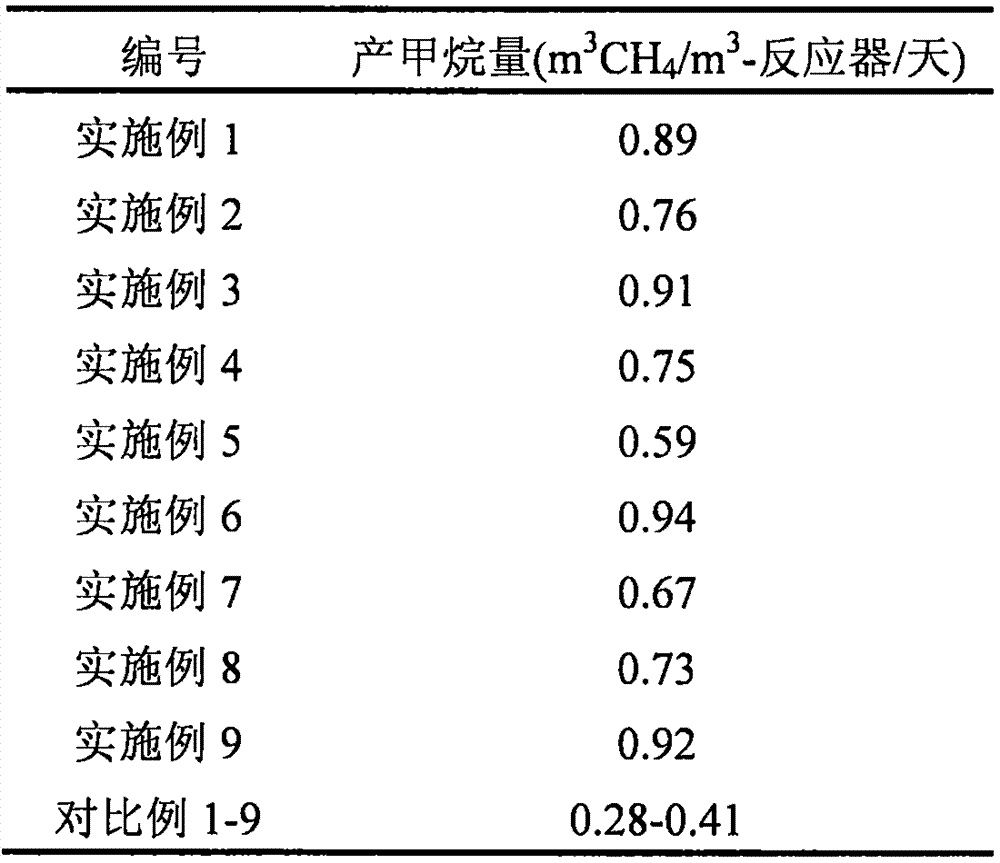

Reinforced method for production of methane from residual sludge

InactiveCN107117788AAchieve reductionIncreased methane production from anaerobic digestionSpecific water treatment objectivesWaste based fuelActivated carbonResource recovery

Belonging to the technical field of environmental protection and resource recovery, the invention in particular relates to a reinforced method for production of methane from residual sludge. Residual sludge of a sewage treatment plant is adopted as the raw material, activated carbon is added into an anaerobic reactor to reach a combined action with anaerobic microorganisms in the sludge, and rich organic matters in the sludge are effectively converted into methane gas. Compared with the prior art, the method provided by the invention has the advantages of simple operation, low investment and treatment cost, and can effectively reinforce anaerobic digestion of residual sludge for production of methane, and at the same time reaches the effect of sludge reduction.

Owner:江苏盐城环保产业工程研发服务中心 +2

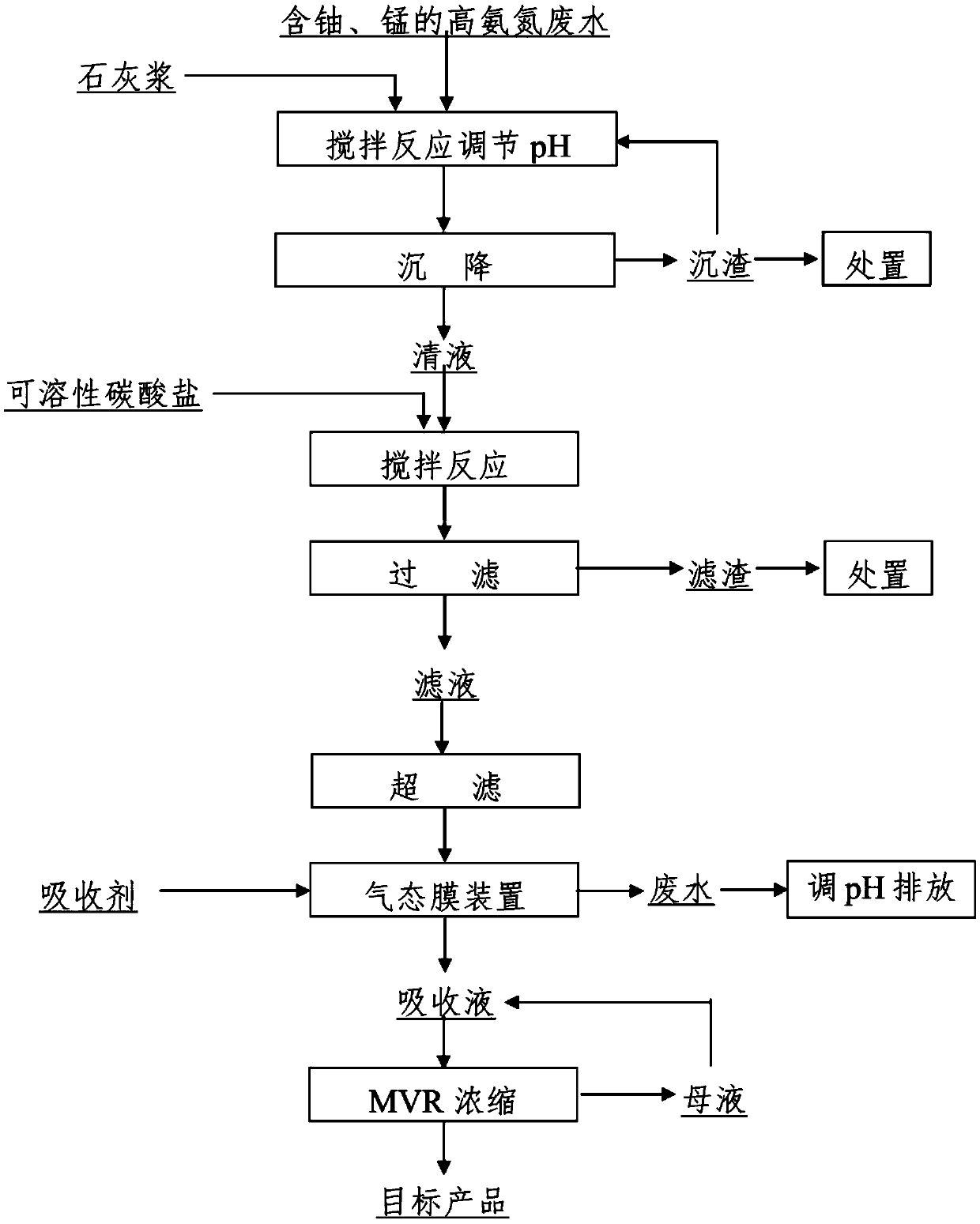

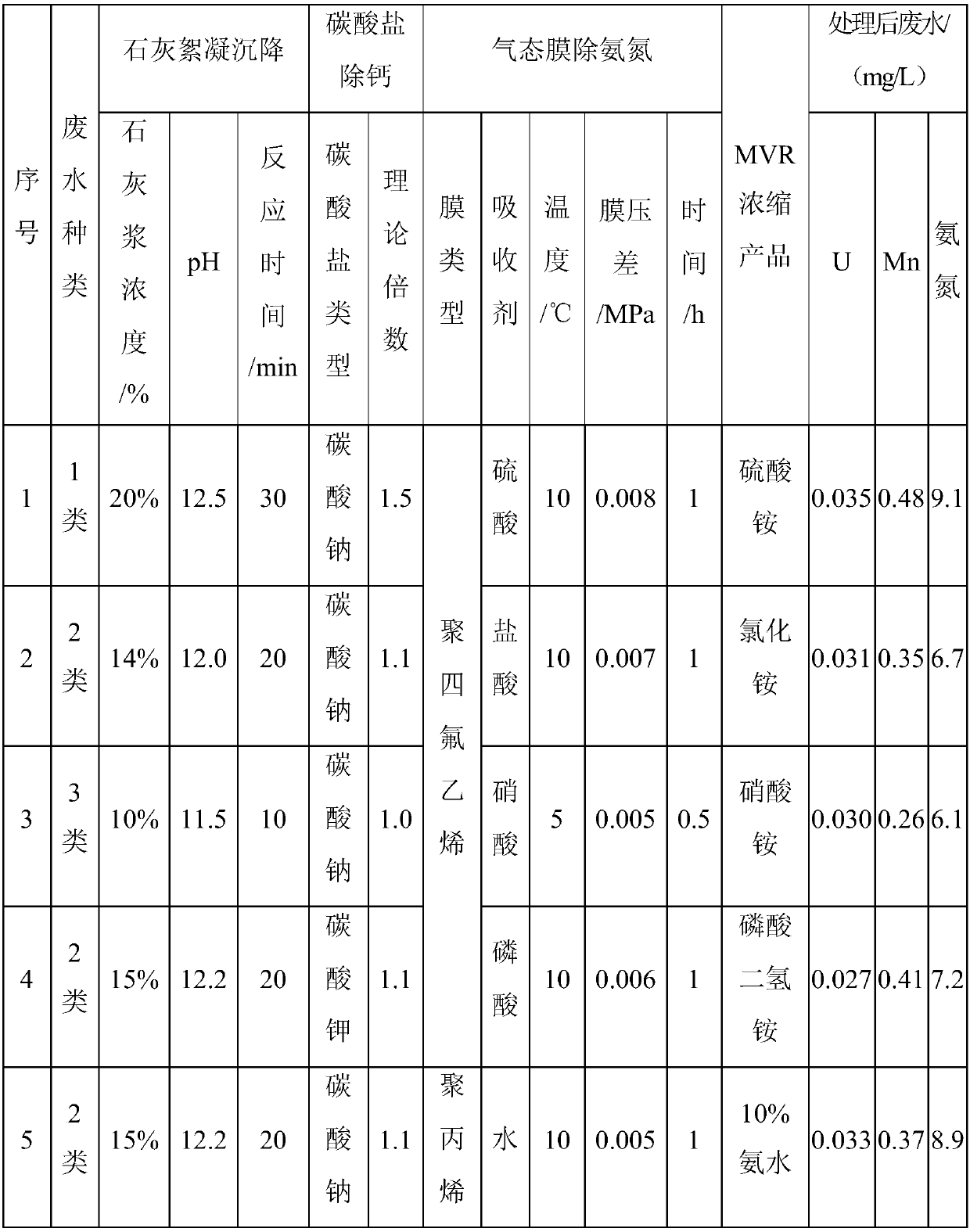

Treatment method for high-ammonia-nitrogen wastewater containing manganese and uranium

InactiveCN109607909AGuaranteed emission standardsAchieve removalRadioactive contaminantsMultistage water/sewage treatmentUltrafiltrationEvaporation

The invention relates to a treatment method for high-ammonia-nitrogen wastewater containing manganese and uranium. The treatment method comprises the following steps: (1) mixing quicklime and water, and performing stirring to a uniform slurry shape to obtain lime slurry; (2) returning sediment obtained in the step (1) to the step (1) when next operation is performed; (3) adding a soluble carbonateinto a supernatant obtained in the step (1) to remove a certain amount of calcium ions; (4) performing ultrafiltration on a filtrate obtained in the step (3), and introducing the obtained substance into a gas film device; and (5) performing evaporation concentration on an absorption liquid obtained in the step (4) to a saturated solution, performing crystallization to obtain a corresponding ammonium salt product, merging the crystallization mother liquid with a next-time absorption liquid, performing evaporation concentration, and performing crystallization. According to the treatment methodprovided by the invention, removal of harmful elements such as the manganese and the uranium in the wastewater is realized, so that qualified discharge of the wastewater is guaranteed; and the ammonianitrogen in the wastewater can be used to prepare by-products such as ammonium sulfate, ammonium chloride, ammonium nitrate, ammonium phosphate and ammonia water, so that the purpose of recycling ofwaste is realized.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

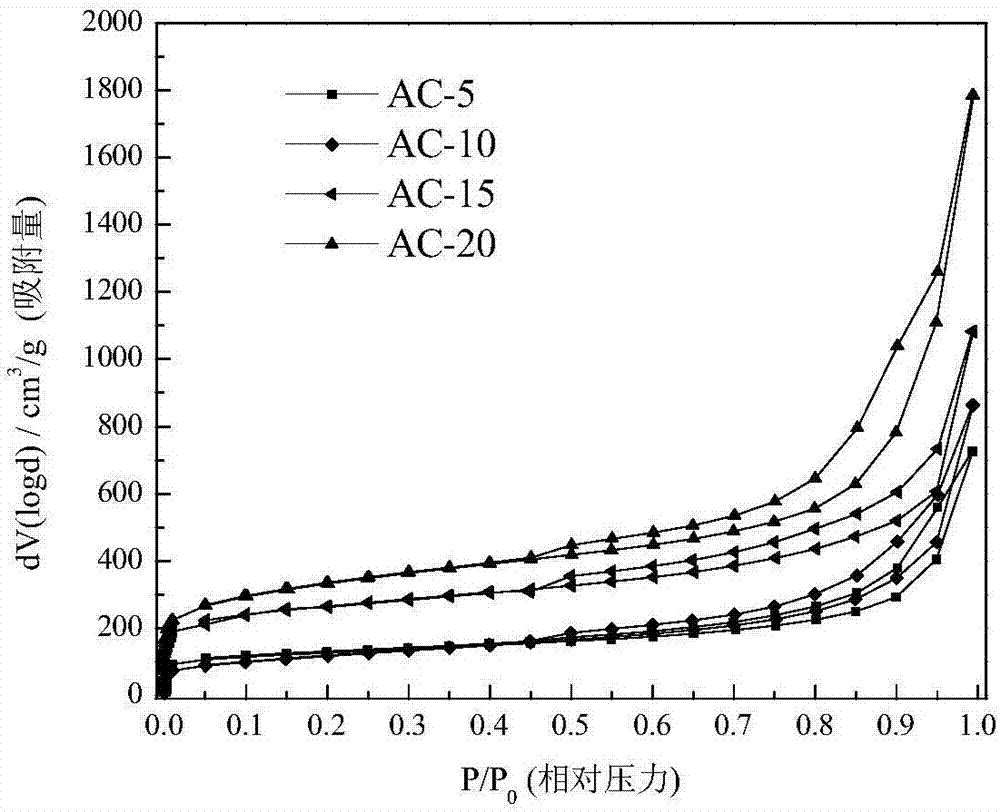

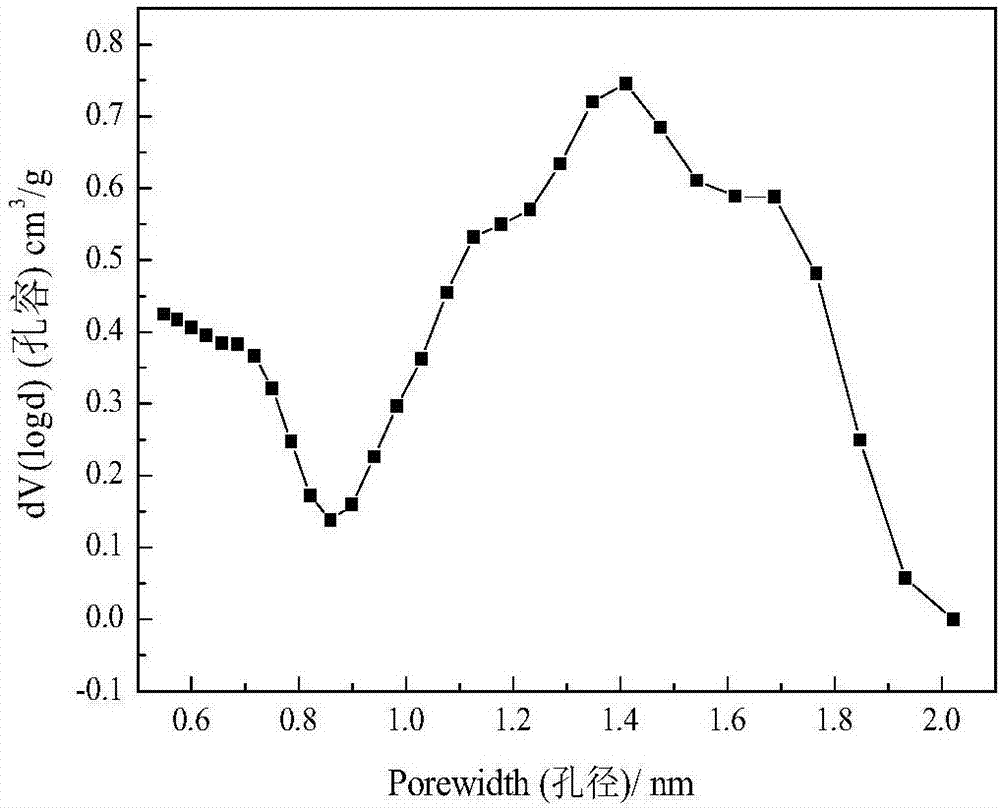

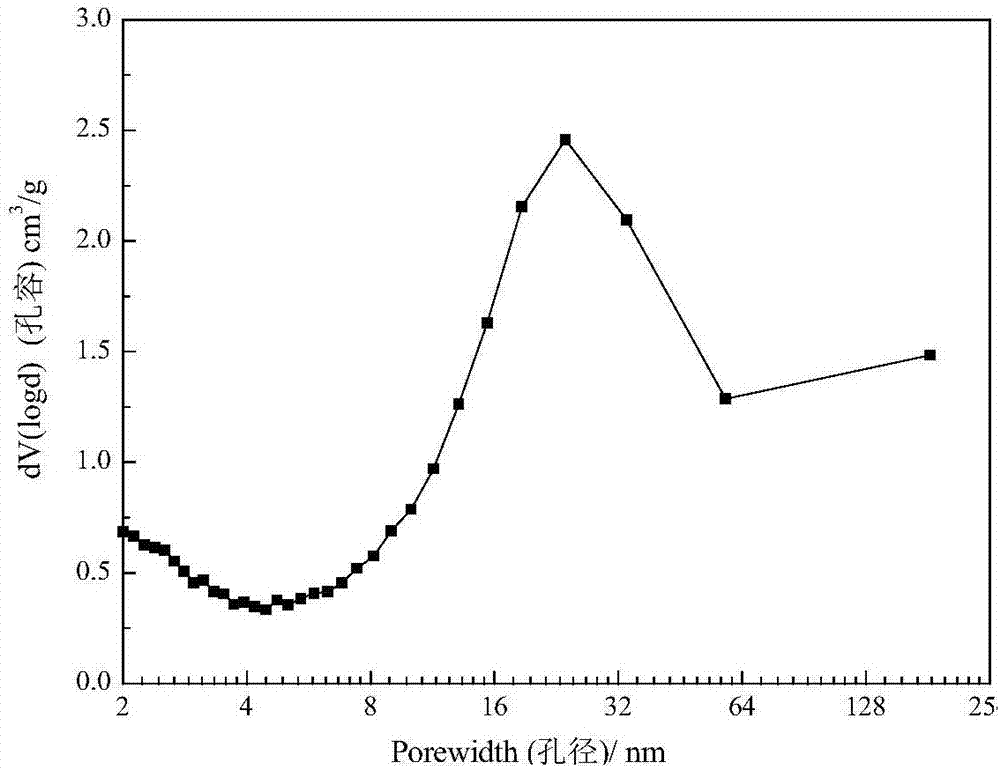

Method for preparing polyester textile waste-based activated carbon by using bittern solution as a templating-chemical activating agent

ActiveCN106904610ALarge specific surface areaOxygen-rich functional groupsCarbon compoundsOther chemical processesPolyesterActivated carbon

The invention discloses a method for preparing polyester textile waste-based activated carbon by using a bittern solution as a templating-chemical activating agent. According to the method, porous activated carbon is prepared by using polyester textile waste as a precursor of carbon and the bittern solution as the templating agent; magnesium chloride is contained in the bittern solution, the bittern solution and the polyester textile waste are mixed and pyrolyzed to form carbon-coated magnesium oxide, and after magnesium oxide particles are dissolved by hydrochloric acid, mesoporous structures with the sizes of 20-40 nanometers are formed on the surface of the carbon; meanwhile, the magnesium chloride has a chemical activating effect, a large number of microporous structures with the sizes of 1.2-1.8 nanometers are formed inside the activated carbon and on the surface of the activated carbon. The specific surface area of the activated carbon prepared by the method is 601-1398 m<2> / g. The preparation method has the advantages of low cost and high efficiency; as an adsorbent material, the obtained activated carbon is high in Cr(VI) adsorption rate and large in Cr(VI) adsorption capacity; the purpose of treating wastes by wastes is achieved while resource utilization of the polyester textile waste is achieved.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

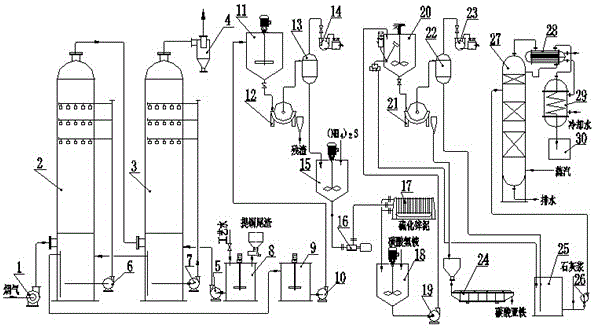

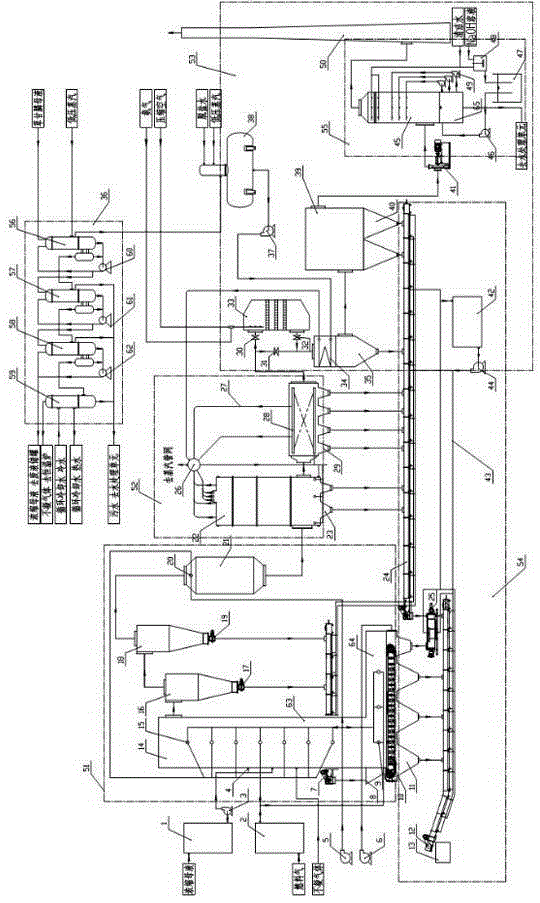

Glyphosate mother liquor resource utilization system

ActiveCN105236376AAchieve reductionRealize harmless treatmentEnergy inputPhosphorus compoundsFlue gasExhaust fumes

The invention discloses a glyphosate mother liquor resource utilization system, and relates to the environmental protection technical field of treating the three wastes of waste liquid, waste gas and solid waste. The system mainly comprises a mother liquor concentration system, a thermal oxidation reaction system, a residual heat recovery system, a flue gas environment-friendly treatment system, and a solid product recovery system. The mother liquor concentration system is respectively communicated with the thermal oxidation reaction system and the residual heat recovery system. The thermal oxidation reaction system is communicated with the residual heat recovery system and the solid product recovery system. The residual heat recovery system is communicated with the flue gas environment-friendly treatment system and the solid product recovery system. The flue gas environment-friendly treatment system is communicated with the solid product recovery system. With the system provided by the invention, chemical engineering waste liquid can be treated with an environment-friendly manner. The chemical engineering waste can be subjected to a thermal oxidation reaction, such that valuable chemical engineering products can be produced, and a purpose of resource utilization is achieved. Also, waste heat is fully utilized, such that energy can be saved.

Owner:大连科林能源工程技术开发有限公司

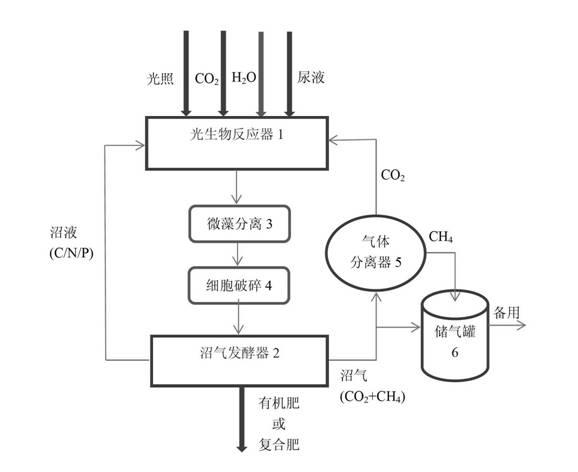

Treatment method for converting urine to resources and energy

ActiveCN102653775AReduce production loadReduce eutrophicationBio-organic fraction processingUnicellular algaePhotobioreactorSlurry

The invention relates to a treatment method for converting urine to resources and energy. The method comprises the following steps that: urine is thrown into a photobioreactor with microalgae inoculated, the microalgae grow fast in the photobioreactor under the effect of the urine, and when the concentrations of the microalgae reach 0.5-50g / L, the microalgae are separated from the photobioreactor and are put into a biogas fermentor to be fermented for 3-45 days to generate biogas, biogas slurry and biogas residues, wherein the biogas is used as energy; the biogas slurry returns to the photobioreactor to be recycled; and the biogas residues are used as organic fertilizers or compound fertilizers. Compared with the prior art, the treatment method has the following advantages: the urine is adopted as the unique nutrient source of the whole system, the whole system can well operate without any other nutrient source, grow the microalgae continuously and stably generate the biogas and the organic fertilizers or compound fertilizers; the urine is taken locally without collection or transportation, does not need to be bought as the unique hand feed of the system and is totally free; and the system has simple structure and low cost and is easy to manufacture and install.

Owner:SHANGHAI JIAO TONG UNIV

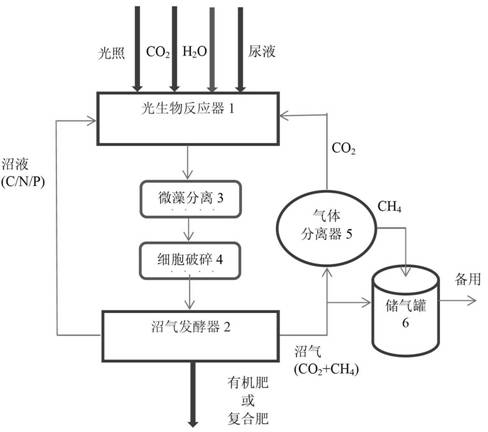

Method for preparing soil conditioner from industrial solid waste

InactiveCN111807905AReduce stockpilesRealize the purpose of resource utilizationCalcareous fertilisersAgriculture tools and machinesWhite PhosphorusPhosphogypsum

The invention discloses a method for preparing a soil conditioner from industrial solid waste. The method comprises the following steps: (1) crushing and neutralizing: adding 2-3% of quick lime into araw material phosphogypsum, and crushing and neutralizing to obtain modified phosphogypsum; (2) mixing and stirring: uniformly stirring the modified phosphogypsum, a white phosphorus fertilizer, phosphate tailings and organic matters according to a weight ratio of (40-50): (35-45): (5-15): (1-5) to obtain a granular soil conditioner; and (3) grinding: grinding the granular soil conditioner into powder to obtain the soil conditioner. The method is simple in preparation process and low in energy consumption; and the industrial solid waste is used as a raw material for preparing the soil conditioner, so the method has important significance in saving the cost, protecting the environment and creating a new circular economy mode for industrial farmers.

Owner:贵州省福泉市恒瑞环保科技有限公司

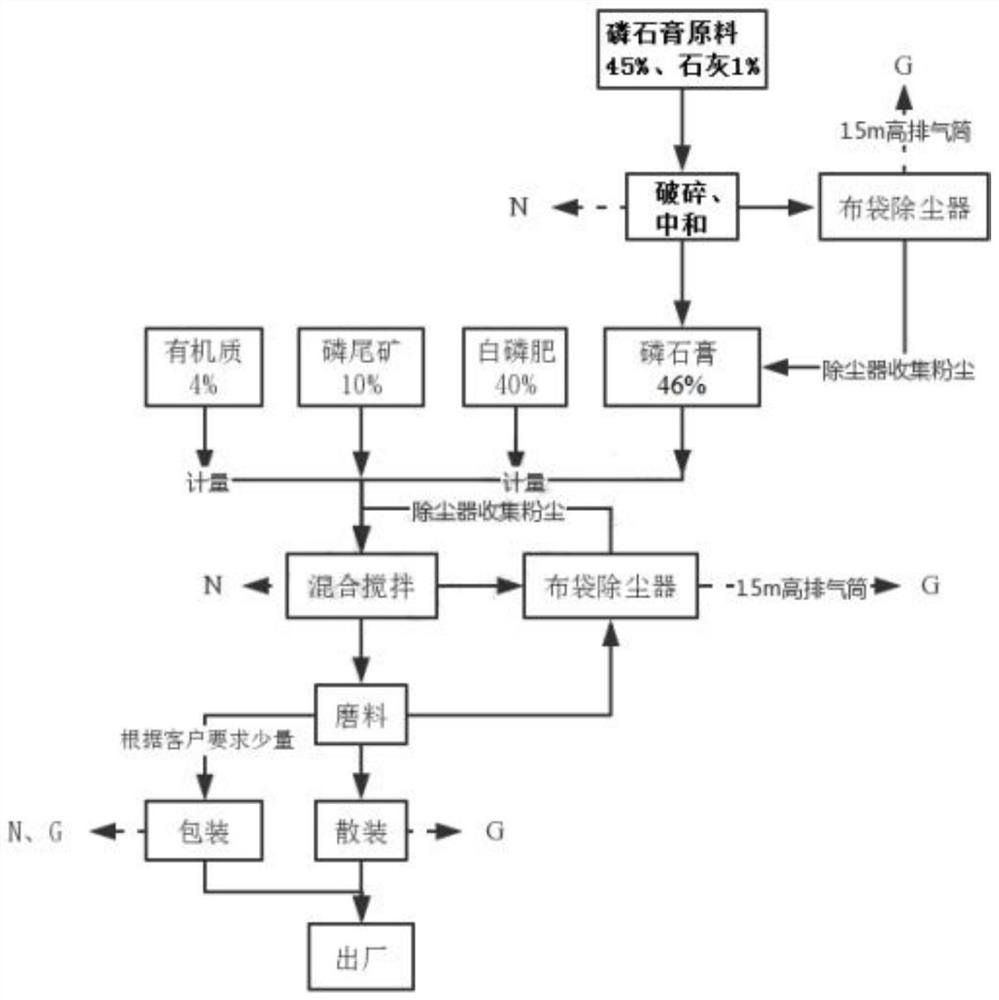

Chromium-containing solid waste and organic material synergistic pyrolysis harmless treatment device and method

PendingCN111117682AImprove heat utilization efficiencyHarm reductionLiquid hydrocarbon mixture productionSpecial form destructive distillationCombustion chamberCombustible gas

The invention discloses a chromium-containing solid waste and organic material synergistic pyrolysis harmless treatment device and method. The device comprises a pyrolysis chamber, a gasification chamber, a combustion chamber and the like. The dried chromium-containing solid waste and organic materials are crushed, mixed and granulated, particles enter the pyrolysis chamber to be pyrolyzed to generate reductive pyrolysis gas and pyrolysis solid, and hexavalent chromium in the chromium-containing solid waste is reduced into trivalent chromium through the pyrolysis gas. Carbon and the like in the pyrolysis solid are subjected to a gasification reaction with water vapor to be converted into synthetic gas, so that residues are reduced, reduced trivalent chromium is prevented from being oxidized again, subsequent chromium recycling is facilitated, and pyrolysis gas and the synthetic gas are finally introduced into the combustion chamber to be combusted to generate high-temperature flue gasto provide heat for the heating chamber. According to the chromium-containing solid waste and organic material synergistic pyrolysis harmless treatment device and method, solid residues are reduced while the chromium-containing solid waste is subjected to harmless treatment, generated gas is clean combustible gas, heat is provided for the system after sufficient combustion, the heat utilization efficiency is improved, and a feasible technical route is provided for harmless, reduction and recycling treatment of the chromium-containing solid waste.

Owner:王凯军 +2

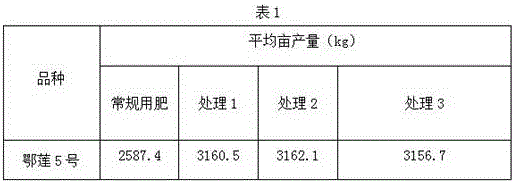

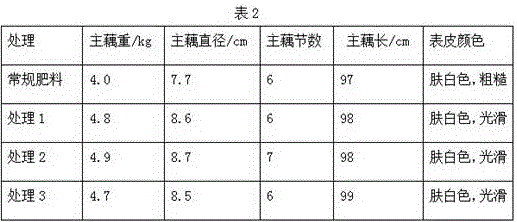

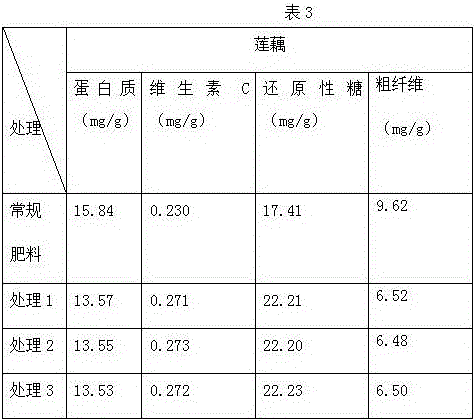

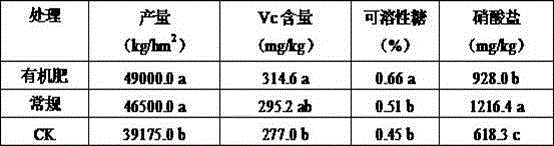

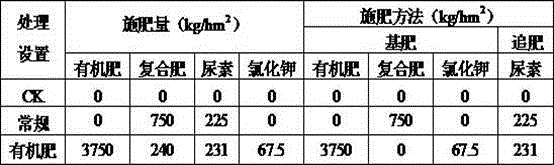

Production method of lotus root special fertilizer

InactiveCN106554230AReduce pollutionImprove the soilCalcareous fertilisersMagnesium fertilisersNutrientChemistry

The invention discloses a production method of a lotus root special fertilizer. The production method comprises the steps of organic fertilizer preparation, proportioning, pelleting and the like. As for the lotus root special fertilizer, according to the fertilizer requirement characteristic of lotus root growth, through compounding of an organic fertilizer and an inorganic fertilizer, the content proportion of nitrogen to phosphorus to potassium is reasonable, the lotus root special fertilizer contains organic matter and a medium quantity of or a trace of element fertilizers, nutrient elements needed by lotus root growth can be provided, meanwhile, the soil environment is improved, the content of the organic matter in soil is increased, the fertilizer utilization rate is increased, and accordingly the effect of increasing both production and income is achieved. After the lotus root special fertilizer is applied, the yield of lotus roots is increased by 20% or over, the production increasing effect is remarkable, and economic benefits are remarkable. In addition, the content of crude fibers of the lotus roots cultivated through the lotus root special fertilizer is low, the content of vitamin C and reducing sugar is high, and by applying the lotus root special fertilizer, a great effect of improving the quality of the lotus roots is achieved.

Owner:广西黎塘远东化肥有限责任公司

Super critical water treatment system of waste organic liquid pollution less discharge and resources utilization

InactiveCN100386268CWarm up fastAvoid cloggingWater/sewage treatment by heatingWater/sewage treatment by oxidationWater treatment systemResource utilization

A supercritical water treating system for reclaiming the rejected organic sewage and recovering its energy without draining of pollutants features that it has three preheaters (gas preheater, liquid preheater and material preheater) for respectively preheating the gas oxidant, liquid oxidant (or reaction medium) and material to suppress the generation of tar and coke and simplifying the design of reactor, and the oxidizing reaction and gasifying reaction are simultaneously preformed in this system.

Owner:XI AN JIAOTONG UNIV

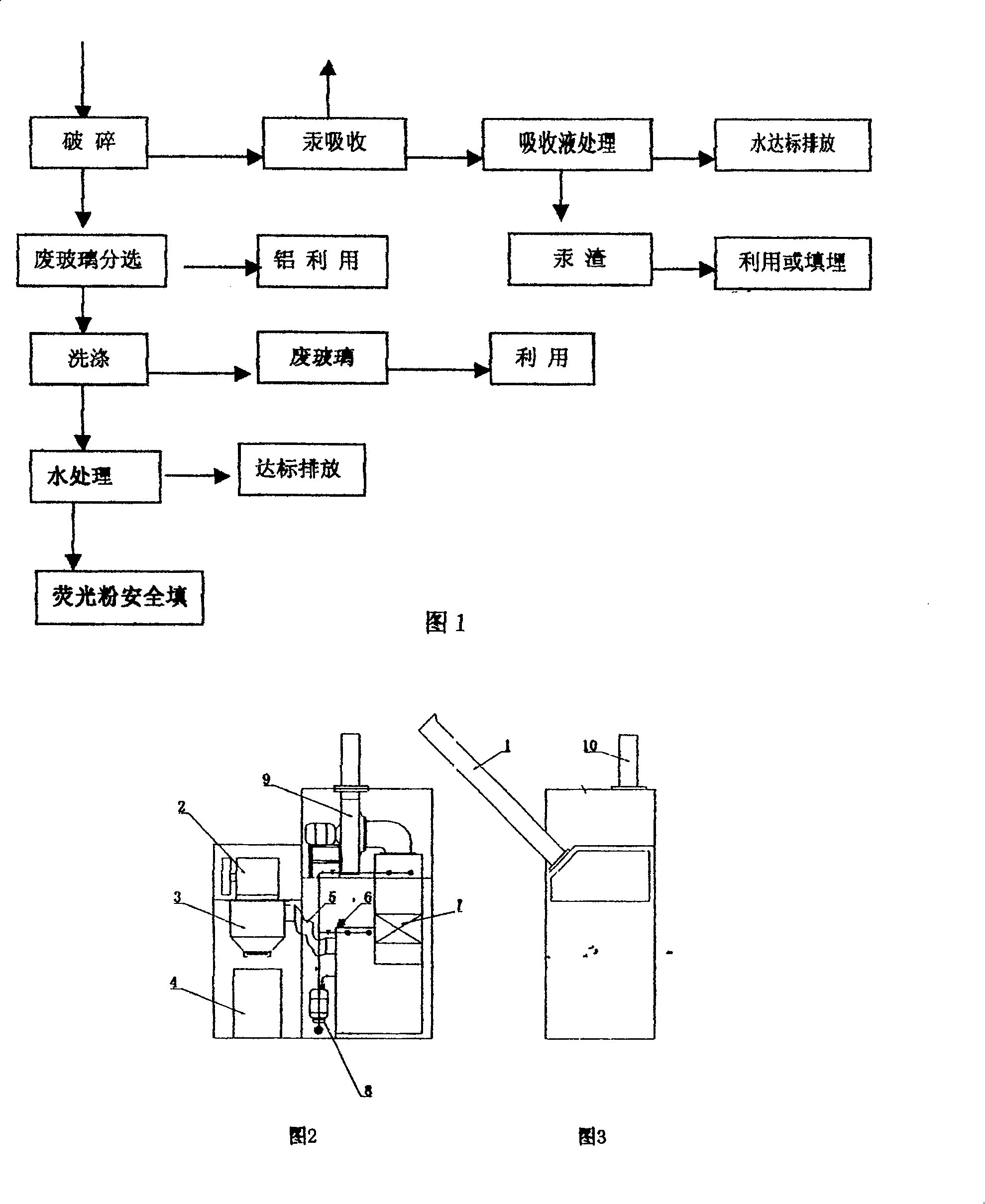

Method for processing worn-out fluorescent tube

InactiveCN100400168CEffective protectionGuaranteed recyclingGas current separationGlass recyclingWastewaterChloride

A method for treating the used fluorescent tube includes such steps as breaking in horizontal rotation breaker, absorbing the Hg gas by a absorbing system consisting of Venturi tubes and sprinkling tower suing the aqueous solution of potassium permanganate, separating metal from glass, washing glass with sulfuric acid solution to recover fluorescent powder, reducing the used solution of potassium permanganate by Fe powder, depositing, filter, treating the dregs, adding calcium chloride to the used sulfuric acid solution, reaction, and adding lime to neutralize the drained water.

Owner:LIDA ENVIRONMENT ENG DALIAN ECONOMIC TECH DEV ZONE

Method for promoting anaerobic fermentation of excess sludge by combining copper sulfate and alkaline pH to produce short-chain fatty acid

ActiveCN104531783AAchieve reductionRealize the purpose of resource utilizationFermentationMicroorganismWastewater

The invention discloses a method for promoting anaerobic fermentation of excess sludge by combining copper sulfate and alkaline pH to produce short-chain fatty acid and belongs to the technical field of environmental protection. According to the method, the excess sludge in a municipal wastewater treatment plant is used as the raw material; firstly, the copper sulfate is added to make the walls of microorganisms in the excess sludge break; secondly, the excess sludge is washed to remove copper ions; lastly, the pH value of the excess sludge is adjusted to be alkaline for anaerobic fermentation. After the excess sludge is pretreated through the copper sulfate, the hydrolysis rate is increased in the anaerobic fermentation process, and the yield of the short-chain fatty acid is increased; besides, the alkaline pH further promotes wall breakage of the microorganisms in the excess sludge and effectively suppresses the activity of methane bacteria produced in the anaerobic fermentation process, so that organic matter in the excess sludge is converted into the short-chain fatty acid to the maximum extent, and meanwhile the short-chain fatty acid is prevented from being converted into methane and is accumulated. The copper sulfate adopted in the method can effectively promote anaerobic fermentation of the excess sludge to produce the short-chain fatty acid at a small dosage, and meanwhile the effect of sludge reduction is achieved.

Owner:BEIJING UNIV OF TECH

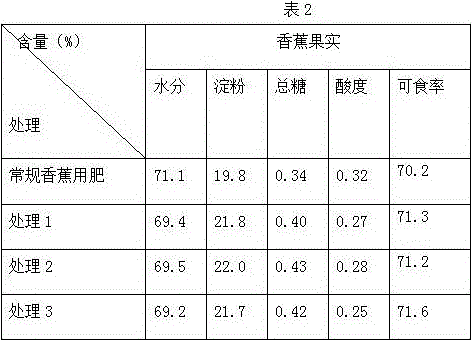

Production method of special fertilizer for banana

InactiveCN106747904AReduce pollutionIncrease contentCalcareous fertilisersMagnesium fertilisersNutrientInorganic fertilizer

The invention discloses a production method of a special fertilizer for a banana. The production method comprises the following steps of the preparation of an organic fertilizer, proportioning, granulation and the like. The special fertilizer for the banana is reasonable in the content ratio of nitrogen, phosphorus and potassium according to the fertilizer requirement characteristic of the growth of the banana and through the compounding of the organic fertilizer and an inorganic fertilizer, further, contains an organic matter, and is a medium-trace-element fertilizer; nutrient elements needed by the growth of the banana can be provided; meanwhile, a soil environment is ameliorated; the content of a soil organic matter is improved, the utilization rate of a fertilizer is improved; thus, the effects of increasing a yield and increasing an income are achieved; by adopting the special fertilizer for the banana, which is provided by the invention, the yield of the banana is increased by 15 percent or above; the yield increasing effect is obvious; the economic benefit is obvious.

Owner:广西黎塘远东化肥有限责任公司

Production method of special fertilizer for sugarcane

ActiveCN106518188AReduce pollutionIncrease contentCalcareous fertilisersBio-organic fraction processingCompound organicTrace element

The invention discloses a production method of special fertilizer for sugarcane. The production method comprises steps of preparation of organic fertilizer, material blending, granulation and the like. According to the fertilizer requiring characteristics of sugarcane growth, by compounding organic fertilizer and inorganic fertilize, reasonably proportioning content of N, P and K and containing organic matter, secondary elements and trace elements, the special fertilizer for the sugarcane can provide nutrient elements required by sugarcane growth, improve soil environment and increase organic content of soil, the fertilizer utilization rate is increased, and both production and income are increased. Compared with conventional fertilizer application, after the special fertilizer for the sugarcane is applied to the sugarcane, the yield per mu is increased by 20% or higher, the sugar per mu is increased by 1% or higher, and the economic performance is improved obviously.

Owner:广西黎塘远东化肥有限责任公司

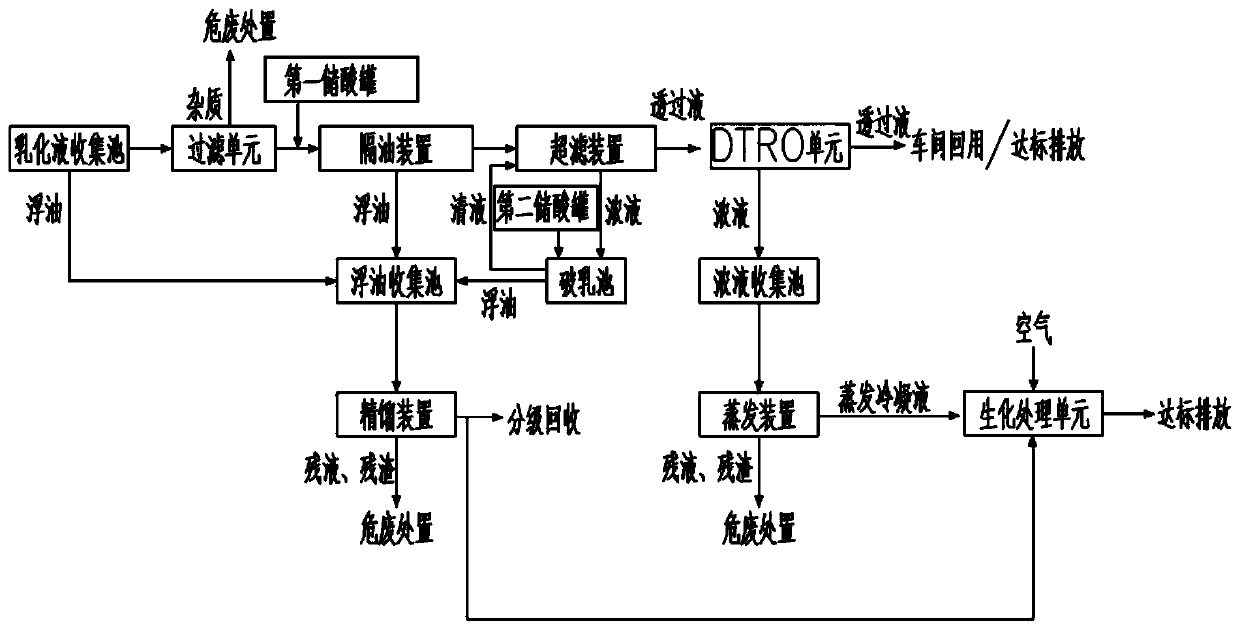

Waste emulsion resource utilization treatment system and process

PendingCN110028201AStabilizationRealize the purpose of resource utilizationFatty/oily/floating substances removal devicesWater contaminantsUltrafiltrationEmulsion

The invention discloses a waste emulsion resource utilization treatment system. The waste emulsion resource utilization treatment system comprises an emulsion collection tank, a filtering unit, a first acid storage tank, an oil separation device, an ultrafiltration device, a second acid storage tank, a demulsification tank, a DTRO unit, a floating oil collection tank, a rectification device, a concentrated liquid collection tank, an evaporation device and a biochemical treatment unit. The invention also discloses a waste emulsion resource utilization treatment process. A purpose of recycling mineral oil extracted from waste emulsion is achieved, and meanwhile, the waste liquid is stably treated to reach the standard.

Owner:杭州齐创环境工程有限公司

Environment-friendly treatment method of domestic garbage

InactiveCN106269817AEliminate pathogenic microbial contaminationLess energy consumption for processingSolid waste disposalBiofuelsDecompositionRotary kiln

The invention belongs to the technical field of environment protection, and particularly relates to an environment-friendly treatment method of domestic garbage. The method comprises the steps that sterilization and anti-corrosion operations are performed, and organic matter decomposition is inhibited; the domestic garbage is shorted and crushed; lime, bonding agents and combustion improvers are added; the materials are mixed; pressing forming or extrusion forming is performed; solidification is performed; formed and solidified block materials are stacked, and are naturally dried in the air; the block materials which are dried in the air are used as low calorie fuel, coal materials or pavement brick base materials for cement production, and are fed into a rotary kiln and a vertical kiln to be directly combusted. The method is used for solving the problems of secondary pollution in the domestic garbage treatment process and useful ingredient waste after the treatment.

Owner:重庆睿容环保科技有限公司

Method for treating and utilizing coal gasification wastewater

InactiveCN103663839AReduce COD valueReduce nitrogen contentMultistage water/sewage treatmentCoal gasification wastewaterWater quality

The invention provides a method for treating and utilizing coal gasification wastewater. The method comprises: sequentially carrying out pretreatment on to-be-treated coal gasification wastewater, biochemical treatment, denitrification treatment, advanced treatment and microalgae purification treatment. The method provided by the invention is used for treating the coal gasification wastewater so as to greatly reduce the COD value and contents of total phenolics and total nitrogen in the wastewater, and the water quality index of the final effluent meets the requirements of GB8978-1996 integrated wastewater discharge primary standard.

Owner:CHINA NAT OFFSHORE OIL CORP +1

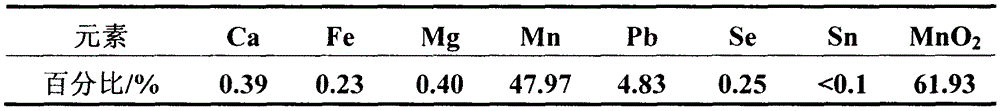

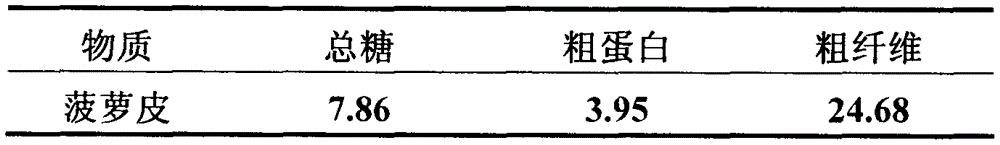

Method for resource utilization of pineapple peel and electrolytic manganese anode slime

InactiveCN104962734AImplement step-by-step extractionAchieve enrichmentProcess efficiency improvementElemental selenium/telluriumActivated carbonFiltration

The invention provides a new method for resource utilization of pineapple peels and electrolytic manganese anode slime. The method comprises the following basic steps: (1) adding manganese anode slime into a reactor, adding pineapple peels with a mass which is 0.18 to 0.30 time of the mass of manganese anode slime and concentrated sulfuric acid with a mass which is 1.8 to 2.5 times of the mass of manganese anode slime, and regulating liquid-to-solid ratio to 3:1 to 5:1; (2) performing reaction at 90 to 98 DEG C for 4 to 8 hours, wherein the leaching rate of manganese reaches more than 95 percent; (3) obtaining residues with lead content of 46 percent, which can be used as lead concentrate; (4) adding 0.4 to 1.0 g / L waste iron scrap in filtrate, adding activated carbon according to iron-to-carbon mass ratio of 2:1 to 4:1 and performing reaction for 30 to 180mins under an agitating condition at 30 to 98 DEG C, wherein selenium is deposited in a solid phase and the recovery rate of selenium reaches 95 percent; (5) performing filtration again and then returning back filtrate for producing electrolytic manganese. The method for resource utilization of pineapple peels and electrolytic manganese anode slime has the advantages that the pineapple peels are used as reducing agent, the wastes are turned into valuable things and the method has environmental and economic dual benefits.

Owner:GUANGXI UNIV

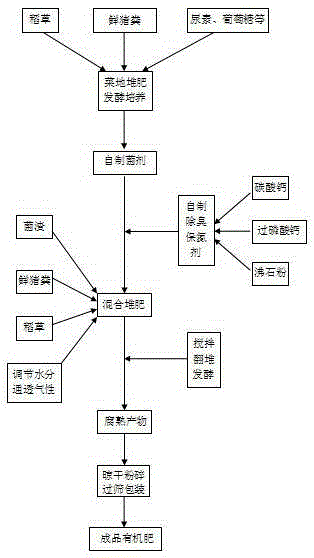

A method for producing organic fertilizer by using bacterial agent to ferment bacterial residue and pig manure mixed compost

InactiveCN103613419BIncrease productionSimple structureBio-organic fraction processingOrganic fertiliser preparationBiotechnologyEnvironmental engineering

The invention discloses a method for producing organic fertilizer by fermenting bacteria dregs and pig manure mixed compost, which is realized through a series of steps such as preparing self-made bacteria agent, self-made deodorant, treating the mixed composting of bacteria dregs and pig manure to produce organic fertilizer. The composting method starts quickly, the fermentation temperature is high, the high temperature lasts for a long time, the compost is thoroughly decomposed, the pathogenic bacteria and harmful insect eggs are completely killed, the nutrient loss is small, the quality of the organic fertilizer is high, and the investment is small, the process is simple, the operation is simple, and the treatment period is short. , Conducive to popularization and promotion. The application of the invention can achieve the dual purposes of reducing the pollution of waste to the environment and realizing resource utilization of waste.

Owner:INST OF SOIL FERTILIZER & RESOURCE ENVIRONMENT JIANGXI ACAD OF AGRI SCI

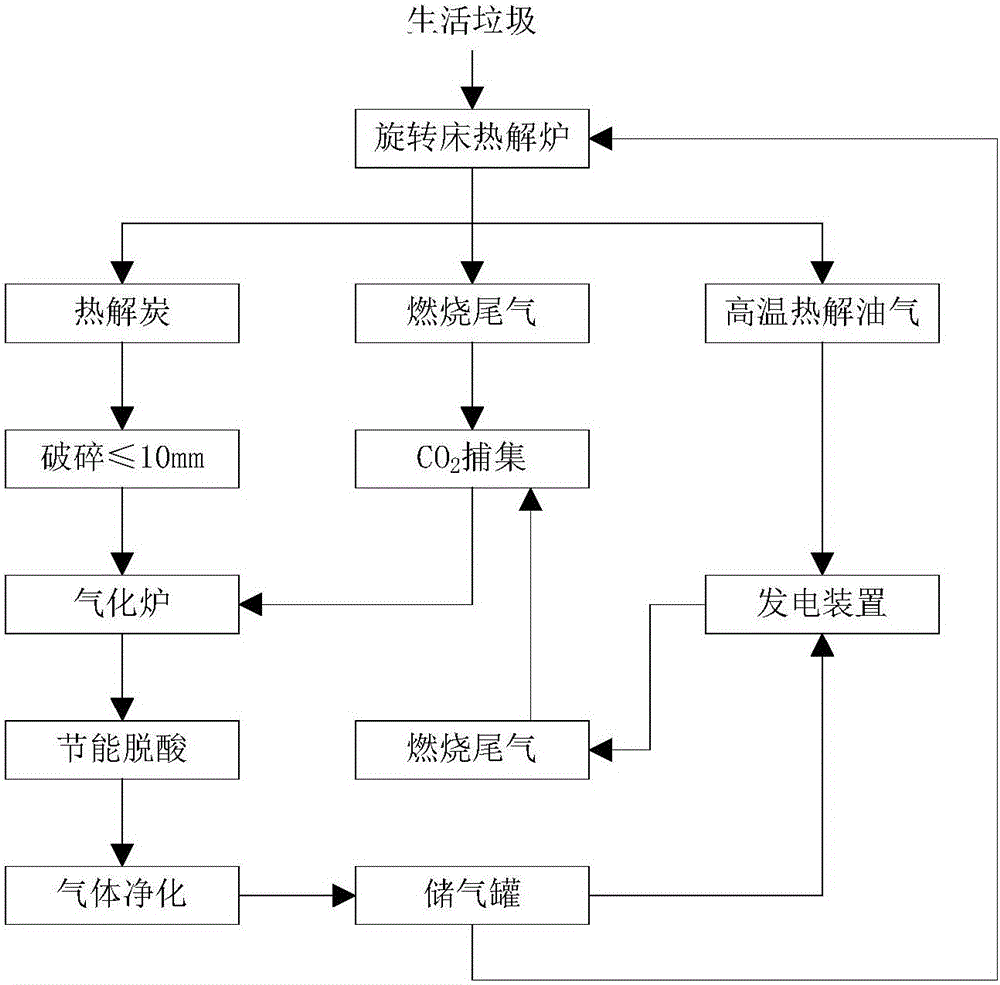

Waste carbon recycling method and system

InactiveCN105885952AEmission reductionAchieve recyclingGasification processes detailsCombustible gas productionReboilerCarbon storage

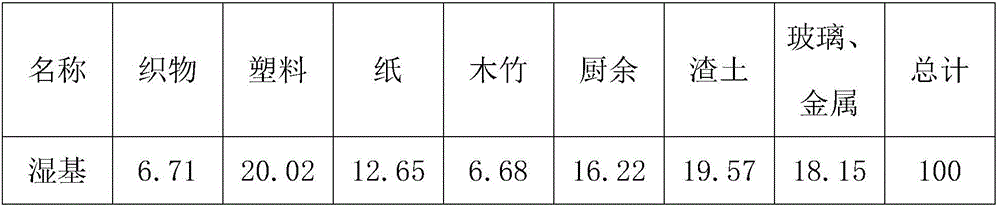

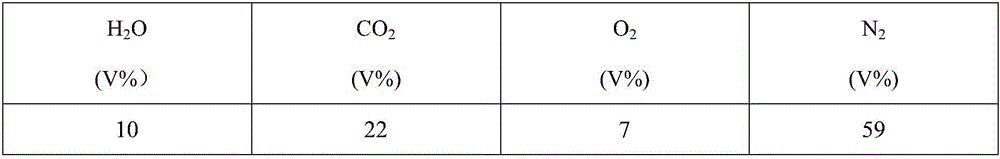

The invention relates to a waste carbon recycling method and system. A waste pretreatment device in the system is formed by sequentially connecting a bag breaking mechanism, a roller screen mechanism, a separation mechanism and a crushing mechanism; a rotating bed pyrolysis furnace is composed of a drying area, a first pyrolytic reaction area, a second pyrolytic reaction area and a third pyrolytic reaction area, the top of each area is provided with a high-temperature pyrolysis oil and gas outlet, and a radiant tube of each area is provided with a fuel gas inlet and a combustion gas outlet; the front end of the drying area is provided with a waste raw material inlet, and the tail ends of the three pyrolytic reaction areas are provided with discharging openings of pyrolytic carbon; a CO2 capturing device is formed by sequentially connecting an absorption tower, a rich liquid, a desorption tower, a reboiler, a gas-liquid separator, a barren liquor pump and a barren liquor cooler, and a first inlet of the absorption tower is connected with the combustion gas outlet; a feeding opening of a crusher is connected with a discharging opening of pyrolytic carbon; an inlet of a gasifier is connected with an outlet of the gas-liquid separator, and a feeding opening of pyrolytic carbon of the gasifier is connected with an outlet of a carbon storage tank of the crusher. By means of the waste carbon recycling method and system, it is beneficial to energy conservation and emission reduction, and economic benefits of living waste pyrolysis treatment are raised.

Owner:SHENWU TECH GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com