Super critical water treatment system of waste organic liquid pollution less discharge and resources utilization

A supercritical water and organic waste liquid technology, applied in the direction of heating water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems of fluid temperature drop, complex reactor structure, product impact, etc., to save fuel costs, realize The effect of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

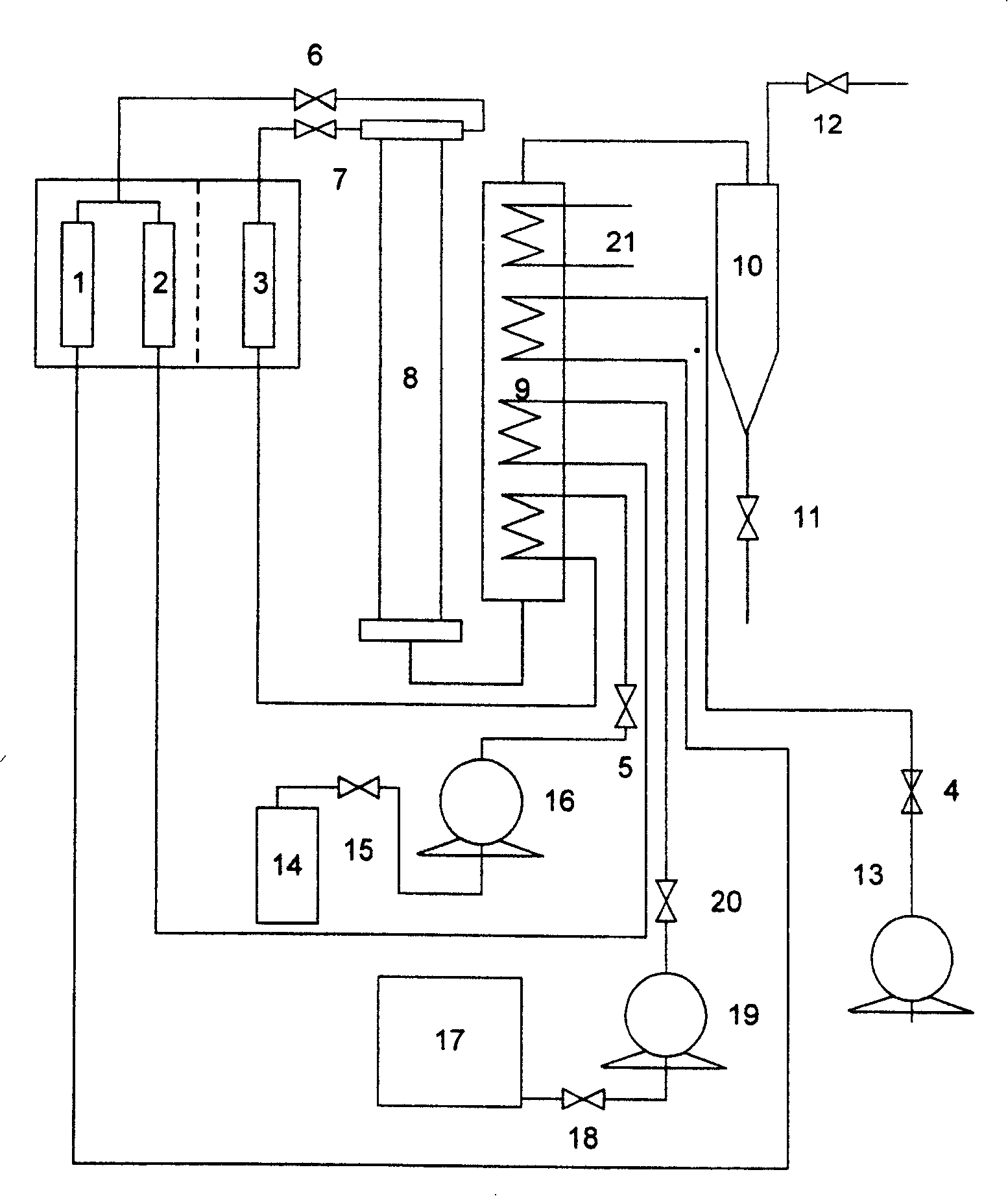

[0023] see figure 1 , the supercritical water treatment system for non-pollution discharge of waste organic waste liquid and resource utilization of the present invention, the preheater in which the oxidant, critical water and material of the system are separated in three ways is respectively a gas preheater 1 and a liquid preheater 2 And material preheater 3, wherein:

[0024] The inlet end of the gas preheater 1 is connected to the heat exchanger 9 through a pipeline, and the heat exchanger 9 is connected to the air compressor 13 through the first valve 4, and the outlet end of the gas preheater 1 is connected to the liquid preheater 2 connected;

[0025] The inlet end of the liquid preheater 2 is connected with the heat exchanger 9 through the pipeline, the heat exchanger 9 is connected with the high-pressure plunger pump 19 through the ninth valve 20, and the high-pressure plunger pump 19 is connected with the water tank through the eighth valve 18 17;

[0026] The inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com