Waste carbon recycling method and system

A technology of recycling waste charcoal, applied in the field of solid waste recycling, can solve the problems of poor market sales, difficult technology promotion, low calorific value of waste charcoal, etc., to improve resource utilization efficiency, increase economic benefits, improve operation low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

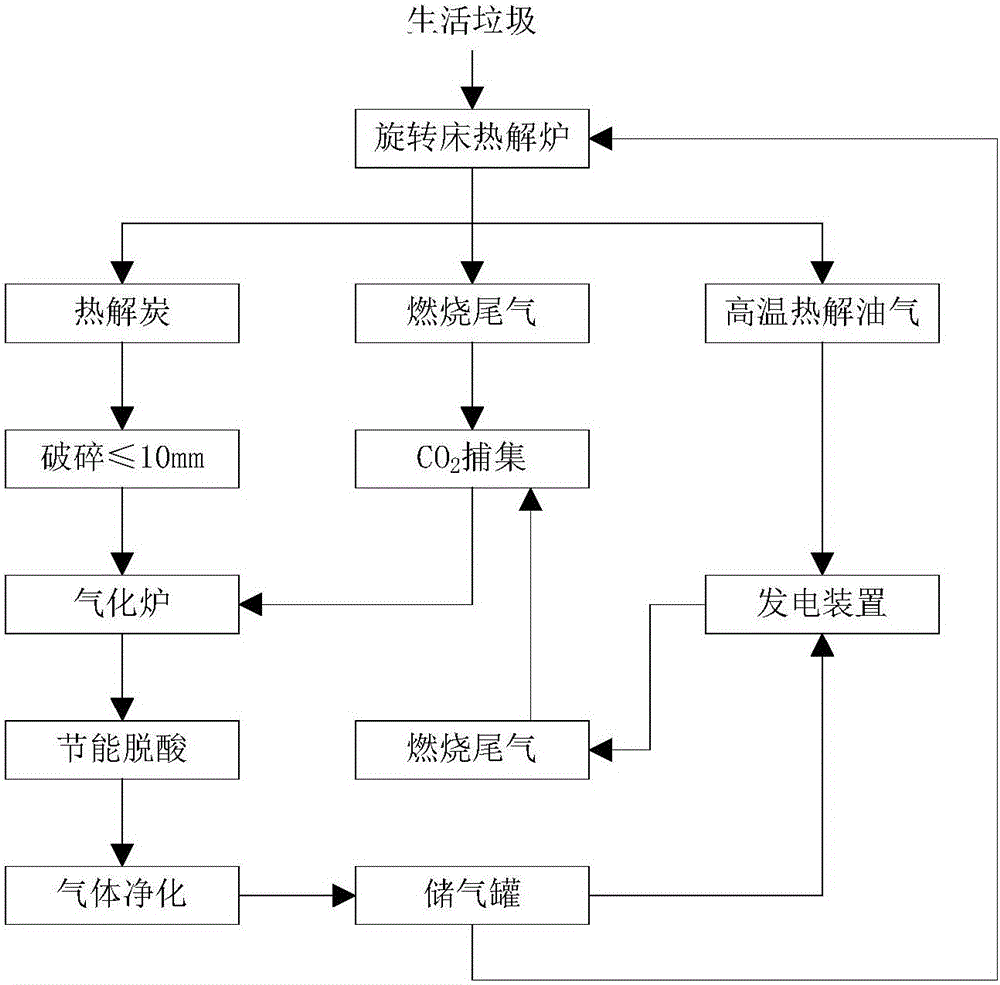

Method used

Image

Examples

Embodiment

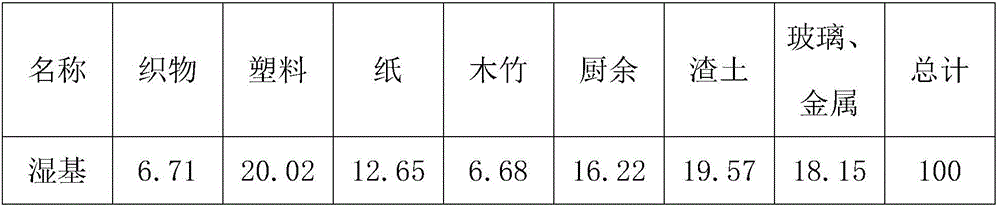

[0060] The domestic waste of a certain city is used as raw material, and the composition of the raw material is shown in Table 1 below.

[0061] Table 1 Household garbage composition (wt%)

[0062]

[0063] The garbage entering the factory is simply sorted to remove large pieces of inorganic matter and metals, and then crushed. The particle size of the pyrolysis raw materials obtained by crushing is less than 20mm;

[0064] The broken garbage is evenly fed into the rotary bed pyrolysis furnace, and the thickness of the cloth is 100mm. In the furnace, the garbage passes through the drying zone, the first pyrolysis reaction zone, the second pyrolysis reaction zone and the third pyrolysis reaction zone to complete the pyrolysis. Reaction, wherein the temperature of the drying zone is 350°C, the temperature of the first pyrolysis reaction zone, the second pyrolysis reaction zone and the third pyrolysis reaction zone is 800°C, and the reaction time is 2-3h.

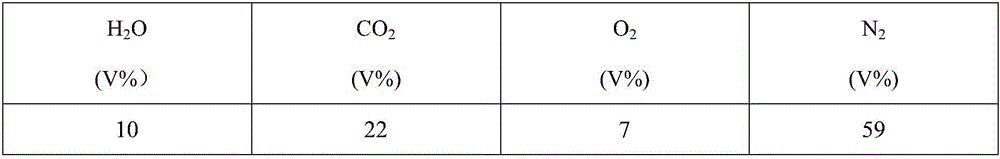

[0065] The composi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com