Method and device for removing SO2 in flue gas with copper extracting tailings and recycling copper extracting tailings

A technology for recycling copper tailings, applied in chemical instruments and methods, separation methods, inorganic chemistry, etc., can solve the problems of inconvenient source of raw materials, difficult treatment, and increased non-point source pollution intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] In the small experiment, the sulfur dioxide cylinder gas, oxygen cylinder gas and nitrogen cylinder gas were used to distribute gas to simulate copper smelting flue gas. The mass flow meter accurately controlled the gas flow. After the gas distribution was stable, the gas was passed into the pulp for desulfurization reaction. The experimental process A medium constant temperature magnetic stirrer controls the temperature and stirring, and the concentration of sulfur dioxide at the inlet and outlet is detected by the HC-6 trace sulfur and phosphorus analyzer.

[0059] SO 2 Import concentration 2856mg / m 3 , normal temperature, solid-liquid ratio 1:7 (mine tailings 16g, distilled water 112g), oxygen content 8%, gas flow 600~700mL / min, within 43 hours of operation, the desulfurization efficiency of the ore pulp is maintained above 90%.

Embodiment 2

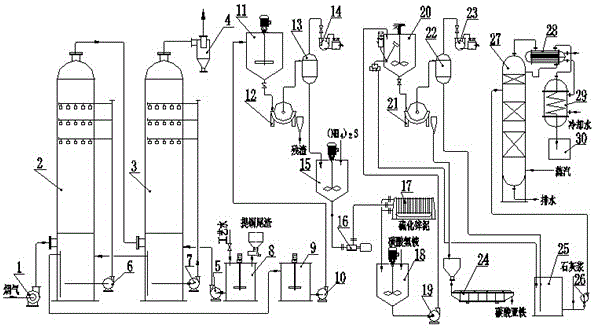

[0061] 300,000 t / a sulfuric acid, sulfuric acid tail gas treatment capacity 100,000Nm 3 / h, SO in exhaust gas 2 Content 2850mg / Nm 3 , the exhaust gas outlet requires SO 2 Content 100mg / Nm 3 . Using secondary desulfurization, the process is as follows figure 1 .

[0062] Sulfuric acid tail gas is pressurized to 0.2~0.3kPa by the pressurized blower 1, sent to the primary desulfurization tower 2 for the first desulfurization, and then into the secondary desulfurization tower 3 for the second desulfurization. The diameter of the desulfurization tower is φ5m, the height is 23.5m, The slurry at the top of the tower needs to be pressurized to 0.25Mpa with circulation pumps 6 and 7 respectively, and the circulation volume is 1500m 3 / h, sent to the tower top nozzle to spray into mist and contact with the flue gas to absorb SO in the flue gas 2 , the liquid-gas ratio is 8L / m 3 , the flue gas after the purification reaches the standard is discharged after demisting by the demister...

Embodiment 3

[0066] 800,000 t / a sulfuric acid, sulfuric acid tail gas treatment capacity 200,000Nm 3 / h, SO in the tail gas of the two-rotation and two-suction sulfuric acid unit 2 Content 800mg / Nm 3 , the exhaust gas outlet requires SO 2 Content 100mg / Nm 3 Below, the desulfurization efficiency is 87.5%. One-stage desulfurization is adopted, and the process refers to figure 1 Just remove the secondary desulfurization tower.

[0067] The sulfuric acid tail gas is pressurized to 0.15-0.2kPa by the pressurized blower 1, and sent to the desulfurization tower. The diameter of the desulfurization tower is 6.2m, and the height is 24.5m. 3 / h, sent to the tower top nozzle to spray into mist and contact with the flue gas to absorb SO in the flue gas 2 , the liquid-gas ratio is 25L / m 3 The flue gas after purification reaches the standard is discharged after demisting by the demister 4; the supplementary amount of copper extraction tailings slurry with a solid content of 15% is 1.5m 3 / h, sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com