Reinforced method for production of methane from residual sludge

A technology for excess sludge and methane production, which is applied in chemical instruments and methods, sludge treatment, biological sludge treatment, etc., to achieve the effect of shortening anaerobic digestion time and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

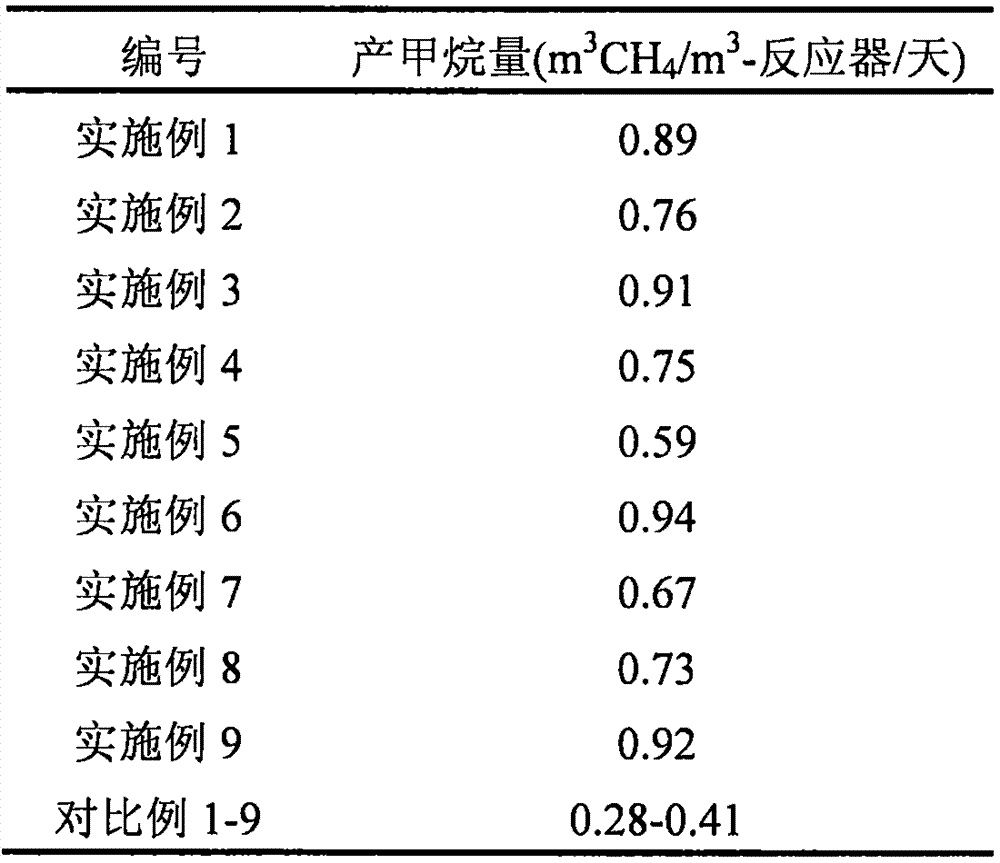

Examples

Embodiment 1

[0025] The excess sludge produced by the sewage treatment plant is added to an anaerobic reactor with a working volume of 10L as the substrate for anaerobic digestion. The anaerobic digestion temperature is 35°C, and activated carbon with a particle size of 0.4mm is added to the reactor. , the mass ratio of its dosage to the dry weight of the sludge is 0.2:1, and the sludge organic matter is converted into methane through the joint action of anaerobic microorganisms in the sludge and activated carbon. The residence time of the sludge in the reactor is 13 days.

Embodiment 2

[0027] The excess sludge produced by the sewage treatment plant is added to an anaerobic reactor with a working volume of 10L as the substrate for anaerobic digestion. The anaerobic digestion temperature is 35°C, and activated carbon with a particle size of 0.4mm is added to the reactor. , the mass ratio of its dosage to the dry weight of the sludge is 0.1:1, and the sludge organic matter is converted into methane through the joint action of anaerobic microorganisms in the sludge and activated carbon. The residence time of the sludge in the reactor is 13 days.

Embodiment 3

[0029] The excess sludge produced by the sewage treatment plant is added to an anaerobic reactor with a working volume of 10L as the substrate for anaerobic digestion. The anaerobic digestion temperature is 35°C, and activated carbon with a particle size of 0.4mm is added to the reactor. The mass ratio of its dosage to the dry weight of the sludge is 0.3:1, and the organic matter of the sludge is converted into methane through the joint action of anaerobic microorganisms in the sludge and activated carbon. The residence time of the sludge in the reactor is 13 days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com