Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

82 results about "Propylene Glycol Diacetate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

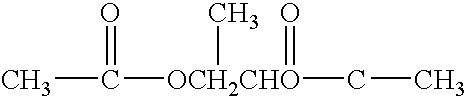

Propylene glycol diacetate may be used as an emulsifier, solubilizer or solvent in pharmaceuticals. General description Propylene glycol diacetate is a non ionic water soluble surfactant.

Microemulsion preconcentrate

InactiveUS20050118254A1Ensure production stabilityBiocideCarbohydrate active ingredientsActive componentMicroemulsion

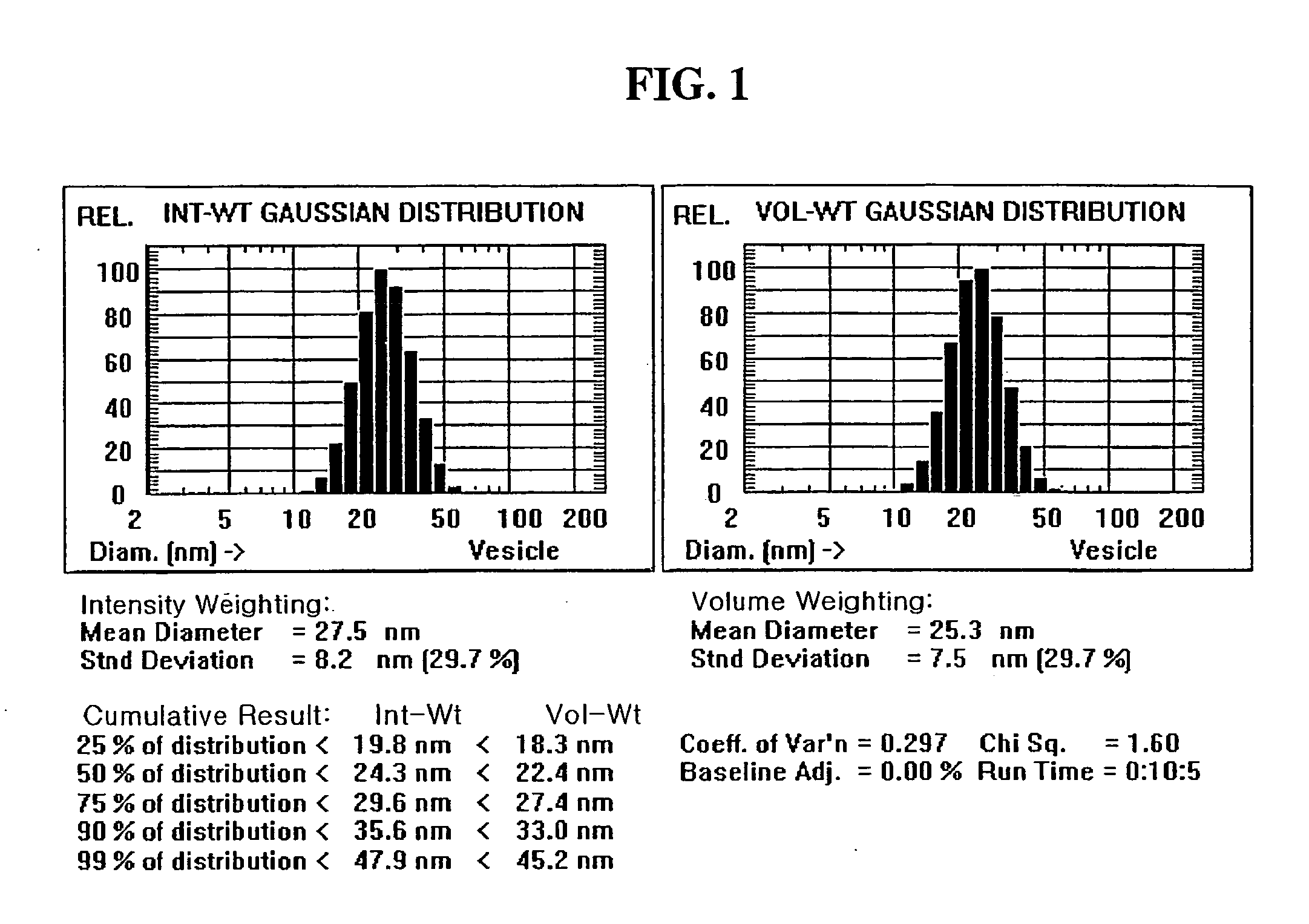

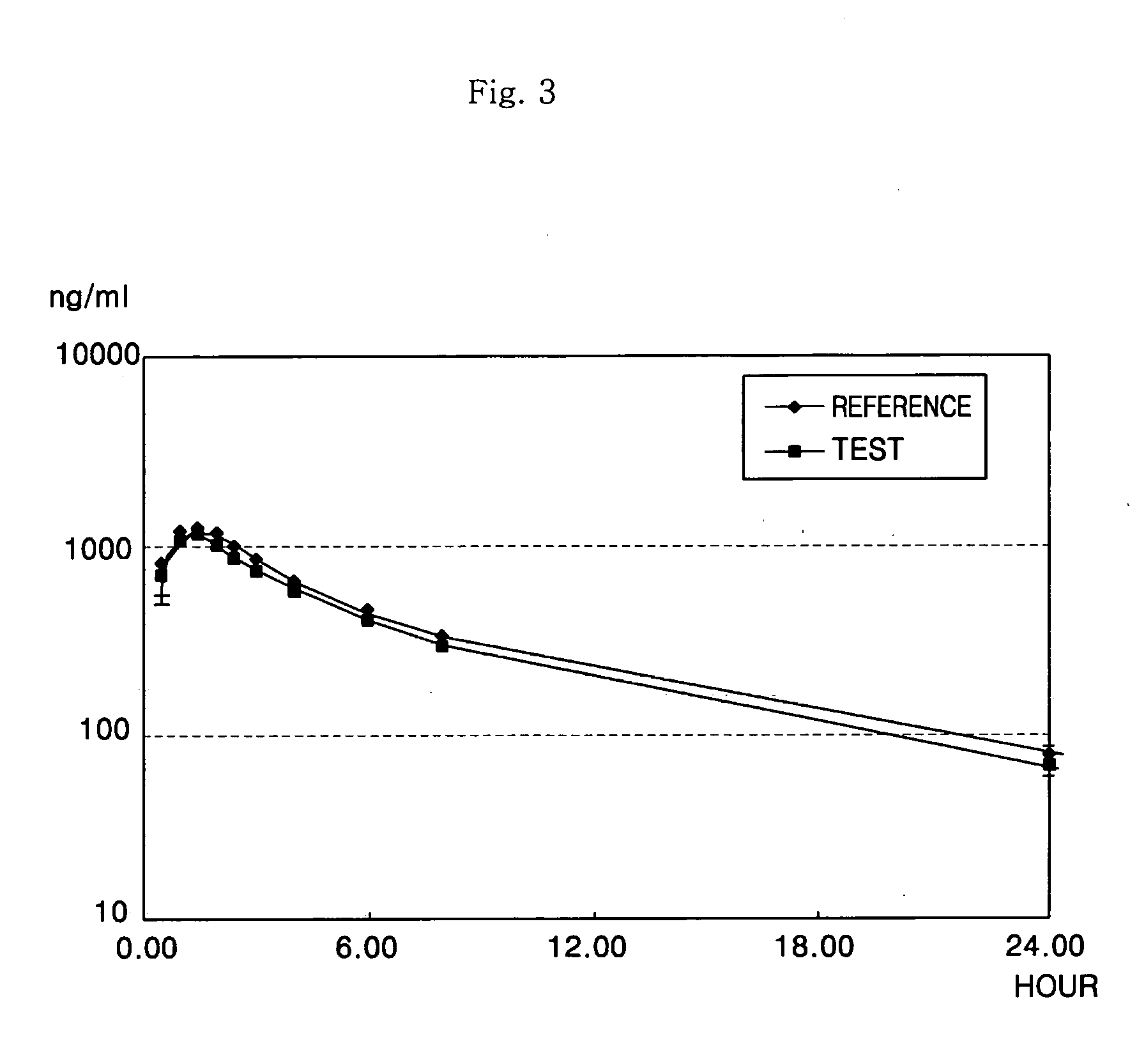

A microemulsion preconcentrate is provided, which comprises an active component, an oil, a surfactant, and a hydrophilic solvent selected from the group consisting of propylene glycol diacetate, propylene glycol monoacetate, and salts of the forgoing materials.

Owner:CJ CORPORATION

Stable Enzymatic Peracid Generating Systems

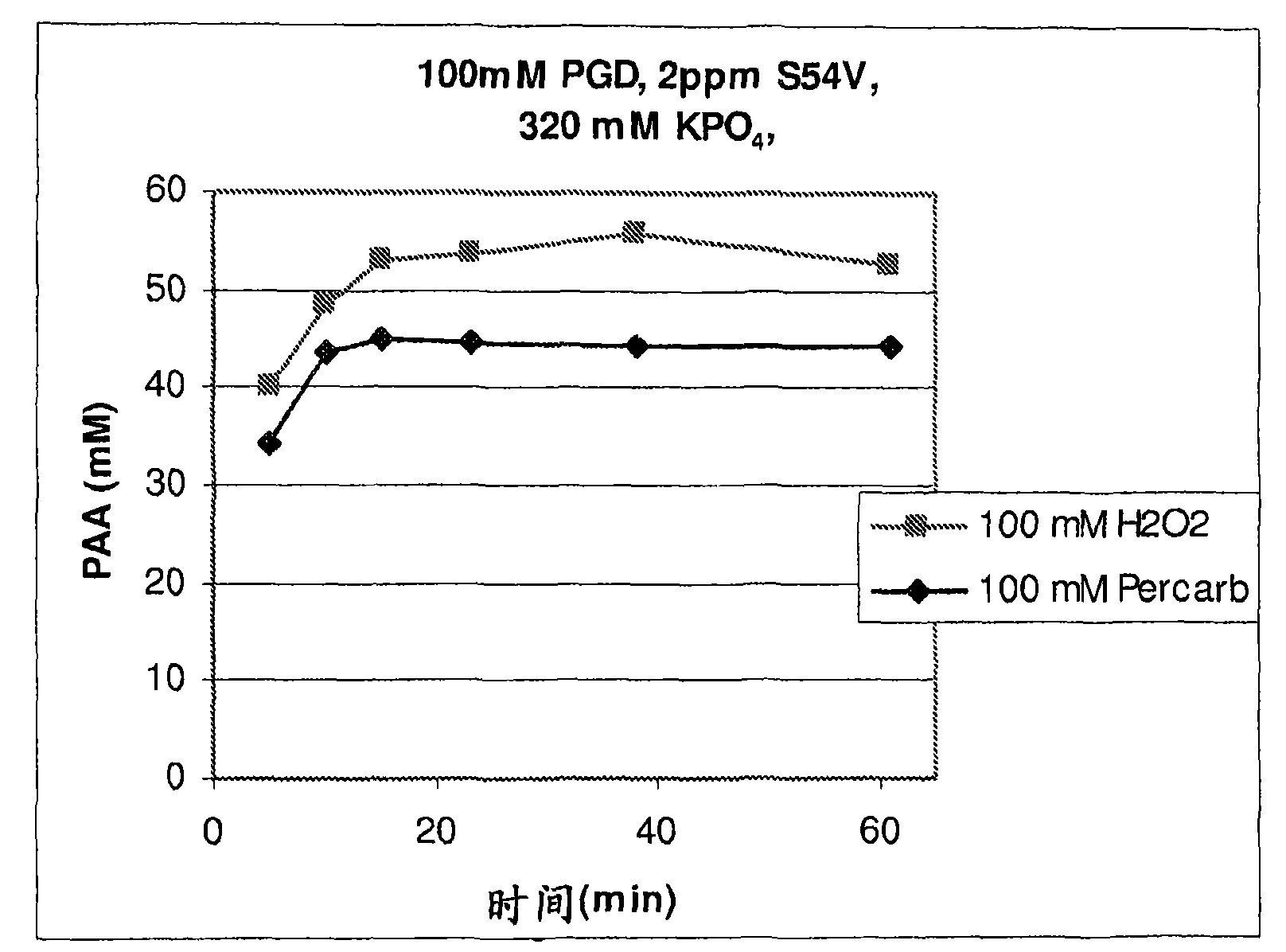

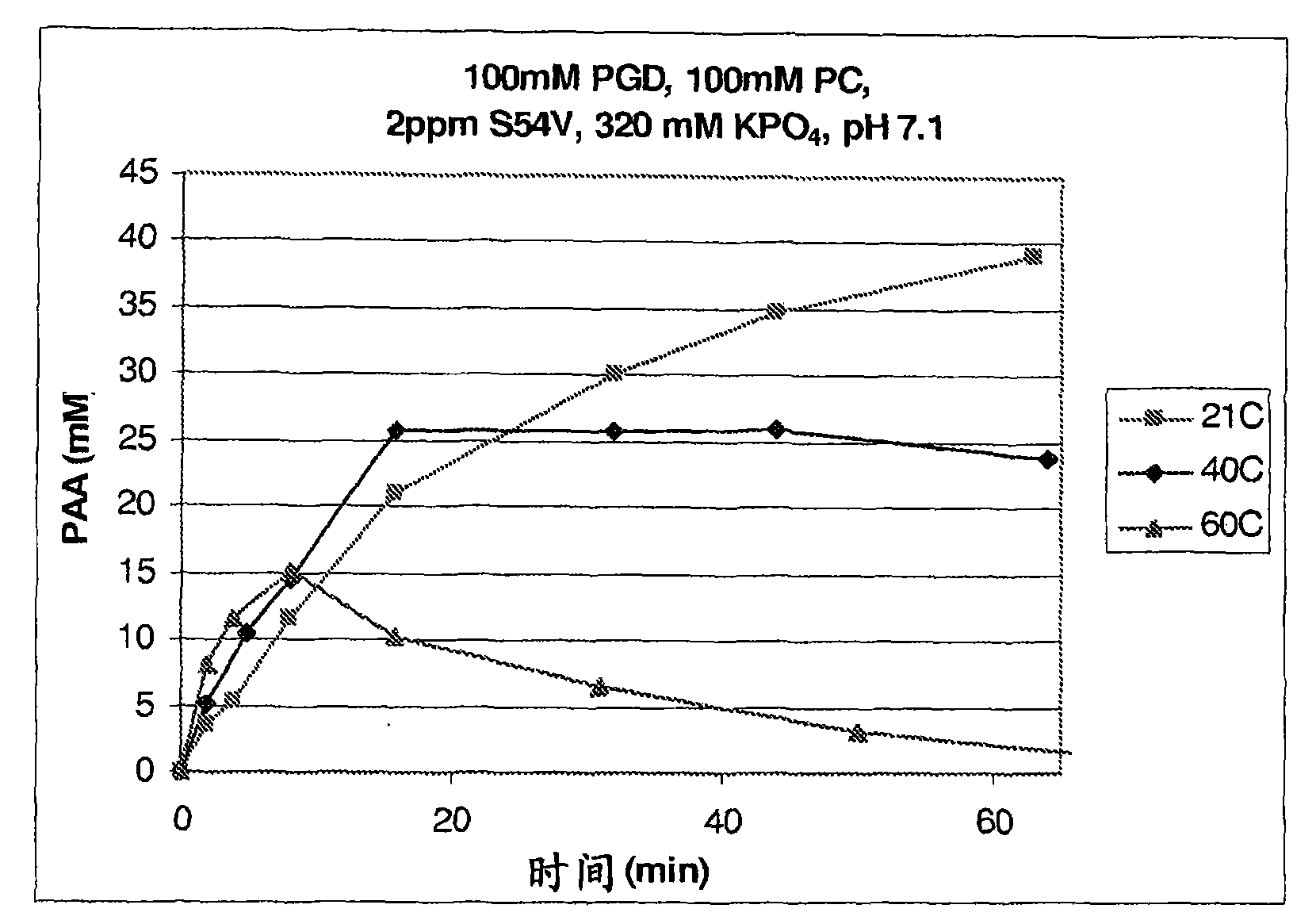

The present invention provides stable compositions comprising a perhydrolase enzyme, a hydrogen peroxide source, and an ester substrate that efficiently generate aqueous peracid solutions. The generated peracid solutions are suitable for decontaminating and / or sanitizing a wide range of materials and equipment contaminated with pathogens or toxic chemicals. In one preferred embodiment, the stable composition comprises an acyl transferase enzyme, sodium percarbonate, and propylene glycol diacetate, and is stable for 30 days or longer. Upon addition to water, the composition is activated and generates an aqueous solution with a high ratio of peracetic acid to acetic acid.

Owner:DANISCO US INC

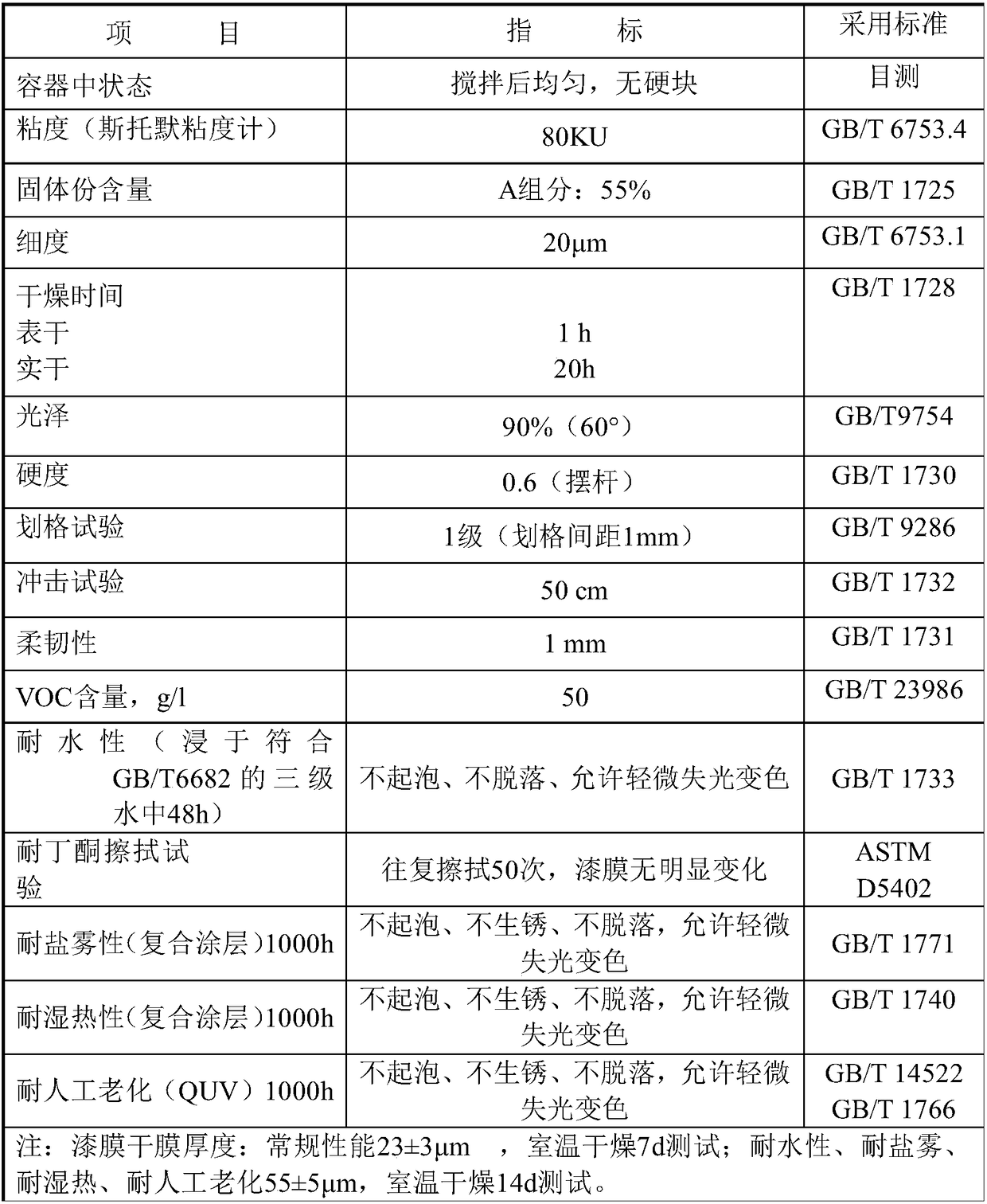

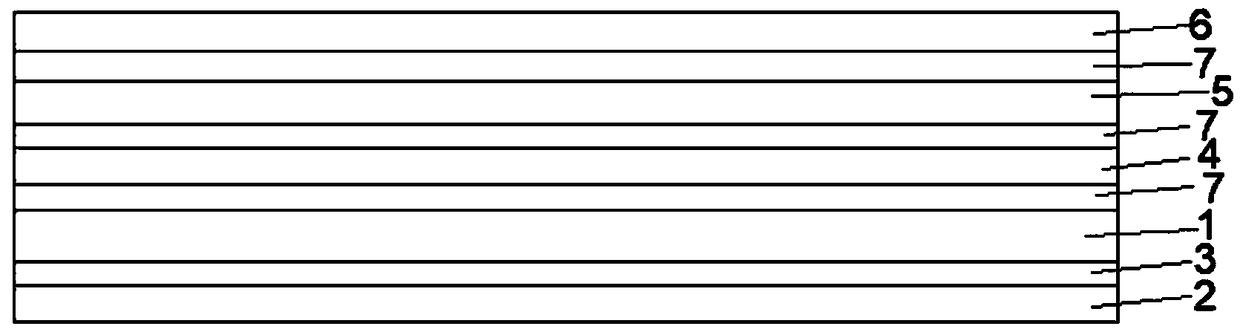

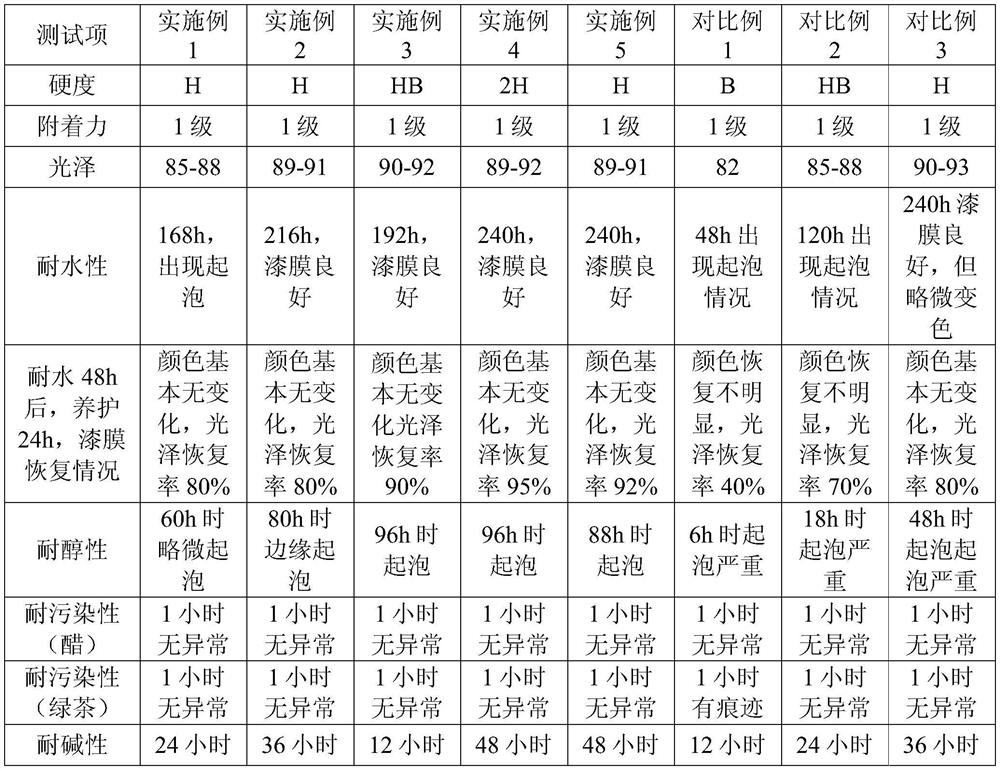

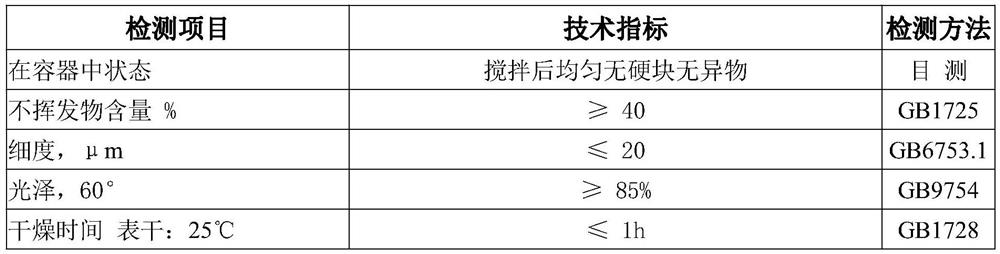

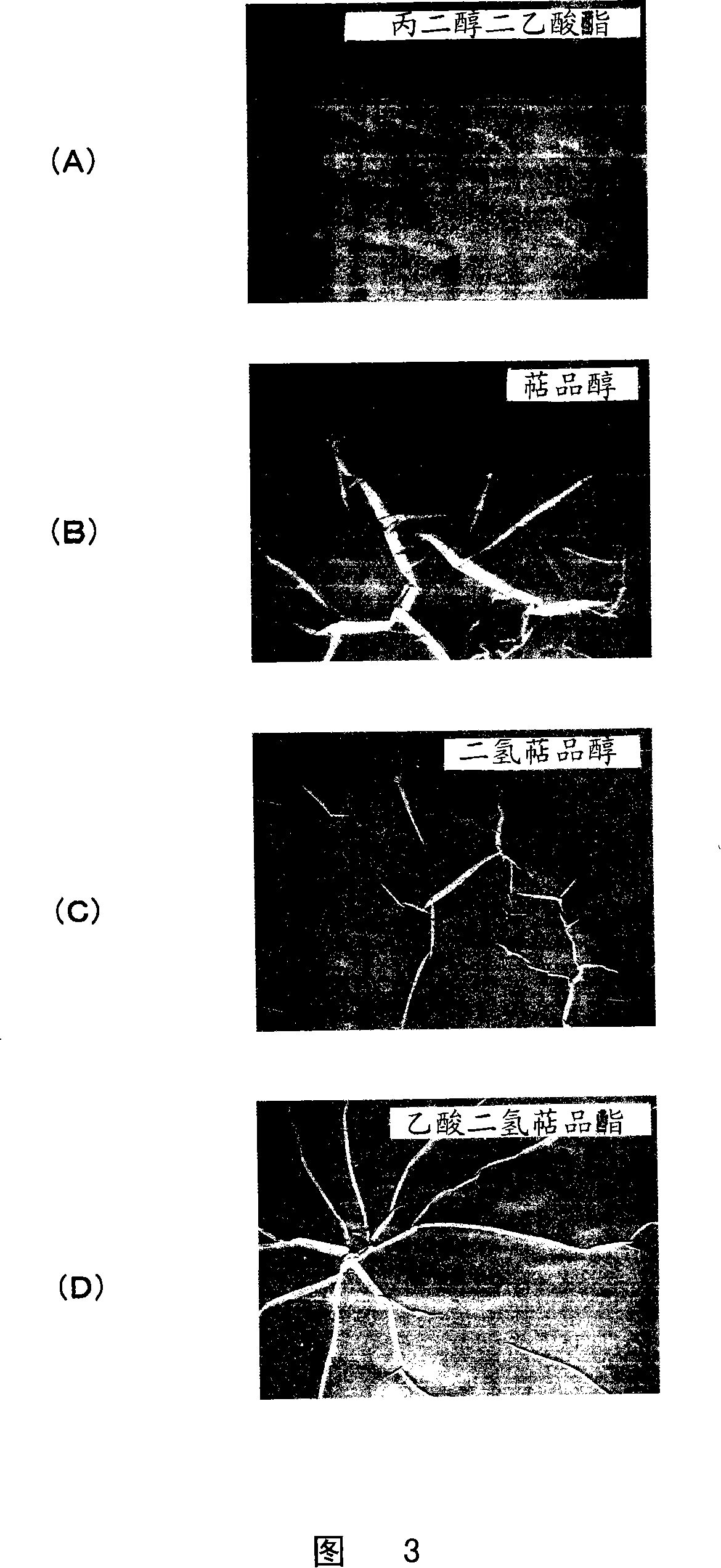

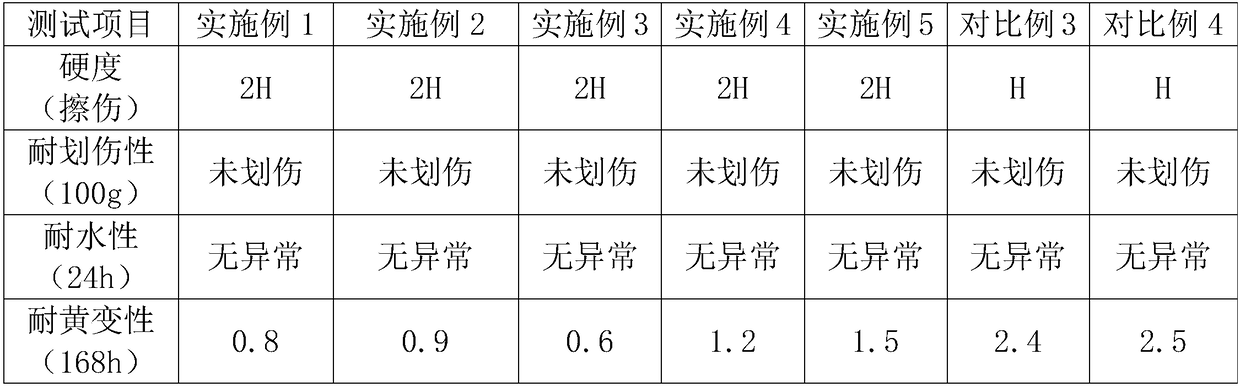

Scratch-resistant double-component waterborne glossy varnish and preparation method thereof

The invention belongs to the field of coatings and relates to double-component waterborne glossy varnish and a preparation method thereof, in particular to scratch-resistant double-component waterborne glossy varnish and a preparation method thereof. The double-component waterborne glossy varnish comprises a component A and a component B, wherein the component A comprises hydroxyl polyacrylate containing secondary dispersoid, waterborne polyurethane dispersoid, a defoaming agent, a coalescing agent, a wax emulsion, a leveling agent, a thickener and water; the component B comprises propylene glycol diacetate and hydrophilic aliphatic polyisocyanate containing hexamethylene diisocyanate. The varnish has the characteristics of excellent glossiness, high fullness, good varnish film surface effect and the like and also has outstanding scratch resistance.

Owner:AODA KOALA PAINT HUIZHOU

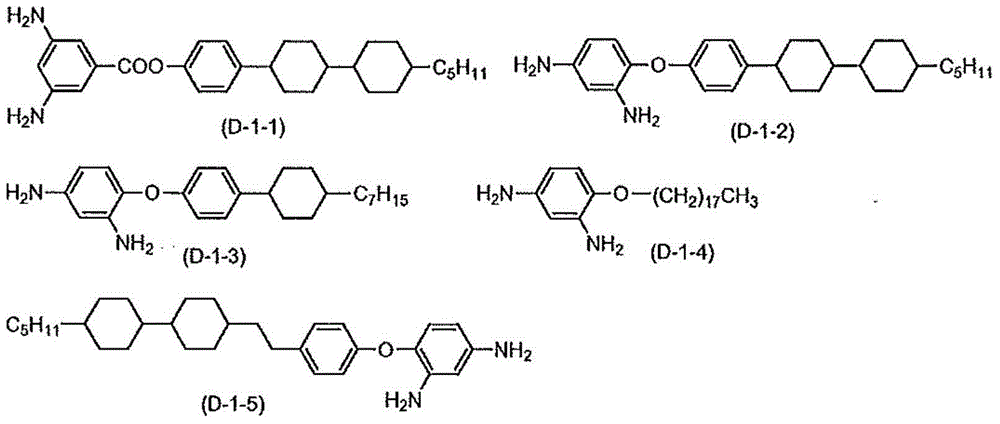

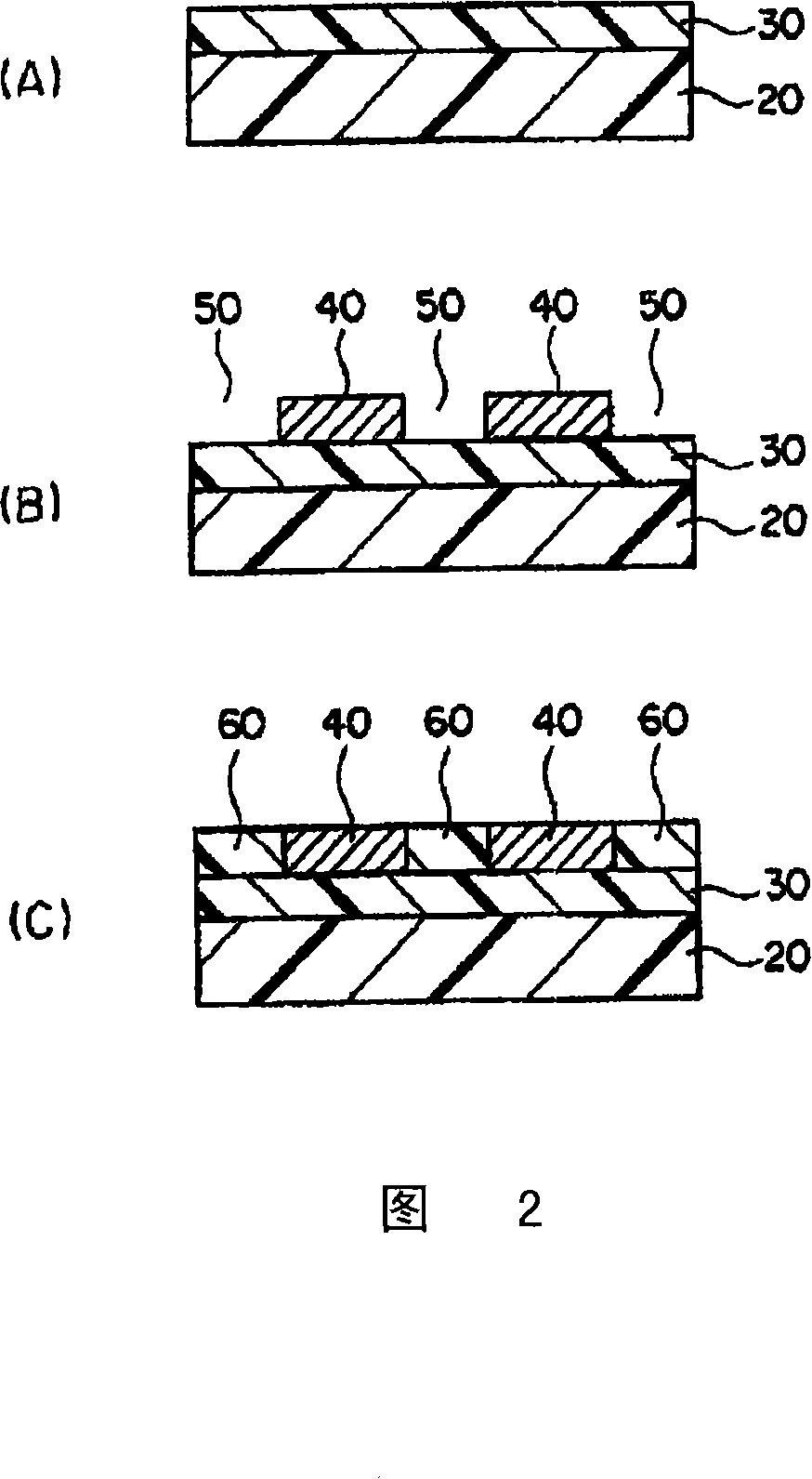

Liquid crystal orientation agent, liquid crystal orientation film, manufacturing method of liquid crystal orientation film, and liquid crystal display element

InactiveCN103666486AImprove yieldUniform coatingLiquid crystal compositionsNon-linear opticsDiacetone alcoholDiethylene glycol diethyl ether

The invention relates to a liquid crystal orientation agent, a liquid crystal orientation film, a manufacturing method of the liquid crystal orientation film, and a liquid crystal display element. The liquid crystal orientation agent has good printing performance with respect to a substrate and good continuous printing performance and prevents swelling of printing plates. The liquid crystal orientation agent contains at last one polymer (A) selected from the group formed by polyamide acid, polyimide, polyamide acid ester and polysiloxane, a first solvent containing more than one of N-ethyl-2-pyrrolidone, 1,3-dimethyl-2-imidazolone, 3-methoxy-N, N-dimethylpropionamide and so on, and a second solvent containing more than one of propylene glycol diacetate, diethylene glycol diethyl ether, diisoamyl ether diacetone alcohol and so on.

Owner:JSR CORPORATIOON

Decontamination formulation with sorbent additive

InactiveUS7282470B2Extended shelf lifeEasy to handleBiocideSolid waste disposalMANNITOL/SORBITOLSorbent

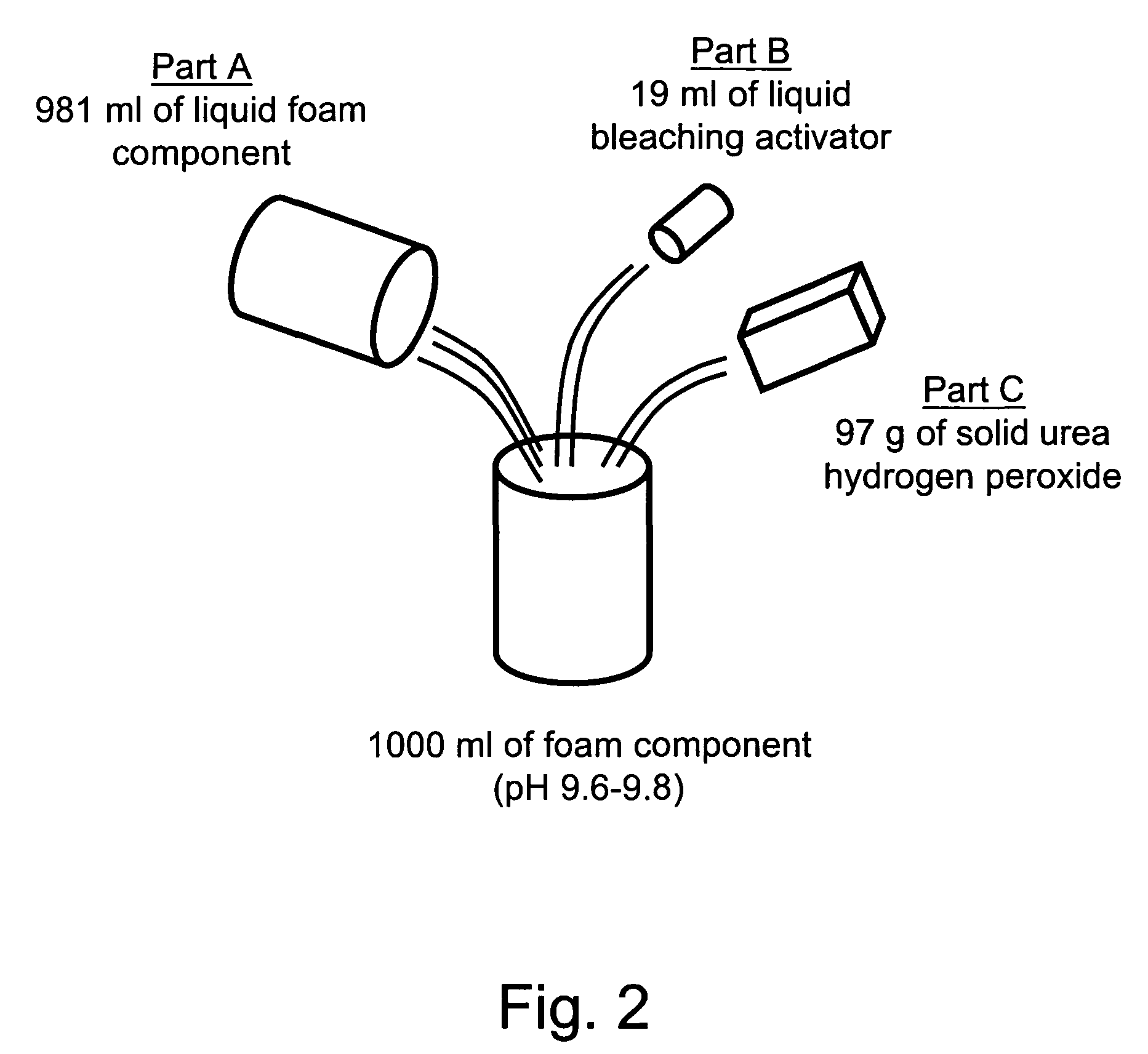

A decontamination formulation and method of making that neutralizes the adverse health effects of both chemical and biological compounds, especially chemical warfare (CW) and biological warfare (BW) agents, and toxic industrial chemicals. The formulation provides solubilizing compounds that serve to effectively render the chemical and biological compounds, particularly CW and BW compounds, susceptible to attack, and at least one reactive compound that serves to attack (and detoxify or kill) the compound. The formulation includes at least one solubilizing agent, a reactive compound, a bleaching activator, a sorbent additive, and water. The highly adsorbent, water-soluble sorbent additive (e.g., sorbitol or mannitol) is used to “dry out” one or more liquid ingredients, such as the liquid bleaching activator (e.g., propylene glycol diacetate or glycerol diacetate) and convert the activator into a dry, free-flowing powder that has an extended shelf life, and is more convenient to handle and mix in the field.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

Liquid crystal aligning agent, liquid crystal aligning film and liquid crystal display element

ActiveCN105001881AReduce non-display areaAchieve narrow frameLiquid crystal compositionsNon-linear opticsDiethylene glycol diethyl etherDiacetone alcohol

The invention provides a liquid crystal aligning agent, a liquid crystal aligning film and a liquid crystal display element. The liquid crystal aligning agent contains at least one polymer (A) selected from the group consisting of polyamic acid, polyamic acid ester and polyimide, and solvents. The solvents contain a specific solvent (X) and a specific solvent (Y). The specific solvent (X) is 1-butoxy-2-propanol; and the specific solvent (Y) contains at least one of the group consisting of diethylene glycol diethyl ether, diacetone alcohol, propylene glycol diacetate and dipropylene glycol monomethyl ether. According to the invention, undesirable film thickness of the end of the coating area of the liquid crystal aligning agent is limited.

Owner:JSR CORPORATIOON

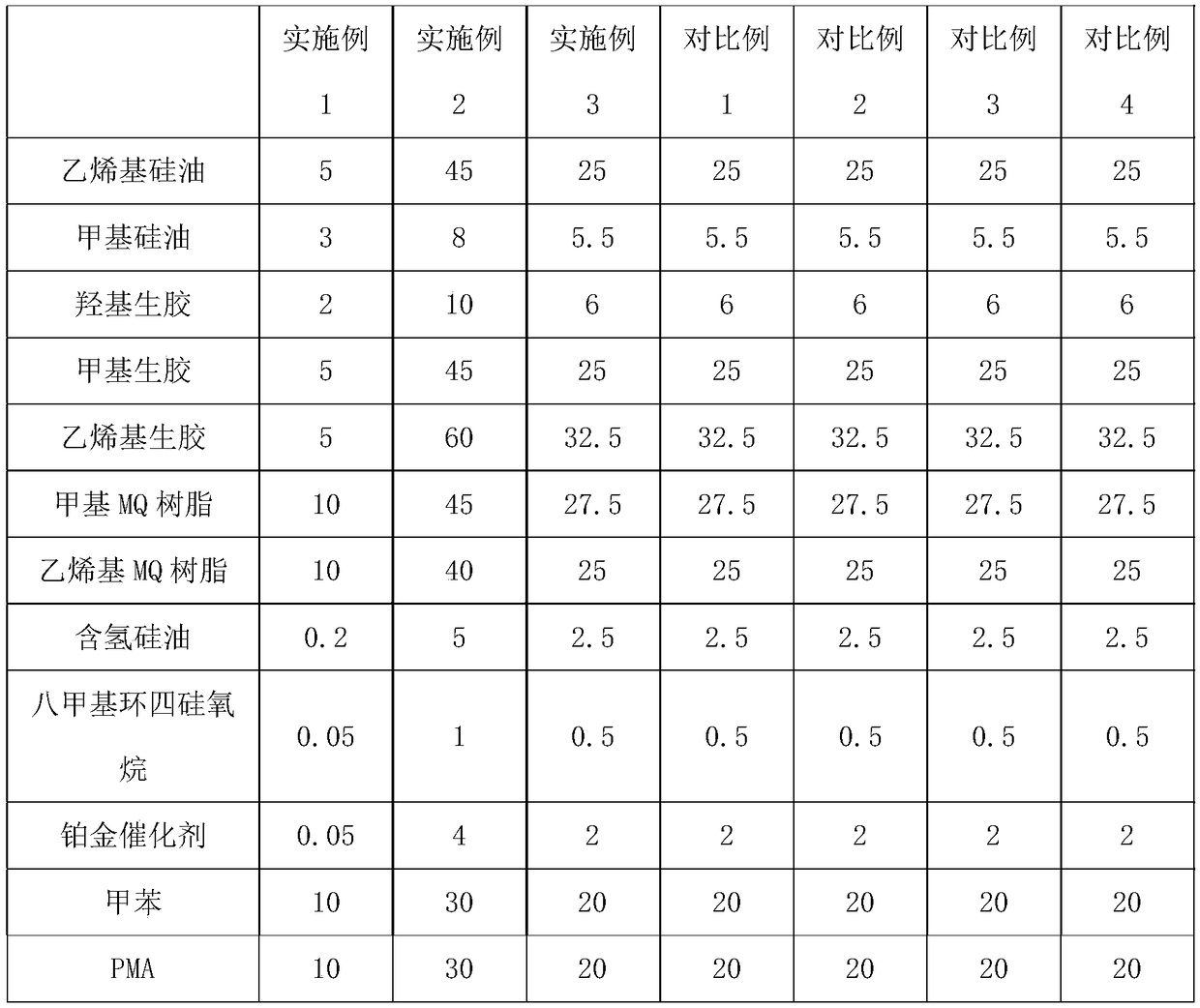

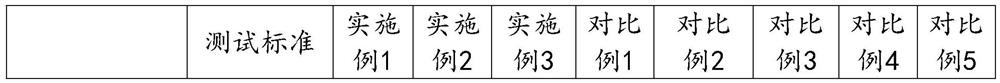

Environmentally-friendly water-based two-component polyurethane coating and preparation method thereof

InactiveCN108165155AGood compatibilityExtended opening hoursPolyurea/polyurethane coatingsWater basedPliability

The invention discloses an environmentally-friendly water-based two-component polyurethane coating and a preparation method thereof. The polyurethane coating is composed of an A component and a B component according to the mass ratio of (2.7-3.0):(0.9-1.0); the A component includes the following materials in percentages by weight: 35-40% of hydroxy acrylate dispersion I, 20%-24% of hydroxy acrylicdispersion II, 0.2%-1.0% of a defoaming agent, 2.0%-3.0% of dipropylene glycol butyl ether, 2.0%-3.0% of ethylene glycol butyl ether, 0.2%-1.0% of a levelling agent, 15%-38% of color paste, and 0.1%-0.3% of a thickener; and the B component includes the following materials in percentages by weight: 30%-33% of propylene glycol diacetate, 43%-49% of polyurethane curing agent I, and 18%-24% of polyurethane curing agent II. The water-based two-component polyurethane coating obtained by the method provided by the invention has better physical and mechanical properties such as hardness, abrasion resistance and flexibility, and performance of water resistance, salt spray resistance, heat and humidity resistance and aging resistance.

Owner:西安经建油漆有限责任公司

Optical grade hydrophobic and oleophobic antifouling anti-blue-ray screen protector

InactiveCN108893073AImprove anti-blue light effectLight release forceNon-macromolecular adhesive additivesMacromolecular adhesive additivesTectorial membraneRefractive index

The invention relates to an optical grade hydrophobic and oleophobic antifouling anti-blue-ray screen protector. A first refractive material layer with a high refractive index and a second refractivematerial layer with a low refractive index are arranged between a base material layer and a protective layer, so that the light transmittance performance of the protector is increased, and the light transmittance reaches 98% or higher; a blue absorber is integrated into an upper PET (Polyethylene Terephthalate) protective layer, the anti-blue-ray effect of the protector is greatly improved, and the rejection rate of harmful blue rays reaches 83% or higher; biodegradable environmental-friendly silicone pressure sensitive adhesive layers are coated on the upper and lower surfaces of the base material so as to serve as release agent layers; non-toxic and environmental-friendly PMA (Propylene Glycol Methyl Ether Acetate), PGDA (Propylene Glycol Diacetate) and ethyl acetate are adopted as solvents, so that the screen protector is environmental-friendly, non-toxic and free of pollution; release force between the release film and the base material is light, and the screen protector is easy totear and free of residues; and the protector disclosed by the invention has excellent antibacterial property, wear resistance, scratch resistance and hydrophobic and oleophobic fingerprint-proof effects, and various performance indexes reach the standards.

Owner:SUZHOU XILIN OPTOELECTRONICS TECH IND

Waterborne polyurethane coating and preparation method thereof

InactiveCN112175497AImprove the gel rateImprove thermal stabilityFireproof paintsAntifouling/underwater paintsPolymer scienceMicrosphere

The invention discloses a waterborne polyurethane coating. The waterborne polyurethane coating comprises a component A and a component B, wherein the component A is prepared from the following raw materials in parts by weight: 50-60 parts of water-based hydroxyl acrylic emulsion, 4-6 parts of a cosolvent, 0.3-0.4 part of a defoaming agent, 0.5-1 part of an ultraviolet absorber, 10-15 parts of silicon dioxide nano microspheres, 5-13 parts of deionized water, 1-2 parts of modified montmorillonite and 0.5-1 part of a composite antibacterial agent; and the component B comprises the following raw materials in parts by weight: 7-14 parts of an isocyanate curing agent and 3-6 parts of propylene glycol diacetate. The invention also discloses a preparation method of the waterborne polyurethane coating, and the waterborne polyurethane coating is high in water resistance and strong in adhesive force after being formed into a film by adding the ultraviolet absorber, the silicon dioxide nano microspheres and the modified montmorillonite; the coating is resistant to high temperature, good in mechanical performance, not prone to aging after being exposed to sunlight for a long time and long in service life.

Owner:上海顺多防水工程有限公司

Fluorine efficient finishes for textiles

InactiveCN1882622ALow yellowing protection propertiesLiquid repellent fibresEmulsion polymerizationDipropylene glycol monomethyl ether acetate

An improved emulsion polymerization process for producing an oil and water repellent finish for textiles wherein the improvement comprises polymerization in an aqueous solution containing 0.1 to 4.9% by weight of dipropylene glycol monomethyl ether acetate or propylene glycol diacetate relative to water is disclosed.

Owner:EI DU PONT DE NEMOURS & CO

Waterborne polyurethane high gloss finish for engineering machinery, and preparation method of waterborne polyurethane high gloss finish paint

ActiveCN107868604AFine foamSolve the problem of foamingPolyurea/polyurethane coatingsDefoaming AgentsCorrosion

The invention provides waterborne polyurethane high gloss finish paint for engineering machinery. The waterborne polyurethane high gloss finish is prepared from a finish paint main agent component A and a composite curing agent component B, wherein the weight ratio of the component A to the component B is equal to (2-6) to 1; every 100 parts of the component A is prepared from the following raw materials in parts by weight: 50-70 parts of emulsion, 3-25 parts of pigment, 5-20 parts of filler, 2-3.5 parts of a wetting and dispersing agent, 2-6 parts of a cosolvent, 0.2-1 part of a leveling agent, 0.2-1 part of a substrate wetting agent, 0.2-1 part of a thickener, 0.2-1 part of a pH regulator, 0.2-1 part of a defoaming agent and the balance of deionized water; the component B is prepared from the following raw materials in parts by weight: 35-75 parts of a curing agent 2655, 20-75 parts of a curing agent 3900, 5-10 parts of a curing agent 401-70 and 20-35 parts of propylene glycol diacetate. The waterborne polyurethane high gloss finish paint provided by the invention solves the problem that a thick-film thick coating is prone to prickly heat, is easy in construction, and does not need a pneumatic mixer; after uniform manual stirring is performed, the deionized water can be added for adjusting the viscosity for realizing construction; a paint film formed by the finish paint is superior in the environmental weather resistance aspects such as salt-spray corrosion, xenon lamp aging, acid and alkali resistance and heat resistance compared with the existing same type of paint.

Owner:湖南梓先新材料有限公司

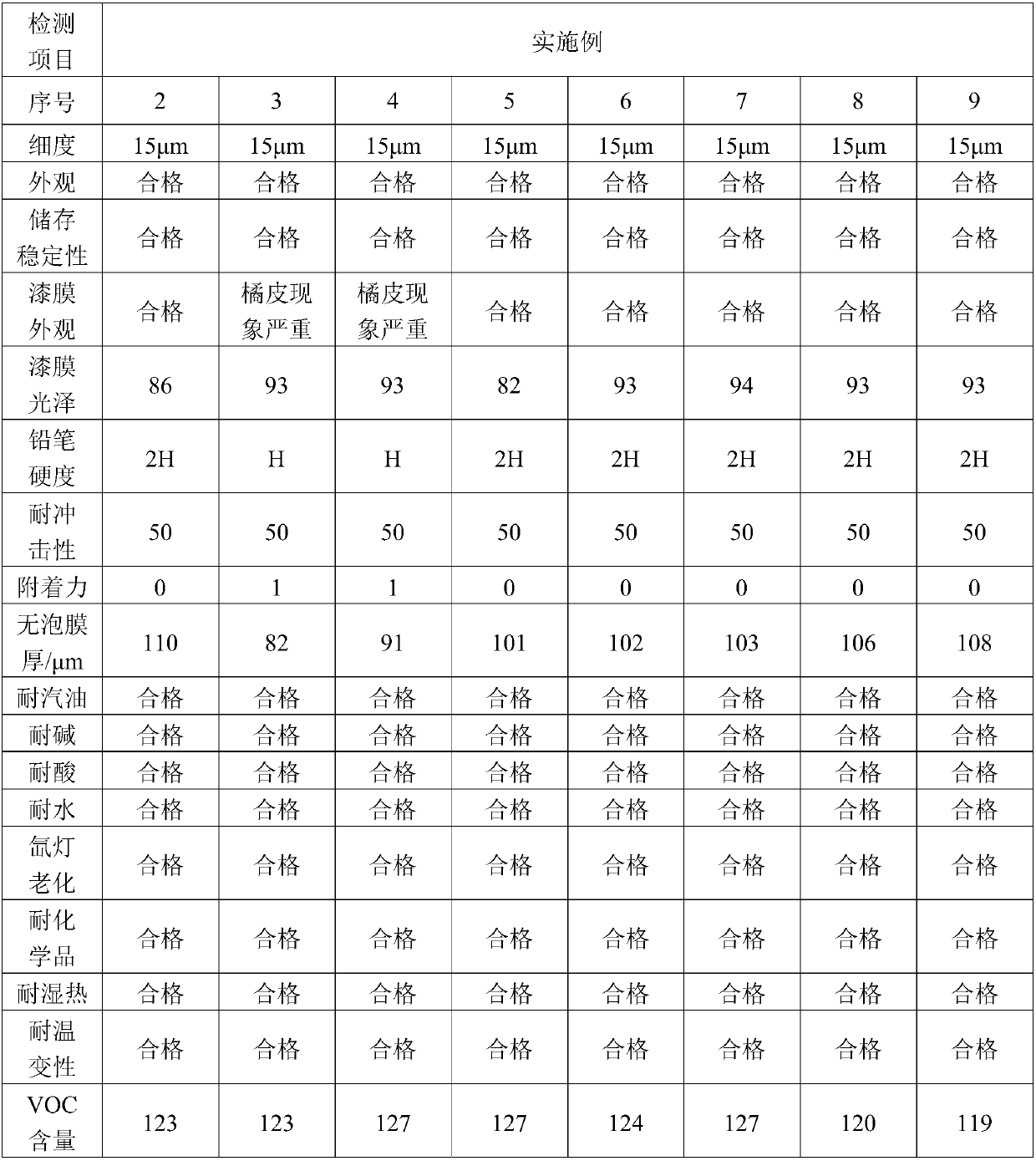

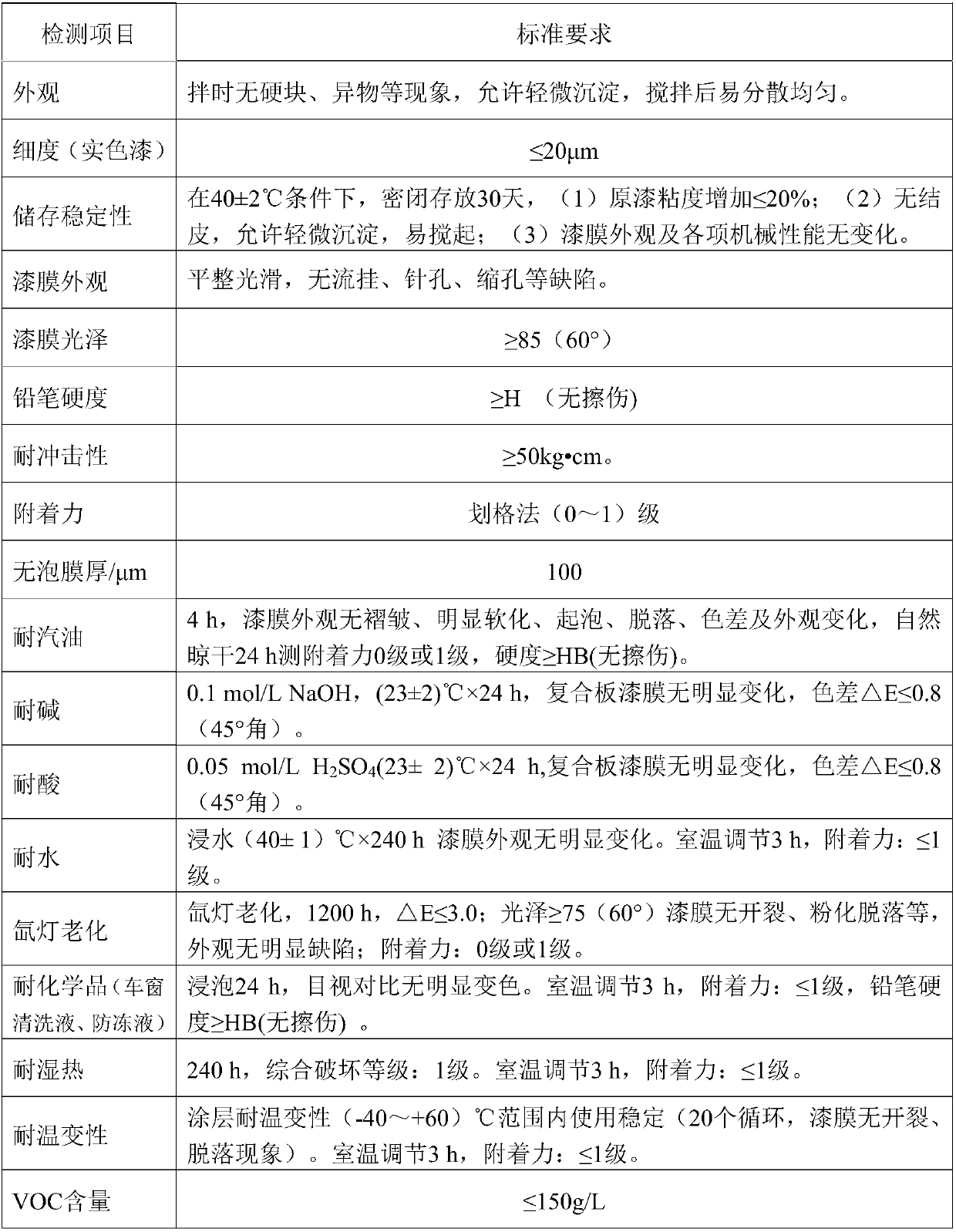

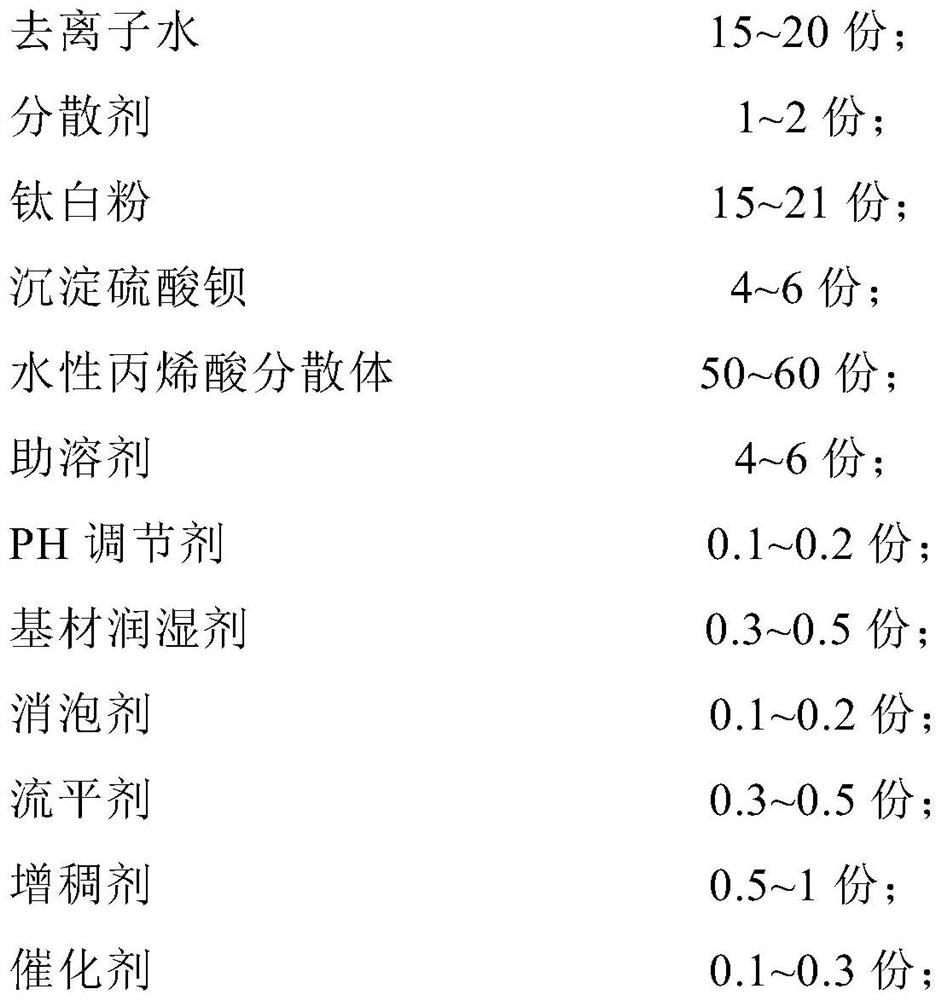

Water-based two-component polyurethane coating and preparation method thereof

InactiveCN111944409AIncrease the speed of crosslinkingExpand the structural networkPolyurea/polyurethane coatingsPtru catalystHigh activity

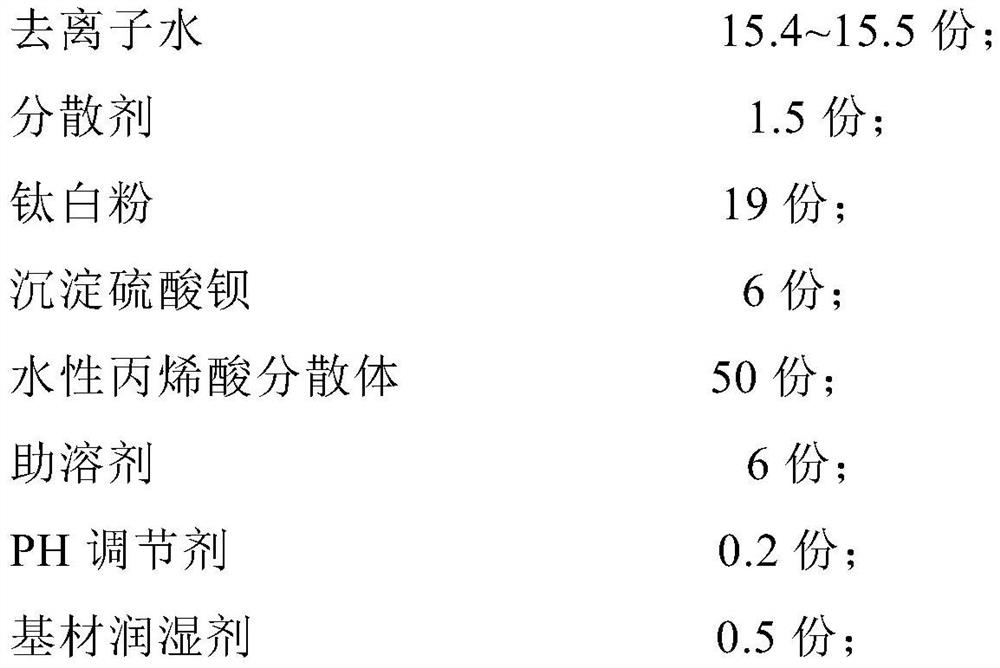

The invention relates to a waterborne two-component polyurethane coating. The waterborne two-component polyurethane coating comprises a main agent and a hardening agent. The main agent comprises the following components in parts by weight: 15-20 parts of deionized water, 1-2 parts of dispersing agent, 15-21 parts of titanium dioxide, 4-6 parts of precipitated barium sulfate, 50-60 parts of waterborne hydroxy acrylic acid secondary dispersion, 4-6 parts of a cosolvent, 0.1-0.2 part of a pH regulator, 0.3-0.5 part of substrate wetting agent, 0.1-0.2 part of a defoaming agent, 0.3-0.5 part of a leveling agent, 0.5-1 part of a thickener and 0.1-0.3 part of a catalyst. The hardening agent comprises the following components in parts by weight: 70 to 80 parts of water-based isocyanate and 20 to 30 parts of propylene glycol diacetate. In addition, autonomously modified high-activity organic metal salt is selected as a catalyst and is added into the main agent. On the premise of not influencingcomprehensive performance, the invention provides a feasible scheme for improving the mechanical performance and chemical resistance of the coating and improving the hard drying speed of the water-based 2K-PU under the condition of room-temperature drying.

Owner:DONGLAI COATING TECH SHANGHAI

Light shading resin composition for color filter and color filter

ActiveCN101045807AAdjust coatingAdjust storage stabilityOptical filtersPhotosensitive materials for photomechanical apparatusSolubilitySolid component

The invention relates to a light shading resin composition for color filter, the characteristic of which is that it contains 80~90 wt% of solvent and solid content; relative to solid content, it contains 8~35 wt% of acrylic acid series photosensitive resin, 45~65 wt% of black pigment, silicon surfactant or fluorin surfactant and initiator for photopolymerization whose HLB value is below 8. The viscosity of the resin composition is between 1.0 and 10.0mPa.s; relative to all solvents, it contains 30~50 wt% of the first solvent having a acetoxyl group in molecule, 0~25 wt% of propylene-glycol diacetate as the second solvent, 30~50 wt% of the third solvent having structure of 3-ethoxy propionic acid in molecule, 10~30 wt% of alicyclic compound having a carbonyl as the fourth solvent. Consequently, it has excellent evenness when coating, dryness of coating substrate and solid components' solubility.

Owner:NIPPON STEEL CHEMICALL &MATERIAL CO LTD

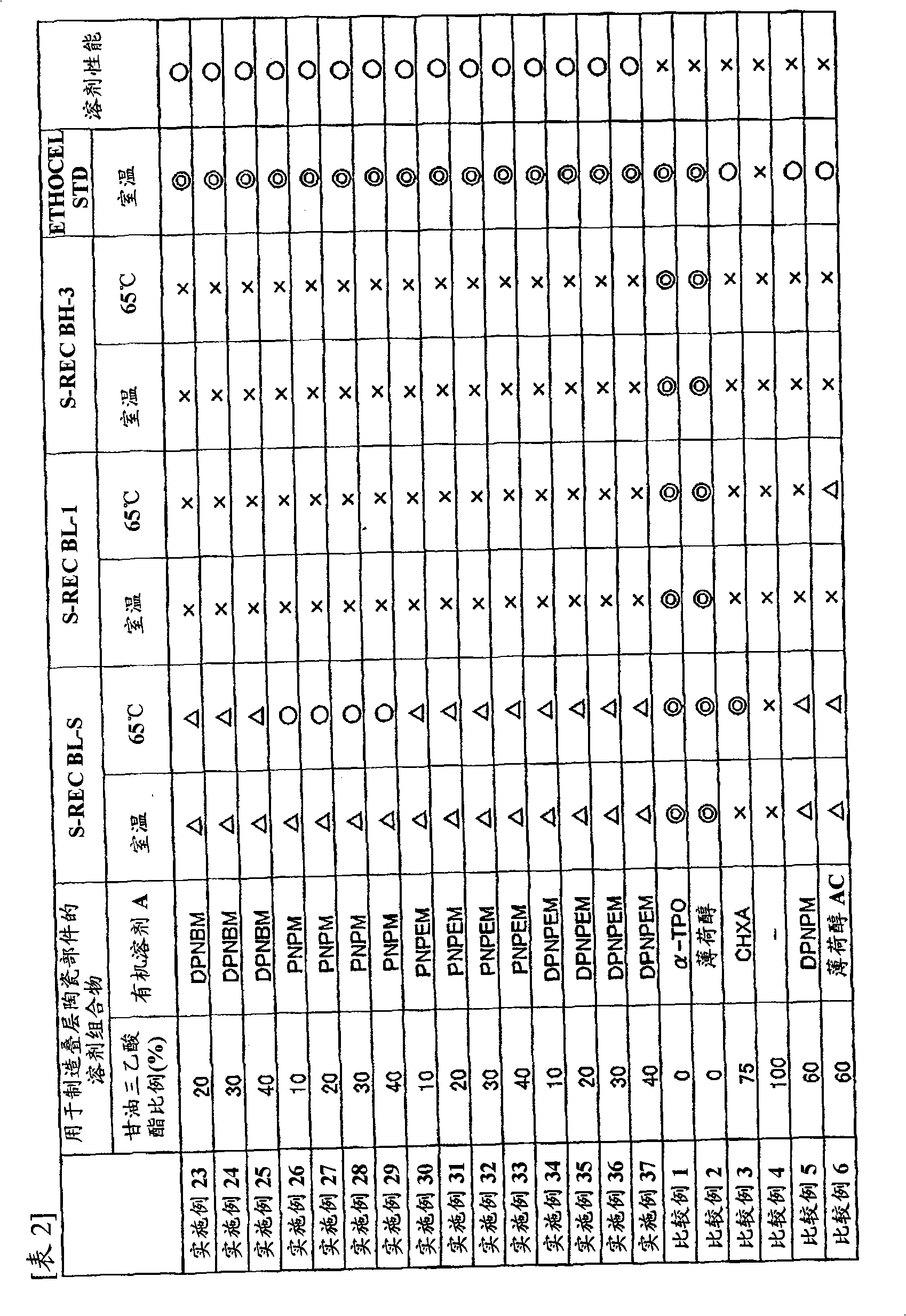

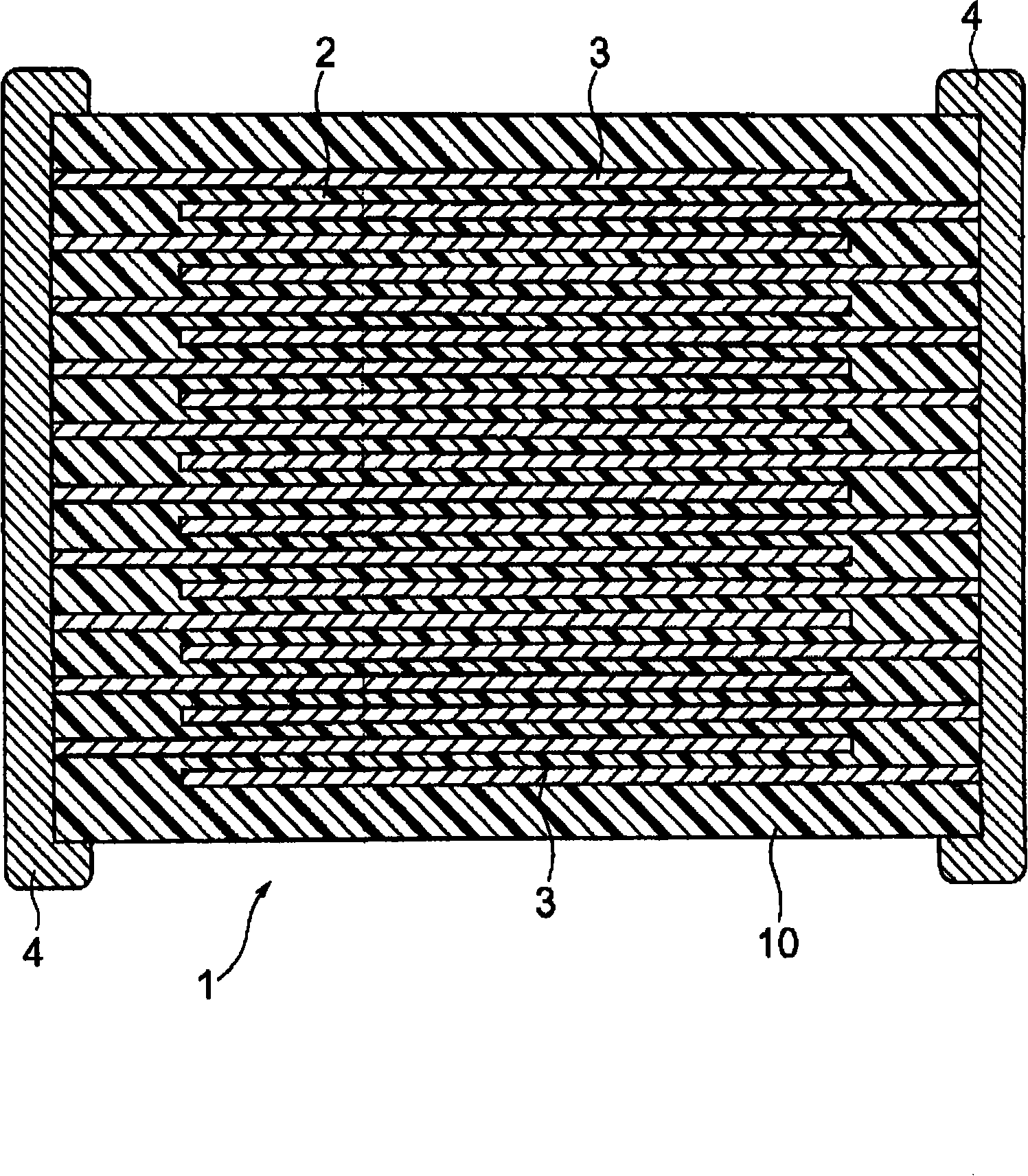

Solvent-containing composition for manufacturing laminated ceramic component

InactiveCN101989494AAvoid softeningAvoid deformationOrganic chemistryFixed capacitor electrodesCoated surfaceEvaporation

An aim of the invention is to provide a solvent-containing composition which is used for manufacturing a laminated ceramic component. The solvent-containing composition can fully exert the adhesive performance of adhesive resins such as ethylcellulose and can form fin pattern or film in high precision at a state of no corrosion to the coated surface component. Furthermore the solvent-containing composition facilitates evaporation drying. The solvent-containing composition for manufacturing laminated ceramic component is characterized by comprising more than 1wt% and less than 60wt% of glycerol triacetate. More preferably, the solvent-containing composition for manufacturing the laminated ceramic component contains more than 1wt% and less than 60wt% of glycerol triacetate, and contains at least one component selected from the following components: propyleneglycol diacetate, propanediol propyl methyl ether, propanediol butyl methyl ether, propanediol thyl ether, dipropylene glycol propyl methyl ether, dipropylene glycol butyl methyl ether, etc.

Owner:DAICEL CHEM IND LTD

Water-based plant-based quick-drying polyurethane finish paint and preparation method thereof

InactiveCN112961590AGood chemical resistanceImprove scratch resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsEmulsionUltraviolet lights

The invention relates to water-based plant-based quick-drying polyurethane finish paint and a preparation method thereof, and belongs to the technical field of water-based paint. The paint comprises a component A and a component B; and the dosage mass ratio of the component A to the component B is (8-10):1. The component A comprises the following components: a water-based hydroxyl acrylic emulsion, a water-based ultraviolet light absorber, a neutralizer, a defoaming agent, a dispersing agent, a pigment, a flatting agent, a base material wetting agent, deionized water, a thickening agent and a catalyst; and the component B comprises aliphatic polyisocyanate and propylene glycol diacetate. According to the water-based plant-based quick-drying polyurethane finish paint, the chemical resistance and scratch resistance of high-end furniture water-based polyurethane finish paint are greatly improved, the drying speed of a paint film is increased, meanwhile, the content of VOC in a formula is greatly reduced, and the water-based plant-based quick-drying polyurethane finish paint better meets the environment-friendly requirement compared with products in the existing market.

Owner:山东七维新材料有限公司

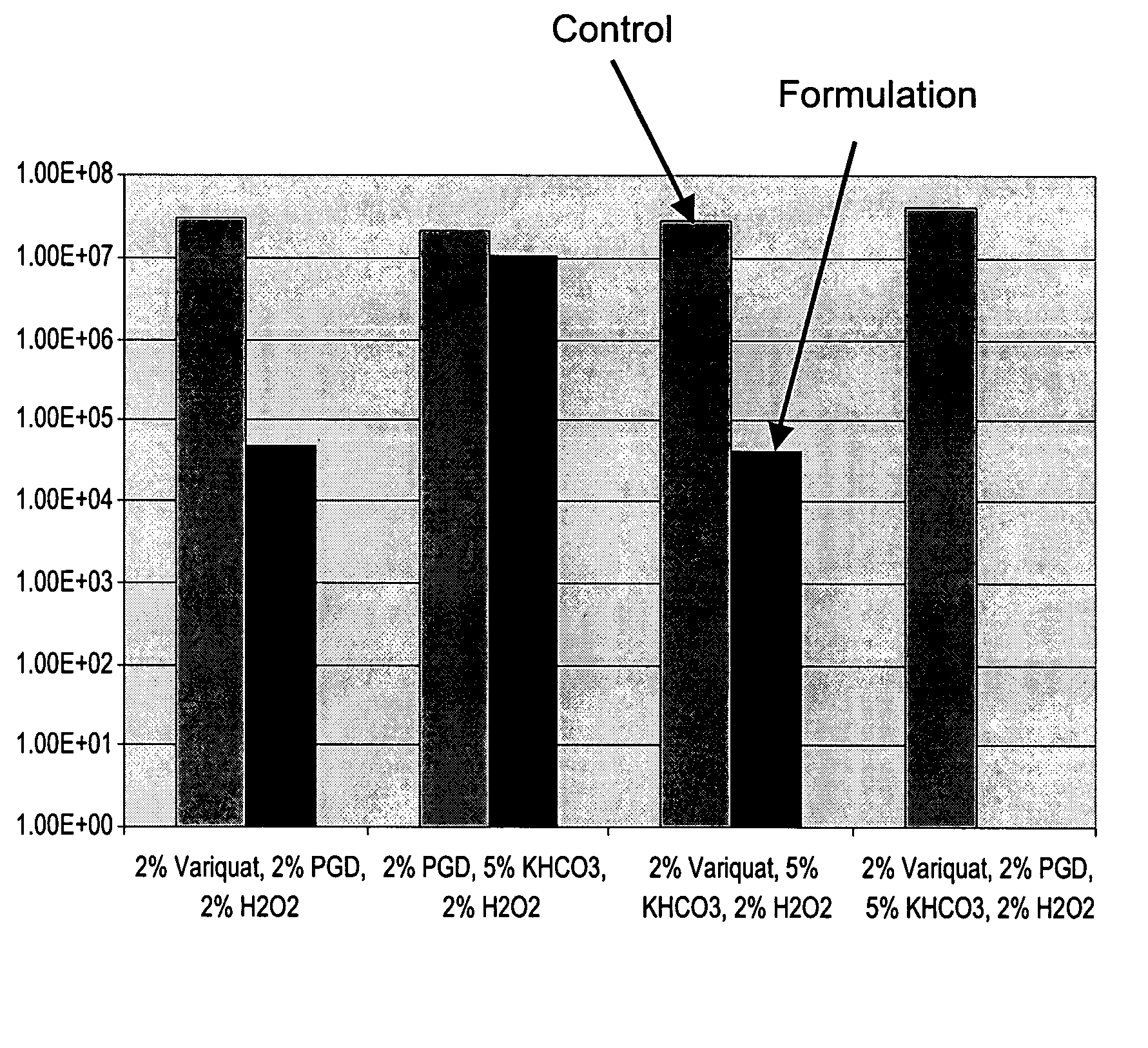

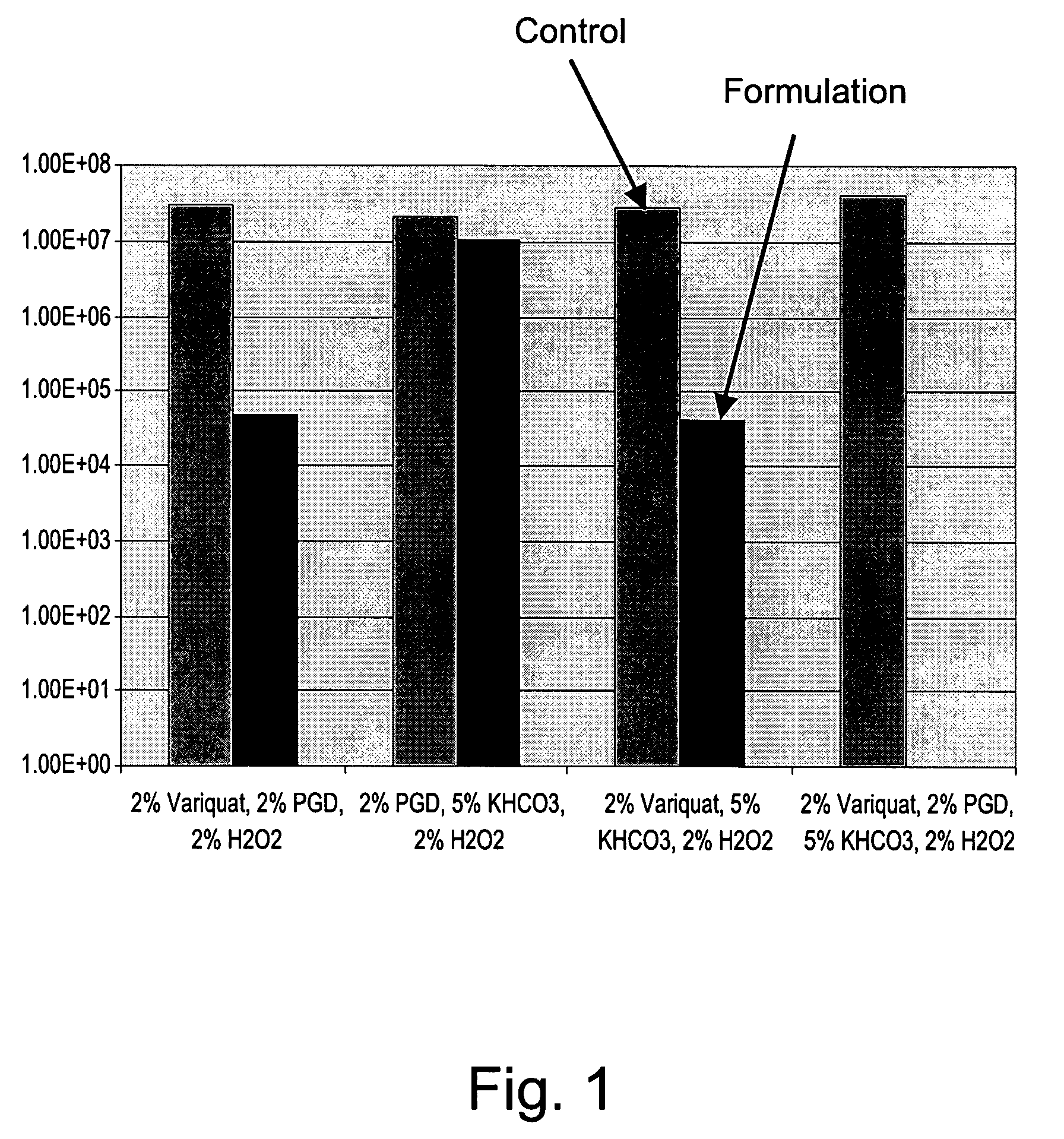

Decontamination formulation with additive for enhanced mold remediation

Decontamination formulations with an additive for enhancing mold remediation. The formulations include a solubilizing agent (e.g., a cationic surfactant), a reactive compound (e.g., hydrogen peroxide), a carbonate or bicarbonate salt, a water-soluble bleaching activator (e.g., propylene glycol diacetate or glycerol diacetate), a mold remediation enhancer containing Fe or Mn, and water. The concentration of Fe2+ or Mn2+ ions in the aqueous mixture is in the range of about 0.0001% to about 0.001%. The enhanced formulations can be delivered, for example, as a foam, spray, liquid, fog, mist, or aerosol for neutralization of chemical compounds, and for killing certain biological compounds or agents and mold spores, on contaminated surfaces and materials.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

Metal surface heat reflection heat insulation type waterborne polyurethane finishing coat and preparation method thereof

InactiveCN112375419AImprove performanceImproved performance, such as storage stabilityLiquid surface applicatorsPolyurea/polyurethane coatingsPolymer scienceCoating system

The invention relates to the technical field of coatings, and discloses a metal surface heat reflection and heat insulation type waterborne polyurethane finishing coat, which comprises a component A and a component B. The component A comprises, by weight, 170-190 parts of purified water, 4-6 parts of a wetting agent, 12-14 parts of dispersing agent, 2-3 parts of a defoamer, 580-630 parts of water-based resin, 100-120 parts of infrared reflection pigment CICP, 12-20 parts of heat insulation powder, 20-30 parts of filler, 4-6 parts of a leveling agent, 4-6 parts of other auxiliaries and 35-45 parts of a cosolvent. The component B comprises the following components in parts by weight: 70-80 parts of a waterborne polyurethane curing agent and 20-30 parts of propylene glycol diacetate, and theweight ratio of the component A to the component B is 5: 1 or 6: 1. The coat has the advantages of favorable weather resistance, favorable temperature change resistance, favorable water resistance, favorable chemical resistance and favorable color retention property. The surface temperature of a coating system can be effectively controlled due to the sunlight reflection and heat insulation capabilities, and the storage stability, the construction performance and the like of the coating can be further improved due to the addition of the functional additive with reflection, heat insulation, environmental protection and energy conservation effects.

Owner:ZHANG ZHOU SAN PAINTS

Environment-friendly waterproof coating material and preparation method thereof

InactiveCN111019453AExtended service lifeNo pungent odorAnti-corrosive paintsPolyether coatingsEpoxyFiber

The invention belongs to the technical field of environment-friendly coating materials, and relates to an environment-friendly waterproof coating material and a preparation method thereof. The environment-friendly waterproof coating material is prepared from the following raw materials in parts by weight: 40-50 parts of an acrylic resin, 30-40 parts of an epoxy resin, 20-30 parts of polyether polyol, 15-25 parts of polyvinyl alcohol, 10-20 parts of a filler, 5-8 parts of a water-soluble adhesive, 4-6 parts of carbon fiber, 3-8 parts of an auxiliary agent, 3-5 parts of nano silicon dioxide, 3-5parts of calcium oxide and 1-3 parts of a drying agent, wherein the drying agent is prepared from the following raw materials in parts by weight: 30 to 40 parts of propylene glycol diacetate, 20 to 30 parts of a polybutenoic acid ester polymer, 10 to 15 parts of microcrystalline cellulose and 3 to 5 parts of cerous sulfate. The waterproof coating material disclosed by the invention is non-toxic,odorless, environmentally-friendly and safe, has good elasticity, impact resistance, wear resistance, flexibility and waterproofness, and can be quickly cured into a film so as to substantially shorten the drying and curing time, so that the next procedure can be quickly implemented, and the construction efficiency is remarkably improved.

Owner:青川源泰建材科技有限公司

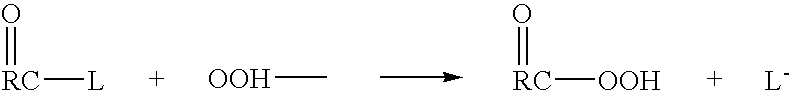

Stable enzymatic peracid generating systems

The present invention provides stable compositions comprising a perhydrolase enzyme, a hydrogen peroxide source, and an ester substrate that efficiently generate aqueous peracid solutions. The generated peracid solutions are suitable for decontaminating and / or sanitizing a wide range of materials and equipment contaminated with pathogens or toxic chemicals. In one preferred embodiment, the stable composition comprises an acyl transferase enzyme, sodium percarbonate, and propylene glycol diacetate, and is stable for 30 days or longer. Upon addition to water, the composition is activated and generates an aqueous solution with a high ratio of peracetic acid to acetic acid.

Owner:DANISCO US INC

Environment-friendly wave-absorbing coating and preparation method thereof

ActiveCN109627832AEasy to useExtended service lifePolyurea/polyurethane coatingsRadiation-absorbing paintsBenzeneMethyl carbonate

The invention discloses an environment-friendly wave-absorbing coating and a preparation method thereof, and belongs to the field of wave-absorbing materials. The environment-friendly wave-absorbing coating comprises 7-73% of matrix resin, 9-63% of a wave-absorbing agent, 4-26% of a solvent, 0.5-2% of a dispersing agent, 0.4-1% of an anti-settling agent and 1-12% of a curing agent; wherein the solvent is selected from at least one of dimethyl carbonate, tert-butyl acetate, dimethyl adipate, dimethyl glutarate, dimethyl succinate, propylene glycol diacetate and propylene glycol methyl ether acetate. The environment-friendly wave-absorbing coating does not contain benzene, ketone and other solvents with high toxicity, high harm and carcinogenic risk, and has the advantages of environmental friendliness, low toxicity, low harm and no pollution; and a cured coating has good mechanical property and wave-absorbing property. The invention also provides a preparation method of the environment-friendly wave-absorbing coating.

Owner:AEROSPACE SCI & IND WUHAN MAGNETISM ELECTRON

Method for detecting odor substances of whole automobile

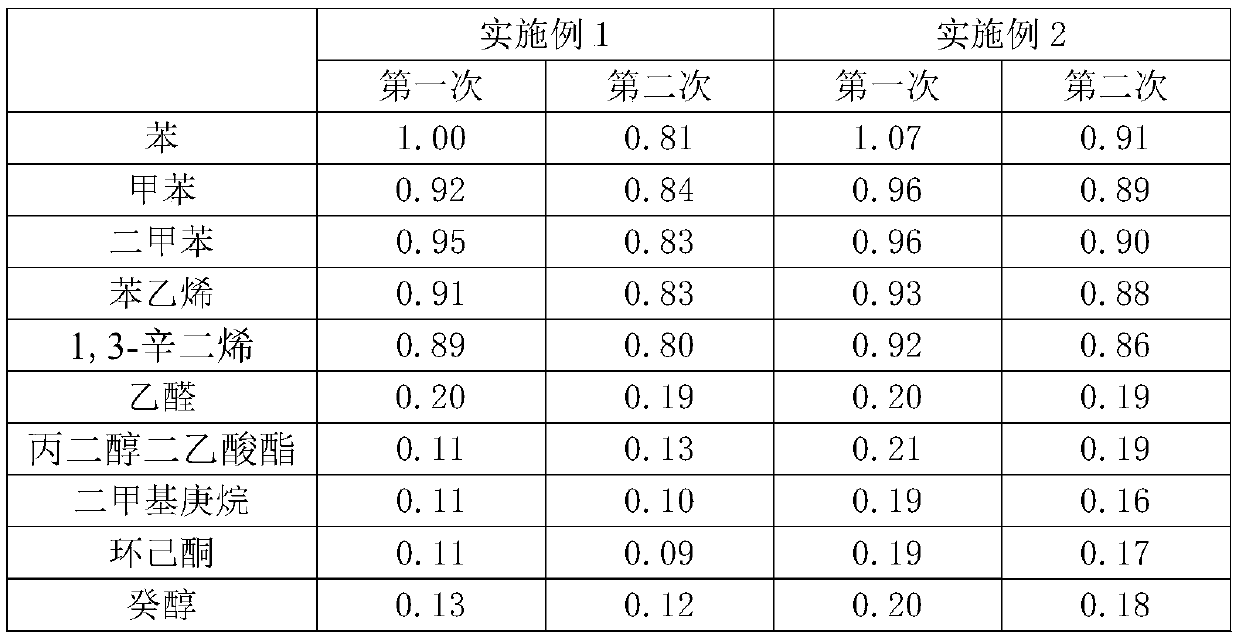

The invention relates to the technical field of automobile volatile odor detection, in particular to a method for detecting odor substances of a whole automobile. The method comprises the following steps: (1) putting an adsorbent into a container containing vehicle odor substances, and adsorbing the odor substances; (2) putting the adsorbent adsorbing the odorous substances into a headspace bottle, desorbing the odor substances in the headspace bottle, and introducing the odor substances into GC-O / MS; and (3) separating through GC-O / MS and qualitatively and quantitatively detecting the components and content of the odor substances in the whole automobile. The method can accurately detect the odor substance components such as benzene, methylbenzene, dimethylbenzene, ethylbenzene, styrene, formaldehyde, acetaldehyde and acrolein in the conventional VOC content standard of the automotive trim material and can also accurately and quantitatively detect certain trace odor components such asdimethyl heptane, cyclohexanone, propylene glycol diacetate and decanol so as to avoid missing of detection of the odor substance components in the whole automobile.

Owner:上海微谱检测科技集团股份有限公司

Production method of 1, 2-propylene glycol diacetate

InactiveCN103467288AHigh airspeedEmission reductionOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsChemical synthesisIon-exchange resin

The invention provides a production method of 1, 2-propylene glycol diacetate, and relates to a chemical synthesis technology. The production method comprises the following steps of carrying out esterification reaction by using propylene glycol monomethyl ether and acetic acid as raw materials in the existence of a catalyst, and rectifying a produced 1, 2-propylene glycol diacetate crude product so as to obtain the high-quality 1, 2-propylene glycol diacetate product, wherein the catalyst is a styrene-divinyl benzenesulfonic acid type acid cation exchange resin which is modified by metal ions and has compound enhancement type macropores, and the cation exchange resin is prepared by sulfonating on a benzene ring after polymerizing styrene and a divinyl benzene monomer, and an ion is any one of Zn<2+>, Fe<3+>, Al<3+>, Na<+>, Fe<2+> or K<+>. The production method has the advantages that the adopted catalyst has high activity and long service life, the selectivity and the yield of the product are high, few byproducts are generated, and after the catalyst is inactivated, the catalyst is filtered, recovered, subjected to acid treatment and dried so as to be recycled.

Owner:JIANGSU HUALUN CHEM

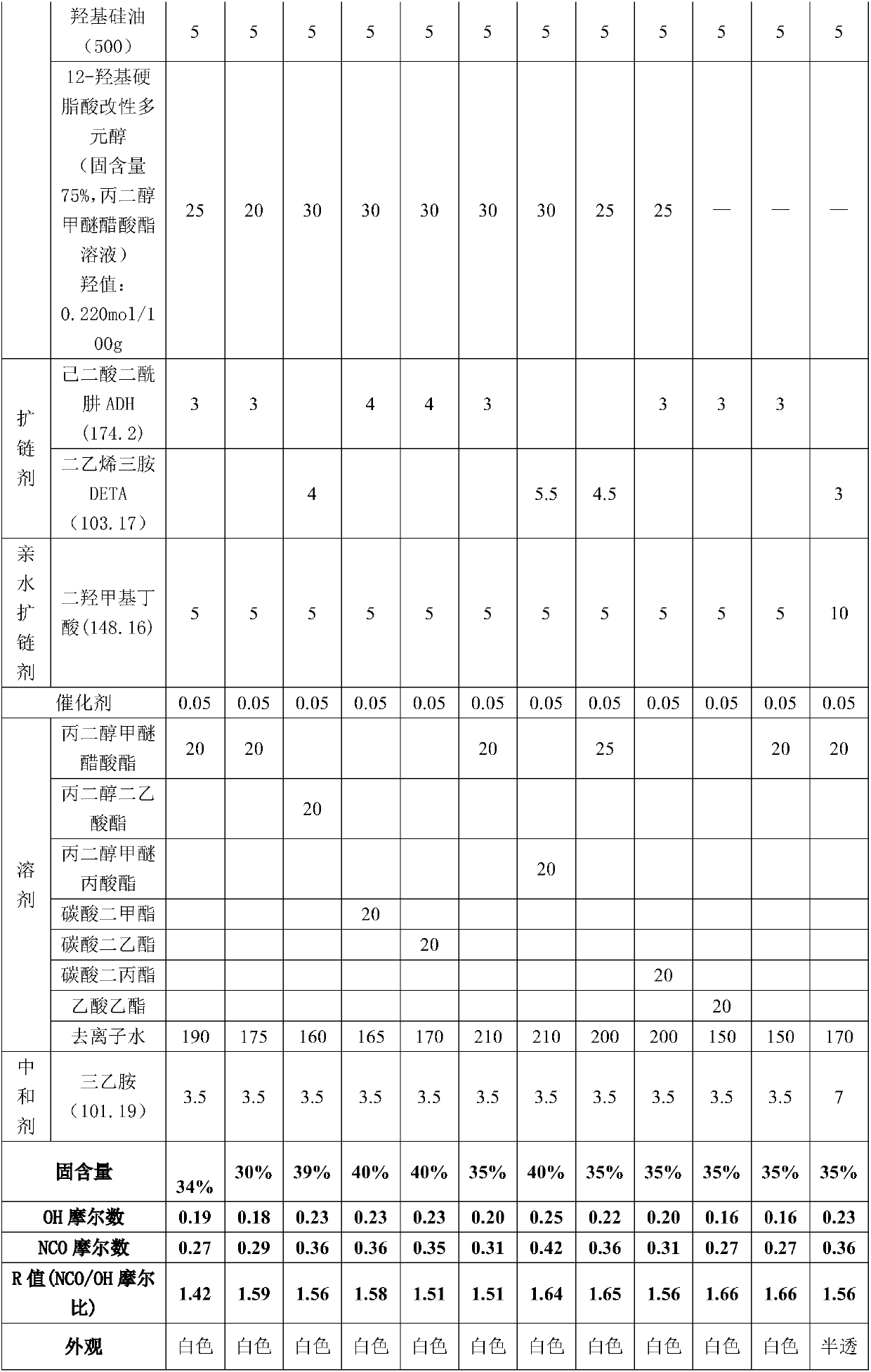

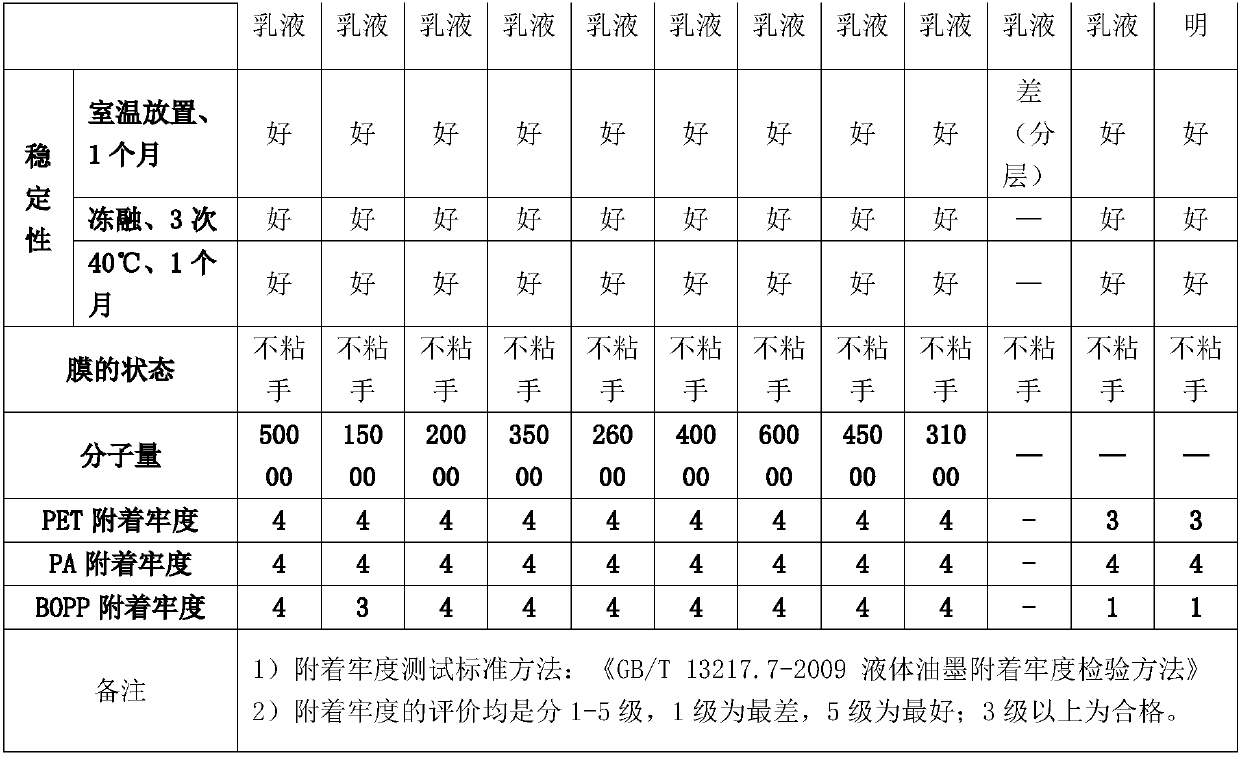

Waterborne polyurethane resin and preparation method thereof

The invention discloses waterborne polyurethane resin and a preparation method thereof, and belongs to the field of preparation of waterborne polyurethane. The waterborne polyurethane resin comprisesthe following components as raw materials in parts by weight: 30-40 parts of an NCO component, 50-115 parts of polyol, 8-10.5 parts of a chain extender, 0.05 part of a catalyst, 3.5 parts of a neutralizer and 180-230 parts of a solvent, wherein the polyol contains 20-30 parts of 12-hydroxystearic acid modified polyol; the chain extender contains 5 parts of a hydrophilic chain extender; the solventis a mixed solvent of one or more of propylene glycol methyl ether acetate, propylene glycol diacetate, propylene glycol methyl ether propionate, dimethyl carbonate, diethyl carbonate and dipropyl carbonate and deionized water. The waterborne polyurethane resin is prepared by a non-acetone method, has good stability and adhesion fastness to a plastic film, and is especially suitable for water-based ink for food package printing.

Owner:苏州博莱特新材料有限公司 +1

Method for preparing electrode altitude difference absorption dielectric paste and laminated ceramic electronic components

InactiveCN101150012APrevent corrosionGood peeling effectFixed capacitor electrodesFixed capacitor dielectricDielectricEtching

The printing past used for absorption of electrode height difference for making laminated ceramic electronic part, the characteristic of which is that it contains ceramic powder and organic carrier and is used combinedly with ceramic young tablet containing butyral resin whose thickness is below 5 micrometer. The main composition of solvent in the organic carrier is 1, 2-propylene glycol diacetate. Even the ceramic young tablet is thinned, tablet etching can be prevented effectively by using the printing past used for absorption of electrode height difference of the invention.

Owner:TDK CORPARATION

Solvent of bismuth-oxide-base ink for glass digital inkjet printing

The invention relates to a solvent of a bismuth-oxide-base ink for glass digital inkjet printing, which is characterized by comprising the following components in percentage by mass: 65-85% of main solvent, 8-22% of dispersing agent, 6-11% of surfactant and 0.1-2% of light stabilizer, totaling 100%. The main solvent is one or mixture of any of 1-(2-methoxy-1-methylethoxy)isopropanol, 1-ethoxy-2-propanol, 1-methoxy-2-propanol and cyclohexanone. The dispersing agent is diethylene glycol butyl ether. The surfactant is 1,2-propylene-glycol diacetate. The light stabilizer is HS-508. The surface tension of the solvent is 28-32 mN / m. The solvent has the advantages of favorable dispersity for bismuth-oxide-base inorganic powder pigments, high volatilization speed and favorable inkjet printing properties. The preparation method is simple and efficient, has the advantages of favorable controllability and low cost, is suitable for industrialized large-scale production, and has wide application prospects in the field of glass digital inkjet printing.

Owner:JIANGSU FANHUA GLASS CO LTD

Waterborne double-component wood coating

InactiveCN109161270AHigh hardnessScratch resistantPolyurea/polyurethane coatingsWater basedUltraviolet

The invention discloses a waterborne double-component wood coating. The water-based double-component wood coating is prepared from two parts including a main agent and a curing agent. The main agent comprises an acrylic emulsion, a waterborne polyurethane dispersion, a coalescing agent, a wetting agent, a leveling agent, an antifoaming agent, wax, a preservative, an ultraviolet absorbent and water. The curing agent comprises components in percentage by mass as follows: propylene glycol diacetate and a cyanate ester mixture; the cyanate ester mixture is a mixture of waterborne isocyanate and hydrogenated xylylene diisocyanate; the mass ratio of the main agent to the curing agent is 1:(1.5-1.8). The double-component wood coating takes acrylic acid and waterborne polyurethane dispersion as main film forming matters, isocyanate is used as the curing agent, a curing reaction is conducted at the normal temperature, the coating has the advantages of high hardness, good scratch resistance, ultraviolet resistance, yellowing resistance and the like, is simple to produce, economical and reasonable and can be widely applied to products such as wooden furniture.

Owner:嘉善蓝欣涂料有限公司

Light-transmitting aqueous polyurethane coating and preparation method thereof

InactiveCN110760254AReduce dosageMeet the needs of environmental protectionAnti-corrosive paintsPolyurea/polyurethane coatingsPolymer scienceEmulsion

The invention discloses a light-transmitting aqueous polyurethane coating and a preparation method thereof, and belongs to the technical field of coatings. The coating comprises a component A and a component B in parts by weight, wherein the component A comprises 45 to 55 parts of aqueous polyurethane emulsion, 4 to 6 parts of a cosolvent, 0.3 to 0.4 part of a defoaming agent, 2 to 3 parts of a dispersing agent, 30 to 40 parts of a pigment and a filler, 0.5 to 1 part of a base material wetting agent, 5 to 13 parts of deionized water, 1 to 2 parts of a thickening agent and 0.5 to 1 part of an anti-settling agent; the component B comprises 7 to 12 parts of an isocyanate curing agent and 3 to 6 parts of propylene glycol diacetate. According to the coating, the water-based polyurethane emulsion is matched with the isocyanate curing agent, and the coating has the advantages of high wear resistance, high transparency and high stability.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Polyester polyurethane high-gloss white stoving varnish and coating process thereof

PendingCN108264835AImprove water resistanceGood weather resistanceAntifouling/underwater paintsPretreated surfacesPolyesterAdipic acid

The invention provides a polyester polyurethane high-gloss white stoving varnish and a coating process thereof, and belongs to the field of coatings. The stoving varnish is composed of the following raw materials in percentages by mass: 35.0-45.0 wt% of polyester polyurethane resin, 1.5-3.5 wt% of a neutralizing agent, 0.5-3.0 wt% of a dispersant, 10.0-20.0 wt% of titanium dioxide, 0.2-1.0 wt% ofan anti-settling agent, 0.1-0.5 wt% of an antifoaming agent, 0.2-1.5 wt% of a bactericide, and 30.0-50.0 wt% of deionized water; and the polyester polyurethane resin is prepared from the following rawmaterials in terms of mass percentage of the polyester urethane resin: 16.0-26.0 wt% of trimethylolethane, 4.0-6.0 wt% of pentaerythritol, 10.0-15.0 wt% of 2,2-dimethyl-1,3-propanediol, 6.0-10.0 wt%of isophthalic acid, 8.0-12.0 wt% of adipic acid, 12.0-17.0 wt% of propylene glycol diacetate, 7.0-11.0 wt% of dimethylolpropionic acid, and 18.0-22.0 wt% of a partially-blocked isocyanate curing agent. The polyester polyurethane high-gloss white stoving varnish provided by the invention performs end capping on an isocyanate curing agent, avoids the problem of an activation period and improves storage stability.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Coating for improving wear resistance of PVC (polyvinyl chloride) whole-core flame-retardant conveyor belt and preparation method of coating

ActiveCN113185902AImprove adhesionGood adhesionFireproof paintsPolyurea/polyurethane coatingsPolyesterPolymer science

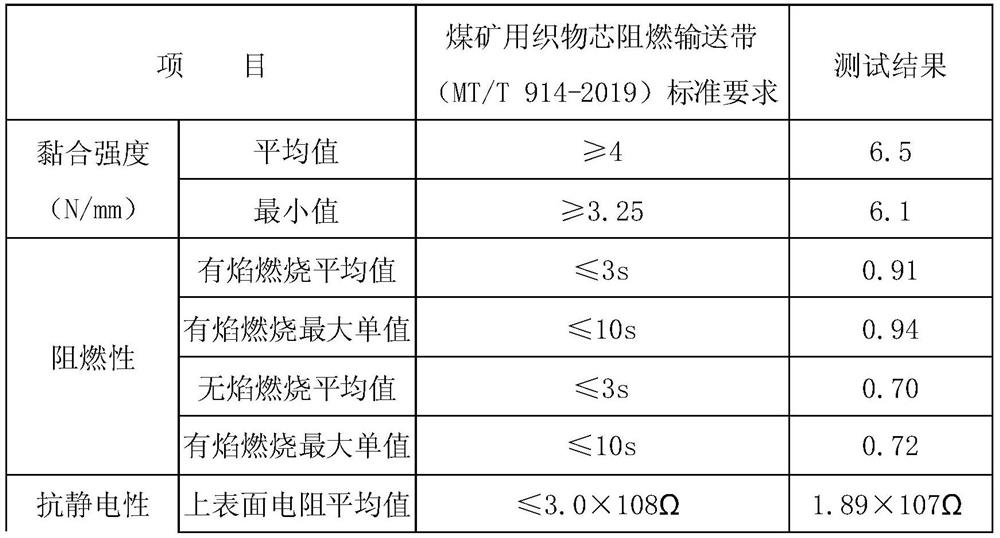

The invention provides a coating for improving wear resistance of a PVC (polyvinyl chloride) whole-core flame-retardant conveyor belt and a preparation method of the coating. The coating comprises an active interface treating agent coating and a modified polyurethane coating which are arranged on the surface of the PVC whole-core flame-retardant conveyor belt. The active interface treating agent contains methyl ethyl ketone, isopropanol, propylene glycol diacetate, dimethyl nylon acid and polyester glycol L3025. The modified polyurethane coating comprises a component A and a component B, polyester diol L3025 is used for preparing a prepolymer component A, and a reactive flame retardant and an antistatic agent are adopted in the component B. After the PVC whole-core flame-retardant conveying belt is treated by an active interface agent, the modified polyurethane coating is coated by using high-pressure spraying equipment to form a wear-resistant coating. The wear-resistant coating provided by the invention has good tensile strength and elongation at break. The coated PVC whole-core flame-retardant conveyor belt composite coating has excellent bonding strength, flame retardance and antistatic property, particularly has excellent wear resistance and is long in service life.

Owner:LIAOYANG YIBANG NEW BUILDING MATERIALS GRP CO LTD

Polishing-free water-based intermediate coating for rail transit and preparation method thereof

InactiveCN111876066AReduce silicon contentDecrease the dyne valuePolyurea/polyurethane coatingsPolymer scienceEthylic acid

The invention relates to the technical field of water-based intermediate coating, in particular to polishing-free water-based intermediate coating for rail transit and a preparation method thereof. The intermediate coating comprises a component A and a component B. The weight ratio of the component A to the component B is 4:1, wherein the component A is prepared from waterborne polyurethane resin,hydroxyl acrylic acid dispersion, an amine neutralizer, a non-silicon high polymer defoaming agent, pigment, filler, a coalescing agent, an anti-settling agent, a thickening agent and deionized water; the component B comprises an isocyanate curing agent and propylene glycol diacetate. The preparation method comprises the following steps: (1) preparing the component A; (2) preparing the componentB; and (3) mixing the component A and the component B. The intermediate coating is low in surface dyne value and good in interlayer adhesion effect with finish paint, and polishing is not needed.

Owner:山东七维新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com