Solvent-containing composition for manufacturing laminated ceramic component

A solvent composition and lamination technology, applied in the direction of laminated capacitors, parts of fixed capacitors, conductive materials dispersed in non-conductive inorganic materials, etc., can solve problems such as deformation, softening of coated surface components, etc. Improve solubility and realize the effect of drying process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

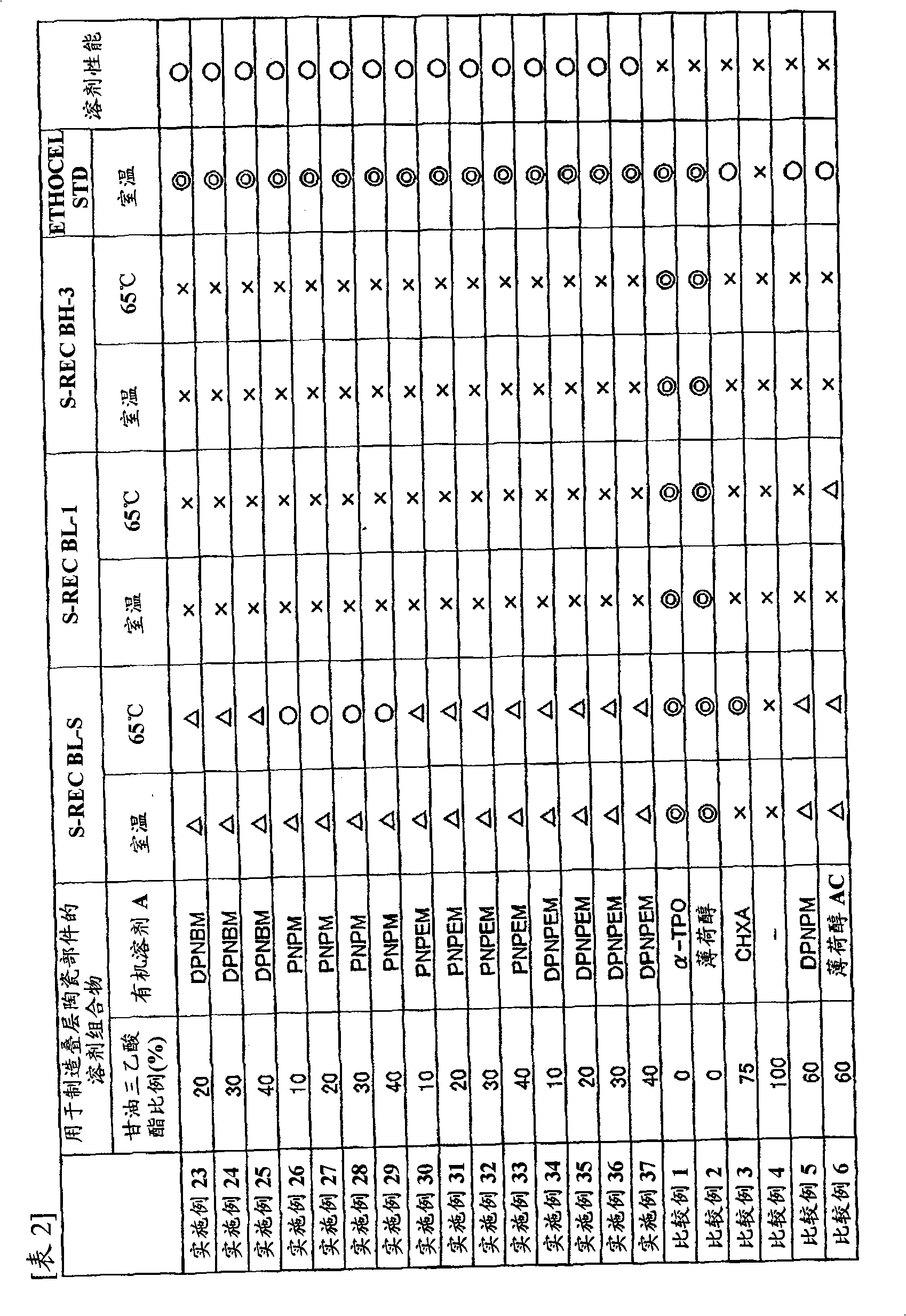

Embodiment 1~37、 comparative example 1~6

[0059]Mix triacetin (trade name "DRA-150", manufactured by Daicel Chemical Industry Co., Ltd.) and organic solvent A in the proportions described in Tables 1 and 2 below to prepare a solvent for the production of laminated ceramic parts combination. This solvent composition was divided into 4 parts, and polyvinyl butyral resin (trade name "S-REC BL-S", manufactured by Sekisui Chemical Co., Ltd.) was added to the first solvent composition, and to the second solvent composition. A polyvinyl butyral resin (trade name "S-REC BL-1", manufactured by Sekisui Chemical Co., Ltd.) was added to the solvent composition, and a polyvinyl butyral resin ( Trade name "S-REC BH-3", produced by Sekisui Chemical Co., Ltd.), ethyl cellulose (trade name "ETHOCEL STD", manufactured by Dow Chemical Co., Ltd.) was added to the fourth solvent composition, and each The resin concentration in the solvent composition was respectively 5% by weight, and after heating and dissolving at a liquid temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com