Waterborne polyurethane high gloss finish for engineering machinery, and preparation method of waterborne polyurethane high gloss finish paint

A water-based technology for construction machinery, applied in the field of water-based polyurethane high-gloss finish paint for construction machinery and its preparation, can solve the problems of poor chemical resistance, high VOC content, inability to apply anti-corrosion coating on the surface of construction cranes, etc., and achieves easy construction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] This embodiment is a preparation method of a water-based polyurethane high-gloss finish paint for engineering machinery, comprising the following steps:

[0062] (1) Preparation of component A: Add deionized water, defoamer, pH regulator, wetting and dispersing agent, pigment and filler into the tank in sequence, disperse evenly and grind to obtain water-based color paste, add water-based color paste Add the substrate wetting agent, leveling agent, thickener and co-solvent in sequence to the water-based hydroxyacrylic acid dispersion to adjust the viscosity to obtain component A;

[0063] (2) Preparation of component B: Pour PGDA into a closed storage tank, add curing agent, and stir evenly to obtain component B.

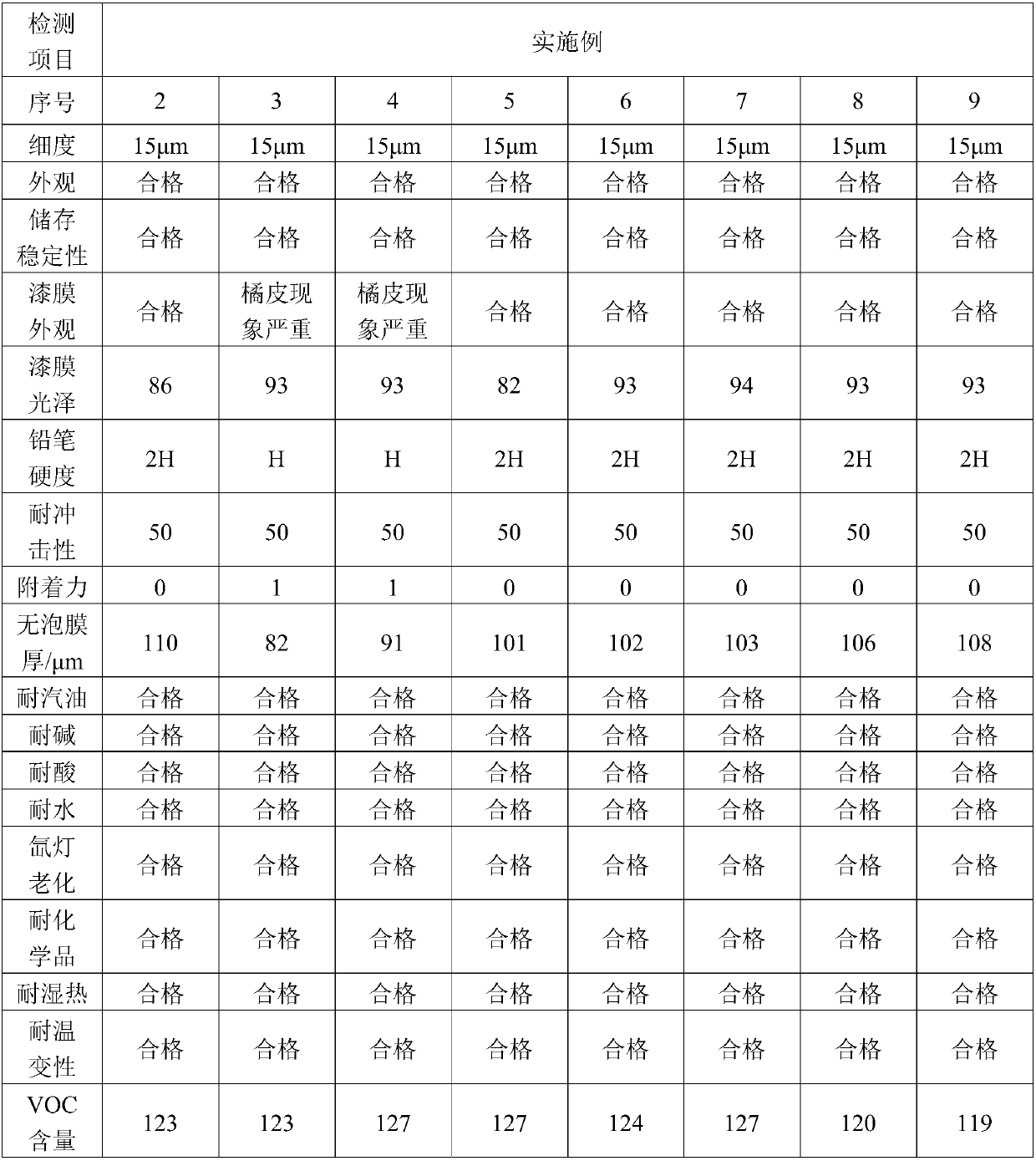

Embodiment 2-9

[0065] The preparation method of A and B components in the embodiment 2-9 is the same as that of Example 1, and the proportioning ratio of each raw material in the A component and the B component is shown in Table 1, and the weight ratio of the A component and the B component is 3 :1.

[0066] Table 1 embodiment 2-9 composition

[0067]

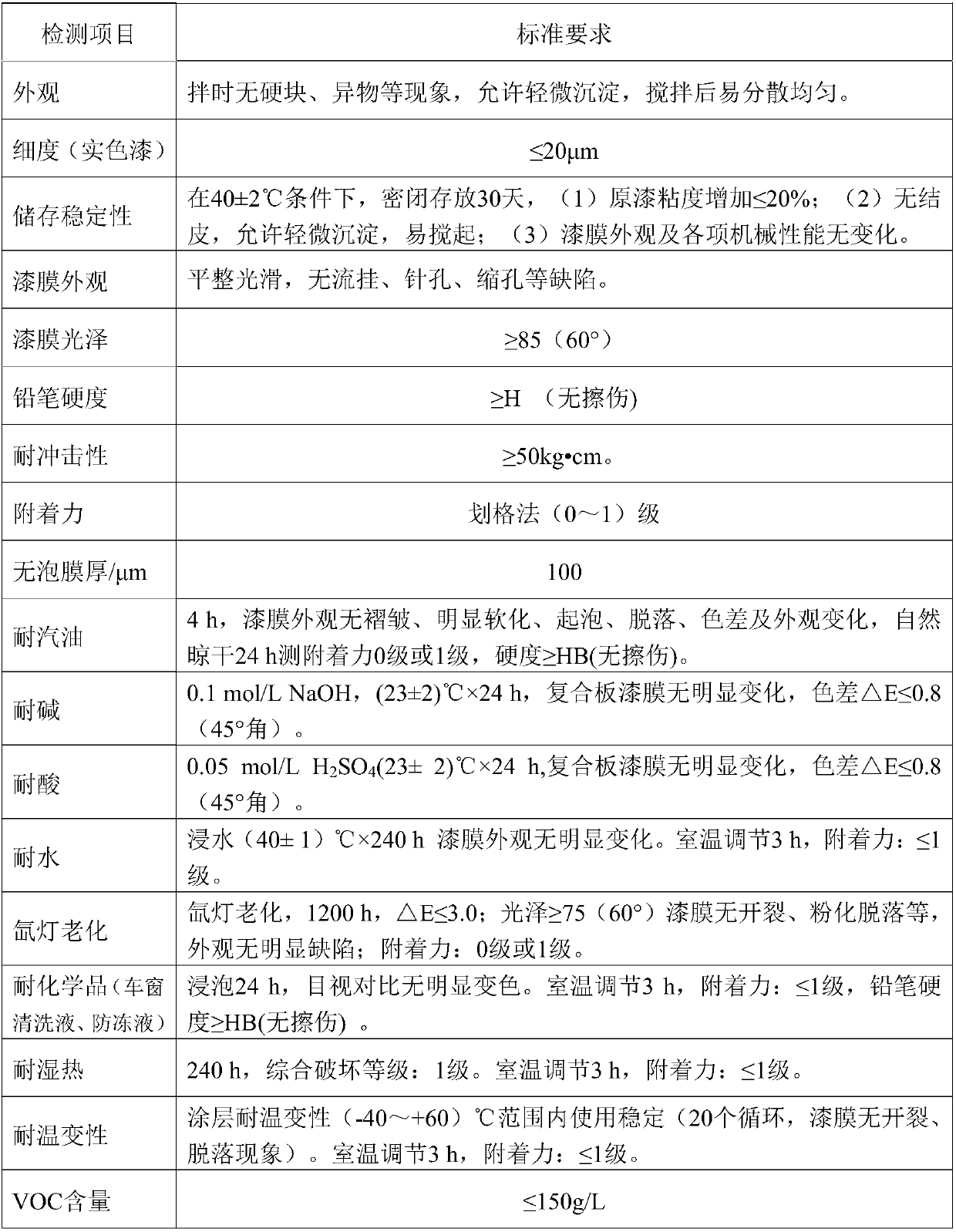

Embodiment 10

[0069] The coatings prepared in Examples 2-9 were applied under the same conditions to obtain paint films, and the performance of each paint film was tested. The performance test results are shown in Table 2, and the result judgment standards are shown in Table 3.

[0070] Table 2 embodiment 2-9 test result

[0071]

[0072] Table 3 Judgment criteria for test results

[0073]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com