Optical grade hydrophobic and oleophobic antifouling anti-blue-ray screen protector

A screen protective film, hydrophobic and oleophobic technology, applied in the direction of pressure-sensitive film/sheet, film/sheet-shaped adhesive, adhesive additive, etc., can solve the aging of retinal pigment epithelial cells, lack of vision of photosensitive cells, anti-blue light Low effect and other problems, to achieve strong solubility, improve anti-blue light effect, and wide range of uses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

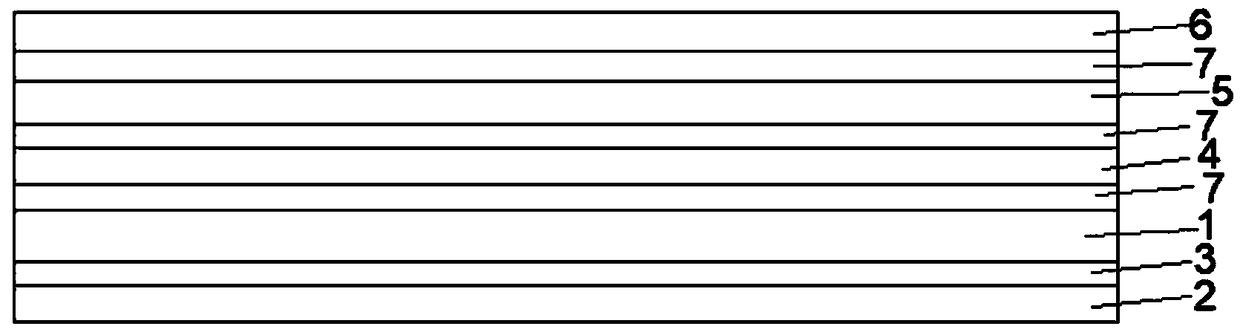

[0019] Such as figure 1 As shown, the present invention discloses an optical-grade hydrophobic, oleophobic, anti-fouling, anti-blue light screen protective film, comprising an optical-grade substrate 1, the surface of the substrate 1 is corona-treated, and the top and bottom of the corona-treated substrate 1 are The surface is coated with a degradable and environmentally friendly silicone pressure-sensitive adhesive layer 3, the lower end of the silicone pressure-sensitive adhesive layer 3 on the lower surface of the substrate 1 is compounded with a PET release film layer 2, and the silicone pressure-sensitive adhesive layer 2 on the upper surface of the substrate 1 The upper end of the sensitive adhesive layer 3 is sequentially compounded with a first refraction material layer 4, a second refraction material layer 5 and an upper PET protective layer 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com