Waterborne polyurethane coating and preparation method thereof

A water-based polyurethane and coating technology, applied in the field of coatings, can solve the problems of hydrogen bond and van der Waals force damage, changes in physical and chemical properties, low water resistance, etc., to improve solvent resistance, increase elongation at break, and improve cohesive strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

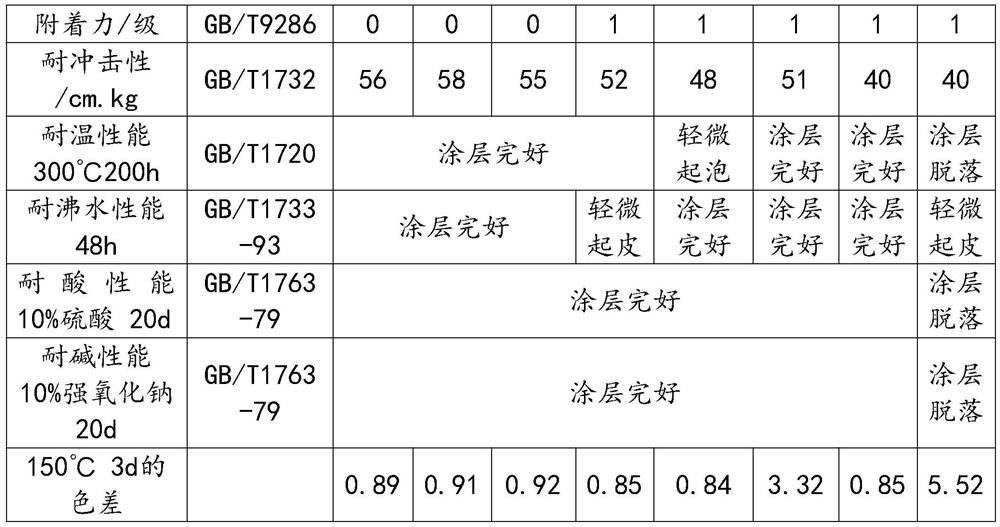

Embodiment 1

[0046] A kind of water-based polyurethane paint, comprises A component and B component, and the mass ratio of A component and B component is 1:1;

[0047] The A component includes the following raw materials in parts by weight: 50 parts of water-based hydroxyacrylic acid emulsion, 4 parts of cosolvent, 0.3 part of defoamer, 0.5 part of ultraviolet light absorber, 10 parts of silica nanospheres, 5 parts of deionized Water, 1 part of modified montmorillonite and 0.5 part of composite antibacterial agent;

[0048] The B component includes the following raw materials in parts by weight: 7 parts of isocyanate curing agent and 3 parts of propylene glycol diacetate.

[0049] The preparation method of this aqueous polyurethane coating specifically comprises the steps:

[0050] The first step, add 60% deionized water, 20% co-solvent, defoamer, ultraviolet light absorber, silica nano-microspheres, modified montmorillonite and composite antibacterial agent into the stirring tank, at roo...

Embodiment 2

[0072] A kind of water-based polyurethane paint, comprises A component and B component, and the mass ratio of A component and B component is 1:1;

[0073] The A component includes the following raw materials in parts by weight: 55 parts of water-based hydroxyacrylic acid emulsion, 5 parts of cosolvent, 0.35 part of defoamer, 0.8 part of ultraviolet light absorber, 13 parts of silica nanospheres, 10 parts of deionized Water, 1.5 parts of modified montmorillonite and 0.8 part of composite antibacterial agent;

[0074] The B component includes the following raw materials in parts by weight: 10 parts of isocyanate curing agent and 5 parts of propylene glycol diacetate.

[0075] The preparation method of this aqueous polyurethane coating specifically comprises the steps:

[0076] The first step, add 60% deionized water, 20% co-solvent, defoamer, ultraviolet light absorber, silica nano-microspheres, modified montmorillonite and composite antibacterial agent into the stirring tank, ...

Embodiment 3

[0098] A kind of water-based polyurethane paint, comprises A component and B component, and the mass ratio of A component and B component is 1:1;

[0099] The A component includes the following raw materials in parts by weight: 60 parts of water-based hydroxyacrylic acid emulsion, 6 parts of cosolvent, 0.4 part of defoamer, 1 part of ultraviolet light absorber, 15 parts of silica nanospheres, 13 parts of deionized Water, 2 parts of modified montmorillonite and 1 part of compound antibacterial agent;

[0100] The B component includes the following raw materials in parts by weight: 14 parts of isocyanate curing agent and 6 parts of propylene glycol diacetate.

[0101] The preparation method of this aqueous polyurethane coating specifically comprises the steps:

[0102] The first step, add 60% deionized water, 20% co-solvent, defoamer, ultraviolet light absorber, silica nano-microspheres, modified montmorillonite and composite antibacterial agent into the stirring tank, at room ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com